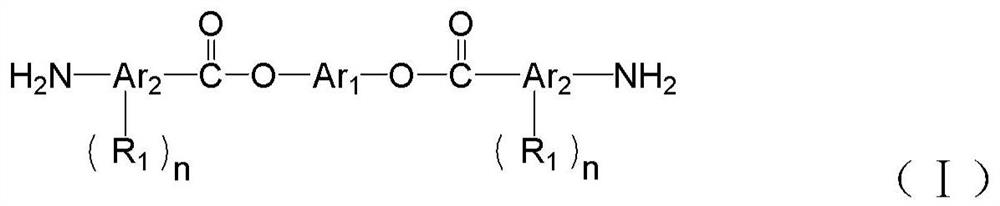

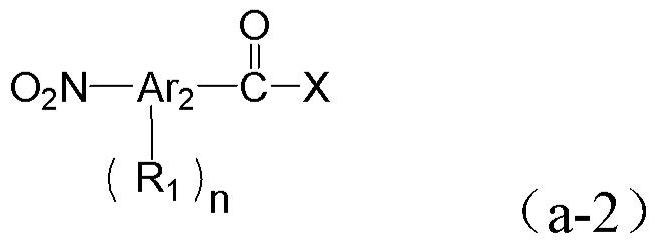

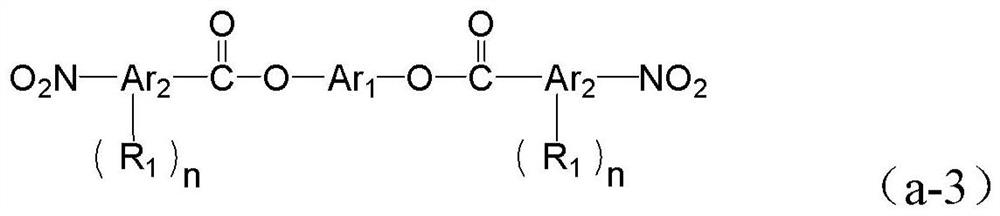

Diamine compound and preparation method thereof, and thermosetting resin composition and application thereof

A technology of resin composition and amine compound, applied in aromatic field, can solve the problems of low crosslinking density and low heat resistance performance of resin cured product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-5

[0072] A thermosetting resin composition containing epoxy resin (A) and diamine compound (B) as essential components and a circuit substrate thereof are prepared as follows: epoxy resin, diamine compound or other curing agents, fillers, and curing accelerators are mixed in a certain proportion Mix evenly in the solvent (see Table 1), control the solid content of the glue to 65%, impregnate the above glue with 7628 glass fiber cloth, control the appropriate thickness, and then bake it in an oven at 145-175°C for 2-15 minutes to make it Prepreg, then 8 prepregs are stacked together, and 1Oz copper foil is stacked on the upper and lower sides. The curing temperature is 190℃~200℃, and the curing pressure is 30~60Kg / cm 2 , and the curing time is 90-120 minutes to make circuit substrates. The specific components, content and board properties are shown in Table 1, and the raw material manufacturers and grades are shown in Table 2.

[0073] Table 1

[0074]

[0075] Table 2

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com