Production method of damp-proof low-formaldehyde urea-formaldehyde resin adhesive

A low-formaldehyde urea-formaldehyde resin and urea-formaldehyde resin technology, which is used in adhesives, adhesive additives, aldehyde/ketone condensation polymer adhesives, etc. , Excellent moisture-proof function, low formaldehyde residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

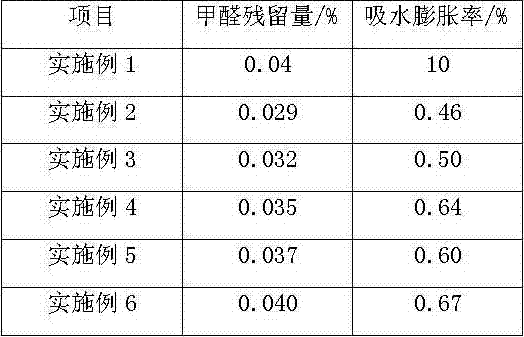

Examples

Embodiment 1

[0023] The production of urea-formaldehyde resin comprises the steps:

[0024] Pre-polymerization stage: put the formaldehyde aqueous solution with a weight concentration of 37% into the reaction kettle, start the agitator, add formic acid to adjust the pH of the solution to 2-2.5 when the temperature is stable at 49-55°C, add the first batch of urea to react with formaldehyde, Make the molar ratio of formaldehyde and urea F / U =10; react at 55-60°C for 35 minutes;

[0025] Polymerization stage: after the reaction in the prepolymerization stage, immediately adjust the pH of the reaction solution to 8.1-8.5 with aqueous sodium hydroxide solution, raise the temperature to 81-85°C, and add the first batch of melamine. The amount of the first batch of melamine accounts for 10% of the total melamine weight. % ~ 30%, after stirring evenly, add the second batch of urea to make formaldehyde and urea F / U = 3, and react for 35 minutes;

[0026] Post-polymerization st...

Embodiment 2

[0028] Take 60 parts of the modified urea-formaldehyde resin obtained in Example 1, take 10 parts of OPE moisture-proof agent, stir and mix evenly, add 15 parts of calcium carbonate, grind with a three-roller mill for 30 minutes, and obtain a moisture-proof and low-formaldehyde urea-formaldehyde resin glue.

Embodiment 3

[0030] Take 65 parts of the modified urea-formaldehyde resin obtained in Example 1, take 11 parts of OPE moisture-proof agent, stir and mix evenly, add 16 parts of kaolin, grind with a three-roll mill for 30 minutes, and obtain a moisture-proof and low-aldehyde urea-formaldehyde resin glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com