Modified urea-formaldehyde resin adhesive for plywood and preparation method thereof

A urea-formaldehyde resin and adhesive technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of reduced bonding strength, poor water resistance, reduced production efficiency, etc., to increase the molecular weight of resins , Low formaldehyde emission, and the effect of improving cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Raw material formula:

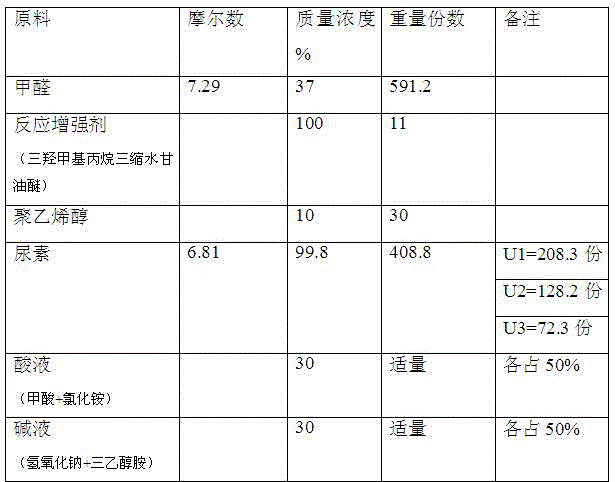

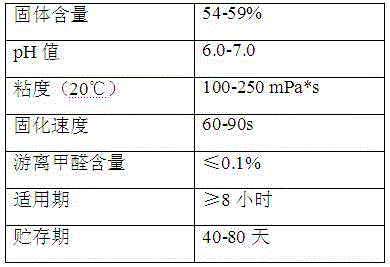

[0020] Table 1 The molar ratio of formaldehyde and urea is 1.07:1 Raw material ratio of urea-formaldehyde resin:

[0021]

[0022] According to the molar ratio of formaldehyde and urea as 1.07:1, the reaction steps include:

[0023] 1) Put 591.2 parts by weight of industrial formaldehyde with a mass concentration of 37% into the reactor, add the first batch of urea 208.3 parts by weight, adjust the pH value of the acid solution to 6.0, keep it at 60°C for 20 minutes, and then heat up to 90°C within 20 minutes , keep the pH at 5.5-6.0, add 30 parts by weight of polyvinyl alcohol solution after incubating at 90° C. for 20 minutes, and incubate for 20 minutes.

[0024] 2) Control the pH value of the lye to 7-9, control the temperature at 85-90°C, add 5 parts by weight of the reaction enhancer dropwise, react until the viscosity is 25°C, apply -4 cups for 22-24 seconds; add the second batch of urea 128.2 parts by weight, adjust the pH value to 7...

Embodiment 2

[0039] Raw material formula:

[0040] Table 3 The molar ratio of formaldehyde to urea is 0.95:1 Raw material ratio of urea-formaldehyde resin:

[0041]

[0042] Be 0.95:1 raw material preparation by formaldehyde and urea mol ratio, reaction step comprises:

[0043] 1) Put 562.1 parts by weight of industrial formaldehyde with a mass concentration of 37% into the reactor, add 208 parts by weight of the first batch of urea, adjust the pH to 6.0, keep the temperature at 60°C for 20 minutes, then raise the temperature to 90°C within 20 minutes, and keep PH5.5-6.0, keep warm at 90°C for 20 minutes, then add 30 parts by weight of polyvinyl alcohol solution, keep warm for 20 minutes.

[0044] 2) Control the pH value to 7-9, control the temperature at 85-90°C, add 8 parts by weight of reaction enhancer dropwise, react to viscosity: 25°C, apply -4 cups for 22-24 seconds; add the second batch of urea 112 by weight part, adjust the pH value to 7-9, add 8 parts by weight of reaction e...

Embodiment 3

[0059] Raw material formula:

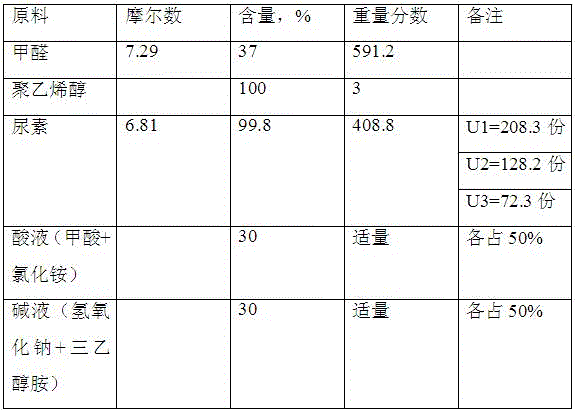

[0060] Table 5 The molar ratio of formaldehyde to urea is 1.1:1 Raw material ratio of urea-formaldehyde resin:

[0061]

[0062] Prepare materials according to the molar ratio of formaldehyde and urea as 1.1:1, and the reaction steps include:

[0063] 1) Put 597.8 parts by weight of industrial formaldehyde with a mass concentration of 37% into the reactor, add 221.2 parts by weight of the first batch of urea, adjust the pH value to 6.0, keep the temperature at 60°C for 20 minutes, then raise the temperature to 90°C within 20 minutes, and keep PH5.5-6.0, keep warm at 90°C for 20 minutes, then add 40 parts by weight of polyvinyl alcohol solution, keep warm for 20 minutes.

[0064] 2) Control the pH value to 7-9, control the temperature at 85-90°C, add 10 parts by weight of reaction enhancer dropwise, react to viscosity: 25°C, apply -4 cups for 22-24 seconds; add the second batch of urea 19.1 by weight part, adjust the pH value to 7-9, add 11 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com