Silicon- and fluorine-containing epoxy (meth) acrylate UV-curing composite coating and preparation method thereof

An acrylate and composite coating technology, applied in the coating and other directions, can solve the problems of difficult to obtain raw materials, easy to wear, poor compatibility between the microphases of composite coatings, etc., to achieve excellent chemical stability and surface activity, good stain resistance. and corrosion resistance, the effect of increasing the curing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

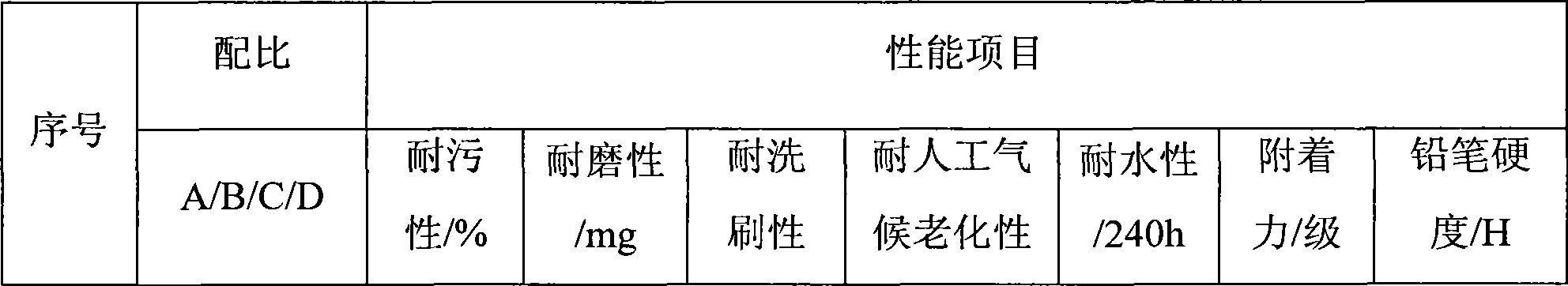

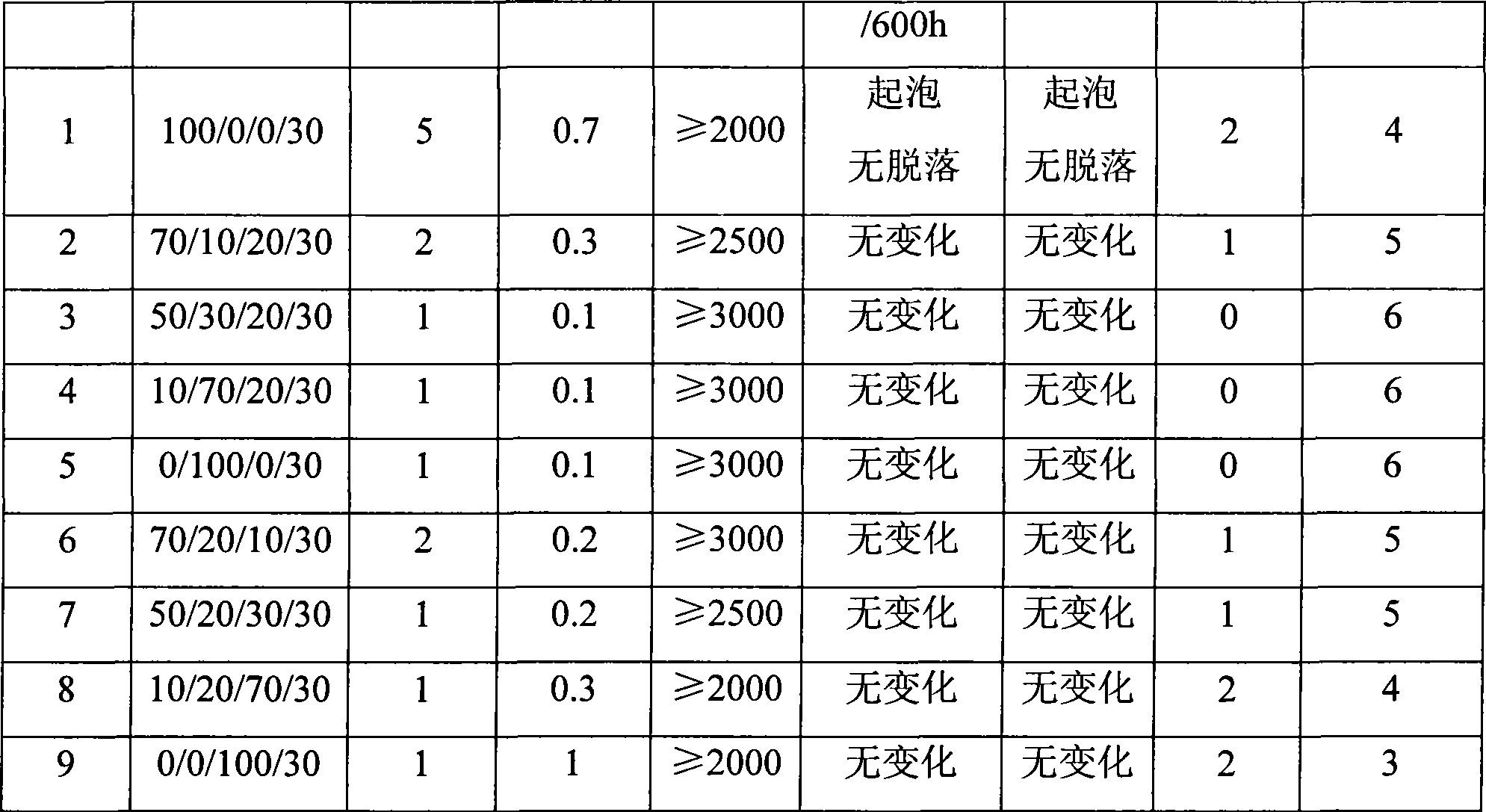

Image

Examples

Embodiment 1

[0034] (1) Take 100 parts by weight of bisphenol A type epoxy resin (epoxy value 0.44) and put it into a reactor equipped with a stirrer, dropping funnel and thermometer, heat and stir to 80°C, add dropwise 37 parts of methacrylic acid, four A mixture of 1.2 parts of butylammonium bromide and 0.02 parts of p-methoxyphenol was heated up to 108°C and reacted for 6 hours to obtain bisphenol A epoxy methacrylate resin;

[0035] (2) Take 1.5 parts of tetramethylammonium hydroxide, 12 parts of water, and 100 parts of isopropanol into a reactor equipped with a stirrer, dropping funnel and thermometer, and slowly add methacryloyloxymethyl trimethyl A mixture of 100 parts of oxysilane and 50 parts of isopropanol, reacted at room temperature for 2 hours, removed isopropanol and water, added 220 parts of toluene, condensed and refluxed at 85 ° C for 3.5 hours, removed toluene and water, and obtained methacryloyl Oxygen cage silsesquioxane;

[0036] (3) 100 parts by weight of bisphenol A...

Embodiment 2

[0044] (1) Take 100 parts by weight of bisphenol A type epoxy resin (epoxy value 0.54) and put it into a reactor equipped with a stirrer, dropping funnel and thermometer, heat and stir to 80°C, add dropwise 37 parts of methacrylic acid, three A mixture of 1.2 parts of ethyl benzyl ammonium chloride and 0.02 parts of p-methoxyphenol was heated to 112°C for 6 hours to obtain bisphenol A epoxy methacrylate resin;

[0045] (2) Get 3 parts of hydrochloric acid, 15 parts of water, and 100 parts of acetone into a reactor equipped with a stirrer, dropping funnel and thermometer, and slowly add 100 parts of methacryloxymethyltriethoxysilane and A mixture of 50 parts of acetone, react at room temperature for 2 hours, remove isopropanol and water, add 200 parts of toluene, reflux at 85°C for 3.5 hours, remove toluene and water, and obtain cage-type silsesquisil containing methacryloyloxy Oxygen;

[0046] (3) 100 parts by weight of bisphenol A type epoxy methacrylate prepared in step 1 i...

Embodiment 3

[0054] (1) Take 100 parts by weight of bisphenol A epoxy resin (epoxy value 0.51) and put it into a reactor equipped with a mixer, dropping funnel and thermometer, heat and stir to 80°C, add dropwise 36 parts of acrylic acid, triethyl A mixture of 1.5 parts of benzyl ammonium bromide and 0.02 parts of p-hydroxyanisole was heated to 110°C for 4 hours to obtain bisphenol A epoxy acrylate resin;

[0055] (2) Get 2.5 parts of formic acid, 10 parts of water, and 150 parts of tetrahydrofuran into a reactor equipped with a stirrer, dropping funnel and thermometer, and slowly add 100 parts of methacryloxypropyltriethoxysilane and A mixture of 30 parts of tetrahydrofuran, react at room temperature for 3 hours, remove isopropanol and water, add 200 parts of toluene, reflux at 85°C for 3.5 hours, remove toluene and water, and obtain cage-type silsesquisil containing methacryloyloxy Oxygen;

[0056] (3) 100 parts by weight of bisphenol A type epoxy acrylate prepared in step 1 is added in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com