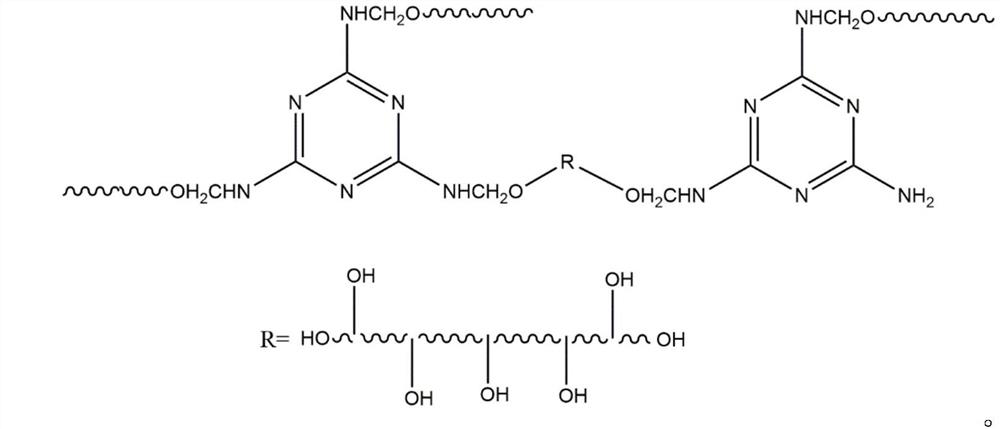

Low-formaldehyde high-elasticity semi-hard melamine foam and preparation method thereof

A high-elasticity, semi-rigid technology, applied in the field of polymer foam materials, can solve the problems of large residual formaldehyde, inability to be widely used, and high powder drop rate, and achieve low formaldehyde residual, good application prospects, and low thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

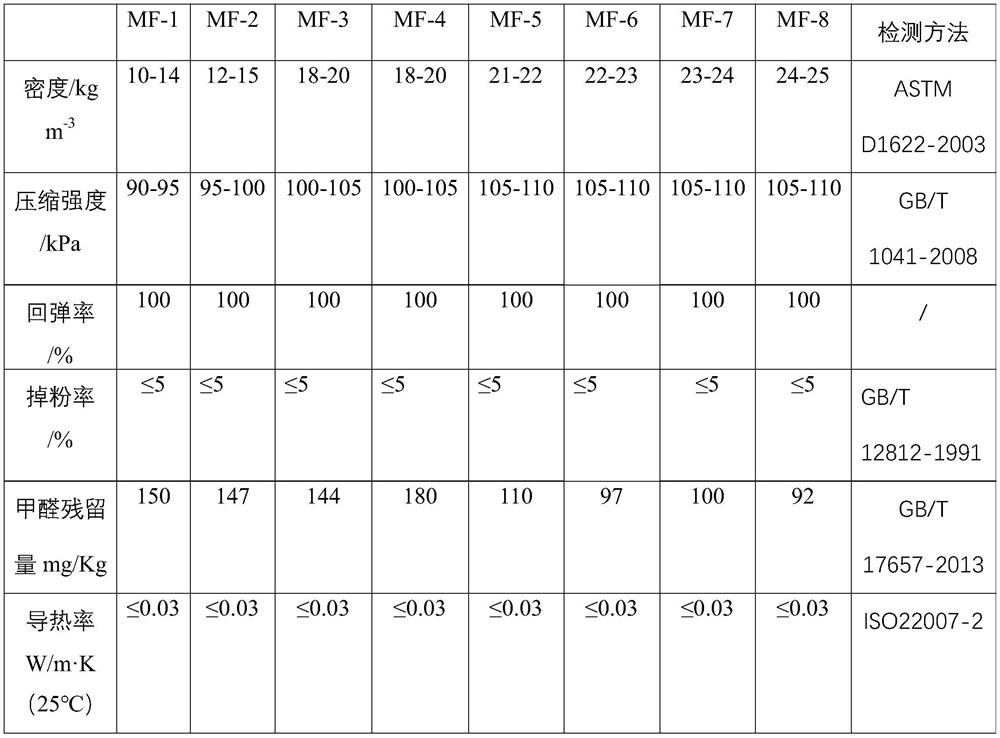

Embodiment 1

[0041] A method for preparing low formaldehyde, highly elastic melamine foam is as follows:

[0042]First, add 50g of water-based phenolic formaldehyde, 200g of paraformaldehyde, 320g of melamine and 200g of water into the reaction kettle, adjust the pH between 8-9, and keep it at 80°C for a period of time. After the solution is clarified, add 50g of polyacrylamide to react for 1 hour , and finally get the foamed prepolymer liquid.

[0043] By weight, 3 parts of OP-10 emulsifier, 8 parts of n-pentane foaming agent, 5 parts of formic acid curing agent, 2 parts of KH550 modifier and 100 parts of foaming prepolymer liquid are passed through a high-speed mixer at 3000r / min rotating speed Mix evenly, pour the mixed foaming liquid into a specific mold, foam by microwave, foaming time is 1min, microwave power is 800W, post-treatment at 140°C for 2h, and MF1 foam is obtained.

Embodiment 2

[0045] A method for preparing low formaldehyde, highly elastic melamine foam is as follows:

[0046] First, add 20g of polyvinyl alcohol, 250g of paraformaldehyde, 400g of melamine and 310g of water into the reactor, adjust the pH between 8-9, and keep it at 80°C for a period of time. After the solution is clarified, add 60g of acrylic acid emulsion to react for 1h , and finally get the foamed prepolymer liquid.

[0047] By weight, 3 parts of OP-10 emulsifier, 8 parts of n-pentane foaming agent, 8 parts of formic acid curing agent, 2 parts of KH560 modifier and 100 parts of foaming prepolymer liquid are passed through a high-speed mixer at a speed of 3000r / min Mix evenly, pour the mixed foaming solution into a specific mold, foam by microwave, the foaming time is 1min, the microwave power is 800W, and post-treatment at 160°C for 4h to obtain MF2 foam.

Embodiment 3

[0049] A method for preparing low formaldehyde, highly elastic melamine foam is as follows:

[0050] First, add 30g polyglycerin, 200g paraformaldehyde, 300g melamine and 220g water into the reaction kettle, adjust the pH between 8-9, keep it at 80°C for a period of time, after the solution is clarified, add 60g polyacrylamide to react for 1h , and finally get the foamed prepolymer liquid.

[0051] By weight, 3 parts of sodium dodecylbenzenesulfonate emulsifier, 8 parts of n-pentane blowing agent, 5 parts of formic acid curing agent, 2 parts of KH550 modifier and 100 parts of foaming prepolymer liquid are passed through high-speed mixer in Mix evenly at a speed of 3000r / min, pour the mixed foaming solution into a specific mold, and foam by microwave, the foaming time is 1min, the microwave power is 1000W, and post-treatment at 160°C for 2h to obtain MF3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com