A kind of decorative painting and its manufacturing method

A production method and decorative painting technology, which are applied in special decorative structures, decorative arts, and specialized techniques of art painting, etc., can solve the problems of difficulty in grasping the viscosity of pulp-pulling printing, affecting the appearance, and being cumbersome, so as to achieve the goal of making raw materials. Rich, easy-to-implement, and simple-to-craft effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Design drawings, according to the drawings on the plastic surface of the woven interlining, use a certain three-dimensional cotton rope to form an abstract flower pattern, and iron a relatively light and elastic plain fabric, and cover the fabric on the already coiled On the patterned interlining, put it into a pressing machine, and press the entire woven fabric evenly, so that the woven interlining and the fabric are evenly bonded, and a three-dimensional pattern of abstract flowers will be formed on the plain fabric, ironed, cut, and finished. The decorative painting of the line-like abstract flower pattern is vivid and lifelike.

Embodiment 2

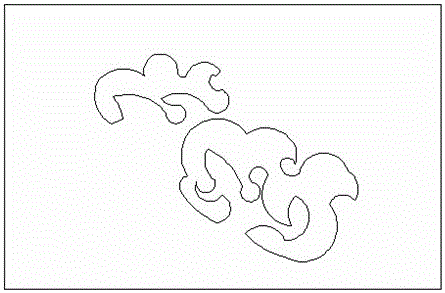

[0018] Design the artwork, and cut out the cloud pattern on the felt cloth according to the artwork. Ironing is relatively thin and has a certain degree of elastic plain fabric, draw a pattern on the back of the fabric, and place the felt cloth pattern cut piece according to the pattern, cover the felt cloth pattern cut piece with the woven interlining cloth, and put it into the pressing machine , evenly pressing the entire woven fabric, so that the woven interlining and the fabric are evenly bonded, and the three-dimensional moiré pattern will be formed on the plain fabric. Ironing, cutting, and the decorative painting of the moiré pattern made are vivid and lifelike .

Embodiment 3

[0020] Design the artwork, and cut out the rural pattern of the hometown on the felt cloth according to the artwork. Ironing is relatively thin and has a certain degree of elastic plain fabric, draw a pattern on the back of the fabric, and place the felt cloth pattern cut piece according to the pattern, cover the felt cloth pattern cut piece with the woven interlining cloth, and put it into the pressing machine , evenly pressing the entire woven fabric, so that the woven interlining and the fabric are evenly bonded, and the three-dimensional village pattern will be formed on the plain fabric. Ironing, cutting, and the decorative painting of the moiré pattern made are vivid and lifelike.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com