High-reliability fast-curing filling glue

A rapid curing and filling technology, applied in the direction of adhesives, epoxy resin glue, polymer adhesive additives, etc., can solve the problems of high curing temperature, low energy consumption cost, lower yield of finished products, etc., and achieve high glass transition temperature, meeting reliability requirements, and increasing the effect of connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The raw material components and dosages of the underfill provided in Examples 1-7 and Comparative Examples 1-2 are shown in Table 1 below.

[0080] In the example,

[0081] In order to obtain representative data, in terms of epoxy resin, bisphenol A epoxy resin is selected from Dow DER331; bisphenol F epoxy resin is selected from Dow DER354; novolac epoxy resin is selected from Dow DEN438; alicyclic epoxy resin The resin is selected from Daicel CELLOXIDE 2021P; the polyphenol glycidyl ether epoxy resin is selected from Huntsman Tactix 742; triglycidyl isocyanurate and its derivatives are selected from Nissan Chemical’s TEPIC-VL, but the present invention is not limited thereto .

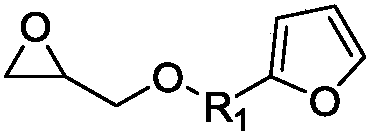

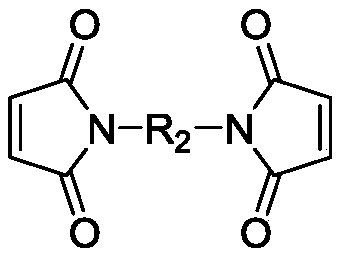

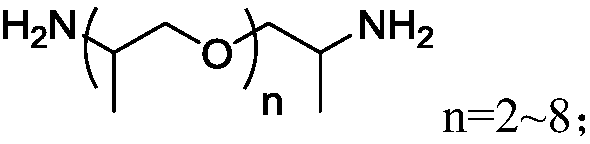

[0082] In order to obtain representative data, in terms of epoxy diluent, dimer acid glycidyl ester chooses GS-120 from CVC in the United States; furanyl glycidyl ether chooses furyl methyl glycidyl ether; oxetane and its derivatives OXT-101 (3-methyl-3-hydroxymethyl oxetane) synthesized by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com