Patents

Literature

33results about How to "Low residual formaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method for low-formaldehyde solid wood composite floor

ActiveCN105235024AAvoid gel effectLow residual formaldehydeLaminationLamination apparatusParquetinaSolid wood

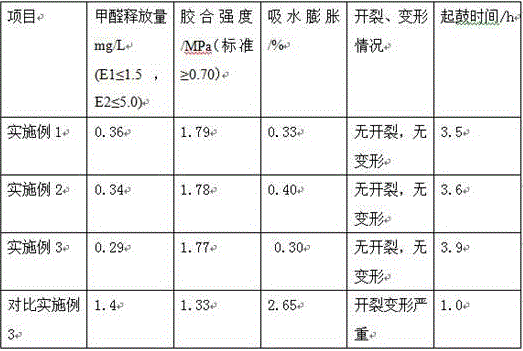

The invention relates to a solid wood composite floor, in particular to a production method for a low-formaldehyde solid wood composite floor. The production method comprises the technological steps of wood plate slicing, drying, repairing, selecting, gluing, pre-pressing, hot pressing, edge cutting and sanding, and finished product obtaining. The key of the production method is that the residual amount of formaldehyde in adhesives is reduced by modifying the used urea-formaldehyde resin adhesives, so that the residual amount of the formaldehyde in the solid wood composite floor is reduced; by adopting high-quality plates and controlling process parameters in the production process, the quality of the produced solid wood composite floor is guaranteed. The content of the formaldehyde in the solid wood composite floor manufactured through the method is low, the quality of the floor is stable, and the floor is not prone to damage; the floor has the characteristics of being comfortable in foot feeling, resistant to abrasion, easy to install and clean, and high in stability.

Owner:DALIAN SHENGYU TECH DEV CO LTD

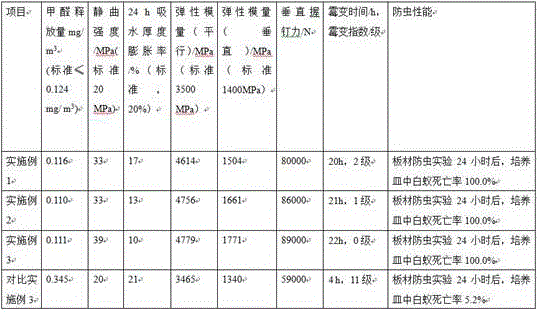

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

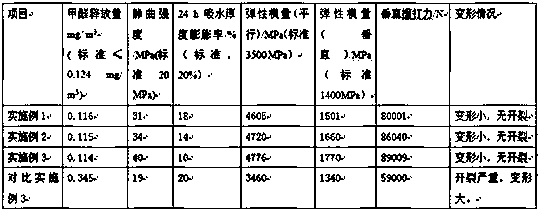

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

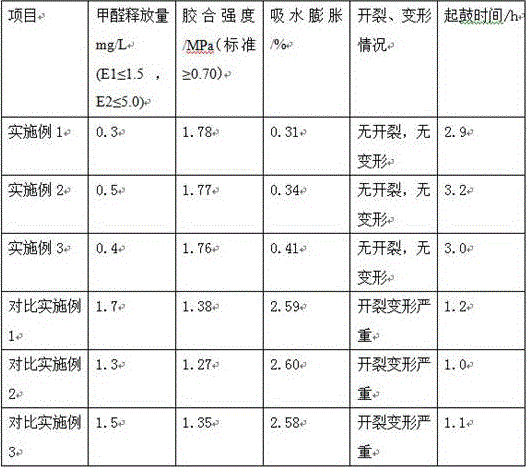

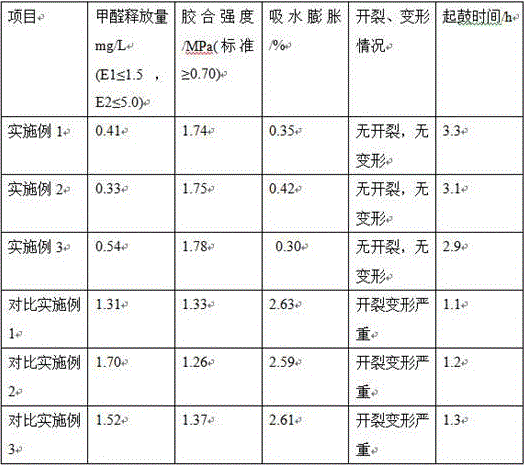

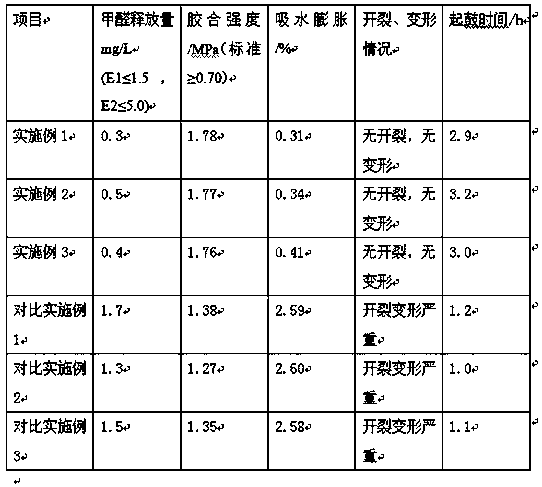

Method for producing particle board by adopting moisture-proof composite urea resin

ActiveCN106313205AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantAdhesive

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

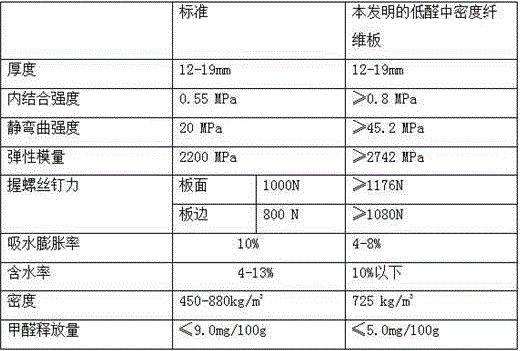

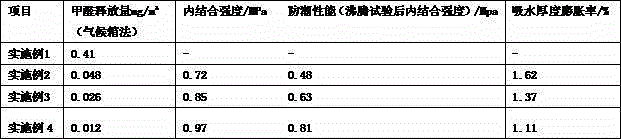

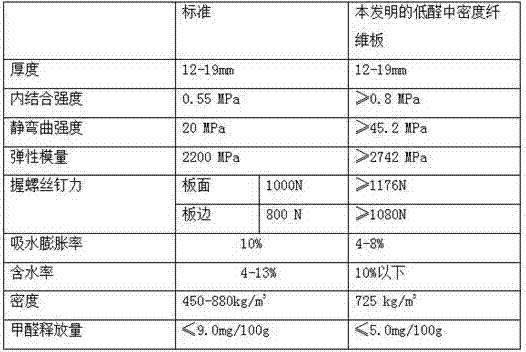

Method for producing low-formaldehyde medium-density fiberboard

ActiveCN105216086AImprove water resistanceGood alkali resistanceFlat articlesDomestic articlesEngineeringPulp and paper industry

The invention relates to a method for producing a low-formaldehyde medium-density fiberboard and belongs to the technical field of wood resource utilization. The method for producing the low-formaldehyde medium-density fiberboard comprises the technological steps of raw material slicing, impurity-removal and screening, boiling, waxing and hot grinding, gluing and drying, mat formation and hot pressing, and finished product obtaining. According to the method, residues, such as battens and waste veneer, generated during wood processing are used for producing the low-formaldehyde medium-density fiberboard, waste materials are recycled, and full utilization of wood resources is effectively achieved; the formaldehyde residual volume of low-formaldehyde urea formaldehyde resin adhesive used for producing the medium-density fiberboard is low, in this way, harm to the health of human bodies is reduced, and the bonding force is high; in addition, the fiberboard has good damp-proof performance and good water-proof performance, the internal structure of the board is uniform, the density is proper, the dimensional stability is high, the quality is stable, and the service life is long.

Owner:霸州市郭仕智能家居科技有限公司

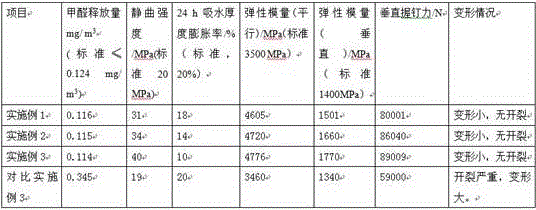

Method for producing high-temperature-resisting oriented particle board by using total-eucalyptus leftover material

ActiveCN106313265AWhite colorGood film formingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesParticle boardImpurity

The invention provides a method for producing a high-temperature-resisting oriented particle board by using a total-eucalyptus leftover material. The method comprises the steps of material preparation, drying, debarking, impurity removing, sorting, storage, respective gluing of a surface layer and a core layer, classified paving, pre-hot-pressing molding, sanding of an overcoating and the like, wherein the surface layer is coated with an isocyanate sawdust powder composite adhesive; the core layer is coated with a high-temperature-resisting composite urea resin adhesive; the core layer wood shaving is of a three-layer structure which comprises a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer; the core layer middle layer is paved longitudinally; the core layer upper surface layer, the core layer lower surface layer and the surface layer are paved horizontally. The oriented particle board prepared by the method provided by the invention is 31MPa to 40MPa in parallel static bending intensity, 4605MPa to 4776MPa in parallel elasticity modulus, 1501MPa to 1770MPa in vertical elasticity modulus, 10% to 18% in thickness swelling rate of 24-h water absorption and as high as 89009N in vertical nail-holding power, and is good in dimensional stability and reliability. Moreover, the oriented particle board prepared by the method provided by the invention is also excellent in heat resistance.

Owner:广西横县新威林板业有限公司

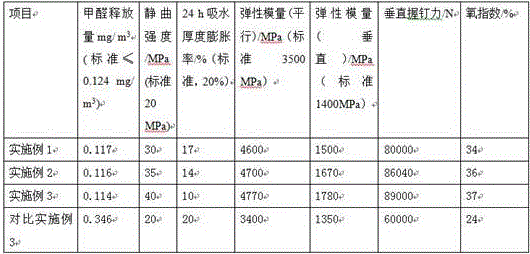

Method for producing flame-retardant oriented strand boards with full eucalyptus wood scraps

InactiveCN106182316AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScrapElastic modulus

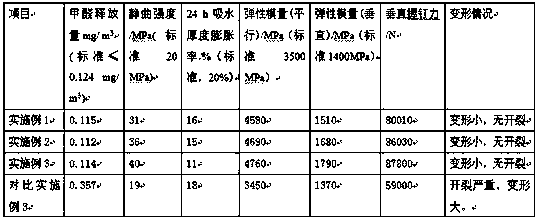

The invention provides a method for producing flame-retardant oriented strand boards with full eucalyptus wood scraps. The method comprises the working procedures of material preparation, drying, debarking and impurity removal, sorting and storage, respective gluing on surface layers and a core layer, graded laying, preheating pressing molding, sanding and finishing, and the like, wherein the surface layers are coated with isocyanate sawdust powder compound adhesive, the core layer is coated with flame-retardant compound urea-formaldehyde resin adhesive, core layer shavings are divided to form a three-layer structure which includes a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer, vertical laying is adopted for the core layer middle layer, and transverse laying is adopted for the core layer upper surface layer, the core layer lower surface layer and the surface layers. According to the oriented strand boards produced with the method, the static bending intensity in the parallel direction ranges from 30 MPa to 40 MPa, the parallel elasticity modulus ranges from 4600 MPa to 4770 MPa, the vertical elasticity modulus ranges from 1500 MPa to 1780 MPa, the thickness swelling rate of water absorption of 24 hours ranges from 10% to 17%, the vertical nail-holding power is as high as 89000 N, and the dimensional stability and reliability are good. In addition, the oriented strand boards produced with the method further have the excellent effect of flame retardance.

Owner:广西横县新威林板业有限公司

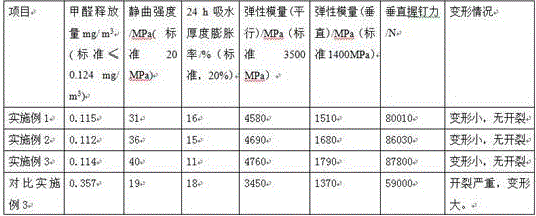

Method for producing weather-resistant oriented strand board by using full-eucalyptus leftover material

ActiveCN106272865AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesOptoelectronicsImpurity

The invention provides a method for producing a weather-resistant oriented strand board by using a full-eucalyptus leftover material. The method includes material preparation, drying, peel and impurity removing, sorting storage, gluing of a surface layer and core layer, classified pavement, pre-hot pressing forming, facing sanding and other working procedures. The surface layer is coated with isocyanate sawdust powder composite adhesives, and the core layer is coated with weather-resistant composite urea-formaldehyde resin adhesives. Core layer wood shavings are divided into three layers of structures and comprise a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and a surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction is 31-40MPa, and the parallel elasticity modulus is 4580-4760MPa; and the vertical elasticity modulus is 1510-1790MPa, the 24 h thickness swelling rate of water absorption is 11%-16%, vertical nail-holding ability reaches up to 87800N, and the dimensional stability and reliability are good. Moreover, the oriented strand board prepared through the method has excellent weather resistance.

Owner:广西横县新威林板业有限公司

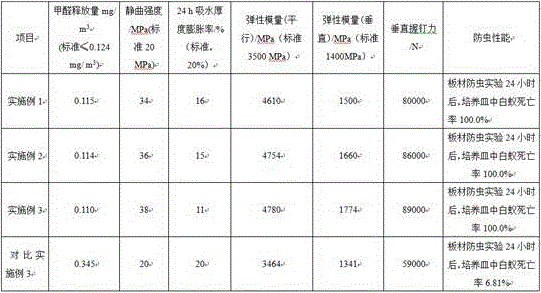

Method for producing antiseptic oriented strand board through full-eucalyptus leftover materials

InactiveCN106239689AWhite colorGood film formingWood veneer joiningDomestic articlesDusting powdersOptoelectronics

The invention provides a method for producing an antiseptic oriented strand board through full-eucalyptus leftover materials. The method comprises the procedures of material preparing, drying, peel and impurity removing, sorting and storing, surface layer and core layer gluing, classified paving, preheating press forming, sanding facing and the like. A surface layer is coated with an isocyanate wood dust powder composite adhesive, a core layer is coated with an antiseptic composite urea-formaldehyde resin adhesive, and core layer wood shavings are of three-layer structures including a core layer middle layer, a core layer upper surface layer and a core layer lower surface layer. The core layer middle layer is longitudinally laid, and the core layer upper surface layer, the core layer lower surface layer and the surface layer are transversely laid. According to the oriented strand board prepared through the method, the static bending intensity in the parallel direction ranges from 34 MPa to 38 MPa, and the parallel elasticity modulus ranges from 4,610 MPa to 4,780 MPa; and the vertical elasticity modulus ranges from 1,500 MPa to 1,774 MPa, the water absorption thickness swelling rate in 24 h ranges from 11% to 16%, and the vertical nail holding force reaches up to 89,000 N. Meanwhile, through adding of an antiseptic agent, the problem that panels are prone to suffering from corrosion of wood-destroying fungi, moulds and white ants is thoroughly solved, and the service life of the panels is prolonged.

Owner:广西横县新威林板业有限公司

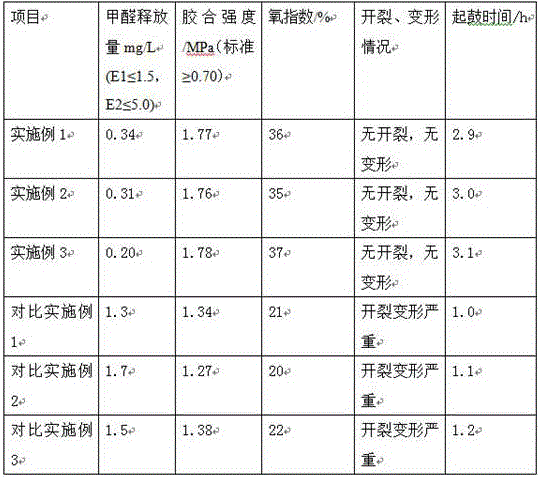

Method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin

InactiveCN106313203ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesVeneer manufactureSilanesAdhesive

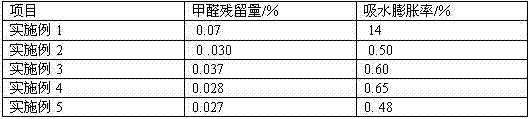

The invention discloses a method for producing total-eucalyptus plywood by adopting moisture-proof composite urea resin. The method comprises the following steps: rotatably cutting wood boards; drying each board; gluing; performing cold pressing for three times; stewing and conditioning; performing hot pressing for three times; cooling and conditioning; determining the thickness of a board blank and sanding the board blank. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and aliphatic polyurethane acrylate is taken as a moisture-proof agent to prepare the composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced total-eucalyptus plywood is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage.

Owner:南宁市创锦胶合板有限责任公司

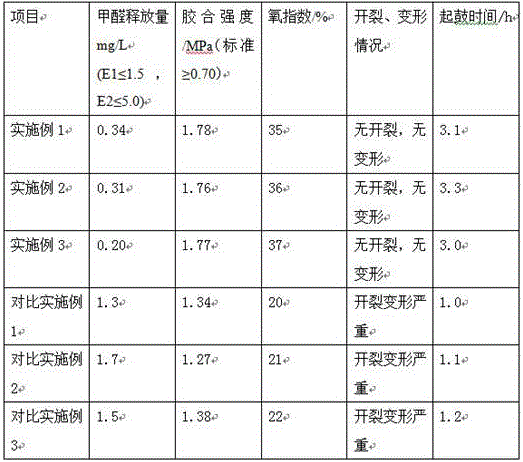

Method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin

InactiveCN106346568AWhite colorGood film formingNon-macromolecular adhesive additivesStarch derivtive adhesivesScavengerAdditive ingredient

The invention relates to a method for producing full-eucalyptus plywood with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as littleformaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effectin case of fire disasters.

Owner:南宁市创锦胶合板有限责任公司

Method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin

InactiveCN106346584AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesLaminationScavengerToughening

The invention relates to a method for producing full-eucalyptus parquet with flame-retardant composite urea-formaldehyde resin, comprising the steps of wood board peeling->veneer drying -> gluing -> three times of cold pressing -> standing for curing->three times of hot pressing ->heat dissipation for curing->slab calibrating and sanding-> substrate surface gluing -> curing and slotting-> leaching paint, drying and shaping. The method is characterized in that the melamine modified urea-formaldehyde resin is used as the main ingredient in the adhesive; the oxidized starch as adhesive compound, the polyving akohol as toughening agent, the hydrogenated rosin as antioxidant, the polyisocyanate as curing agent, i-butyltriethoxanesilane as bridging agent, phenolic lignin as formaldehyde scavenger and flame retardant agent are added together to produce the flame-retardant composite urea-formaldehyde resin. The flame-retardant composite urea-formaldehyde resin has such advantages as little formaldehyde residue, perfect flame resistance and lowering combustion temperature by internal endothermic reaction so that the full-eucalyptus parquet contains little formaldehyde residue and has good flame-retardant effect in case of fire disasters.

Owner:南宁市林润木业有限公司

Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

ActiveCN105108841AResidue reductionImprove water resistanceLaminationLamination apparatusAdhesiveMoisture resistance

The invention relates to a building material for home furnishing, in particular to a method for manufacturing a moth-proof and low-formaldehyde wardrobe plate. The method for manufacturing the moth-proof and low-formaldehyde wardrobe plate is characterized by comprising the steps of lathing a plank into pieces, conducting drying, trimming edges, applying adhesive, conducting prepressing, conducting hot-pressing, sanding cut edges, conducting moth proofing treatment, attaching abrasion resistant paper, conducting decoration veneering and sealing the edges. According to the method for manufacturing the wardrobe plate, the formaldehyde residual amount is small, an aluminum alloy frame is inlaid at the periphery of the wardrobe plate, moisture in the air can be effectively prevented from permeating the plate, the moisture resistance and water resistance of the wardrobe plate are improved, the wardrobe plate obtained through the manufacturing method has good moth prevention performance, mold prevention performance, moisture protection performance and abrasion resistant performance, the formaldehyde residual amount is small, damage to a human body is reduced, the obtained wardrobe plate is stable in quality, the dimension stability is good, the plate is not prone to being cracked, damaged or deformed, and the service life is long.

Owner:广州市艾依格家居制品有限公司

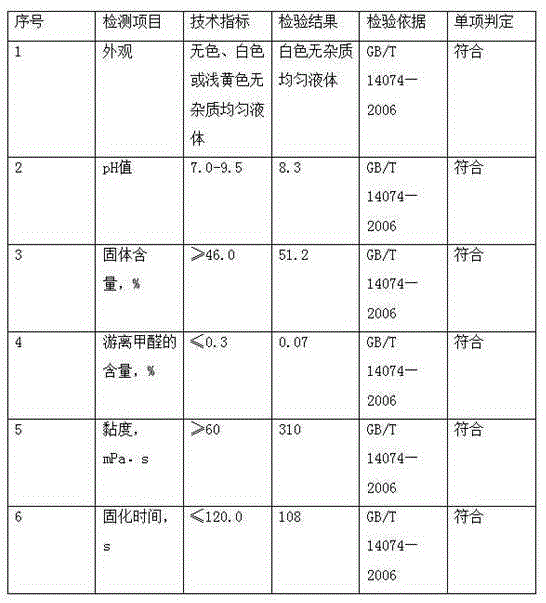

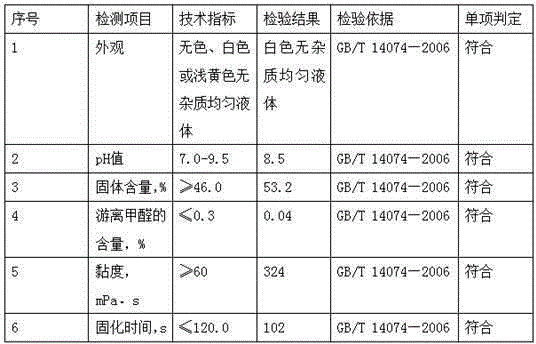

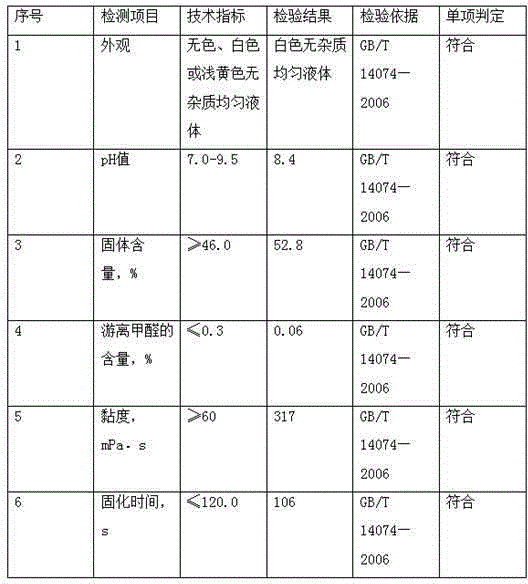

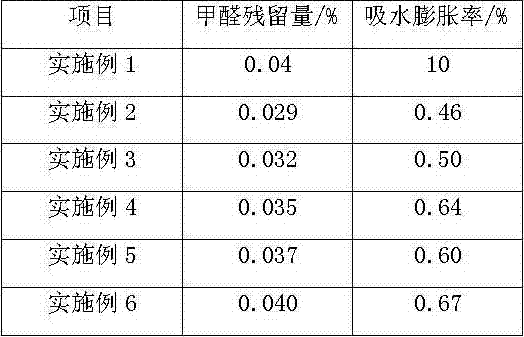

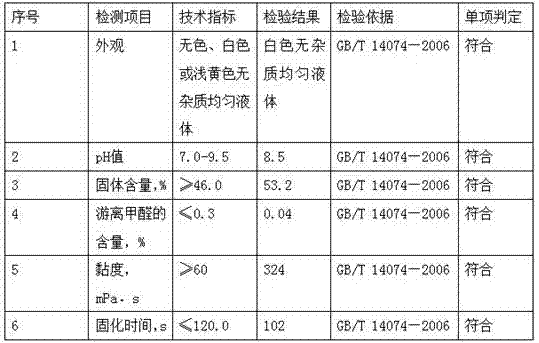

Production method of moisture-proof modified urea resin adhesive

ActiveCN104762047AAvoid gel effectLow residual formaldehydeNon-macromolecular adhesive additivesStarch adhesivesIntermediate stageEmulsion

The invention provides a moisture-proof modified urea resin adhesive. The moisture-proof modified urea resin adhesive is prepared from the following raw materials in parts by weight: 55-75 parts of modified urea resin, 4-8 parts of polyvinyl acetate emulsion, 0.4-0.9 part of vinyltrimethoxysilane and 25-35 parts of filler; the preparation method of the moisture-proof modified urea resin adhesive comprises the following steps: firstly, preparing the modified urea resin, adding formaldehyde at a time, adding urea at three times, and adding oxidized starch and furfuryl alcohol in the reaction process as modifiers, wherein the production of the modified urea resin is divided into three stages, namely a reaction initial stage, a reaction middle stage and a reaction later stage; adding the polyvinyl acetate emulsion and triethoxyisobutylsilane after polymerication at the later stage, stirring and mixing evenly and then adding the filler; due to the process, the gelation phenomenon in the polymerization process is avoided; the obtained urea resin is improved in water resistance and low in formaldehyde residue; if the urea resin is applied to producing an artificial board, the obtained artificial board can be applied to a high-humidity environment in the south, and is low in formaldehyde release amount.

Owner:广西崇左市中港木业有限公司

Method for manufacturing cabinet board

ActiveCN105082300AUniform structureSmall expansion and contractionDomestic articlesFlat articlesProcess engineeringCupboard

The invention discloses a method for manufacturing a cabinet board. The method is characterized by comprising the following steps of raw material chipping, impurity removing and screening, stewing, wax applying and hot grinding, glue applying and drying, paving and prepressing, sticking of a waterproof board and veneering and side sealing. The cabinet board manufactured with the method has the good properties of water resistance, wear resistance, fire prevention and high temperature resistance; the residual amount of formaldehyde is low, and the hurt to a human body is reduced; and the board is stable in quality, good in strength, excellent in waterproof performance, good in size stability, not prone to cracking and being damaged and long in service life.

Owner:河南瀚之源实业有限公司

Process for removing formaldehyde from synthetic protein fibres

InactiveCN1376817AAlso has a bleaching effectLow residual formaldehydeCellulose/protein filament chemical after-treatmentFiberSynthetic protein

A process for removing formaldehyde from synthetic protein fibres to prevent the damage of residual formaldehyde to human body includes such steps as preparing 40% aqueous solution of sodium hydrogensulfite, washing the acetalized protein fibres with water, immersing in said aqueous solution at 40-60 deg.C for 5-10 min, water washing and centrifugal drying. Its advantages are high effect, simpleprocess, and bleaching action.

Owner:胡宗善 +1

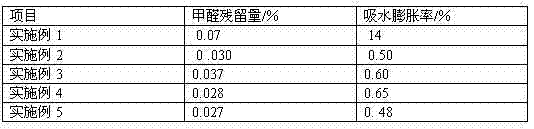

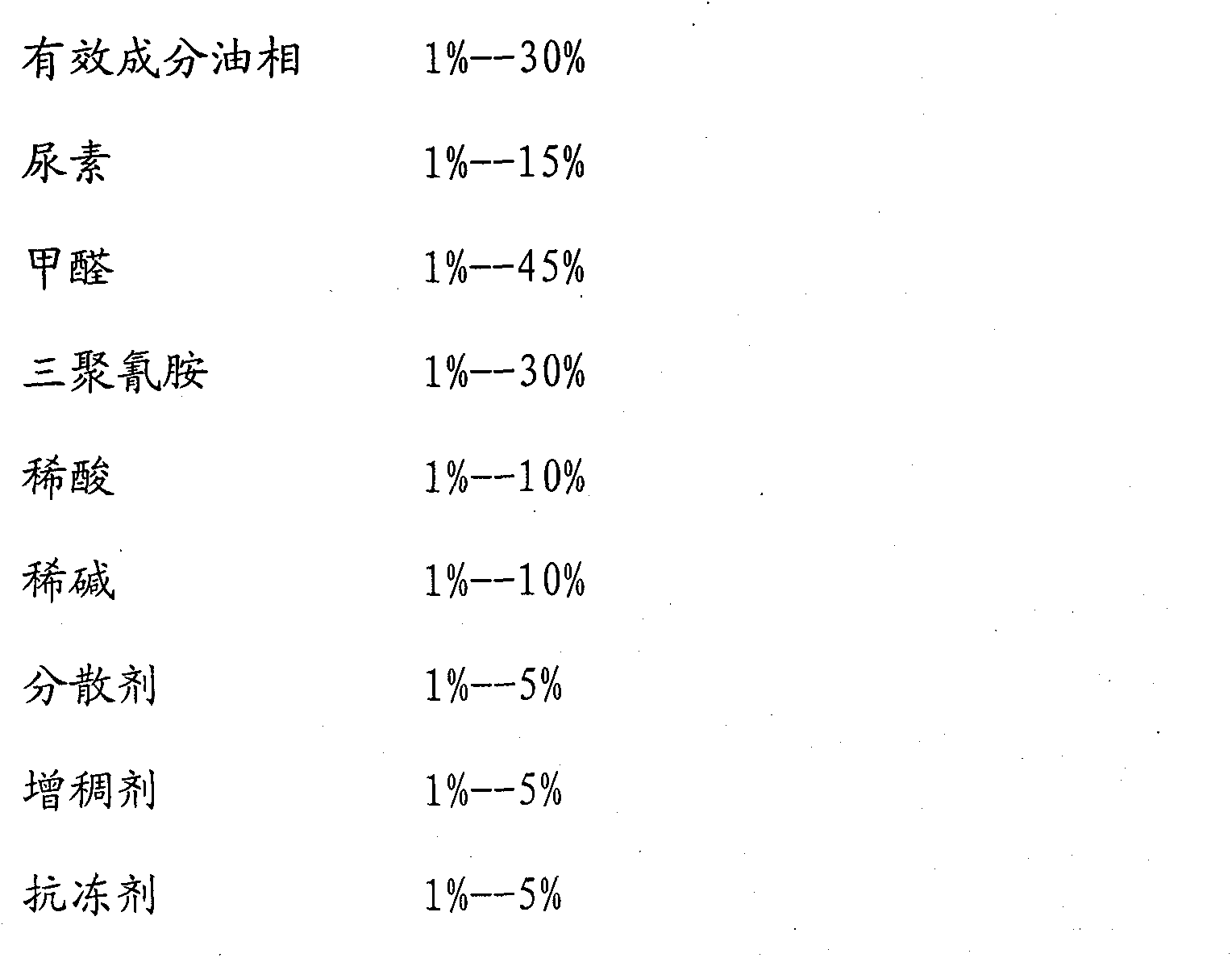

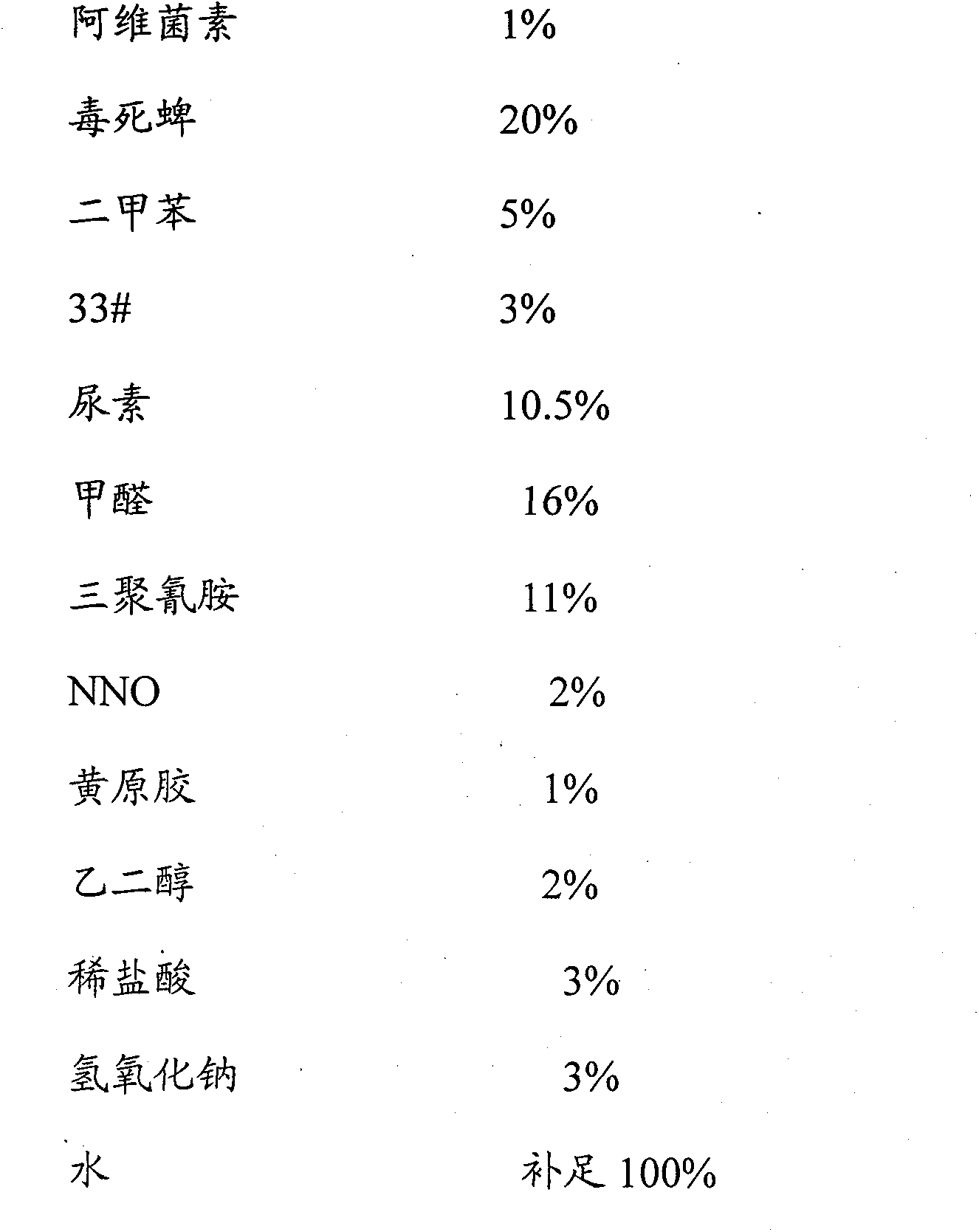

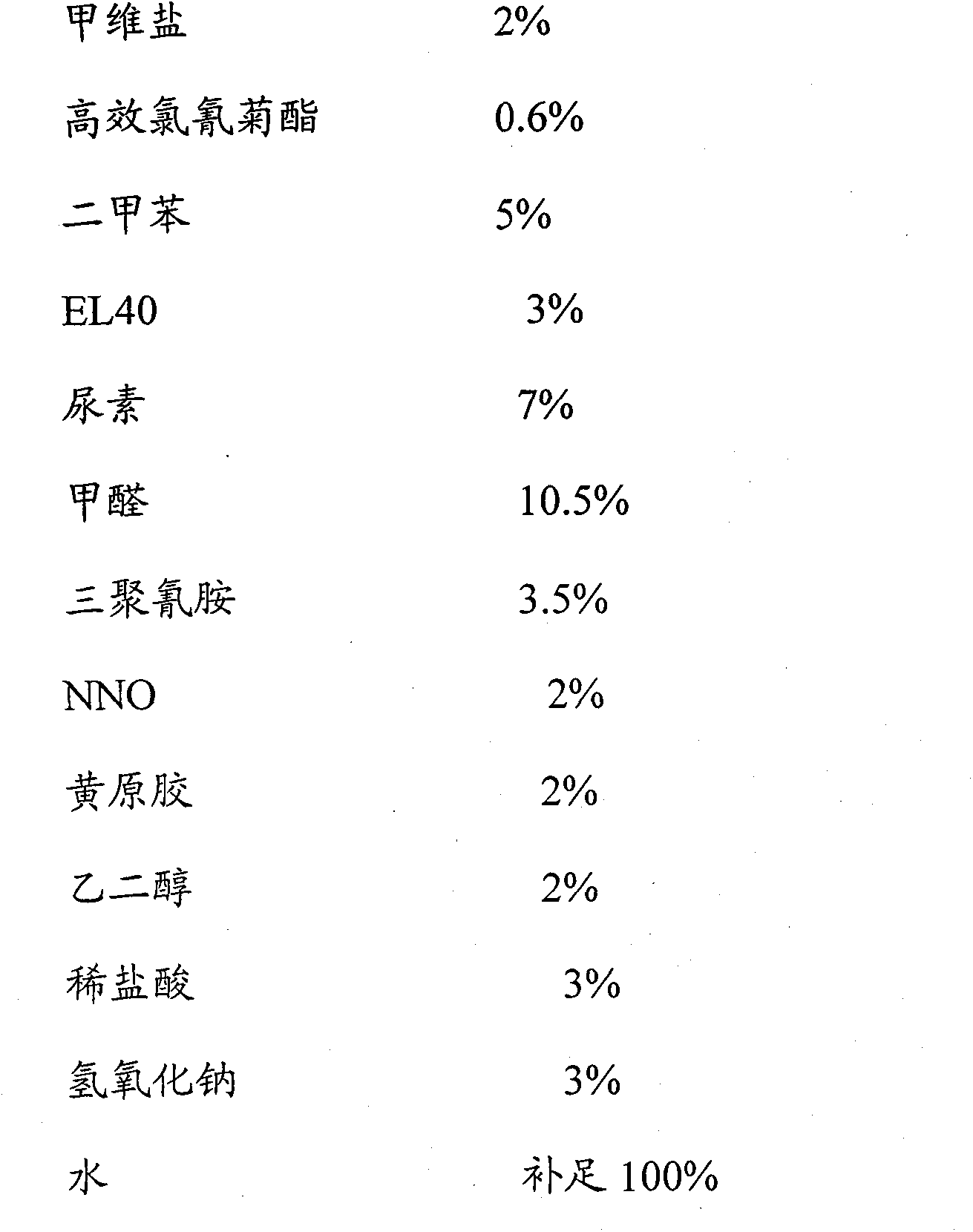

Preparation technology for pesticide microcapsule

InactiveCN103977750AImprove thermal stabilityHigh mechanical strengthBiocideAnimal repellantsSuspending AgentsThermal stability

The invention discloses a preparation technology for a pesticide microcapsule. According to the preparation technology for the pesticide microcapsule, by introducing a third monomer on the basis of a routine urea-formaldehyde condensation method, the thermal stability, the mechanical strength and the capsule size distribution of microcapsule particles are substantially improved. The preparation technology for the microcapsule is simpler and easier to operate compared with the routine urea-formaldehyde condensation technology in the industrial production process, the pesticide microcapsule suspending agent prepared by employing the technology completely accords with all national indexes, and the formaldehyde residual quantity is obviously lower than that of a microcapsule suspending agent prepared by employing a routine urea-formaldehyde condensation technology, and therefore the preparation technology helps to relatively well protect environment and is relatively friendly to environment.

Owner:CHINESE ACADEMY OF AGRI SCI LANGFANG PESTICIDE PILOT PLANT

Production method for damp-proof ceiling decoration density board

InactiveCN105150353ALow residual formaldehydeAvoid it happening againNon-macromolecular adhesive additivesWood working apparatusNatural ventilationWear resistant

The invention provides a production method for a damp-proof ceiling decoration density board. The production method includes the steps that broken wood materials or broken gains such as various types of straw and nutshells which are generated after crops are harvested and damp-proof urea-formaldehyde resin adhesives are mixed and pressed into a board, and the board and melamine-soaked paper or aluminium oxide wear-resistant paper are pressed and attached at a high temperature to form the damp-proof ceiling decoration density board. Three times of cold pressing, three times of hot pressing and two times of heat dissipation regimens are adopted for board forming. The cold pressing temperature is the room temperature, the cold pressing pressure is 2.5 MPa, and the hot pressing pressure is 1.5-2.0 MPa. The temperature of the first time of hot pressing is 130-135 DEG C. The temperature of the second time of hot pressing is 125-130 DEG C. The temperature of the third time of hot pressing is 120-125 DEG C. The heat dissipation regiments are achieved by lowering the temperature of a constant temperature room to the room temperature through natural ventilation cooling, and the time ranges from 3 h to 4 h. The melamine-soaked paper or the aluminium oxide wear-resistant paper is attached to the surface of the board at a temperature of 150 DEG C and under the pressure of 1.5 MPa.

Owner:钱秀英

Production method of damp-proof low-formaldehyde urea-formaldehyde resin adhesive

ActiveCN104762046ALow residual formaldehydeImprove water resistanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesThree stageResin adhesive

The invention provides a damp-proof low-formaldehyde urea-formaldehyde resin adhesive which comprises the following raw materials in parts by weight: 60-80 parts of modified urea-formaldehyde resin, 10-14 parts of an OPE damp-proof agent and 15-20 parts of a filling material. A production method of the damp-proof low-formaldehyde urea-formaldehyde resin adhesive comprises the steps of preparing urea-formaldehyde resin, wherein the formaldehyde is fed once, and urea is fed three times, production of the urea-formaldehyde resin is carried out in three stages, namely pre-polymerization, polymerization and later polymerization, and a coupling agent can be added into the urea-formaldehyde resin in the later stage of polymerization to increase the degree of crosslinking; and adding the OPE damp-proof agent after later stage of polymerization, adding the filling material after the OPE damp-proof agent and the urea-formaldehyde resin are uniformly mixed and stirred, and grinding for 30min by a three-roll grinder to obtain the damp-proof low-formaldehyde urea-formaldehyde resin adhesive. The damp-proof low-formaldehyde urea-formaldehyde resin adhesive provided by the invention has excellent water resistance, good humidity resistance and a small amount of residual formaldehyde, and solves a problem in the shaving board and density board industry today.

Owner:香河天亚木业有限公司

Method for producing particle board by adopting flame-retardant composite urea resin

ActiveCN106313259AWhite colorGood film formingNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryRosin

The invention discloses a method for producing particle board by adopting flame-retardant composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, hydrogenated rosin is taken as an antioxidant, polyisocyanate is taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a flame retardant is also added to prepare the flame-retardant composite urea resin; the composite urea resin has the advantages of low formaldehyde residual volume and good flame retardance; by internal heat absorption reaction, the combustion temperature is reduced, so the produced particle board is low in formaldehyde residual volume and is effectively flame-resistant when a fire occurs.

Owner:广西横县新威林板业有限公司

Method for producing full-eucalyptus parquet through dampproof composite urea resin

InactiveCN106239646AReduce formaldehyde contentGood gluing propertiesNon-macromolecular adhesive additivesStarch derivtive adhesivesFiberPolyvinyl alcohol

A method for producing a full-eucalyptus parquet through dampproof composite urea resin comprises the following steps of wood board sheet rotary cutting, veneer drying, gluing, three-time cold pressing, standing curing, three-time hot pressing, heat dissipation curing, slab fixed-thickness sanding, base material surface layer gluing, curing slotting and spraying drying sizing. According to the key of the production method, melamine modified urea resin is adopted as a main adhesive material, and oxidized starch is added as a sticky complexing agent; polyvinyl alcohol serves as a toughening agent; magnesium oxide serves as an anti-aging agent; hexamine and triglycidyl isocyanurate serve as a curing agent; vinyltriethoxysilane serves as a bridging fiber agent; and phenolate lignin is the dampproof composite urea resin prepared through a formaldehyde capture agent and an added dampproof agent. The composite urea resin has the beneficial effects of being low in formaldehyde residual volume and good in water resistance and dampproof performance, so that the produced full-eucalyptus parquet is low in formaldehyde residual volume and is not prone to expansion after absorbing water, arching and deformation are not likely to happen, and an abrasion resisting layer is not prone to damage.

Owner:南宁市创锦胶合板有限责任公司

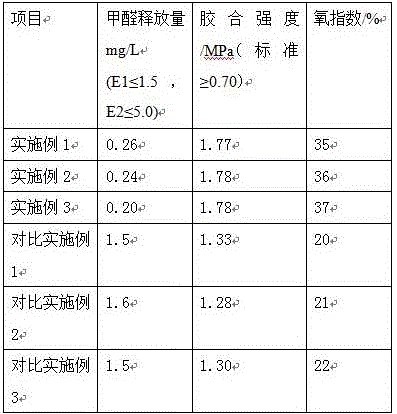

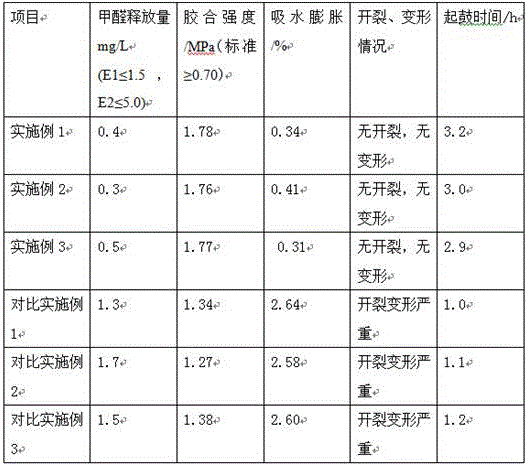

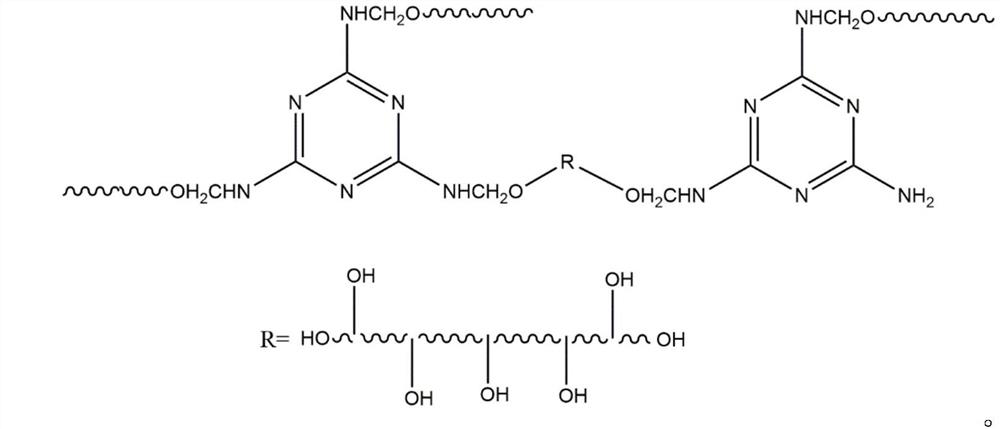

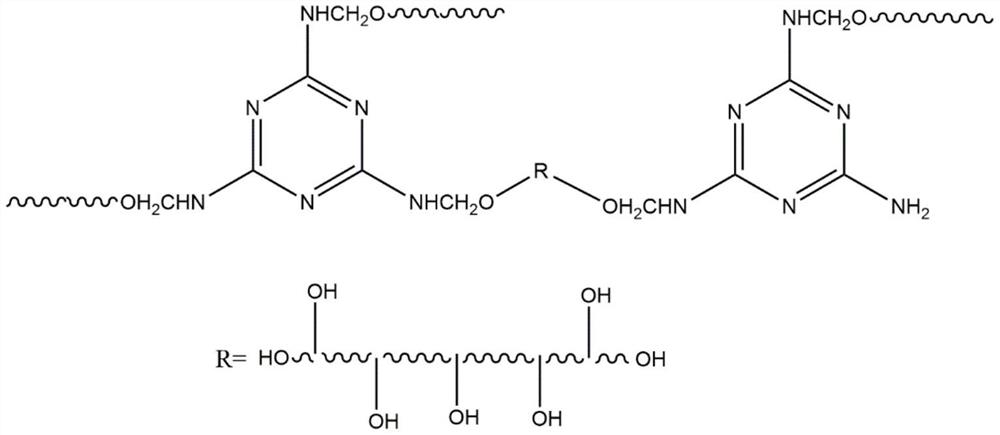

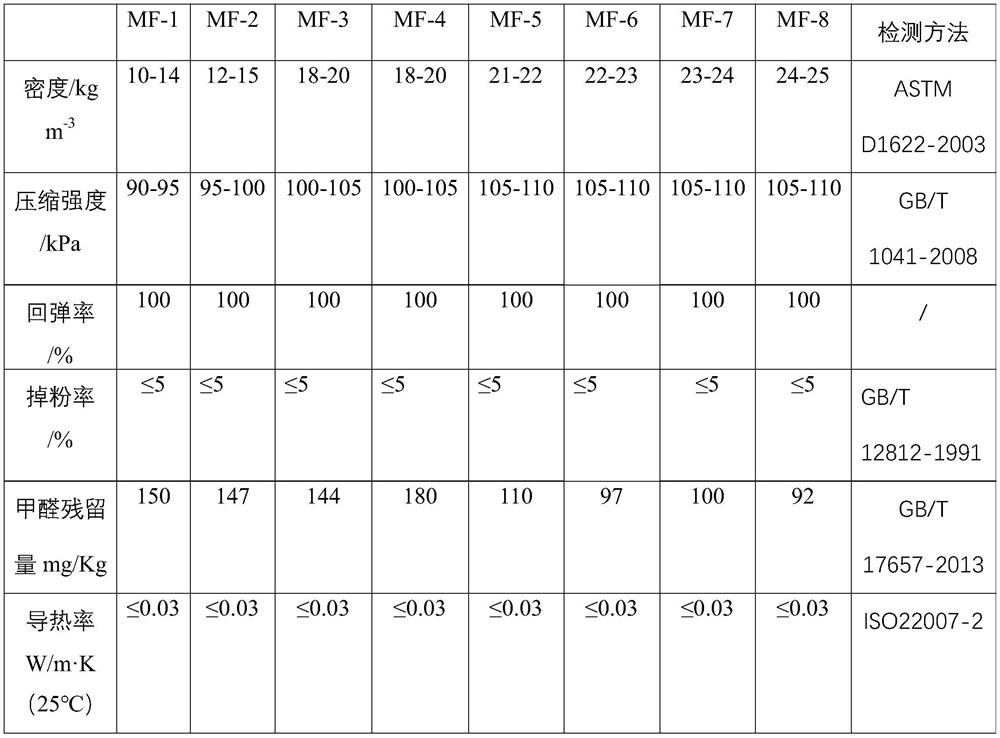

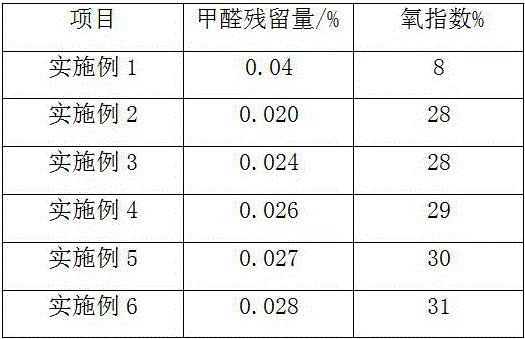

Low-formaldehyde high-elasticity semi-hard melamine foam and preparation method thereof

The invention relates to low-formaldehyde high-elasticity semi-hard melamine foam and a preparation method thereof.The preparation method comprises the steps that 1-10 parts of polyhydroxy compound, 15-35 parts of formaldehyde, 25-40 parts of melamine, 10-40 parts of water and 5-20 parts of flexibilizer are prepared to obtain block type foaming prepolymerization liquid; and adding an emulsifier, a foaming agent, a curing agent and a modifier to prepare the melamine foam by taking the foaming prepolymerization liquid as a main body. Compared with the prior art, the melamine foam disclosed by the invention has the advantages of intrinsic flame-retardant property, excellent heat resistance, excellent sound absorption property, excellent thermal insulation property and low formaldehyde content, so that the melamine foam has a wide application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for producing cabinet board by adopting damp-proof composite urea resin

InactiveCN106313260ATake advantage ofSolve insufficient resourcesOther plywood/veneer working apparatusNon-macromolecular adhesive additivesEngineeringResin adhesive

The invention relates to home building materials, in particular to a method for producing a cabinet board by adopting damp-proof composite urea resin. The cabinet board structurally comprises decorative paper, a China fir veneer, a chipboard and a backboard from top to bottom, wherein the four sides of the cabinet board are edged with aluminum alloy; damp-proof composite urea resin adhesives are smeared between the China fir veneer and the chipboard; damp-proof composite urea resin adhesives are smeared between the chipboard and the backboard; and the chipboard in the cabinet board adopts damp-proof composite urea resin adhesives as well. The cabinet board manufactured through the method has the properties of high water resistance, high adhesive strength and low formaldehyde residual volume and the damp-proof function. The raw materials adopted by the chipboard in production of the cabinet board are waste materials-leftover materials which can not be used in the process of manufacturing a multi-layer eucalyptus board after rotary cutting of the eucalyptus board. The leftover materials are used, so that wood materials are saved, and the production cost is reduced for enterprises.

Owner:南宁市林润木业有限公司

Method for producing high temperature resistant oriented strand board from whole eucalyptus wood scraps

ActiveCN106313265BLow costReduce energy consumptionNon-macromolecular adhesive additivesMacromolecular adhesive additivesParticle boardHigh-temperature corrosion

Owner:广西横县新威林板业有限公司

A kind of production method of moisture-proof modified urea-formaldehyde resin adhesive

ActiveCN104762047BLow residual formaldehydeAvoid it happening againNon-macromolecular adhesive additivesStarch adhesivesMoistureResin modified

The invention provides a moisture-proof urea-formaldehyde resin adhesive. The raw materials and parts by weight include: 55-75 parts of modified urea-formaldehyde resin, 4-8 parts of polyvinyl acetate emulsion, 0.4-0.9 parts of vinyltrimethoxysilane, 25 to 35 parts of filler; the preparation method is to first prepare modified urea-formaldehyde resin, add formaldehyde at one time, add urea three times, and add oxidized starch and furfuryl alcohol as modifiers during the reaction process, and the production of modified urea-formaldehyde resin There are three stages: the initial stage of the reaction, the middle stage of the reaction, and the late stage of the reaction; after the late polymerization, polyvinyl acetate emulsion and isobutyl triethoxysilane are added, and the filler is added after mixing evenly. Through this process, the gel phenomenon in the polymerization process is avoided. The resulting urea-formaldehyde resin has improved water resistance and low residual formaldehyde. It is used for the production of wood-based panels and can be used in places with high humidity in the south, and the formaldehyde emission is low.

Owner:广西崇左市中港木业有限公司

Method for producing weather-resistant oriented strand board from whole eucalyptus wood scraps

ActiveCN106272865BLow costReduce energy consumptionNon-macromolecular adhesive additivesStarch derivtive adhesivesOptoelectronicsImpurity

Owner:广西横县新威林板业有限公司

Method for producing particleboard with moisture-proof composite urea-formaldehyde resin

ActiveCN106313205BTake advantage ofReduce formaldehyde contentNon-macromolecular adhesive additivesStarch derivtive adhesivesWear resistantSilanes

The invention discloses a method for producing particle board by adopting moisture-proof composite urea resin. The method comprises the steps of material preparation, drying, debarking, sand removing, sorting, grinding, glue blending, hot pressing molding and the like. The key points of the production method disclosed by the invention are that melamine modified urea resin is adopted as a main material of an adhesive and is added with oxidized starch to form a viscous compound, polyvinyl alcohol is taken as a toughening agent, magnesium oxide is taken as an antiaging agent, hexamine and triglycidyl isocyanurate are taken as a curing agent, isobutyl triethoxy silane is taken as a bridging agent, phenolated lignin is taken as a formaldehyde catcher and a moisture-proof agent is also added to prepare the moisture-proof composite urea resin; the composite urea resin has the advantages of being low in formaldehyde residual volume, good in water resistance and good in moisture resistance; therefore, the produced particle board is low in formaldehyde residual volume, hard to expand after absorbing water and hard to arch and deform, and a wear-resistant layer is hard to damage. The particle board produced by the method disclosed by the invention is low in formaldehyde residual volume, also stable in quality, hard to damage, good in water resistance and good in moisture resistance.

Owner:广西横县新威林板业有限公司

A method for making an insect-proof and low-aldehyde wardrobe board

ActiveCN105108841BResidue reductionImprove water resistanceLaminationLamination apparatusWear resistantAgricultural engineering

The invention relates to a home building material, in particular to a method for making an insect-proof low-aldehyde wardrobe board. The method for making insect-proof and low-aldehyde wardrobe boards is characterized in that it includes the following steps: plank rotation—drying—repair—adhesive coating—pre-pressing—hot pressing—edge trimming and sanding—insect-proof treatment—wear-resistant paper sticking— Decorative veneer - edge banding. The formaldehyde residue of the adhesive used to make the wardrobe board in the present invention is low, and the aluminum alloy frame is inlaid around the wardrobe board, which can effectively prevent moisture and moisture in the air from penetrating into the inside of the board, and improve the moisture resistance and water resistance of the wardrobe board. The wardrobe board prepared by the present invention has good properties such as moth-proof, mildew-proof, moisture-proof, wear-resistant, etc., the residual amount of formaldehyde is low, and the harm to the human body is reduced, and the quality of the wardrobe board obtained is stable, the size stability is good, and it is not Easy to crack and damage, not easy to deform, long service life.

Owner:广州市艾依格家居制品有限公司

Production method of moisture-proof ceiling decorative board

ActiveCN103433993BAvoid it happening againReduce releaseNon-macromolecular adhesive additivesWood working apparatusNatural ventilationWear resistant

The invention provides a production method of a damp-proof ceiling decorative sheet. The production method is characterized in that particles such as various straw and nut shells produced after wood particles or crops are collected are mixed with damp-proof urea-formaldehyde resin adhesives to manufacture a panel in a pressing mode, and melamine impregnated paper or aluminums oxide wear-resistant paper is stuck to the panel in a pressing mode under a high temperature; three times of cold pressing and three times of hot pressing are adopted in forming the panel, and twice heat-dissipation maintenance is performed; the temperature of cold pressing is the room temperature, the pressure is 2.5MPa, and the pressure of hot pressing is 1.5-2.0MPa; the temperature of the first time of hot pressing is 130-135 DEG C, the temperature of the second time of hot pressing is 125-130 DEG C, and the temperature of the third time of hot pressing is 120-120 DEG C; heat dissipation maintenance is performed by cooling a constant-temperature room to be in the room temperature through natural ventilation for 3-4h; the melamine impregnated paper or the aluminums oxide wear-resistant paper is stuck to the surface of the panel under the temperature of 150 DEG C and the pressure of 1.5MPa.

Owner:SHENZHEN STYLE DECORATION

A kind of production method of low-aldehyde medium density fiberboard

ActiveCN105216086BImprove water resistanceGood alkali resistanceFlat articlesDomestic articlesResource utilizationWood machining

The invention relates to a method for producing a low-formaldehyde medium-density fiberboard and belongs to the technical field of wood resource utilization. The method for producing the low-formaldehyde medium-density fiberboard comprises the technological steps of raw material slicing, impurity-removal and screening, boiling, waxing and hot grinding, gluing and drying, mat formation and hot pressing, and finished product obtaining. According to the method, residues, such as battens and waste veneer, generated during wood processing are used for producing the low-formaldehyde medium-density fiberboard, waste materials are recycled, and full utilization of wood resources is effectively achieved; the formaldehyde residual volume of low-formaldehyde urea formaldehyde resin adhesive used for producing the medium-density fiberboard is low, in this way, harm to the health of human bodies is reduced, and the bonding force is high; in addition, the fiberboard has good damp-proof performance and good water-proof performance, the internal structure of the board is uniform, the density is proper, the dimensional stability is high, the quality is stable, and the service life is long.

Owner:霸州市郭仕智能家居科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com