Halogen-free resin composition and cover film, copper-clad plate and printed wiring board prepared from same

A technology of resin composition and copper clad laminate, applied in the direction of epoxy resin glue, printed circuit parts, adhesive type, etc., can solve the problem of heat resistance, storage stability to be further improved, low transparency of rubber, easy to whiten And yellowing and other problems, to achieve the effect of high curing crosslinking density, high transparency and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

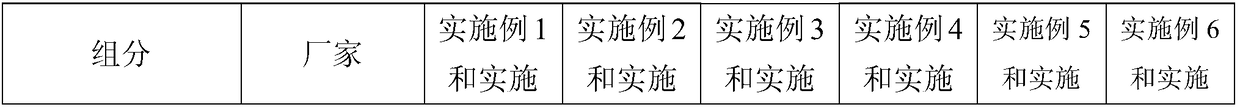

[0057] Prepare a resin composition according to the components shown in Table 1, and dilute it with toluene and butanone as solvents to obtain a glue solution, and make a cover film sample according to the following cover film production method.

[0058] Use a coating machine to coat the halogen-free resin composition on a polyester film with a thickness of 25 μm, control the thickness of the glue (dry glue) to be 15 μm, and then bake it in a high-temperature test box at 140° C. for 2 minutes to form a polyester film. A partially cross-linked and cured adhesive layer is formed on the ester film, and then a release film is laminated with the adhesive layer to obtain a cover film for a flexible printed circuit board.

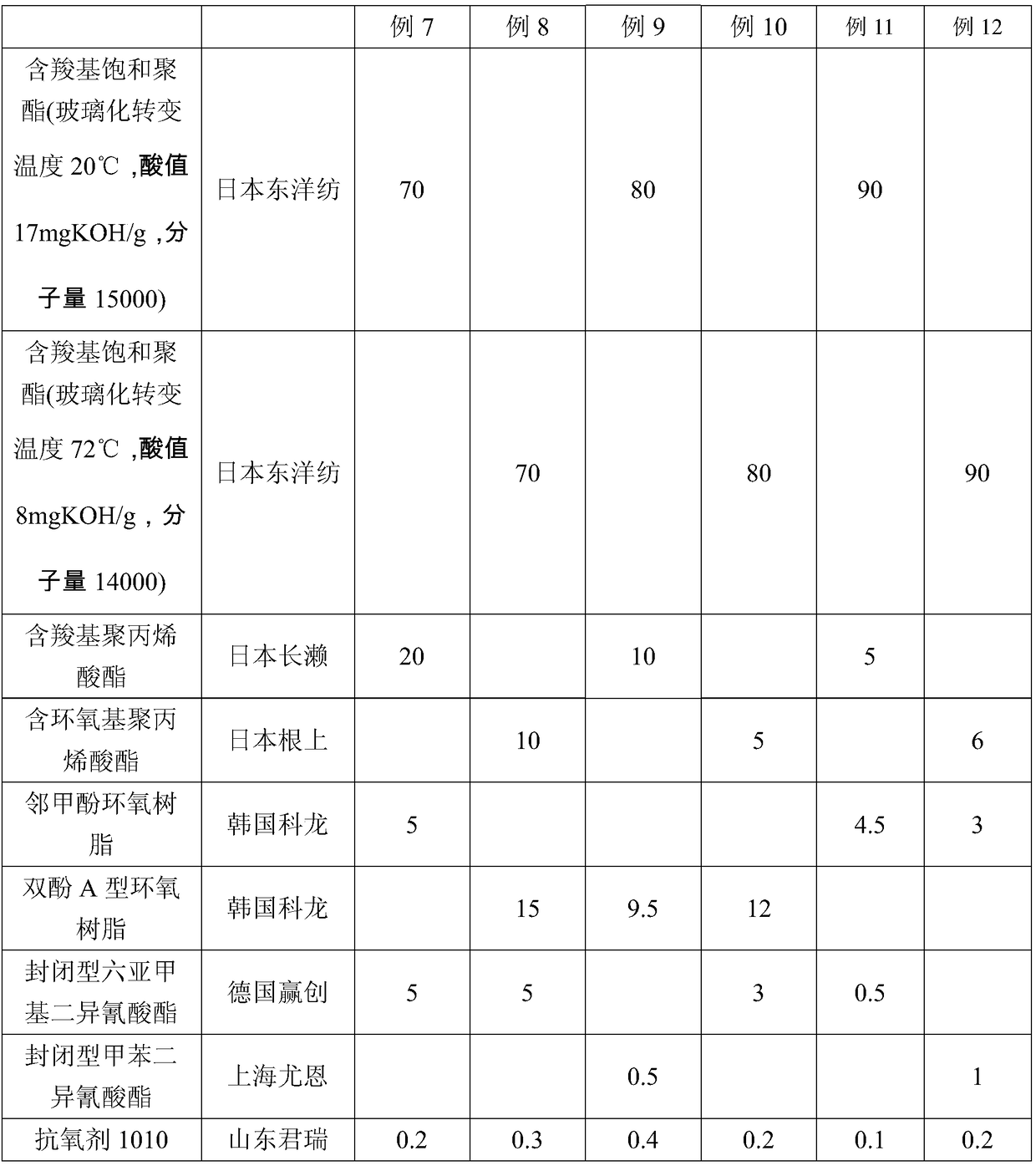

Embodiment 7-12

[0060] Prepare the resin composition by the components shown in table 1 (embodiment 7 uses the resin composition of embodiment 1, and embodiment 8 uses the resin composition of embodiment 2, and embodiment 9 uses the resin composition of embodiment 3, and embodiment 10 uses the resin composition of embodiment 4, and embodiment 11 uses the resin composition of embodiment 5, and embodiment 12 uses the resin composition of embodiment 6), and dilutes with toluene and methyl ethyl ketone as solvent, obtains glue solution, according to Copper-clad laminate samples were prepared as follows.

[0061] The halogen-free resin composition was coated on a 25 μm polyester film, and the thickness of the glue (dry glue) was controlled to be 15 μm. The polyester film coated with the halogen-free resin composition is placed in a 140°C high-temperature test box and baked for 2 minutes to semi-cure, and then a rolled copper film with a size of 40cm (length) × 25cm (width) × 18μm (thickness) Foil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com