Production method for damp-proof ceiling decoration density board

一种生产方法、密度板的技术,应用在粘合剂类型、家用元件、应用等方向,能够解决易起鼓、变形、板材翘曲变形、使用寿命短等问题,达到提高耐水性、提高密封性能、防潮性能好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

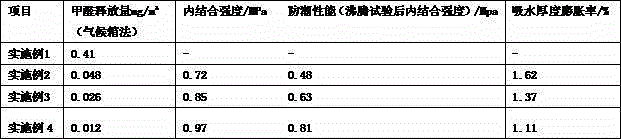

Examples

Embodiment 1

[0022] The production of urea-formaldehyde resin includes the following steps: Pre-polymerization stage: add formaldehyde solution to the polymerization reactor at one time, adjust the pH value to 2-2.5 with formic acid, add urea with 15% weight of the formaldehyde solution, heat up to 46°C, and keep warm for 60 minutes .

[0023] Polymerization stage: at the end of the pre-polymerization stage, add alkali to adjust the pH value of the reaction solution to 8-8.5, add urea with 30% weight of formaldehyde solution, and complete the addition within 40-60 minutes, then raise the temperature of the reaction solution to 88-92°C, and keep it warm for 90 minutes .

[0024] Post-polymerization stage: at the end of the polymerization stage, add urea with 30-40% of the weight of formaldehyde solution, and finish adding within 40-60 minutes, then lower the reaction temperature to 70-85°C, react for 60-90 minutes, and cool down to room temperature to obtain urea-formaldehyde resin; 46 par...

Embodiment 2

[0026] Add the moisture-proof urea-formaldehyde resin adhesive that 150kg embodiment 1 obtains to 1m3 sawdust, stir evenly with a mixer, put into the plate mold, compress with compressor under normal temperature, the pressure is 2.5Mpa; Then put into the hot press, at 130 ~135°C, hot pressing at 1.5Mpa; put the plate into a constant temperature room for natural ventilation and cooling for 3~4h, compress it with a compressor at room temperature, the pressure is 2.5Mpa; put it in a hot press, and press it for the second time at 125 ~130°C, pressure 1.5Mpa, put the board in a constant temperature room for natural ventilation and cooling for 3~4h; compress it with a compressor at room temperature, the pressure is 2.5Mpa; put it into a hot press, and press it for the third time, the temperature is 120 ~120°C, pressure 1.5Mpa; then heat up to 150°C, paste melamine-impregnated paper on both sides of the board under a pressure of 1.5Mpa, cool to room temperature by blowing air, and obt...

Embodiment 3

[0028] Add 180kg of the moisture-proof urea-formaldehyde resin adhesive obtained in Example 1 to 1m3 nut shell particles, stir evenly with a mixer, put it into a plate mold, compress it with a compressor at normal temperature, and the pressure is 2.5Mpa; 130~135℃, hot pressing at 1.8Mpa; put the plate in a constant temperature room for natural ventilation and cooling for 3~4 hours, and compress it with a compressor at room temperature, with a pressure of 2.5Mpa; 125~130℃, the pressure is 1.8Mpa, put the plate into the constant temperature room for natural ventilation and cooling for 3~4 hours; use a compressor to compress at room temperature, the pressure is 2.5Mpa; then put it into the hot press, and heat the third time, the temperature is 120~120℃, the pressure is 1.8Mpa; then the temperature is raised to 150℃, the two sides of the board are covered with aluminum oxide wear-resistant paper under the pressure of 1.5Mpa, and the air blast is cooled to room temperature a to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com