Patents

Literature

37results about How to "Increased curing crosslink density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

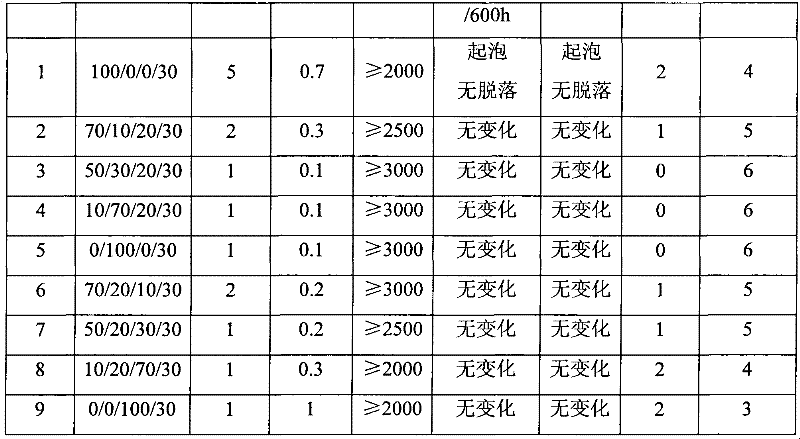

Silicon- and fluorine-containing epoxy (meth) acrylate UV-curing composite coating and preparation method thereof

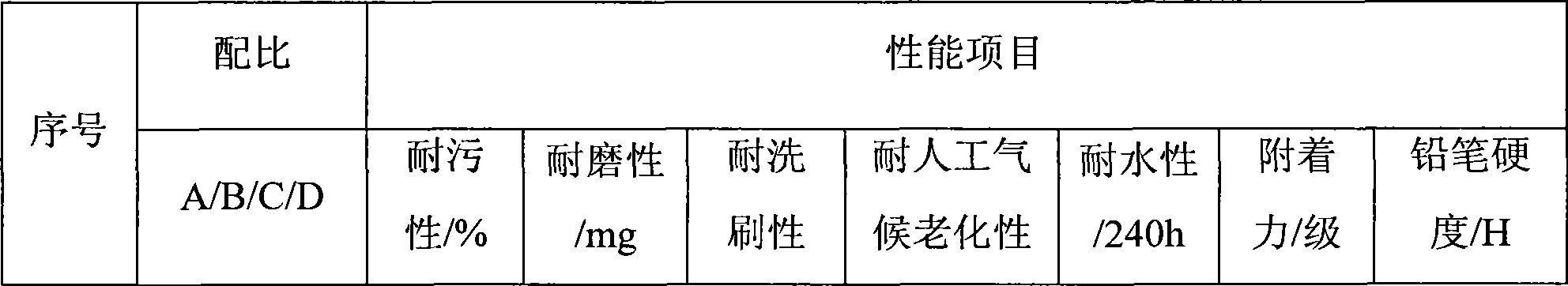

The invention discloses a silicon and fluorine-containing epoxy (meth) acrylate UV-curing composite coating, comprising the following ingredients of: epoxy (meth) acrylate, polyhedral iligomeric silsesquioxane, fluorine-containing (meth) acrylate, an active diluent monomer, a photoinitiator and an auxiliary agent. Such a composite coating, with excellent fouling resistance, corrosion resistance, weather resistance, abrasive resistance, water resistance, fouling resistance and dynamic performance, is an environmentally friendly coating which is suitable for building material, optical fiber wrapping and the coating of the surface of metal element.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method of phenolic resin combined honeycomb activated carbon

The invention relates to a preparation method of phenolic resin combined honeycomb activated carbon, which can be used for preparing the honeycomb activated carbon by the steps of: mixing dry powder, preparing plastic pug by mixing and kneading through a wet method, vacuum pugging, extrusion molding, drying, curing treatment and secondary heat treatment. Besides the function of bonding and improving the mechanical strength of the activated carbon, the phenolic resin also remarkably improves the heat-resisting property and water resistance of the honeycomb activated carbon; and furthermore, the honeycomb activated carbon is added with porous mineral, thus better effectively improving the mechanical strength and the specific surface area of the honeycomb activated carbon. The preparation method has lower heat treatment temperature and low production energy consumption, and effectively reduces the production cost; and the preparation technique and equipment thereof are simple, and the production investment is lower, so that the cost is further reduced.

Owner:TSINGHUA UNIV

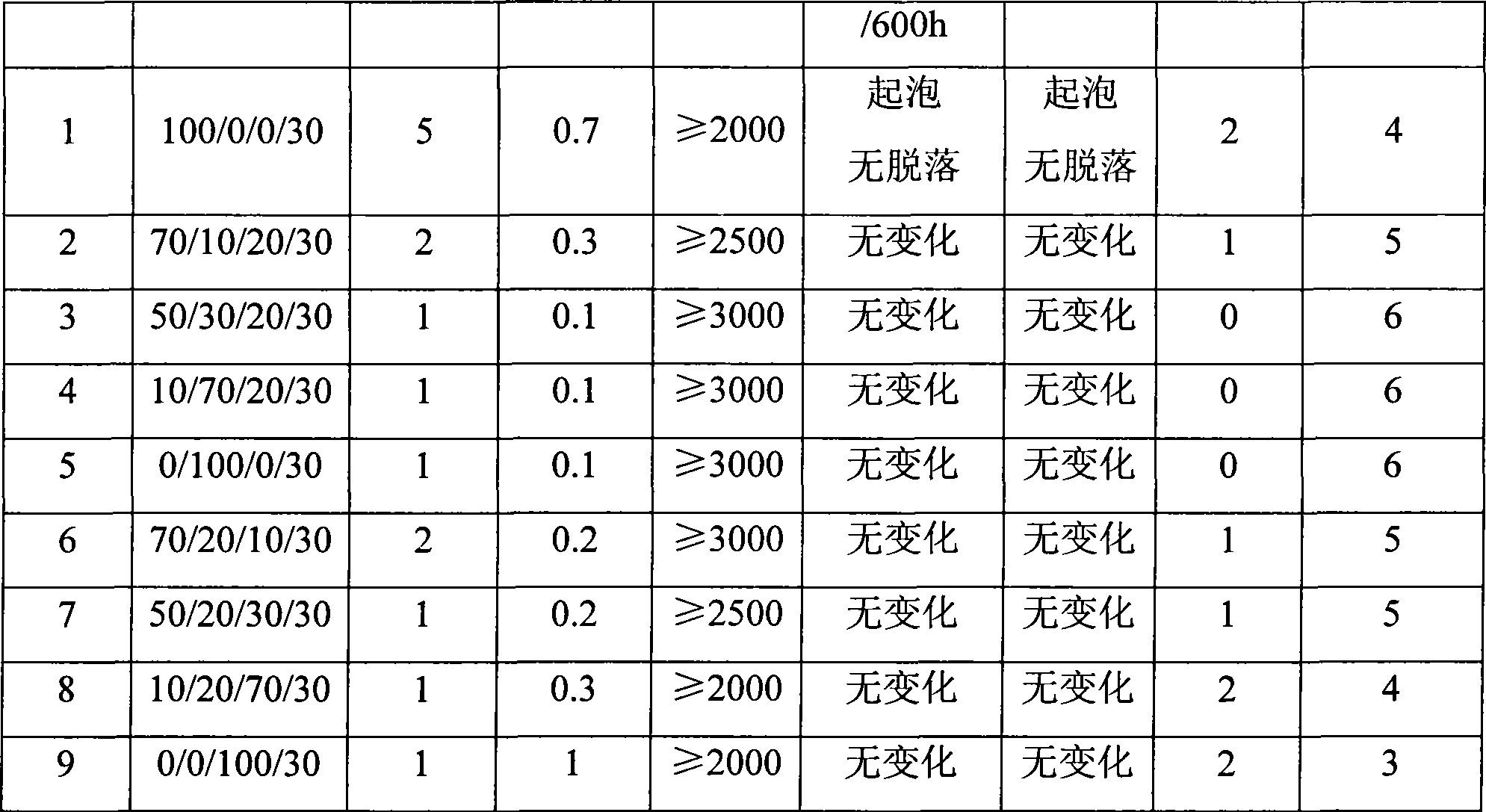

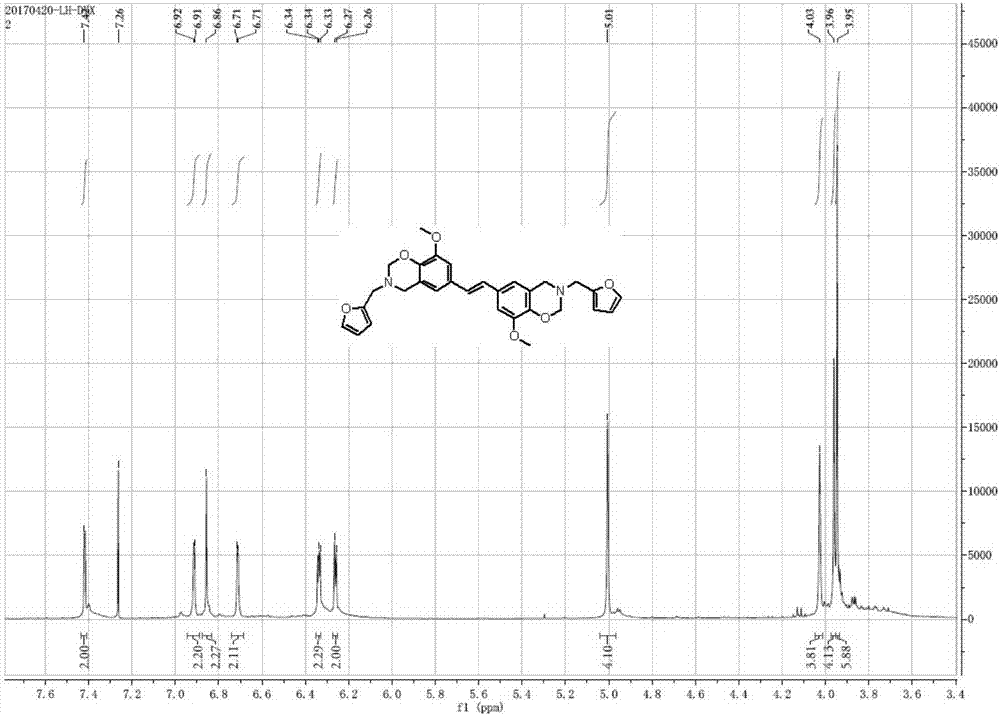

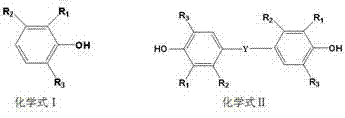

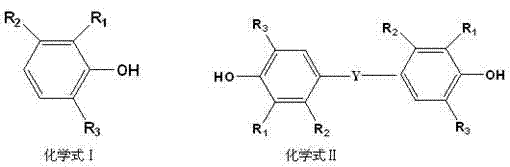

Biology base benzoxazine containing double bond active functional groups and preparation method thereof

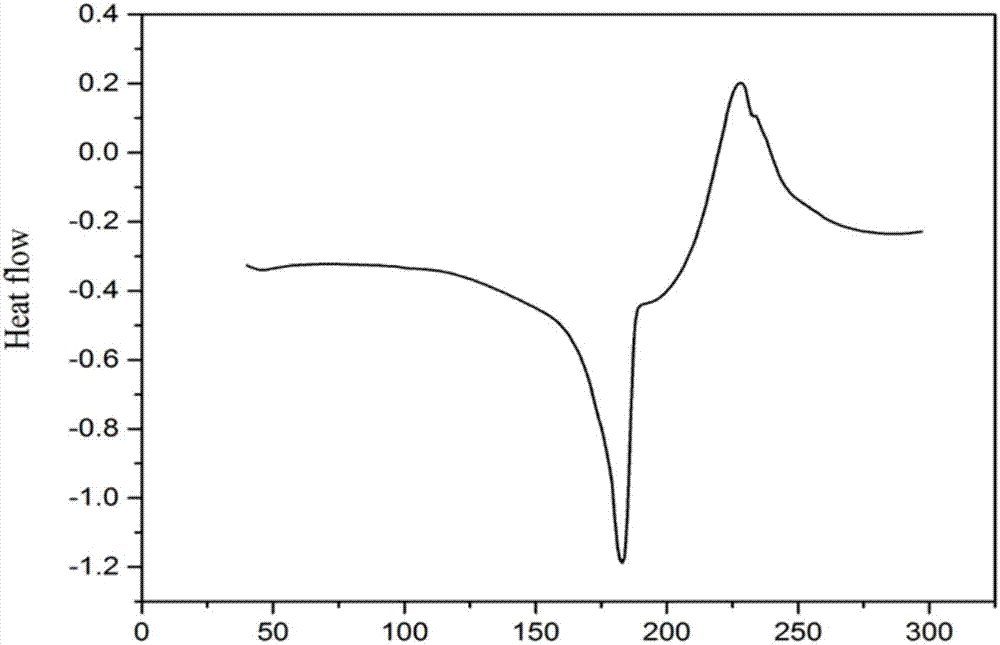

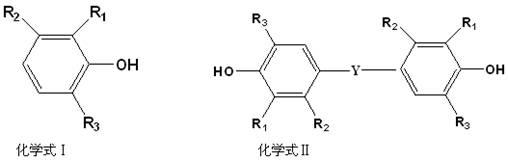

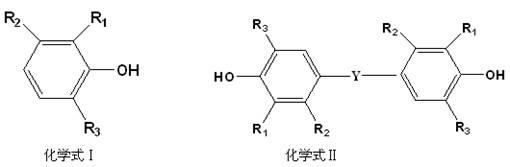

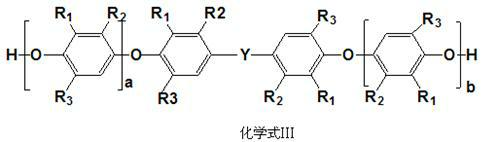

InactiveCN107459512AHigh carbon residue rateIncreased curing crosslink densityOrganic chemistryDouble bondSolvent

The invention discloses biology base benzoxazine containing double bond active functional groups. Bisphenol (E)-1,2-bis(3-methoxy-4-hydroxyl phenyl)ethylene, primary amine compounds and formaldehyde compounds react to generate the benzoxazine. Bisphenol (E)-1,2-bis(3-methoxy-4-hydroxyl phenyl)ethylene is obtained by causing reproducible vanillin to undergo Mcmurry coupling reaction. The method for preparing benzoxazine comprises the steps of adding bisphenol (E)-1,2-bis(3-methoxy-4-hydroxyl phenyl)ethylene, the primary amine compounds and the formaldehyde compounds into a round-bottom flask containing solvent benzene or toluene, performing heating reflux water diversion reaction, performing extraction and drying, and performing column chromatography isolation to obtain the product. The benzoxazine has high thermal stability and high residual carbon rate, can be used alone as a monomer or mixed with other benzoxazine monomers or phenolic resin or epoxy resin for use, and an obtained cured product is good in heat resistance and can be used for the fields of high-performance structural materials, ablation-resistant materials and electronic packaging materials.

Owner:SOUTHWEST PETROLEUM UNIV

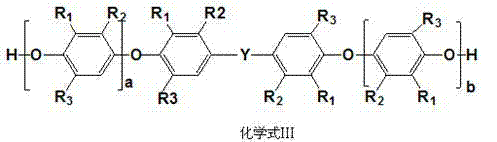

Preparation method for amination polyphenyl ether

ActiveCN102516532AImprove electrical performanceIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsEpoxyPolymer science

The invention discloses a preparation method for amination polyphenyl ether, which is characterized by including the following steps that low-molecular-weight polyphenyl ether with double hydroxyl is generated through oxidation, coupling and copolymerization of two kinds of phenol, and low-molecular-weight polyphenyl ether resin with double amino is obtained through a process such as nitration. Compared with conventional polyphenyl ether resin, the polyphenyl ether resin with the double amino is more in active groups cross-linked with epoxy, larger in cross-linking degree with epoxy resin, can remarkably improve poly-p-phenylene oxide / epoxy (PPO / EP) compatibility, can increase proportion of the polyphenyl ether resin in a PPO / EP system, and accordingly remarkably improves condensate electrical property of a resin system.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber

ActiveCN106085325AGuaranteed toughening effectIncreased curing crosslink densityRubber derivative adhesivesEpoxy resin adhesivesCross-linkGlass transition

The invention discloses an epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber. The adhesive is prepared from the following components in parts by weight: 100 parts of bisphenol-A or bisphenol-F epoxy resin, 8 to 60 parts of amine curing agent and 10 to 70 parts of tertiary-amide modified liquid nitrile butadiene rubber. The curing condition is that all components are uniformly mixed and are cured at a room temperature for 4 to 7 days or are cured at a temperature of 50 DEG C for 1 day. The adhesive has main properties that the tensile strength is 20 to 40 MPa, the elongation at break is 5 percent to 30 percent, the impact strength is 20 to 150 kJ / m2 and high-temperature glass transition temperature is 90 to 120 DEG C. The toughened epoxy adhesive disclosed by the invention has the advantages that excellent mechanical property and excellent toughness are obtained; the curing cross-linking density of the epoxy resin is improved, the high-temperature glass transition temperature of the epoxy adhesive is not reduced, and the high-temperature usage temperature of the adhesive is not reduced while the adhesive is toughened by utilization of the characteristics of catalyzing and curing epoxy functional groups by a tertiary amine group.

Owner:NANJING UNIV

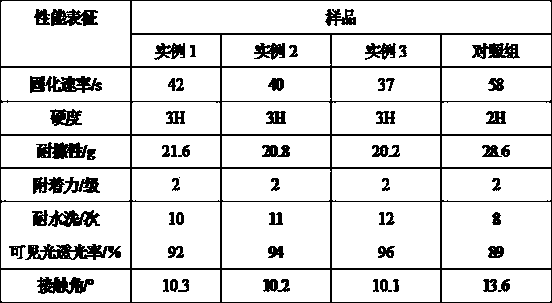

Halogen-free resin composition and cover film, copper-clad plate and printed wiring board prepared from same

InactiveCN109135647AHigh transparencyGood adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesEpoxyPolyester

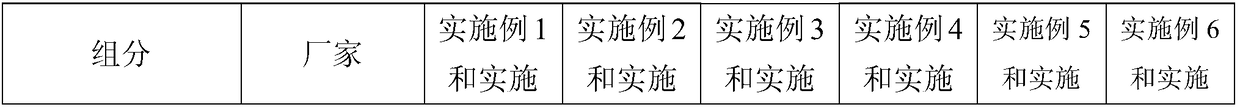

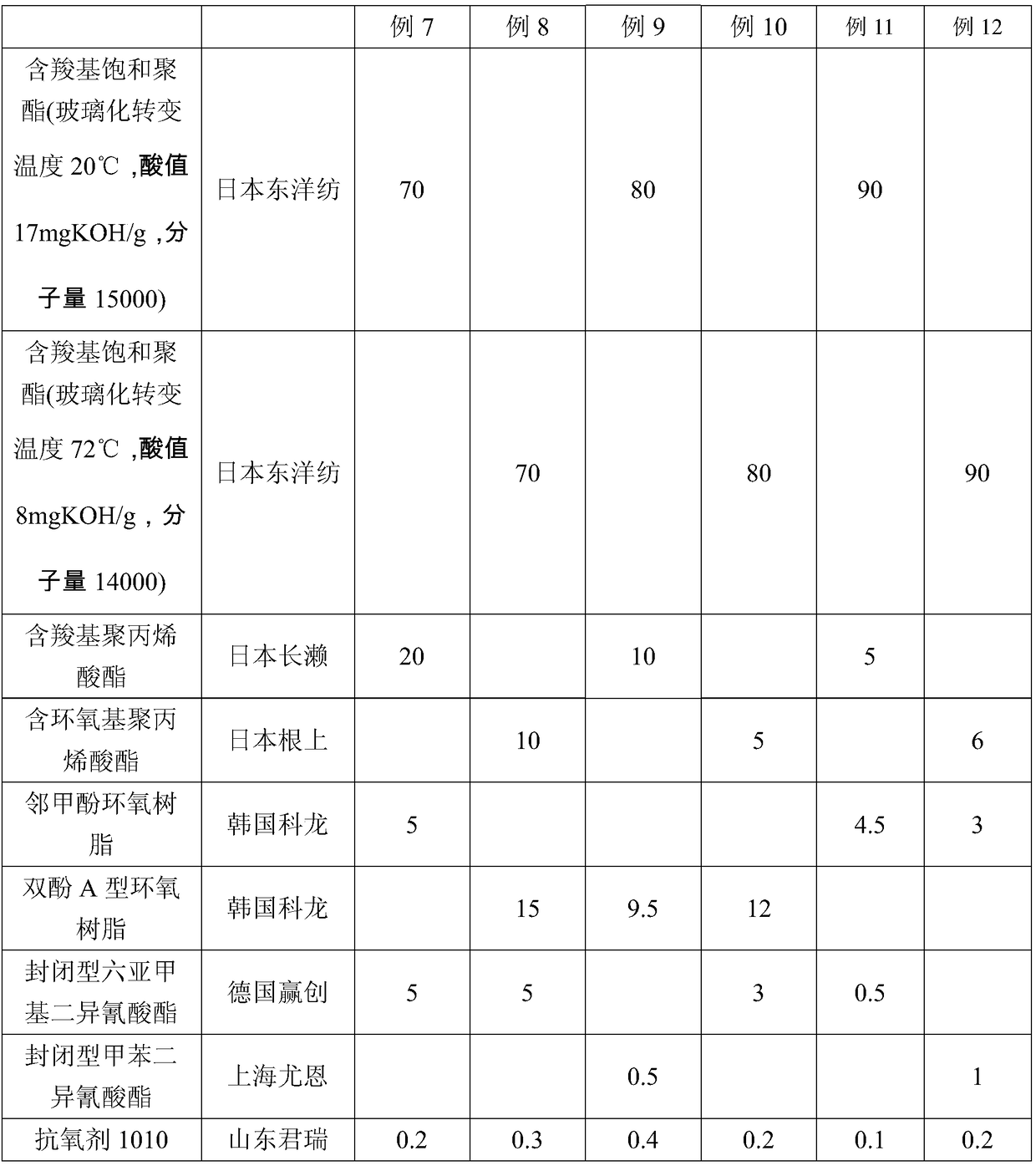

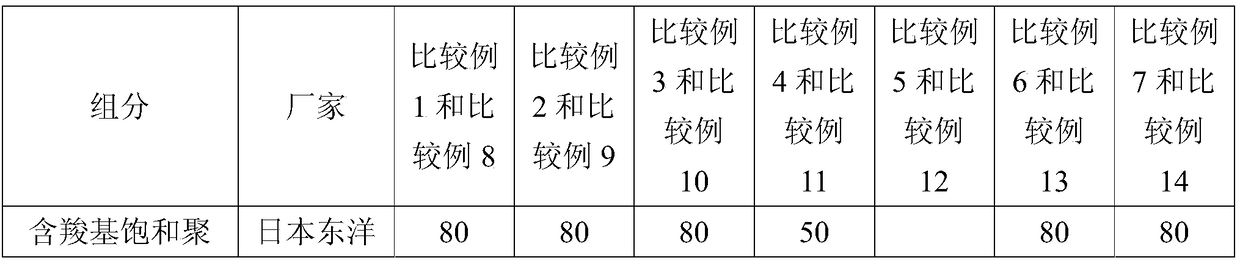

The invention provides a halogen-free resin composition and a cover film, a copper-clad plate and a printed wiring board prepared from the same. The halogen-free resin composition comprises, by weight, 70-90 parts of carboxyl-saturated polyester, 5-20 parts of polyacrylate, 3-15 parts of epoxy resin and 0.5-5 parts of blocked isocyanates. The carboxyl-saturated polyester and the polyacrylate are adopted as main resins, so that the resin composition is high in transparency and good in adhesion. The epoxy resin and the blocked isocyanates adopted as curing agents cooperate with each other to cure the carboxyl-saturated polyester and the polyacrylate, so that the resin composition has good storage stability and high curing and crosslinking density. The cover film prepared from the halogen-free resin composition is good in shape covering and high in visible light transmittance and peel strength. The copper-clad plate prepared from the halogen-free resin composition is also high in visiblelight transmittance and peel strength.

Owner:GUANGDONG SHENGYI SCI TECH

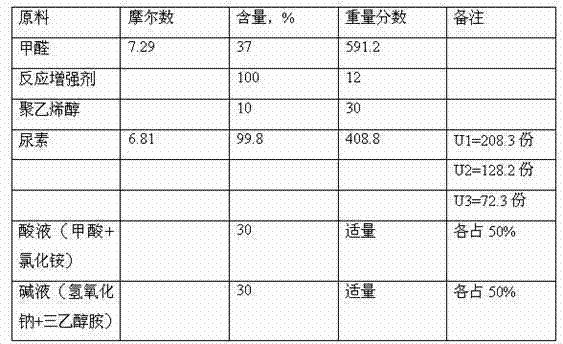

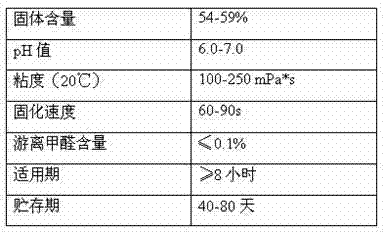

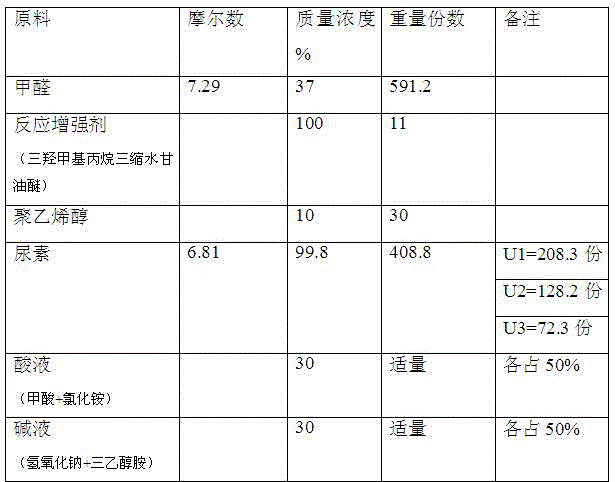

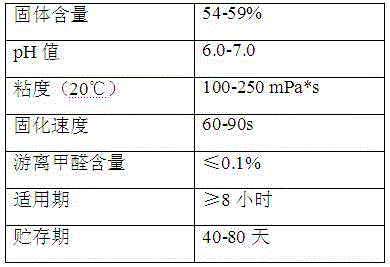

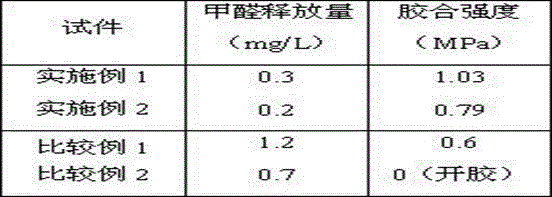

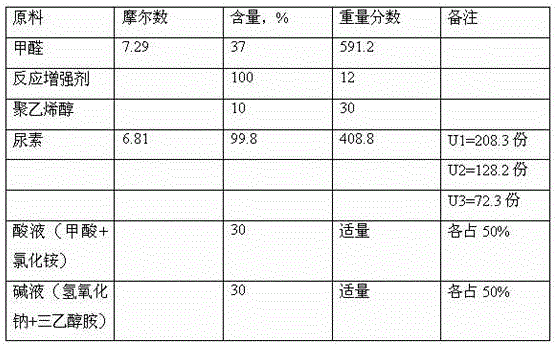

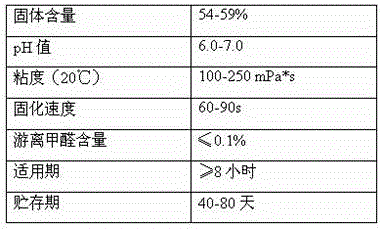

Modified urea resin adhesive and preparation method thereof

InactiveCN104762041AIncrease the degree of molecular branchingHigh molecular weightAldehyde/ketone condensation polymer adhesivesResin adhesiveEpichlorohydrin

The invention discloses a modified urea resin adhesive and a preparation method thereof. According to the preparation method, formaldehyde and urea in a low molar ratio are taken as raw materials, and a poly-functionality reaction enhancer is taken as a polycondensation agent to replace an acidic polycondensation condition, and the urea resin is synthesized by use of an acid-alkali-acid process; the molecular branching coefficient of the urea resin is increased, the molecular weight of the urea resin is increased under the same viscosity, and the curing cross-linking density of the urea resin can be increased, and furthermore, the bonding strength is improved and the formaldehyde release amount of the bonded products is reduced. The preparation method of the low-toxicity urea resin adhesive has the advantages that non-traditional melamine-epoxy chloropropane-sodium hydroxide reactants are taken as polycondensation agents and the acid-alkali-acid synthesis process is adopted, the basic procedure is close to the conventional process, the process is simple, the operations are convenient, and the existing equipment does not need to be modified.

Owner:SCHOLAR HOME SHANGHAI NEW MATERIAL CO LTD

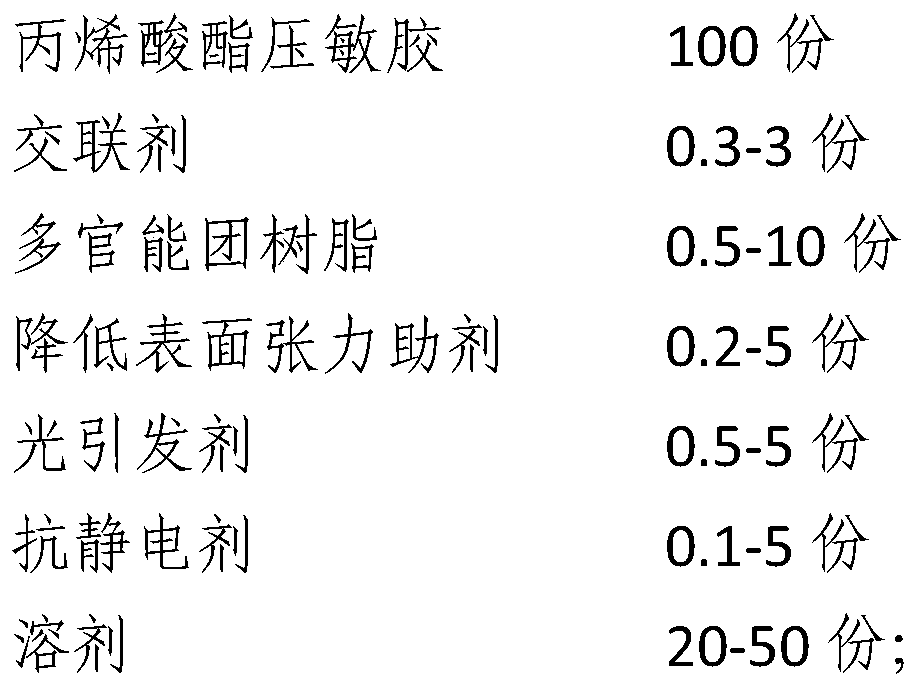

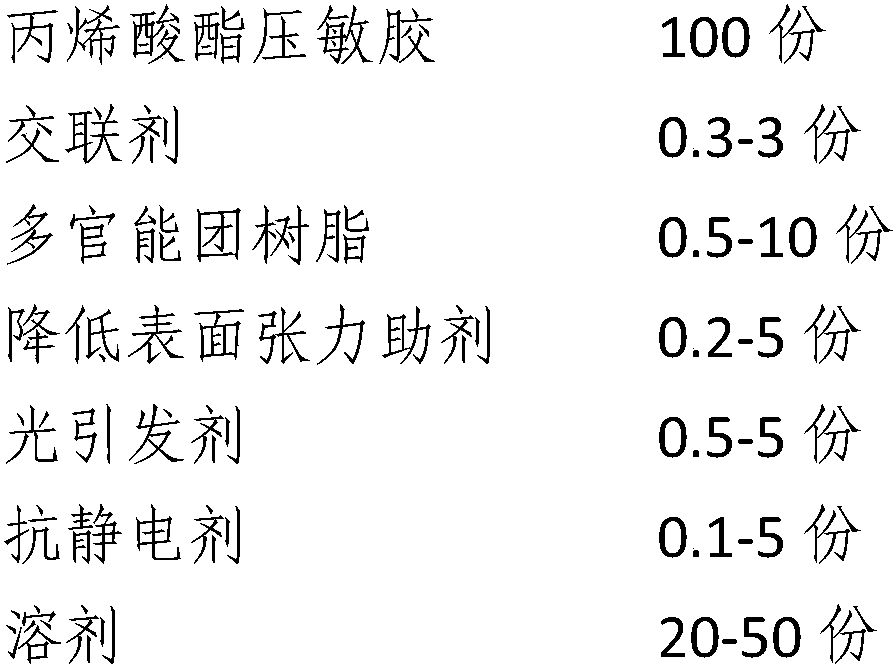

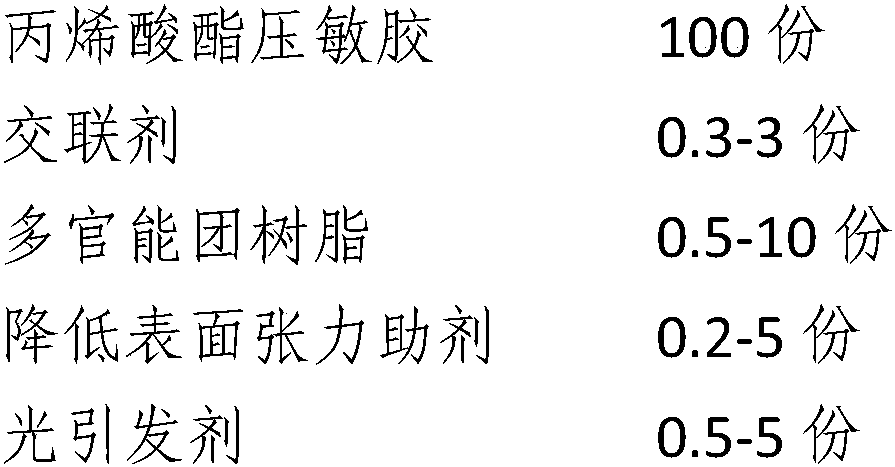

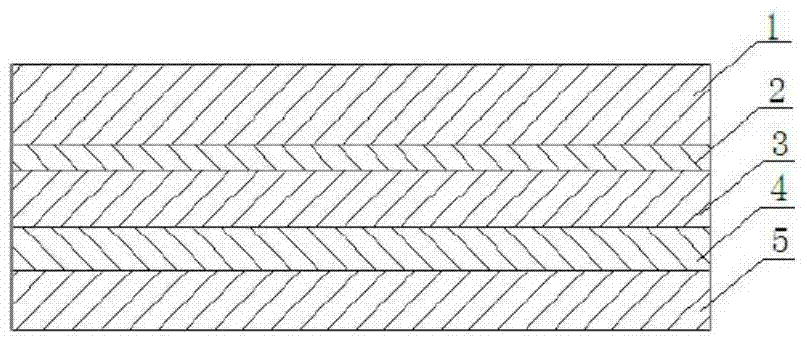

Plasticizer-precipitation-preventing UV viscosity-reducing adhesive tape and preparation method thereof

InactiveCN110903779APrecipitation controlIncreased curing crosslink densityFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses a plasticizer-precipitation-preventing UV viscosity-reducing adhesive tape. The adhesive tape comprises a release film, a plasticizer-precipitation-preventing UV viscosity-reducing adhesive layer and a base film which are sequentially arranged. The plasticizer-precipitation-preventing UV viscosity-reducing adhesive layer comprises acrylate pressure-sensitive adhesive resin,a cross-linking agent, a photoinitiator, an antistatic agent, a surface tension reducing aid and a solvent. The acrylate pressure-sensitive adhesive resin comprises a polyfunctional oligomer or a polyfunctional monomer or a composition thereof and a polyacrylate pressure-sensitive adhesive. The surface tension reducing aid comprises polyether modified polydimethylsiloxane of an acrylate functional group. The curing cross-linking density of the glue is increased, the surface tension of the coating is reduced, the precipitation of the plasticizer can be effectively controlled, and the plasticizer is prevented from permeating into the glue layer.

Owner:SUZHOU HI TECH ELECTRONICS CO LTD

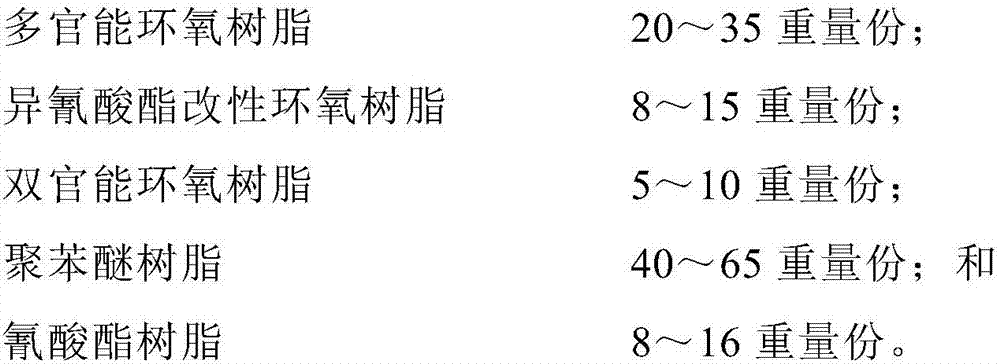

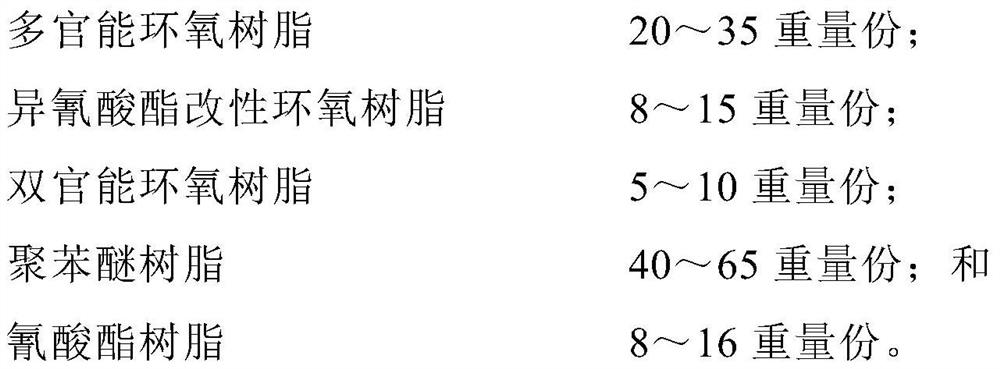

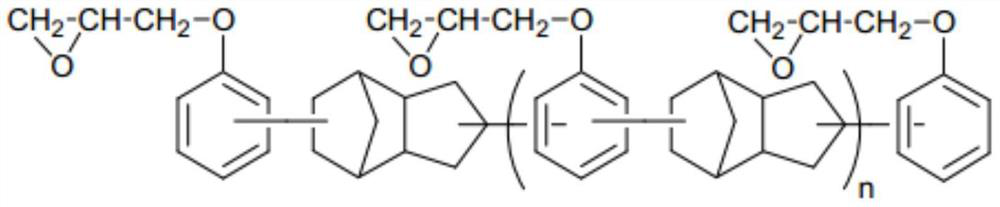

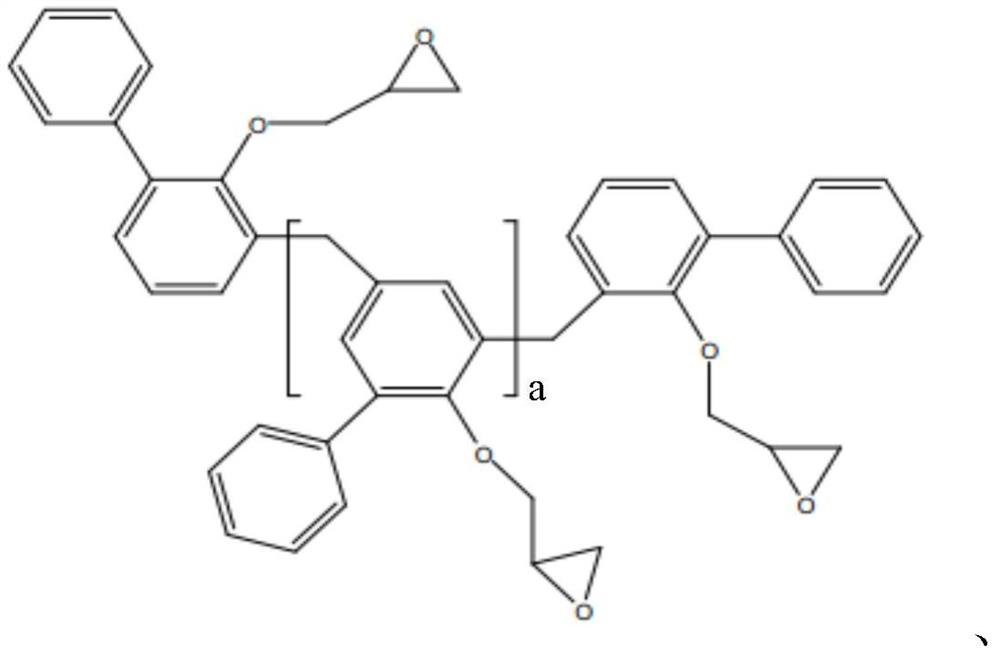

Resin composition and application thereof

ActiveCN107286325AGood flexibilityGood Metallization PropertiesFilm/foil adhesivesSynthetic resin layered productsDielectric lossHeat resistance

The invention relates to a resin composition and application thereof. In particular, the invention relates to the resin composition. The resin composition comprises 20 to 35 parts by weight of multifunctional epoxy resin, 8 to 15 parts by weight of isocyanate modified epoxy resin, 5 to 10 parts by weight of bifunctional epoxy resin, 40 to 65 parts by weight of polyphenyl ether resin and 8 to 16 parts by weight of cyanate ester resin. The invention also relates to a product of the resin composition. The product of the resin composition comprises a resin film, a bonding sheet, a prepreg, a composite material, a laminated board and a printed circuit board. Through combination of different resin, superposition of product performance is realized, so that the product has good appearance and also has the comprehensive effects of heat resistance, low dielectric loss and easiness in processing.

Owner:KUANG CHI INST OF ADVANCED TECH

Epoxy resin daub for building joint filling and preparation method thereof

The invention discloses epoxy resin daub for building joint filling. The epoxy resin daub for building joint filling comprises a component A and a component B. The component A is prepared from the main raw materials in parts by weight: 45-55 parts of bisphenol A 128 epoxy resin, 15-20 parts of modified epoxy resin, 10-15 parts of terminal carboxyl nitrile rubber, 10-15 parts of polyimide resin, 8-11 parts of a modified carbon nanotube, 12-16 parts of filler and 1-2 parts of a coupler. The component B contains a low-temperature curing agent, a polyamide curing agent, a phenolic amine curing agent and dibutyl phthalate. The mass ratio of the component A to the component B is 10: (2-3). The invention also discloses a preparation method of the epoxy resin daub. By adding the modified epoxy resin, terminal carboxyl nitrile rubber and polyimide resin and matching with the modified carbon nanotube in use, the obtained daub is high in mechanical property, high in toughness, excellent in comprehensive performance, simple in preparation process and easy to produce.

Owner:上海固瑞泰复合材料科技有限公司

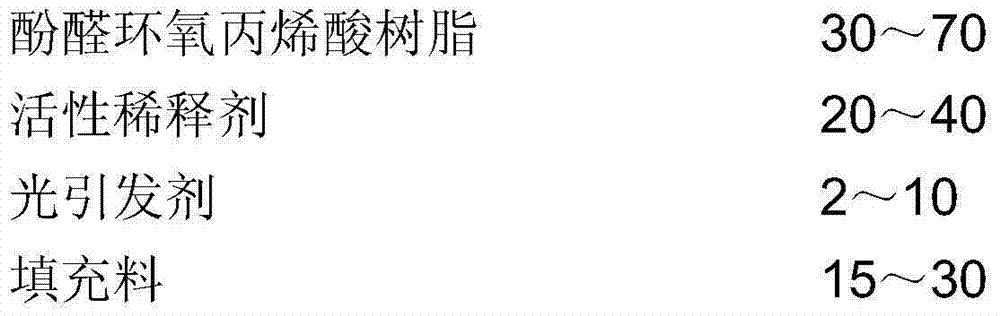

Acid resistance type protective ink and preparation method thereof

ActiveCN104845441AGood resistance to hydrofluoric acidGood dehydration effectInksHydrofluoric acidEpoxy

The invention discloses acid resistance type protective ink and a preparation method thereof. Phenolic epoxy acrylic resin which comprises a multi-reaction functional group and a hydrophilic group is synthesized, the screening of filling materials, a defoaming agent and other additives is integrated with the phenolic epoxy acrylic resin as a main body, and the acid resistance type protective ink with the good hydrofluoric acid resistance and the dehydration effect is prepared. According to the acid resistance type protective ink and the preparation method thereof, the superior adhesion is presented on OGS (One Glass Solution) touch screen glass, the time of the resistance to the 20% of hydrofluoric acid can reach more than 30 minutes, the film stripping can be achieved through the ordinary hot water, the harm to the glass is not produced, a protective film falls off in a flaked mode during film stripping, the filtration and the separation are easy, the degree of automation of the process is high, and the safe and environment-friendly effect is achieved.

Owner:国科广化(南雄)新材料研究院有限公司 +1

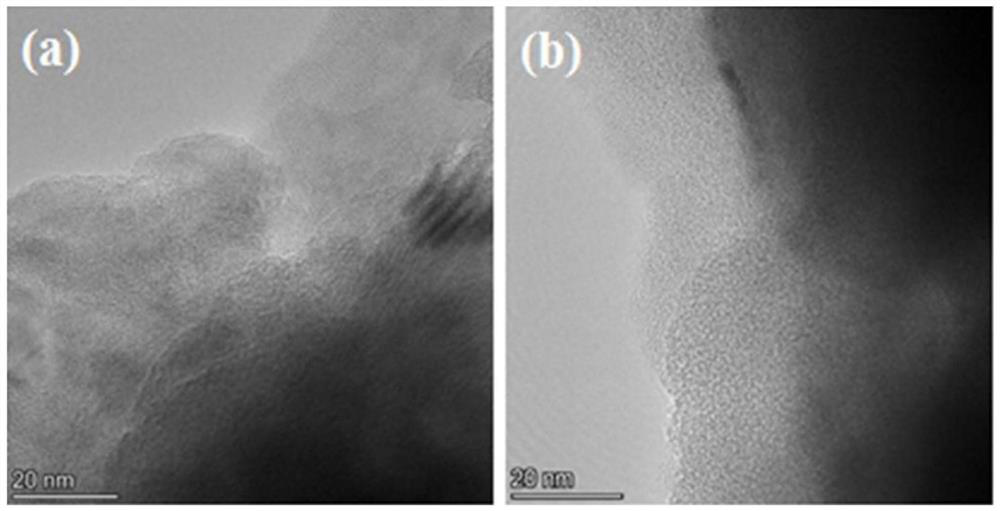

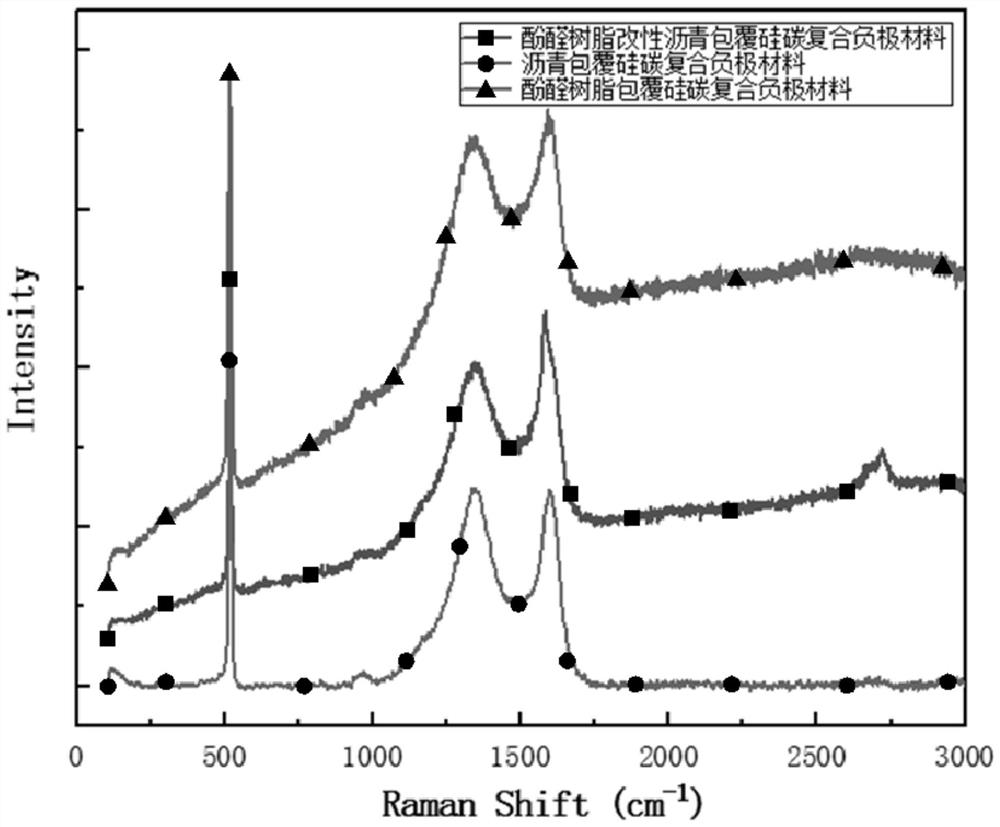

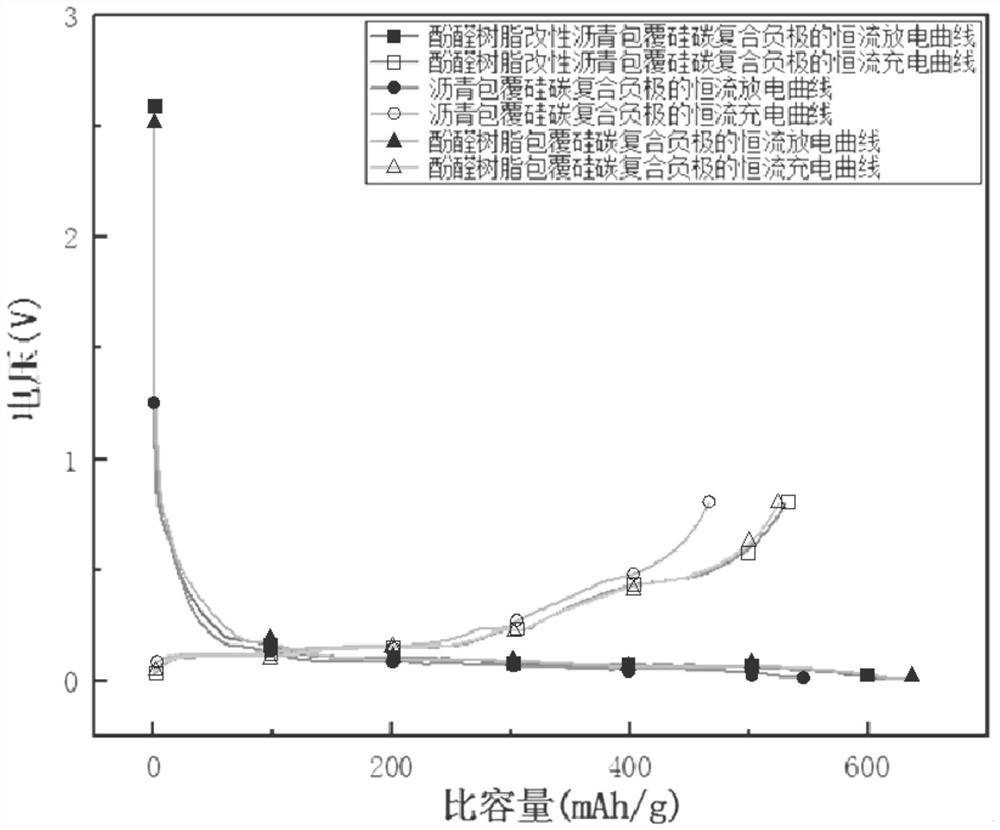

Modification method for coating silicon-carbon composite negative electrode material interface with modified asphalt

PendingCN112768644AHigh carbon residue rateHigh first rateSecondary cellsNegative electrodesCarbon compositesBattery capacity

The invention relates to the technical field of lithium battery materials, and in particular relates to a modification method for coating a silicon-carbon composite negative electrode material interface with modified asphalt. The asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing specially selected phenolic resin, so that the silicon-carbon composite negative electrode material with high rate performance and high first rate is prepared. And a compact nano carbon coating layer with low pore defect degree is formed, so that the defects such as cracks and holes on the surfaces of nano silicon and graphite can be effectively repaired, irreversible consumption of a large number of active lithium ions in the charging and discharging process of a battery is avoided, and irreversible reduction of the battery capacity is remarkably reduced. Therefore, the asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing the mutual synergistic effect of the phenolic resin and the asphalt, the capacity diving condition during high-current charging and discharging of the battery is obviously delayed, and the rate capability and coulombic efficiency of the material are improved.

Owner:西安英纳吉科技有限公司

Tertiary Amine Modified Liquid Nitrile Rubber Toughened Epoxy Adhesive

ActiveCN106085325BGuaranteed toughening effectIncreased curing crosslink densityRubber derivative adhesivesEpoxy resin adhesivesCross-linkGlass transition

The invention discloses an epoxy adhesive toughened by tertiary-amide modified liquid nitrile butadiene rubber. The adhesive is prepared from the following components in parts by weight: 100 parts of bisphenol-A or bisphenol-F epoxy resin, 8 to 60 parts of amine curing agent and 10 to 70 parts of tertiary-amide modified liquid nitrile butadiene rubber. The curing condition is that all components are uniformly mixed and are cured at a room temperature for 4 to 7 days or are cured at a temperature of 50 DEG C for 1 day. The adhesive has main properties that the tensile strength is 20 to 40 MPa, the elongation at break is 5 percent to 30 percent, the impact strength is 20 to 150 kJ / m2 and high-temperature glass transition temperature is 90 to 120 DEG C. The toughened epoxy adhesive disclosed by the invention has the advantages that excellent mechanical property and excellent toughness are obtained; the curing cross-linking density of the epoxy resin is improved, the high-temperature glass transition temperature of the epoxy adhesive is not reduced, and the high-temperature usage temperature of the adhesive is not reduced while the adhesive is toughened by utilization of the characteristics of catalyzing and curing epoxy functional groups by a tertiary amine group.

Owner:NANJING UNIV

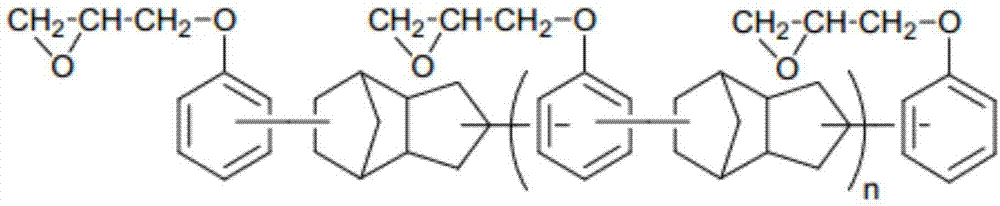

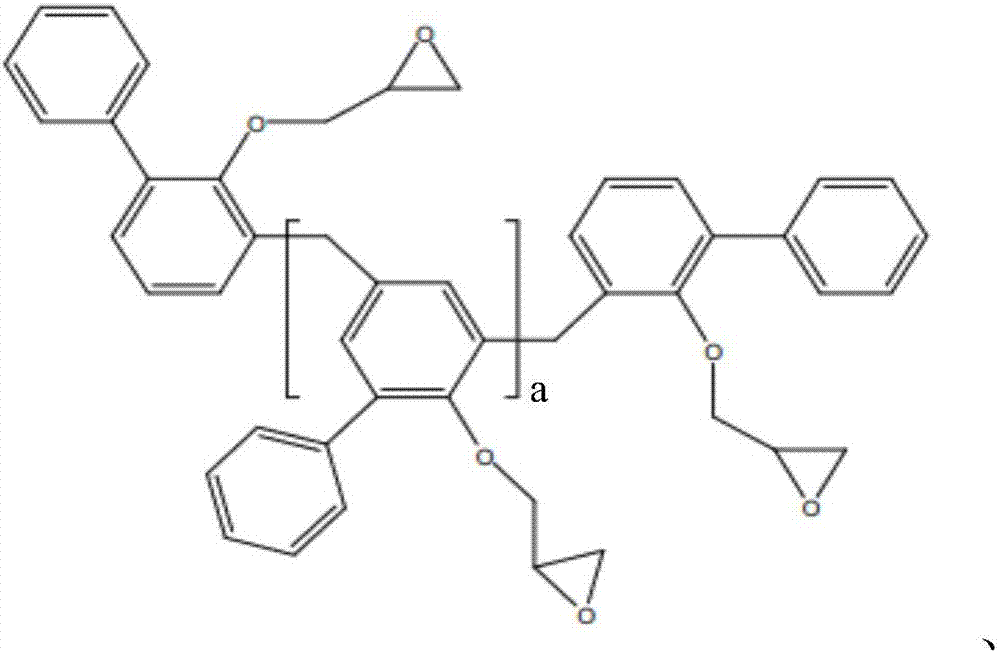

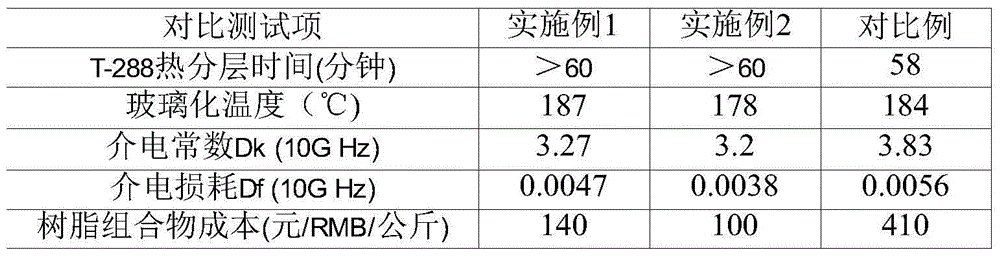

Resin composition and preparation methods of prepreg, composite substrate and PCB (printed circuit board) substrate

InactiveCN104559054AImprove heat resistanceExcellent dielectric propertiesSynthetic resin layered productsLaminationMetal foilComposite substrate

The invention discloses a resin composition and preparation methods of a prepreg, a composite substrate and a PCB (printed circuit board) substrate. The resin composition comprises the following components in parts by weight: 20-30 parts of multifunctional epoxy resin, 50-78 parts of a modified acid anhydride, 10-22 parts of cyanate resin, 11-72 parts of a filler and 0.01-0.05 part of an accelerant. The preparation method of the prepreg comprises the following steps: mixing the resin composition with an organic solvent to obtain a resin solution, wherein the solid content by mass fraction in the resin solution is 50-65%; and immersing glass fiber cloth into the resin solution to obtain a preimpregnated material and then drying the preimpregnated material for manufacturing. The composite substrate is formed by stacking the prepregs according to a perdetermined number and pressing. The PCB substrate is formed by stacking the prepregs according to the perdetermined number, applying metal foils on double sides or single sides of the prepregs and pressing. The resin composition disclosed by the invention has the advantages of high heat resistance, low dielectric loss and significant cost advantage.

Owner:KUANG CHI INNOVATIVE TECH

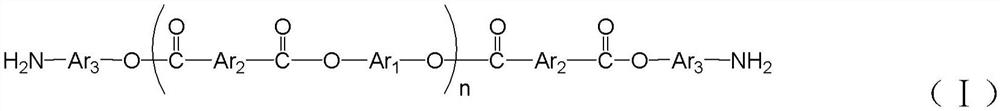

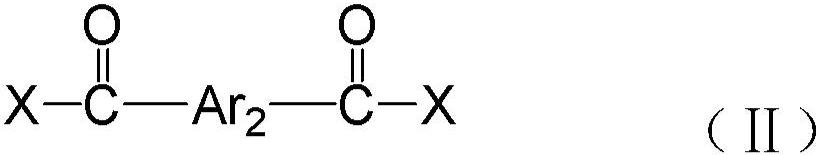

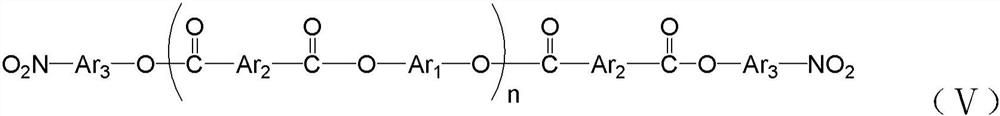

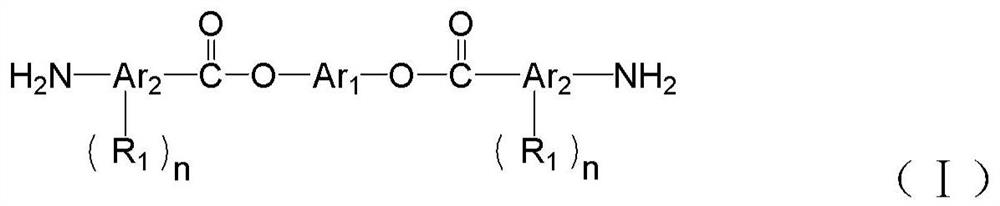

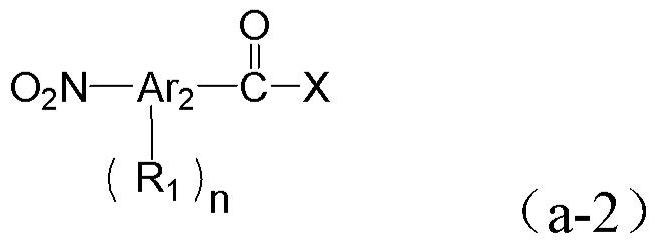

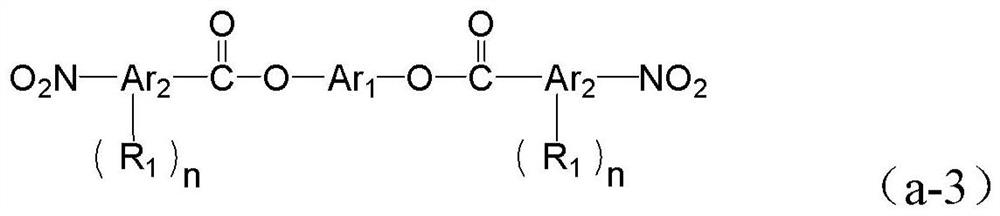

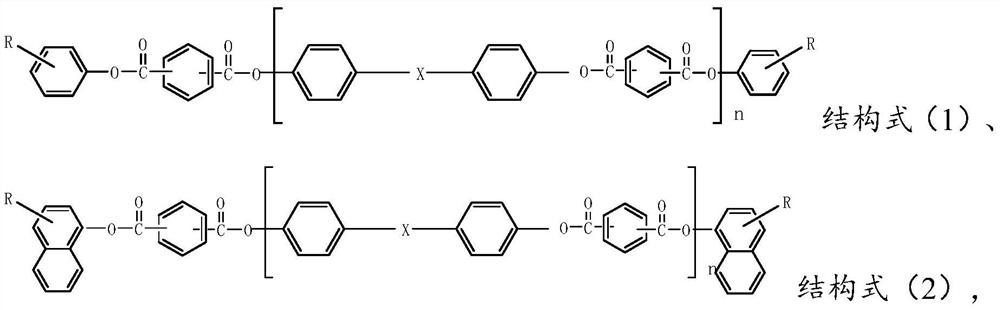

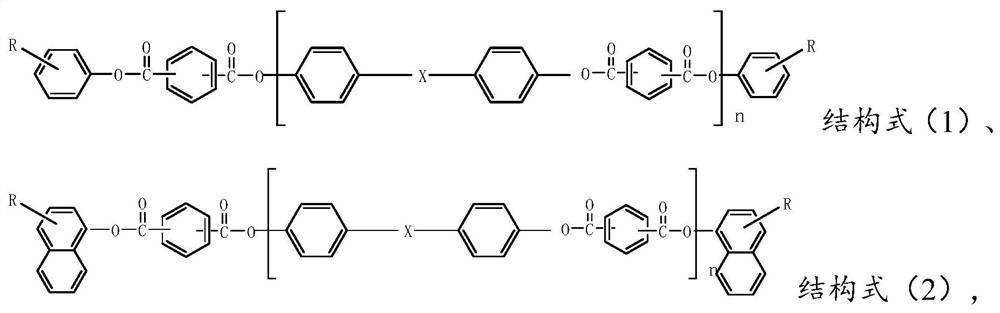

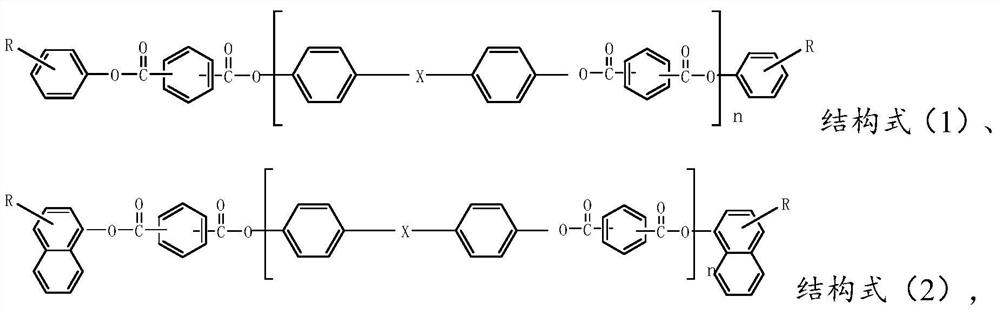

Double-amino-terminated active ester and preparation method thereof, and thermosetting resin composition and application thereof

ActiveCN111960956AHigh reactivityIncreased curing crosslink densityOrganic compound preparationAmino-hyroxy compound preparationArylPolymer science

The invention provides a double-terminal amino active ester and a preparation method thereof, and a thermosetting resin composition. The double-terminal amino active ester has a structure representedby a structural formula (I), wherein the main chain structure of the double-terminal amino active ester has aryl ester groups and aromatic amino functional groups at the same time. According to the invention, by using the double-terminal amino active ester as a curing agent for an epoxy resin, the thermosetting resin composition of the double-terminal amino active ester has a low dielectric constant, a low dielectric loss factor, good heat resistance and toughness and excellent bonding force with metal.

Owner:GUANGDONG SHENGYI SCI TECH

Solvent-resistant scrubbing powder coating and preparation method thereof

InactiveCN108753133AIncreased curing crosslink densityHigh hardnessPolyurea/polyurethane coatingsPowdery paintsPolyesterCross-link

The invention discloses a solvent-resistant scrubbing powder coating and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing a modified polyester from raw materials, namely 40-70% of a polyurethane resin, 10-50% of a high-acidity polyester, 5-10% of aluminum hydroxide and 0.5-1% of aids; preparing the solvent-resistant scrubbing powder coating from raw materials, namely 40-60% of the modified polyester, 10-30% of a curing agent, 0.5-1% of the aids and 10-30% of packing. By adopting the preparation method, the modified polyester is firstly synthesized, two resins are mixed according to a certain ratio, the catalyst and the filler, namely the aluminum hydroxide, are further added, and the solvent-resistant scrubbing powder coating is prepared through mixing, extrusion and crushing; due to adoption of the specific solvent-resistant aids, the curing cross-linking density of a powder product can be increased, the surface density and the hardness can be improved, and excellent solvent-resistant properties can be achieved.

Owner:广东合邦新型粉末涂料科技股份有限公司

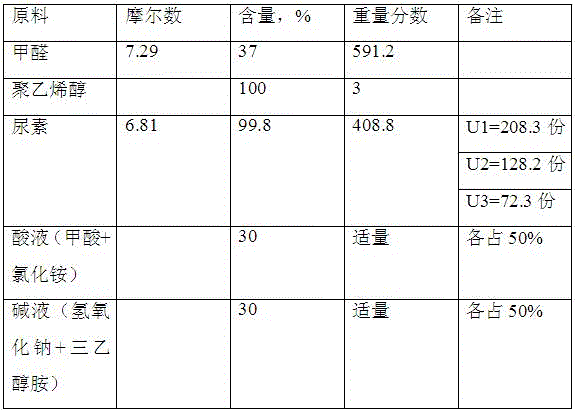

Modified urea-formaldehyde resin adhesive for plywood and preparation method thereof

ActiveCN104726044BIncrease the degree of molecular branchingHigh molecular weightAldehyde/ketone condensation polymer adhesivesResin adhesiveViscosity

The invention discloses a modified urea formaldehyde resin adhesive for veneer sheets and a preparation method thereof. Formaldehyde and urea in low mole ratio are used as raw materials, a polyfunctional reaction enhancer is used as a polycondensation agent instead of the acidic polycondensation agent, and an acid-alkali-acid technique is utilized to synthesize the urea formaldehyde resin, thereby enhancing the molecular branching degree of the urea formaldehyde resin, increasing the molecular weight of the urea formaldehyde resin under the condition of the same viscosity, enhancing the curing crosslinking density of the urea formaldehyde resin, further enhancing the bonding strength and lowering the formaldehyde release amount of the bonded product. The basic process is approximate to the common technique. The method is simple in technique and easy to operate, and does not need to modify the existing equipment.

Owner:江苏福庆木业有限公司

Diamine compound and preparation method thereof, and thermosetting resin composition and application thereof

ActiveCN111960960AHigh reactivityIncreased curing crosslink densitySemiconductor/solid-state device detailsSolid-state devicesEpoxyPolymer science

The invention provides a diamine compound and a preparation method thereof, and a thermosetting resin composition, wherein the diamine compound has a structure represented by a structural formula (I),and the diamine compound structurally has aromatic amino and aromatic ester functional groups at the same time. By using the diamine compound as a curing agent for an epoxy resin, the thermosetting resin composition of the diamine compound has a low dielectric constant, a low dielectric loss factor, good heat resistance, toughness and excellent bonding force with metal.

Owner:GUANGDONG SHENGYI SCI TECH

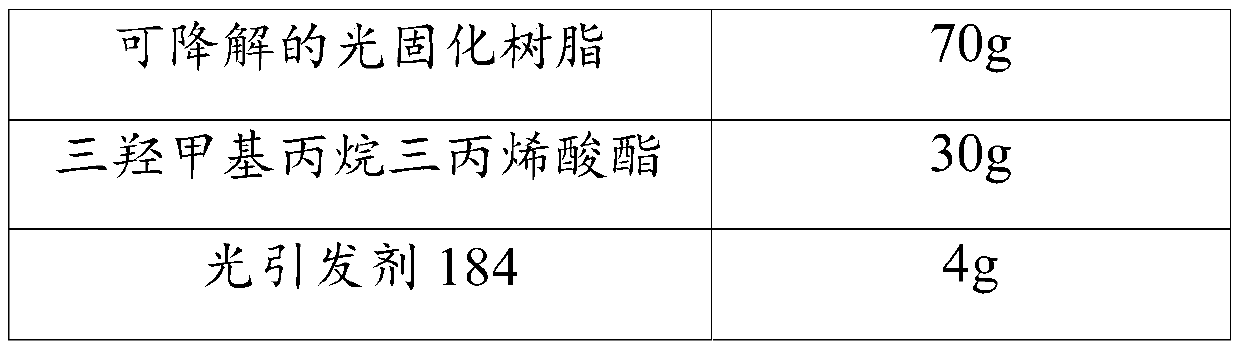

Degradable light-cured resin and preparation method and application thereof

The invention provides degradable light-cured resin and a preparation method and application thereof. The degradable light-cured resin comprises the following raw materials in parts by weight: 200 parts of polylactic acid diol, 10 to 42 parts of unsaturated cyclic anhydride or olefinic-bond-containing binary acid and 9 to 55 parts of an end-capping reagent, wherein the number-average molecular weight of the polylactic acid diol is 400 to 4000. According to the degradable light-cured resin provided by the invention, the solubility of the degradable light-cured resin in a reactive diluent can beimproved by limiting the number-average molecular weight of the polylactic acid diol; the polylactic acid diol and the unsaturated cyclic anhydride or olefinic-bond-containing binary acid are adoptedas raw materials, and the number-average molecular weight of the polylactic acid diol is limited, so the curing crosslinking density, hardness and mechanical properties of a cured product can be improved; and moreover, the end-capping reagent is not limited to be compounds containing reactive groups such as double bonds or epoxy groups, so the selection range of the end-capping reagent is expanded.

Owner:上海抚佳精细化工有限公司

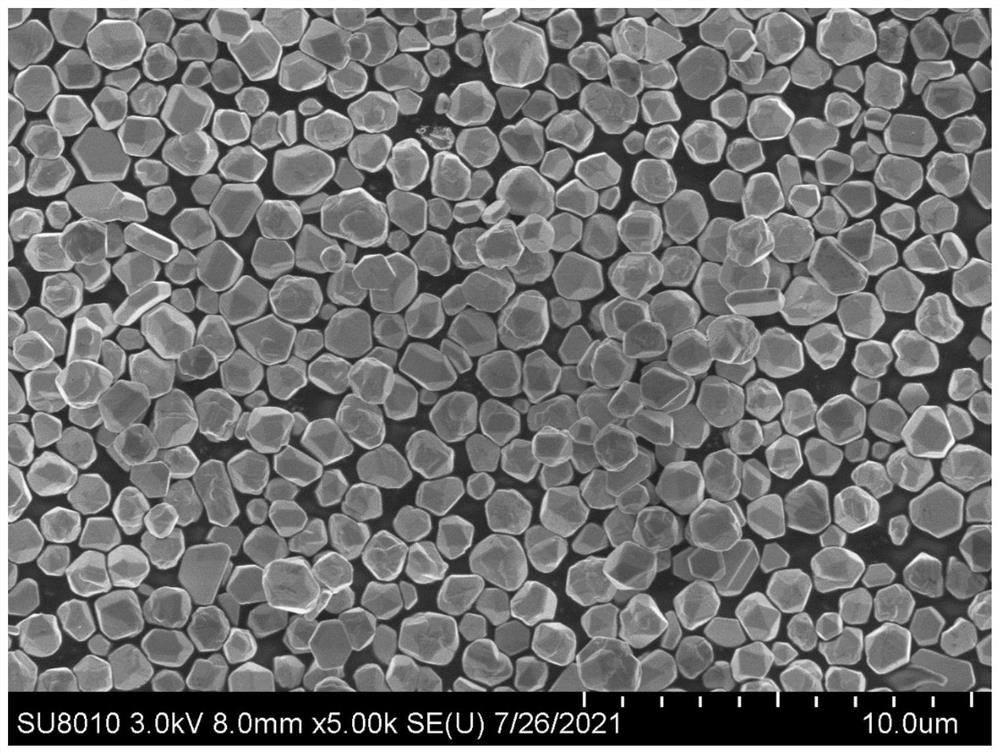

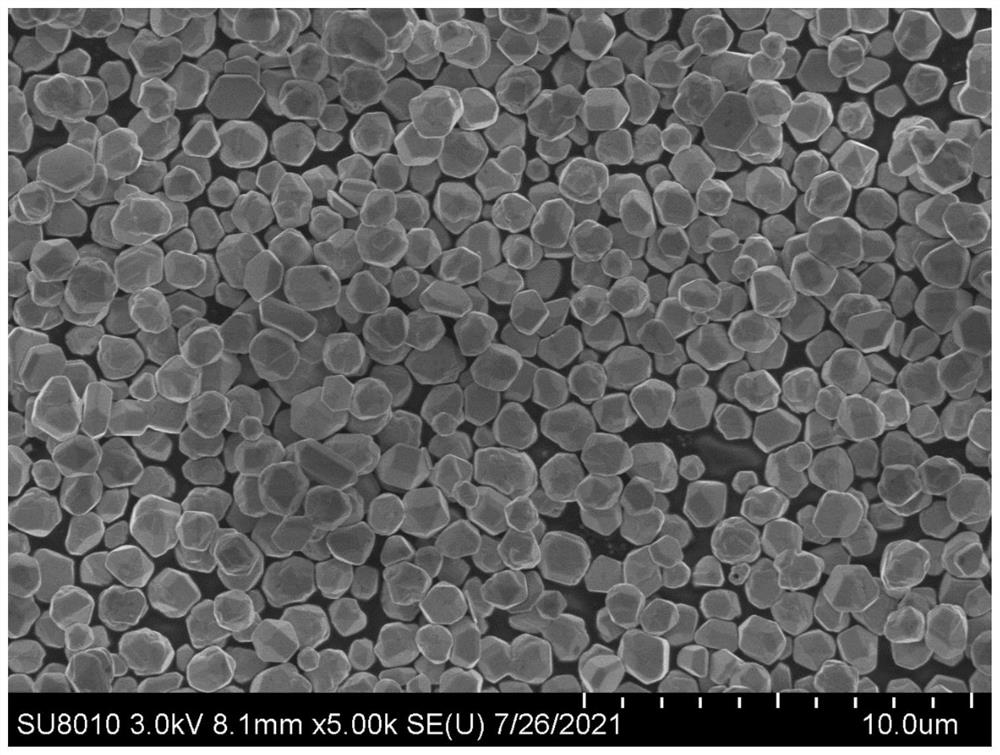

High-crystallization silver powder, low-cost heterojunction silver paste and preparation method and application of high-crystallization silver powder and low-cost heterojunction silver paste

PendingCN114188066AEasy to grow crystalDoes not affect electrical conductivityApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialSilver pasteSilver salts

The invention discloses high-crystallization silver powder and low-cost heterojunction silver paste and a preparation method and application thereof.The preparation method comprises the steps that inorganic powder is subjected to surface smoothing treatment and then mixed with an anti-flocculating agent, a dispersing agent and water to obtain inorganic powder dispersion liquid, then the inorganic powder dispersion liquid is mixed with a reducing agent, a particle size control agent and water-soluble silver salt, and the high-crystallization silver powder and low-cost heterojunction silver paste is obtained. The surface of the inorganic powder is coated with a silver layer through a chemical reduction method, and therefore the silver-coated inorganic matter nanometer powder type high-crystallization ball-like silver powder is synthesized. According to the silver paste formula, the high-dispersity flaky silver powder is added to be matched with the high-crystallization silver powder, the conductivity of the silver paste is effectively improved, and meanwhile the fine printing performance of the silver paste is reserved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

A kind of modified urea-formaldehyde resin adhesive and preparation method thereof

InactiveCN104762041BIncrease the degree of molecular branchingHigh molecular weightAldehyde/ketone condensation polymer adhesivesCross-linkEpoxy

The invention discloses a modified urea resin adhesive and a preparation method thereof. According to the preparation method, formaldehyde and urea in a low molar ratio are taken as raw materials, and a poly-functionality reaction enhancer is taken as a polycondensation agent to replace an acidic polycondensation condition, and the urea resin is synthesized by use of an acid-alkali-acid process; the molecular branching coefficient of the urea resin is increased, the molecular weight of the urea resin is increased under the same viscosity, and the curing cross-linking density of the urea resin can be increased, and furthermore, the bonding strength is improved and the formaldehyde release amount of the bonded products is reduced. The preparation method of the low-toxicity urea resin adhesive has the advantages that non-traditional melamine-epoxy chloropropane-sodium hydroxide reactants are taken as polycondensation agents and the acid-alkali-acid synthesis process is adopted, the basic procedure is close to the conventional process, the process is simple, the operations are convenient, and the existing equipment does not need to be modified.

Owner:SCHOLAR HOME SHANGHAI NEW MATERIAL CO LTD

Resin composition, prepreg, laminated board and printed wiring board

ActiveCN114230972AIncrease the cross-linked network structureThe cross-linked network structure is tightElectrical equipmentGlass/slag layered productsPolymer scienceMetal foil

Compared with the existing resin composition, the resin composition provided by the invention has the advantages of higher glass transition temperature, high heat resistance, high toughness and favorable dielectric property; the invention also provides a prepreg, an insulating film, a metal foil-coated laminated board and a printed circuit board which are prepared by using the resin composition.

Owner:SHENGYI TECH SUZHOU

A kind of preparation method of underfill glue with high electrical insulation performance

ActiveCN111394031BHigh volume resistivityHigh glass transition temperatureEpoxy resin adhesivesPolymer scienceAdhesive

Owner:YANTAI DARBOND TECH

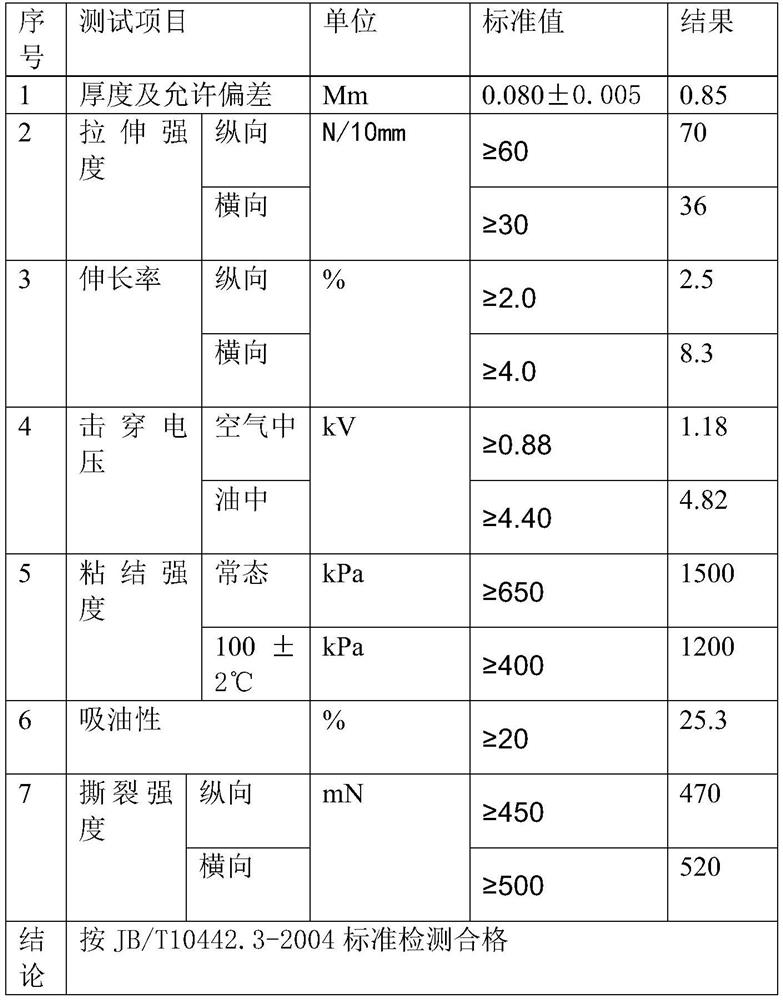

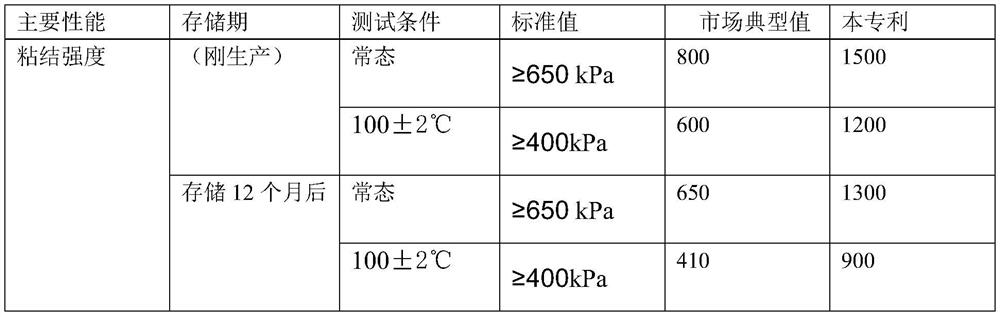

Adhesive for diamond lattice dispensing insulation paper and preparation method of adhesive

ActiveCN112300739AHigh bond strengthGood storage performanceEpoxynovolac adhesivesEthylaminesFirming agent

The invention discloses an adhesive for diamond-grid dispensing insulation paper and a preparation method of the adhesive, and the adhesive comprises the following raw materials in percentage by mass:6.2%-7.1% of a solvent, 2.5%-3.1% of a curing agent A, 8.0%-9.0% of epoxy resin A, 20%-23% of epoxy resin B, 11.2%-13% of epoxy resin C, 1.1%-1.6% of a curing agent B and 44%-48% of acetone, whereinthe curing agent A is DDM, DDS or m-phenylenediamine; the curing agent B is dicyandiamide, a modified amine latent curing agent or a boron trifluoride ethylamine complex; the epoxy resin A is E44 epoxy resin, E51 epoxy resin or EF180 epoxy resin; the epoxy resin B is o-cresol formaldehyde epoxy resin, E20 epoxy resin or E12 epoxy resin; and the epoxy resin C is F44 novolac epoxy resin, F51 novolacepoxy resin or F53 novolac epoxy resin. Dispensing paper produced by adopting the adhesive prepared by the invention has the characteristics of high bonding strength and good storage performance, andhas good application prospect and economic benefit.

Owner:西安西电电工材料有限责任公司 +1

Silicon- and fluorine-containing epoxy (meth) acrylate UV-curing composite coating and preparation method thereof

The invention discloses a silicon and fluorine-containing epoxy (meth) acrylate UV-curing composite coating, comprising the following ingredients of: epoxy (meth) acrylate, polyhedral iligomeric silsesquioxane, fluorine-containing (meth) acrylate, an active diluent monomer, a photoinitiator and an auxiliary agent. Such a composite coating, with excellent fouling resistance, corrosion resistance, weather resistance, abrasive resistance, water resistance, fouling resistance and dynamic performance, is an environmentally friendly coating which is suitable for building material, optical fiber wrapping and the coating of the surface of metal element.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

Preparation method for amination polyphenyl ether

ActiveCN102516532BImprove electrical performanceIncrease the degree of cross-linkingPlastic/resin/waxes insulatorsEpoxyPolymer science

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Preparation method of phenolic resin combined honeycomb activated carbon

The invention relates to a preparation method of phenolic resin combined honeycomb activated carbon, which can be used for preparing the honeycomb activated carbon by the steps of: mixing dry powder, preparing plastic pug by mixing and kneading through a wet method, vacuum pugging, extrusion molding, drying, curing treatment and secondary heat treatment. Besides the function of bonding and improving the mechanical strength of the activated carbon, the phenolic resin also remarkably improves the heat-resisting property and water resistance of the honeycomb activated carbon; and furthermore, the honeycomb activated carbon is added with porous mineral, thus better effectively improving the mechanical strength and the specific surface area of the honeycomb activated carbon. The preparation method has lower heat treatment temperature and low production energy consumption, and effectively reduces the production cost; and the preparation technique and equipment thereof are simple, and the production investment is lower, so that the cost is further reduced.

Owner:TSINGHUA UNIV

Method for preparing hydrophilic antifogging coating

ActiveCN108300079AGood dispersionIncreased double bond functionalityCoatingsSmall dropletDouble bond

The invention discloses a method for preparing a hydrophilic antifogging coating, and belongs to the technical field of antifogging coatings. A material is modified with a gemini quaternary ammonium salt surfactant to improve the dispersion property of the resin base material in the coating improve the functionality of double-bonds in the coating, so the curing crosslinking density is effectivelyincreased, the mechanical properties of a prepolymer coating layer are effectively improved, and the curing time of the coating is greatly shortened; and a photocatalyst added in the invention effectively promotes photocatalysis and photodegradation effects and effectively decomposes the gemini quaternary ammonium salt surfactant formed by the hybridization of sodium alginate, so an uneven nano-coating layer structure is formed on the surface of the coating layer through photocatalytic degradation after the coating layer is cured, the antifogging property of small droplets is enhanced, the applicability of the antifogging coating layer is improved, the hydrophobic performance of the material is effectively improved, and the antifogging property of the material is improved.

Owner:上海大杉新材料科技有限公司

Preparation method of underfill adhesive with high electrical insulation property

ActiveCN111394031AHigh volume resistivityHigh glass transition temperatureEpoxy resin adhesivesPolymer scienceAdhesive

The invention relates to an underfill adhesive with high electrical insulation property. The underfill adhesive is prepared from the following raw materials in parts by weight: 25-35 parts of self-synthesized diaminodiphenyl sulfone modified epoxy resin, 15-20 parts of low-viscosity epoxy resin, 25-35 parts of biphenyl epoxy resin, 0.1-0.4 part of black pigment and 15-20 parts of curing agent. Theunderfill adhesive prepared by the method has the advantages of high volume resistivity, high glass-transition temperature, low water absorption, good electrical insulation property after aging in ahumid and hot environment and the like and is suitable for packaging various semiconductor electronic components mounted on bare chips.

Owner:YANTAI DARBOND TECH

Resin composition and its application

ActiveCN107286325BGood flexibilityGood Metallization PropertiesFilm/foil adhesivesSynthetic resin layered productsPolymer sciencePolyphenyl ether

The present invention relates to resin composition and its application. Specifically, the present invention relates to a resin composition, which contains: 20 to 35 parts by weight of multifunctional epoxy resin; 8 to 15 parts by weight of isocyanate modified epoxy resin; 5 to 15 parts by weight of difunctional epoxy resin 10 parts by weight; 40-65 parts by weight of polyphenylene ether resin; and 8-16 parts by weight of cyanate resin. The present invention also relates to products of the resin composition, including resin films, adhesive sheets, prepregs, composite materials, laminates and printed circuit boards. Through the combination of different resins, this application realizes the superimposition of product performance, so that the product not only has a good appearance, but also has the comprehensive effects of heat resistance, low dielectric loss and easy processing.

Owner:KUANG CHI INST OF ADVANCED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com