Preparation method for amination polyphenyl ether

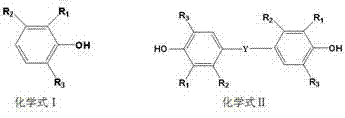

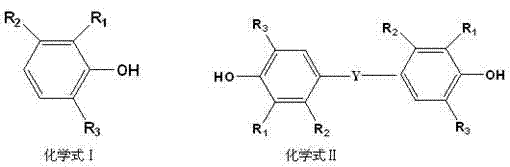

A polyphenylene ether, amination technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve problems such as increasing industrialization and environmental protection, and achieve excellent mechanical properties, electrical properties, and compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

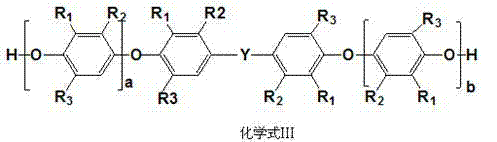

[0054] In a reactor equipped with a reflux condenser, stirring, and a thermocouple, 1.35 g (0.0061 mol) of copper bromide, 6.34 g (0.0491 mol) of dibutylamine, and 1180 g of methanol were added successively, and complexed at room temperature for 10 min. Add 116g (0.409mol) 3,3,5,5-tetramethylbisphenol A and 200g (1.637mol) 2,6-dimethylphenol, (the molar ratio of the two monomers is 1:4,) to maintain the temperature At 25°C, under the condition of vigorous stirring, air was introduced at a speed of 1.637 NL / min, and the reaction was carried out for 2 hours. Terminate the reaction with 1 mL of acetic acid with a concentration of 1 mol / L, filter, then wash with deionized water, methanol, and dry to obtain 230 g of white powder, which is PPO-2OH, with a yield of 73%. Mn=1507g / mol, Mw=2828g / mol, D=1.87 measured by GPC (gel permeation chromatography).

Embodiment 2

[0056] In a reactor equipped with a reflux condenser, stirring, and a thermocouple, 2.024g (0.009mol) of copper bromide, 4.43g (0.09822mol) of dimethylamine, and 3681g of ethanol were added successively, and complexed at room temperature for 10min. Add 209.4g (0.818mol) 3,3,5,5-tetramethylbisphenol F and 200g (1.637mol) 2,6-dimethylphenol, (the molar ratio of the two monomers is 1:2,) keep The temperature was 60°C, under the condition of vigorous stirring, air was introduced at a speed of 0.2 NL / min, and the reaction was carried out for 2.5 hours. Terminate the reaction with 1 mL of oxalic acid with a concentration of 1 mol / L, filter, then wash with deionized water, methanol, and dry to obtain 227.6 g of white powder, which is PPO-2OH, with a yield of 55.5%. Mn=1031 g / mol, Mw=1912 g / mol, D=1.85 were measured by GPC.

Embodiment 3

[0058] In a reactor equipped with a reflux condenser, stirring and thermocouple, add 0.5485g (0.0025mol) of copper bromide, 1.8g (0.0246mol) of diethylamine, 782g of 40% methanol and 60% ethanol in sequence mixed solvent, complexed at room temperature for 10min, added 34.8g (0.1227mol) 3,3,5,5-tetramethylbisphenol A and 300g (2.456mol) 2,6-dimethylphenol, (two mono The volume molar ratio is 1:20,) keeping the temperature at 10°C, under the condition of vigorous stirring, the air was passed in at a speed of 0.082NL / min, and the reaction was carried out for 10h. Terminate the reaction with 1 mL of hydrochloric acid with a concentration of 1 mol / L, filter, wash with deionized water, methanol, and dry to obtain 286 g of white powder, which is PPO-2OH, with a yield of 85.4%. Mn=2631 g / mol, Mw=5098 g / mol, D=1.94 were measured by GPC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com