Resin composition, pressure-sensitive adhesive composition, pressure-sensitive adhesive layer, pressure-sensitive adhesive sheet, and surface protective film

A technology of resin composition and pressure-sensitive adhesive, applied in the fields of pressure-sensitive adhesive sheet and surface protection film, pressure-sensitive adhesive layer, and pressure-sensitive adhesive composition, can solve the problem of producing adhesive residue, thickness variation, and pressure-sensitive adhesive properties. adverse effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

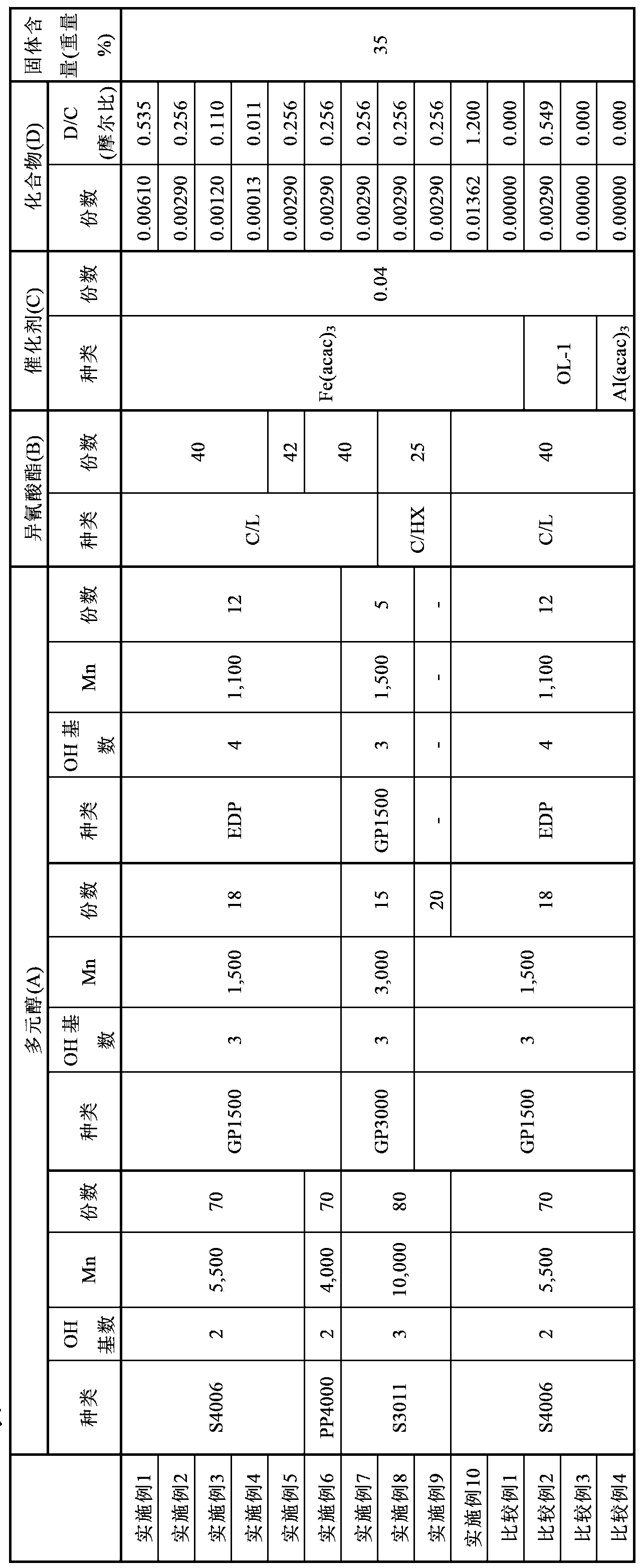

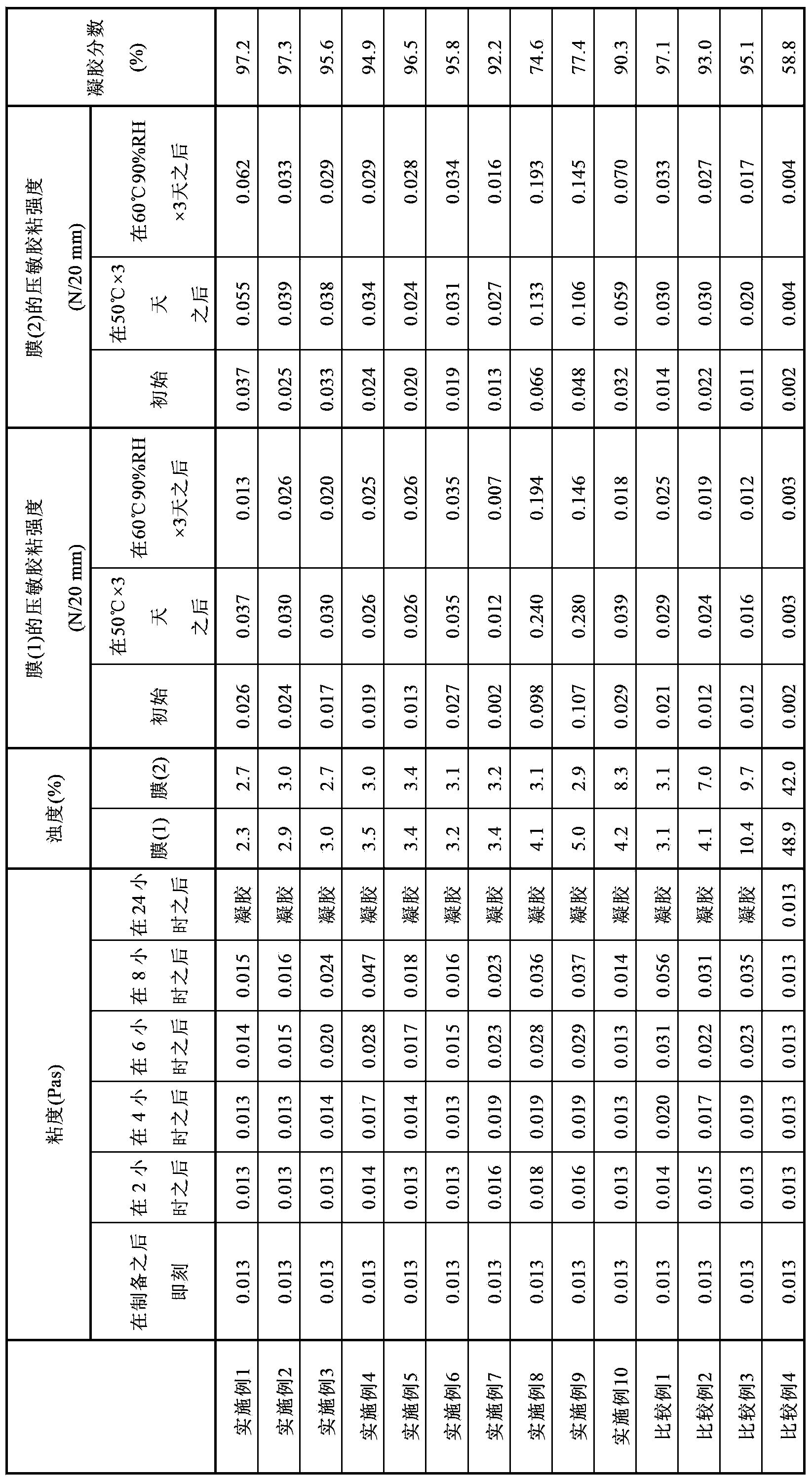

Embodiment 1

[0112] To the polyol (A) 70 parts by weight of a polyol having two OH groups and a number average molecular weight Mn of 5500 (manufactured by ASAHI GLASS CO., LTD., PREMINOL S4006), 18 parts by weight of a polyol having three A polyhydric alcohol having four OH groups and a number average molecular weight Mn of 1500 (manufactured by Sanyo Chemical Industries, Ltd., SANNIX GP-1500) and 12 parts by weight of a polyhydric alcohol having four OH groups and a number average molecular weight Mn of 1100 To alcohol (manufactured by ADEKA CORPORATION, EDP-1100), 40 parts by weight of trimethylolpropane / toluene diisocyanate trimer adduct (manufactured by Japan Nippon Polyurethane Industry Co., Ltd. (manufactured by Nippon Polyurethane Industry Co., Ltd., trade name: CORONATE L), 0.04 parts by weight of tris(acetylacetonate)iron as a catalyst (C) (provided by Nippon Chemical Industry Co., Ltd. (NIHON KAGAKU SANGYO CO., LTD.), trade name: Nacem Ferric Iron) and 0.0061 parts by weight of ...

Embodiment 2

[0116] Resin composition (2) was obtained in the same manner as in Example 1 except that the amount of acetylacetone (AcAc) used was changed to 0.0029 parts by weight.

[0117] The obtained resin composition (2) was defined as the pressure-sensitive adhesive composition (2) and various evaluations were performed on the resin composition (2) or the pressure-sensitive adhesive composition (2).

[0118] Tables 1 and 2 show the results.

Embodiment 3

[0120] Resin composition (3) was obtained in the same manner as in Example 1 except that the amount of acetylacetone (AcAc) used was changed to 0.0012 parts by weight.

[0121] The obtained resin composition (3) was defined as a pressure-sensitive adhesive composition (3) and various evaluations were performed on the resin composition (3) or the pressure-sensitive adhesive composition (3).

[0122] Tables 1 and 2 show the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com