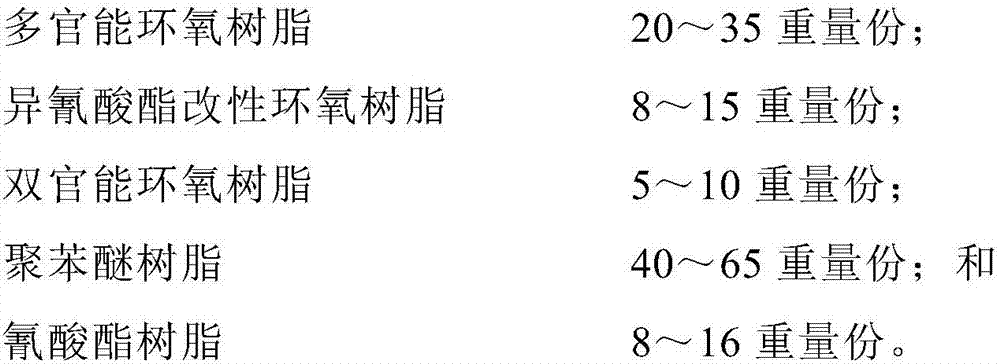

Resin composition and application thereof

A resin composition and resin technology, applied in applications, epoxy resin adhesives, and other household appliances, can solve the problems of low metal-clad peel strength, low mechanical strength, and poor moldability of prepreg paving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

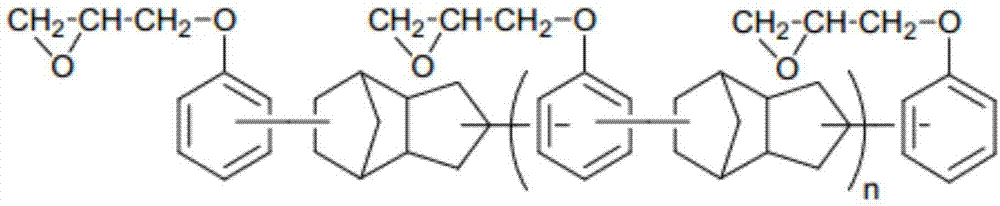

[0112] Weigh 20 parts by weight of dicyclopentadiene type polyfunctional epoxy resin, 8 parts by weight of MDI modified epoxy resin, 5 parts by weight of epoxy resin containing alicyclic ring, 40 parts by weight of polyphenylene ether, 8 parts by weight of bisphenol A Add cyanotype ester and 0.01 parts by weight of 2-methylimidazole (2-MI) into 122 parts by weight of butanone to form a resin solution with a solid content of 60%.

[0113] Use 8 sheets (200mm*200mm) of 7628 quartz cloth to immerse in the above resin solution for impregnation. Bake in an oven at 80°C / 2 minutes + 130°C / 3 minutes + 175°C / 5 minutes to make a semi-cured adhesive sheet.

[0114] Superimpose and align the above 8 adhesive sheets, with a 35um copper foil on the top and bottom. In the vacuum press, according to the temperature of 210 ℃, the pressure of 25kgf / cm 2 Conditions, pressed for 160 minutes to make a double-sided copper clad laminate with a thickness of 1.6mm.

Embodiment 2

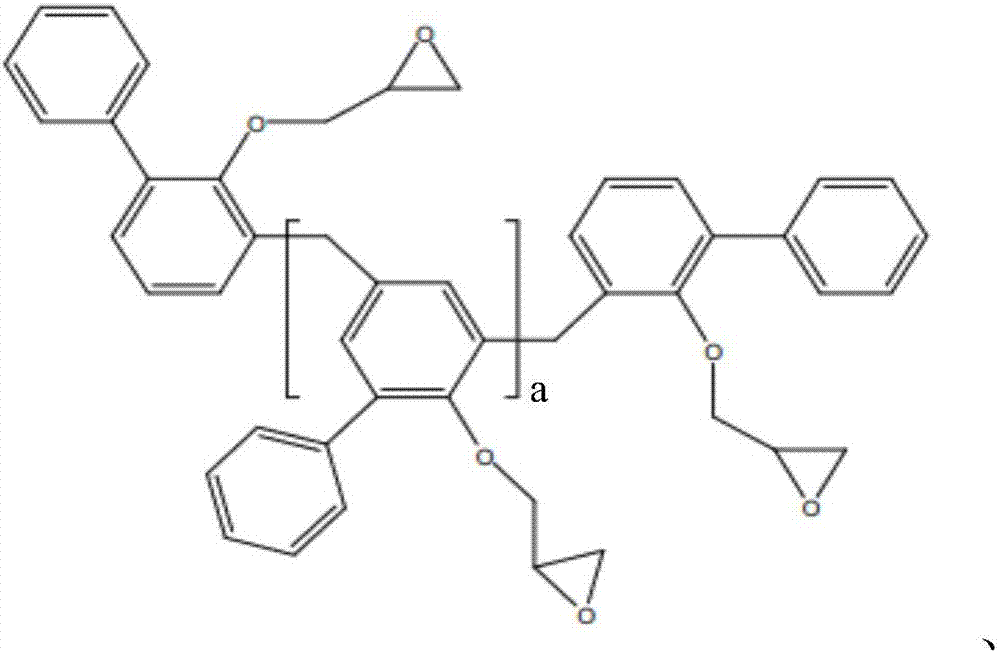

[0116] Take by weighing 35 parts by weight of o-phenyl phenolic type polyfunctional epoxy resin, 15 parts by weight of MDI modified epoxy resin, 10 parts by weight of epoxy resin containing alicyclic ring, 65 parts by weight of polyphenylene ether, 16 parts by weight of dicyclopentadiene Phenolic cyanate resin and 0.05 parts by weight of 2-methylimidazole (2-MI) were added to 212 parts by weight of butanone to form a resin solution with a solid content of 60%.

[0117] Use 8 sheets (200mm*200mm) of 7628 quartz cloth to immerse in the above resin solution for impregnation. Bake in an oven at 80°C / 2 minutes + 130°C / 3 minutes + 175°C / 5 minutes to make a semi-cured adhesive sheet.

[0118] Superimpose and align the above 8 adhesive sheets, with a 35um copper foil on the top and bottom. In the vacuum press, according to the temperature of 210 ℃, the pressure of 25kgf / cm 2 Conditions, pressed for 160 minutes to make a double-sided copper clad laminate with a thickness of 1.6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com