A kind of low toxicity urea-formaldehyde resin adhesive and preparation method thereof

A urea-formaldehyde resin and adhesive technology, applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of reduced bonding strength, poor water resistance, and increased product cost, and achieve improved cross-linking. Density, low formaldehyde emission, and the effect of increasing the degree of branching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A modified urea-formaldehyde resin adhesive, the raw material formula is shown in the following table 1:

[0023] Table 1 The molar ratio of formaldehyde to urea is 1.07:1 Raw material ratio of urea-formaldehyde resin:

[0024] raw material moles content,% weight fraction Remark formaldehyde 7.29 37 591.2 response enhancer 100 10 polyvinyl alcohol 10 30 urea 6.81 99.8 408.8 U1=208.3 copies U2=128.2 parts U3=72.3 copies Acid solution (formic acid + ammonium chloride) 30 Appropriate amount 50% each Lye (sodium hydroxide + triethanolamine) 30 Appropriate amount 50% each

[0025] A kind of preparation method of above-mentioned modified urea-formaldehyde resin adhesive, is 1.07 to prepare raw materials by formaldehyde and urea molar ratio, and reaction step comprises:

[0026] 1) Put 591.2 parts by weight of 37% industrial formaldehyde into the reactor, add 208.3 ...

Embodiment 2

[0043] A modified urea-formaldehyde resin adhesive, the raw material formula is shown in the following table 3:

[0044] Table 3 The molar ratio of formaldehyde to urea is 1:0.98 Raw material ratio of urea-formaldehyde resin:

[0045] raw material moles content,% weight fraction Remark formaldehyde 7.12 37 569.8 response enhancer 100 15 polyvinyl alcohol 10 50 urea 7.04 99.8 430.2 U1=210.8 copies U2=140.5 parts U3=78.9 parts Acid solution (formic acid + ammonium chloride) 30 Appropriate amount 50% each Lye (sodium hydroxide + triethanolamine) 30 Appropriate amount 50% each

[0046] A kind of preparation method of above-mentioned modified urea-formaldehyde resin adhesive, is that 1:0.98 is prepared raw material by formaldehyde and urea molar ratio, and reaction step comprises:

[0047] 1) Put 569.8 parts by weight of 37% industrial formaldehyde into the reactor, add ...

experiment example

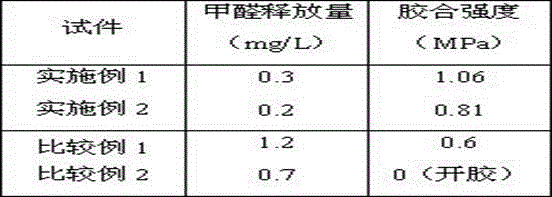

[0064] Add 0.6% ammonium chloride and 0.4% citric acid to the urea-formaldehyde resins of the above examples and comparative examples respectively, and then add 30% flour to make three-layer plywood of 400×400mm.

[0065] Poplar veneer: dry to 10-14% moisture content; thickness 1.5mm;

[0066] The veneer adhesive used the product of Example 1-2 of the present invention and the product of Comparative Example 1-2.

[0067] Plywood is prepared according to the normal process as follows:

[0068] Glue sizing: double-sided sizing of the core board, the amount of glue applied is 300-320g / m 2 ;

[0069] Aging method and time: closed aging, 20-30 minutes;

[0070] Pre-compression pressure and time: pre-compression 40 minutes, pressure 0.9MPa;

[0071] Hot pressing pressure: 1.0MPa, hot pressing temperature is 110-120°C, hot pressing time is 60s / mm.

[0072] According to the test method of GB / T17657-1999 "Physical and Chemical Properties of Wood-Based Panels and Decorated Wood-bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com