Patents

Literature

30results about How to "Embossed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Washing machine panel glass processing technology

InactiveCN104746307ANot dullAvoid wear and tearOther washing machinesCoatingsScreen printingPrinting ink

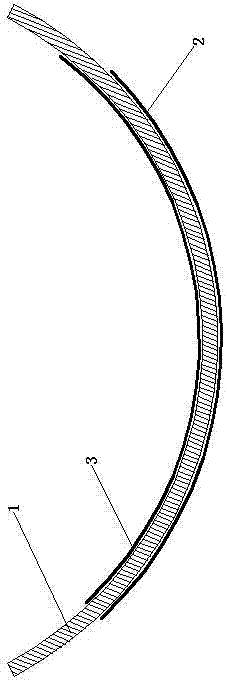

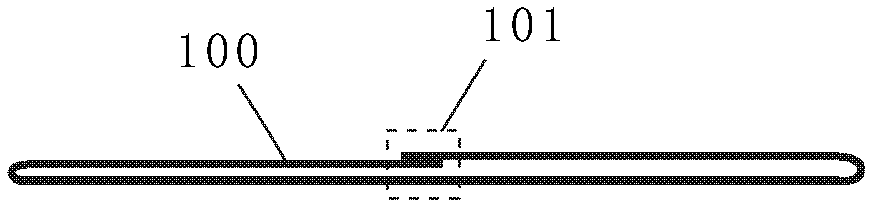

The invention relates to a washing machine panel glass processing technology. The method comprises the following steps: 1, coating one side face of panel glass with a high temperature printing ink pattern layer in a printing mode; 2, sending the panel glass coated with the high temperature printing ink pattern layer into a toughening furnace for conducting the toughening treatment; 3, coating the other side face of the panel glass obtained after the toughening treatment with a low temperature printing ink pattern layer. By means of the panel glass of an arc-shaped structure, an aesthetic contour curve is provided, so that the appearance of a washing machine is not rigid; the printing ink pattern layers both bulge on the panel glass, and the panel glass is sensed to have convex textures by hand and has the skidproof characteristic; both surfaces are coated with the printing ink pattern layers, the aestheticism can be embodied on the both surfaces, after high temperature printing ink is printed through silk-screen printing, the high temperature heating of the toughening furnace is utilized right for sintering the high temperature printing ink so that the high temperature print ink can be adhered to the panel glass, and meanwhile after the toughening treatment is finished, low temperature printing ink is printed so that it can be prevented components on the toughening furnace from abrading the low temperature printing ink pattern layer under the condition that the printing ink is not dry.

Owner:苏州市灵通玻璃制品有限公司

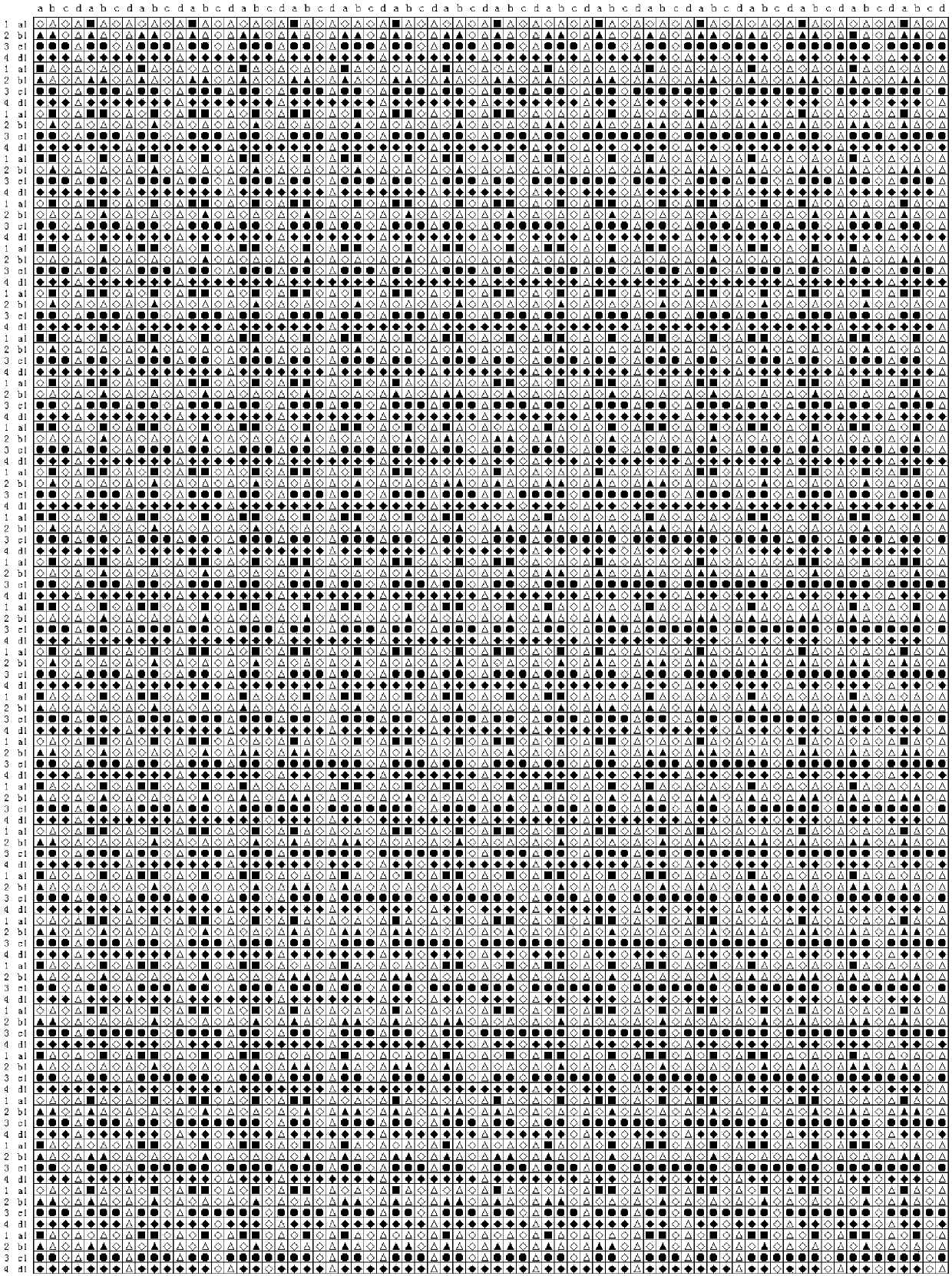

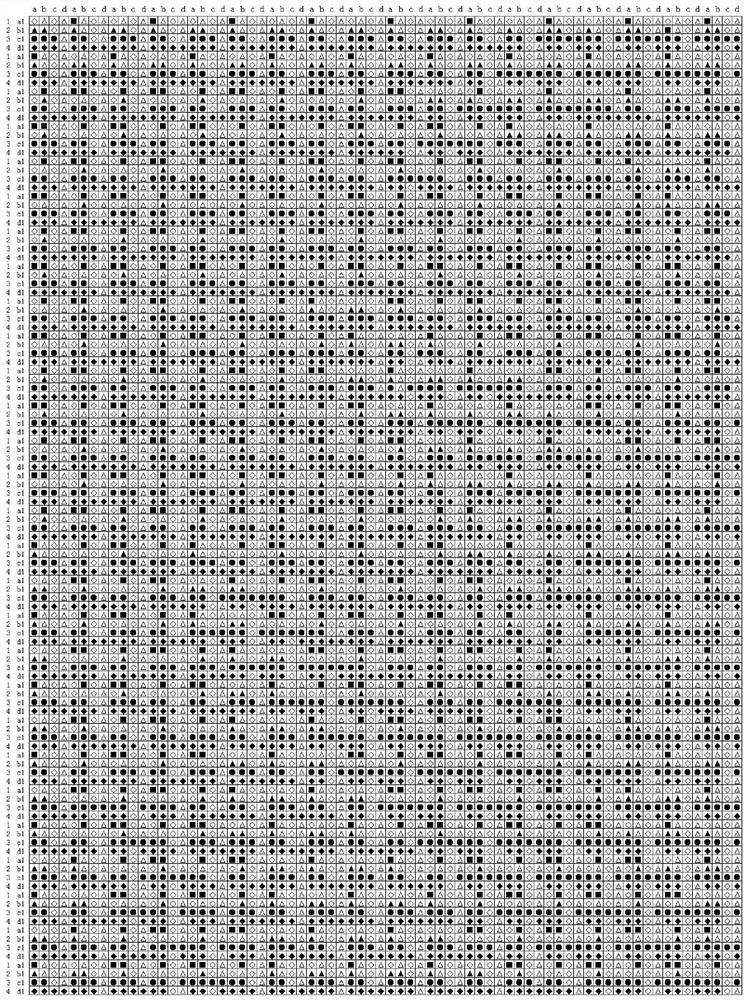

Double-sided-embossed and different-flower-pattern multi-layer non-loop towel and quilt fabric and weaving method thereof

ActiveCN107740216AGuaranteed softnessEmbossedBed linenHeating/cooling textile fabricsHigh volume manufacturingEngineering

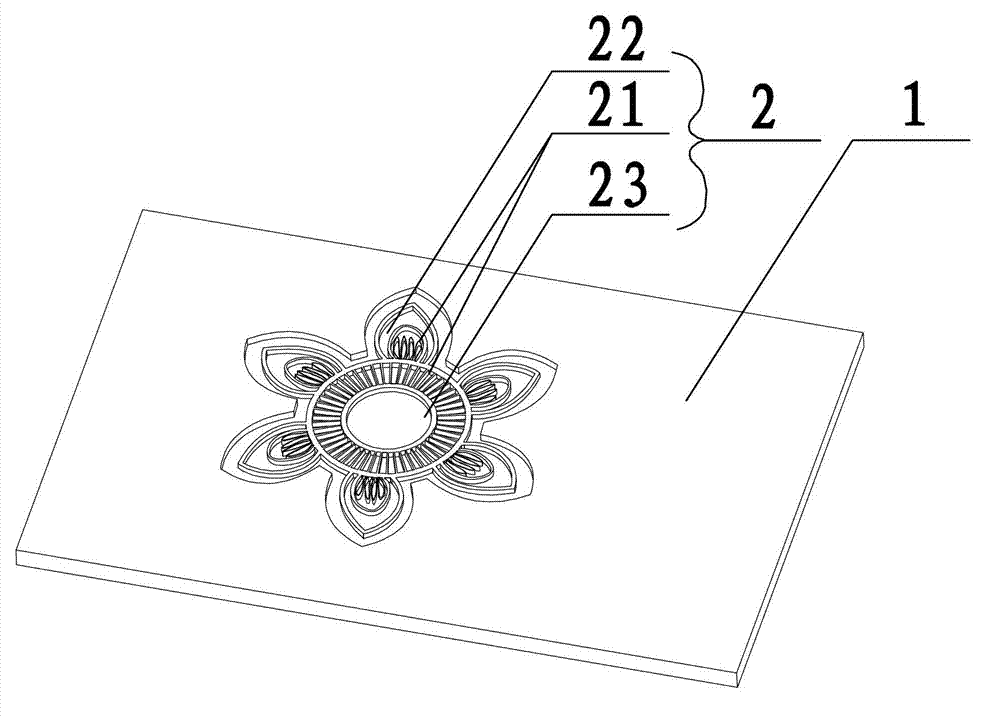

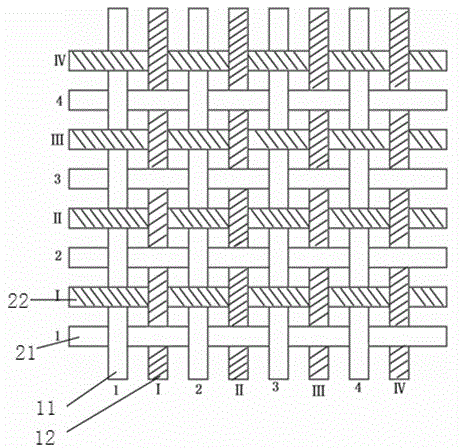

The invention discloses a double-sided-embossed and different-flower-pattern multi-layer non-loop towel and quilt fabric and a weaving method thereof. The fabric is formed by interweaving a nap warp,a ground warp and a weft yarn into at least four layers, wherein a first group of weft yarns and a first group of ground warps or a first group of nap warps are interwoven into a first A-side textureof a first layer, a second group of weft yarns and the first group of nap warps or the first group of ground warps are interwoven into a second A-side texture of a second layer, a third group of weftyarns and a second group of ground warps or a second group of nap warps are interwoven into a first B-side texture of a third layer; a fourth group of weft yarns and the second group of nap warps or the second group of ground warps are interwoven into a second B-side texture of a fourth layer, and the first A-side texture and the second A-side texture are different fabric textures; the first B-side texture and the second B-side texture are different fabric textures, and at least four layers of textures are connected together by interlayers in a staggered way. The fabric provided by the invention has no distinction between the front and the back, and has the advantages of improving the utilization ratio of the product, realizing that one towel has multiple purposes, improving the functionality of the product, having high weaving efficiency and being suitable for mass production.

Owner:SUNVIM GROUP

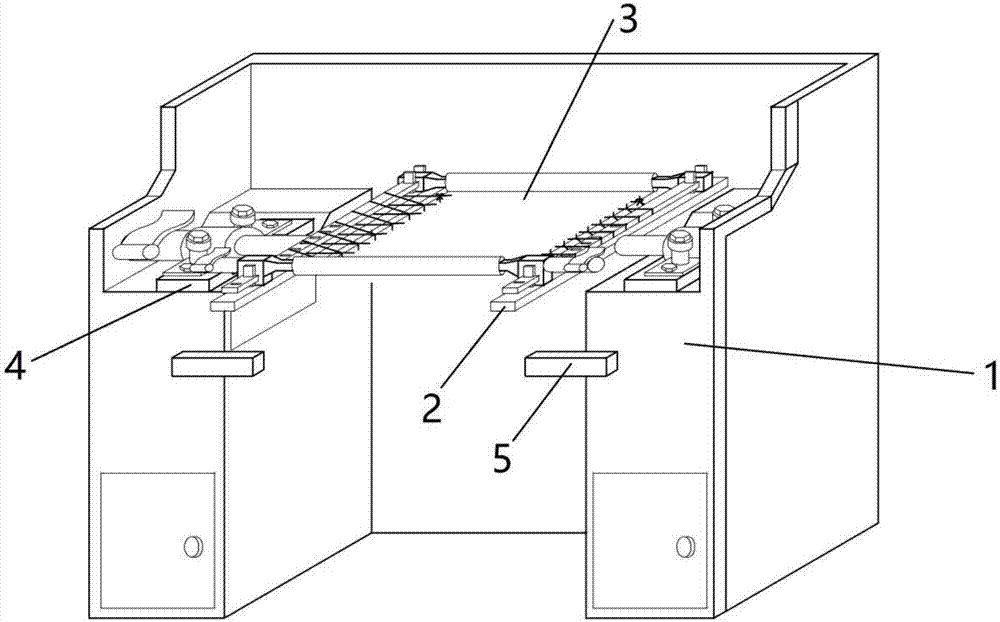

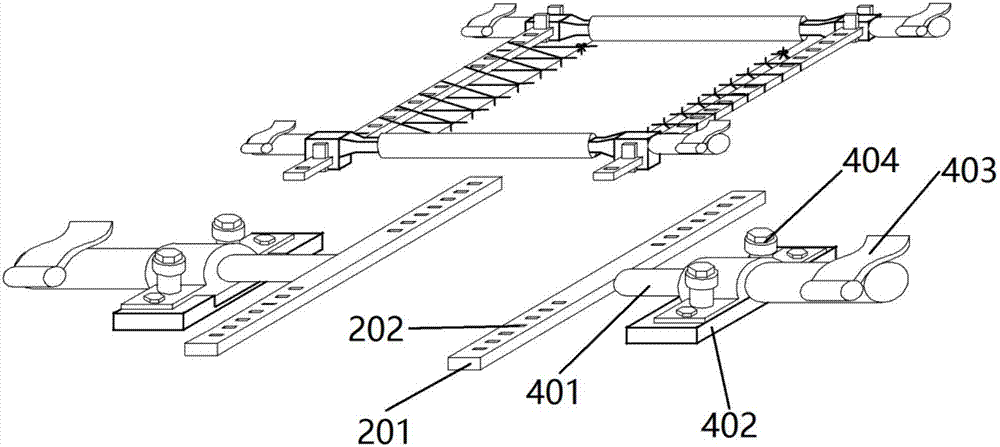

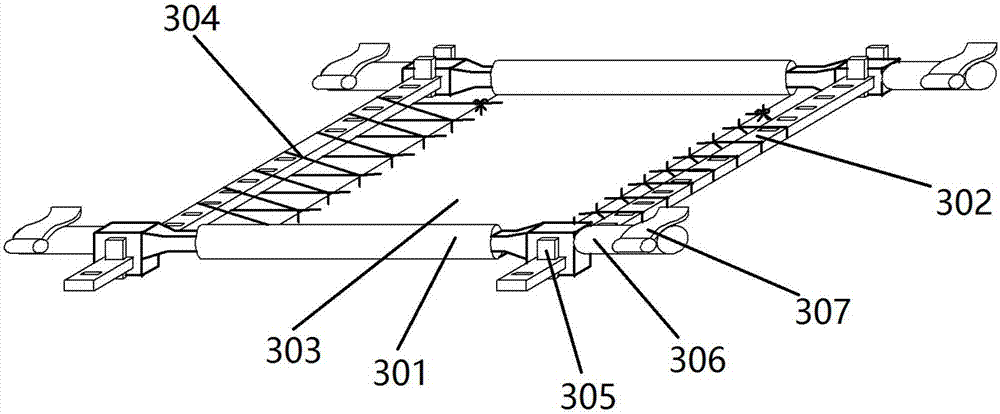

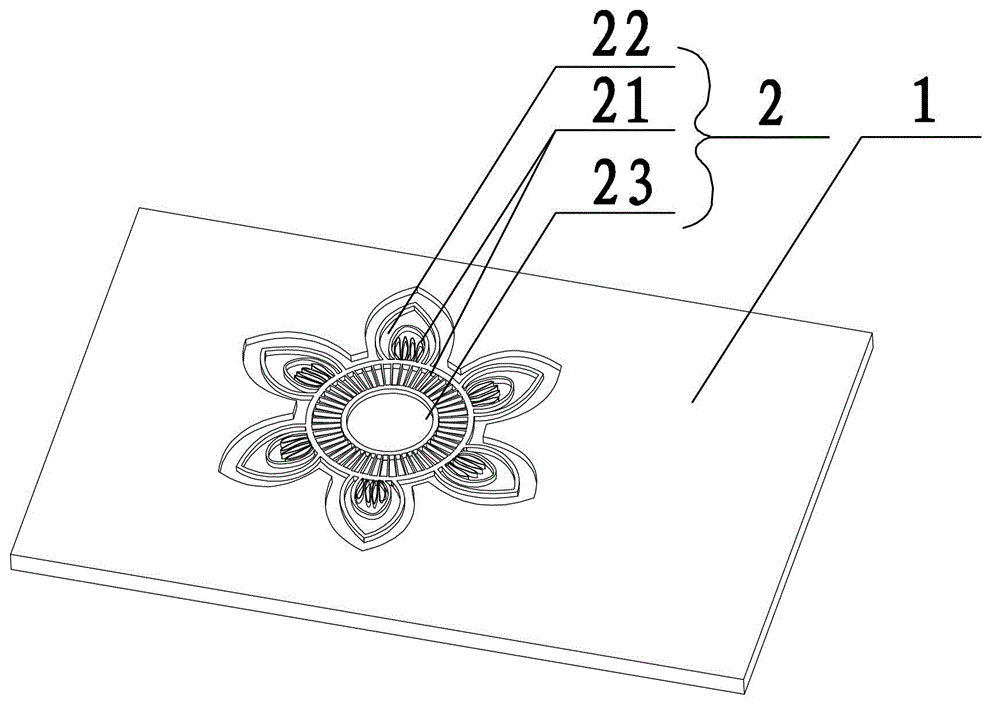

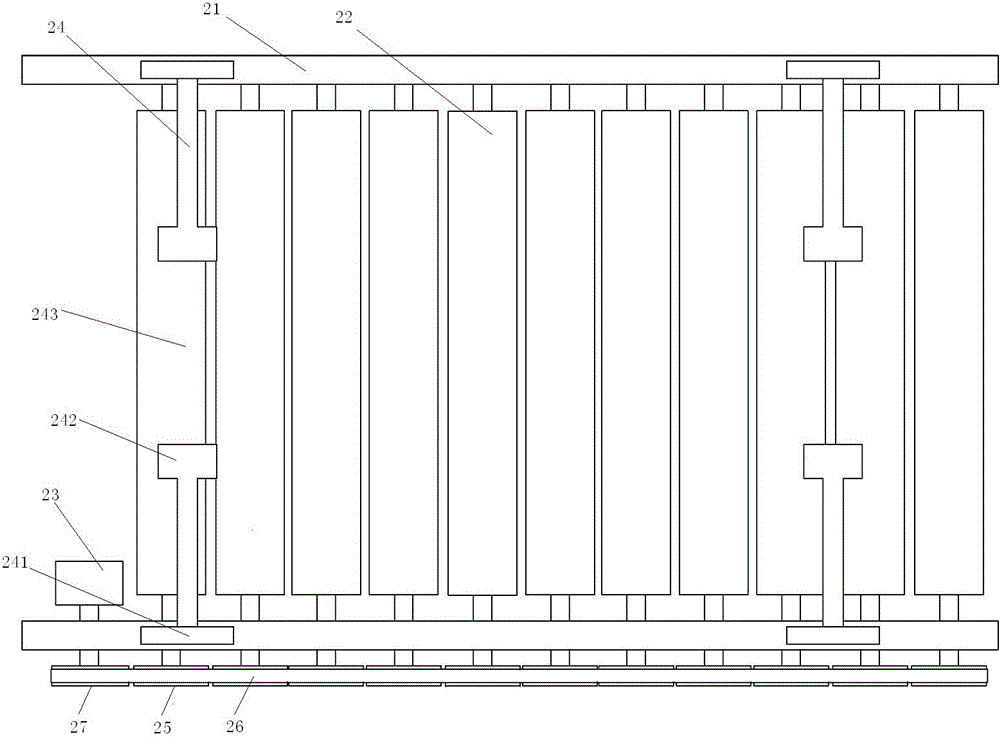

Turnover type embroidery worktable and embroidery method for double-faced seed embroidery

ActiveCN107881675AMeet embroidery requirementsPrevent embossingHand embroideringStructural engineeringMechanical engineering

The invention discloses a turnover type embroidery worktable and an embroidery method for double-faced seed embroidery. The worktable comprises a work tabletop, embroidery frame fixing mechanisms, anembroidery frame, turnover control mechanisms and limiting mechanisms, wherein the two turnover control mechanisms are respectively and symmetrically fixed on the work tabletop; the two embroidery frame fixing mechanisms are respectively and fixedly connected with the two turnover control mechanisms; the embroidery frame is detachably fixed on the embroidery frame fixing mechanisms; the limiting mechanisms are fixedly arranged below the work tabletop; the embroidery frame fixing mechanisms are turned over by the turnover control mechanisms; in the turning process, coordination limit is carriedout by the tail ends of the embroidery frame fixing mechanisms and limiting mechanisms; during embroidering, if the front side is identical with the back side in color, a double-faced seed embroiderystitching method is adopted; if the front side is different from the back side in color, a double-sided different-color-shape seed embroidery stitching method is adopted and different colors are shielded by adopting a stitch hiding method. The turnover type embroidery worktable disclosed by the invention has the advantages of simple structure and low cost; patterns of an embroidery product are more stereo with a sense of a relief and a stronger artistic feeling.

Owner:大冶刘小红刺绣艺术文化有限公司

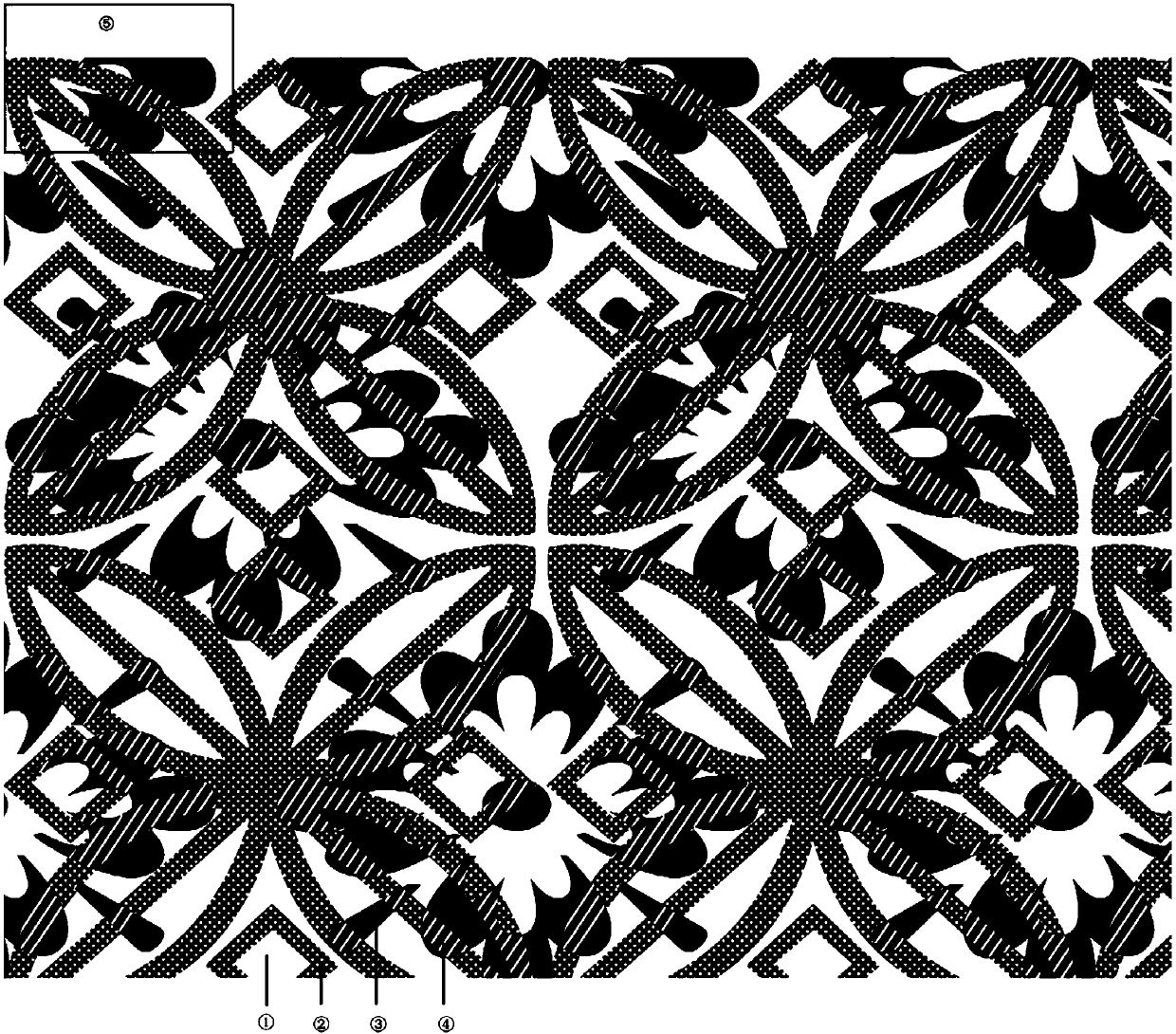

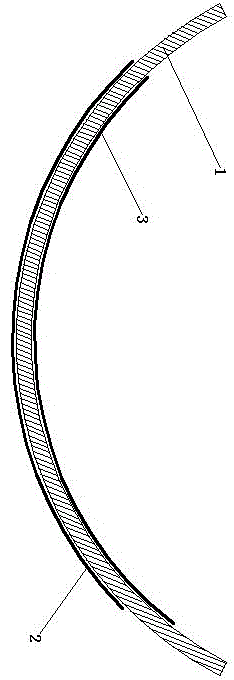

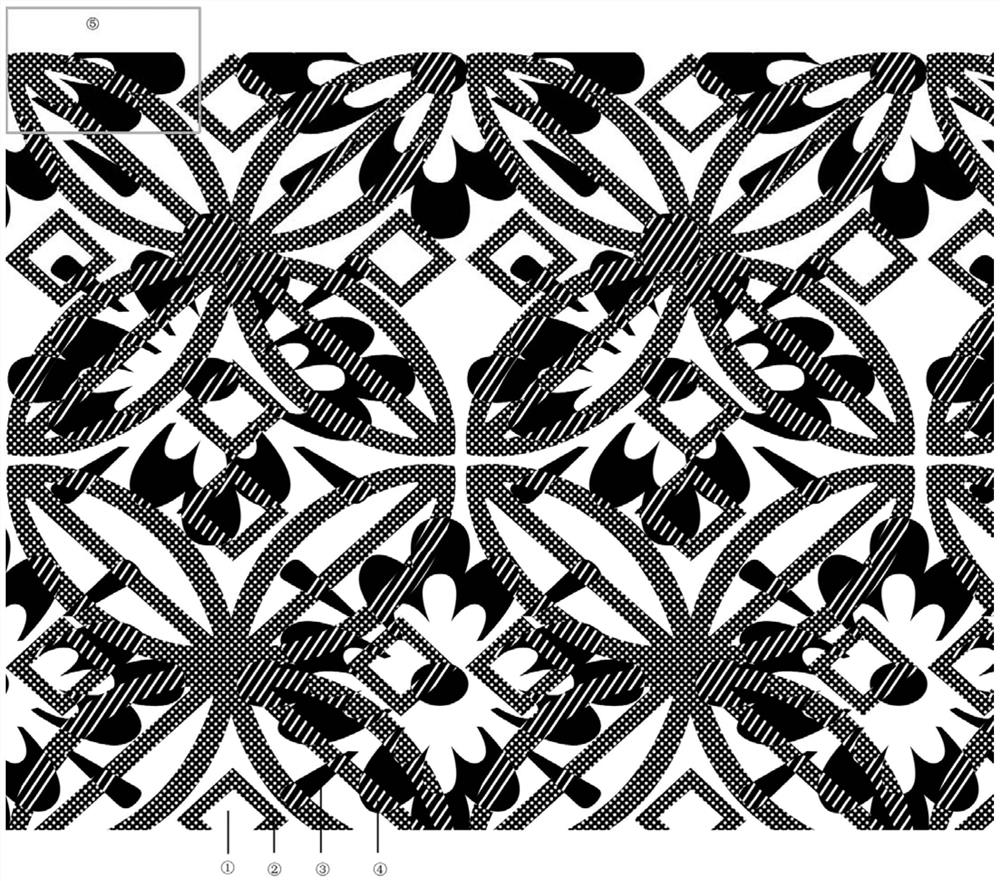

A relief fabric with light and shadow effects

ActiveCN104452018BStrong three-dimensional senseEmbossedSwivel-woven fabricsLappet-woven fabricsShadow effectMaterials science

The invention discloses an embossed fabric with light and shadow effects, which comprises a ground weave and a jacquard weave; the jacquard weave includes an upper fabric and a lower fabric separated from each other; The plain weave structure is formed by the interweaving of the two weft yarns according to the interweaving rule of one up and one down; the upper fabric of the jacquard weave is a twill structure formed by interweaving the second warp yarn and the second weft yarn according to the interweaving rule of one up and three down warp yarns; the lower fabric of the jacquard weave The twill structure is formed by interweaving the first warp yarn and the first weft yarn according to the interweaving rule of warp yarns one up and three down; the first warp yarn, the second warp yarn and the first weft yarn are cotton yarns, and the second weft yarn is made of viscose filament. Therefore, the fabric of the present invention has a better embossed jacquard appearance, and the embossed part has a better luster, and has a better light and shadow effect compared with the ground part.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Elastic fiber fabric solution

The invention relates to an elastic fiber fabric solution, belonging to the technical field of special woven fabrics. The solution comprises the following compositions in percentage by weight: 88% of N,N-dimethylformamide, 2% of dibutyltin dilaurate, and 10% of mineral oil. The solution and sodium alginate paste are mixed for use. By applying the technical scheme in the printing process of the elastic blended fabric, the elastic fiber dissolved fabric which is excellent in breathability, uniform in color, regular in patterns, and good in three-dimensional effect can be obtained.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Dissolving printing technique of elastic fiber fabric

ActiveCN103774472AGuaranteed feelFeel goodHeating/cooling textile fabricsTextile decorationFiberDibutyl tin dilaurate

The invention relates to a dissolving printing technique of an elastic fiber fabric, belonging to the technical field of preparing special woven fabric. The dissolving printing technique comprises the steps of winding, loosening, pre-setting, pretreatment, printing, aging, washing, dehydration, drying and setting sequentially, the printing consists of dyeing and dissolving treatment, the solution for dissolving treatment is mixed with a dyeing auxiliary sodium alginate paste for use, after the solution and the sodium alginate paste are evenly mixed, the elastic blended fabric is dissolved into designed flower types and patterns through a mould, flat scream printing or manual smearing, and the solution comprises the following compositions in percentage by weight: 88% of N,N-dimethylformamide, 2% of dibutyltin dilaurate, and 10% of mineral oil. By adopting the technical scheme, the elastic fiber fabric has the advantages of excellent in breathability, low processing cost and good three-dimensional effect, and is convenient and fast to operate.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Treating fluid for elastic fiber fabric

The invention discloses treating fluid for an elastic fiber fabric and belongs to the technical field of printing treatment for the elastic fiber fabric. The treating fluid comprises sodium alginate paste and rigidifying fluid, wherein the rigidifying fluid is matched with the sodium alginate paste for use and comprises the following components according to weight percentages: 35-40 wt% of diethylene glycol, 2-5 wt% of potassium acetate, 50-55 wt% of white oil and 5-10 wt% of alkylbenzene sulfonate. The elastic fiber fabric treated by the treating fluid for the elastic fiber fabric provided by the technical scheme of the invention has the advantages of uniform coloring, very neat patterns on the fabric even after washing for multiple times, and good stereoscopic effect. Simultaneously, the whole production process can be applied in the conventional printing equipment and printing process without adding more equipment, so that the production control is convenient, and the production cost is lower, thus being capable of being applied in the printing process and the like.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Embossment shell fabric with light and shadow effect

ActiveCN104452018AStrong three-dimensional senseEmbossedSwivel-woven fabricsLappet-woven fabricsEngineeringShadow effect

The invention discloses embossment shell fabric with the light and shadow effect. The embossment shell fabric comprises a ground weave and a figured texture weave; the figured texture weave comprises upper-layer shell fabric and lower-layer shell fabric which are separated; the ground weave is of a tabby structure formed by interweaving first warp yarns, first weft yearns, second warp yarns and second weft yearns according to the one-up-one-down interweaving rule; the upper-layer shell fabric of the figured texture weave is of a twill structure formed by interweaving second warp yarns and second weft yearns according to the one-up-three-down interweaving rule; the lower-layer shell fabric of the figured texture weave is of a twill structure formed by interweaving first warp yarns and first weft yearns according to the one-up-three-down interweaving rule; the first warp yarns, the second warp yarns and the first weft yearns are cotton yarns, and the second weft yearns are viscose filament yarns. In this way, the embossment shell fabric has the good embossment jacquard appearance; in addition, the embossment jacquard part has the excellent gloss sensitivity, and the light and shadow effect is achieved compared with a ground part.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

Curtain fabric with embossment effect and preparation method thereof

InactiveCN103882636AEmbossedImprove the artistic effectHeating/cooling textile fabricsWoven fabricsYarnPolyester

The invention discloses a curtain fabric with an embossment effect and a preparation method of the curtain fabric. The curtain fabric with the embossment effect comprises patterns with an embossment effect, and eight-heddle satin which is taken as a carrier of the pattern of the curtain, wherein the patterns with the embossment effect are formed by embroidering woolen yarns and silk yarns, wherein the woolen yarns comprises seven three-strand threads, and the silk yarns comprise ten four-strand threads; the eight-heddle satin is 50D* 50D modified polyester fiber. The preparation method of the curtain fabric with the embossment effect comprises the steps of carrying out pattern design and color design, platemaking, printing a figure, embroidering, spraying glue, shaping, finishing, etc. The finally obtained curtain fabric with the embossment effect is thick, has a thermal insulation function and a very strong artistic effect, and is as good as an exquisite wall hanging.

Owner:VIOLET HOME TEXTILE TECH

Elastic fabric solution

Owner:ZHEJIANG GANGLONG WEAVING TECH

A Dissolution Printing Process for Elastic Fiber Fabric

ActiveCN103774472BGuaranteed feelFeel goodHeating/cooling textile fabricsTextile decorationFiberN dimethylformamide

Owner:ZHEJIANG GANGLONG WEAVING TECH

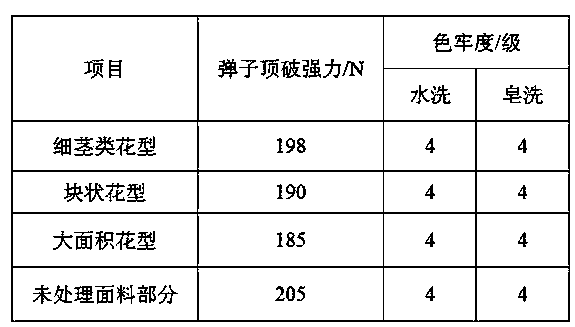

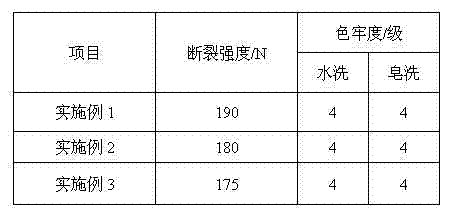

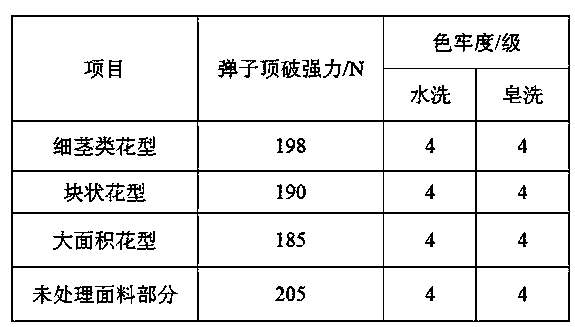

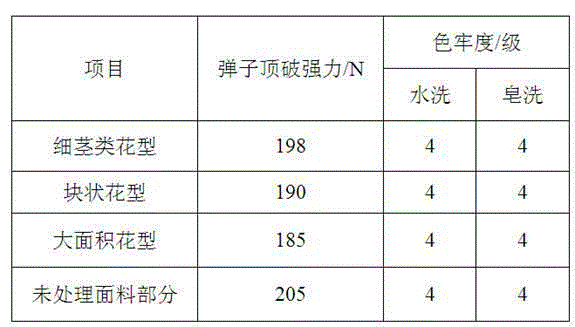

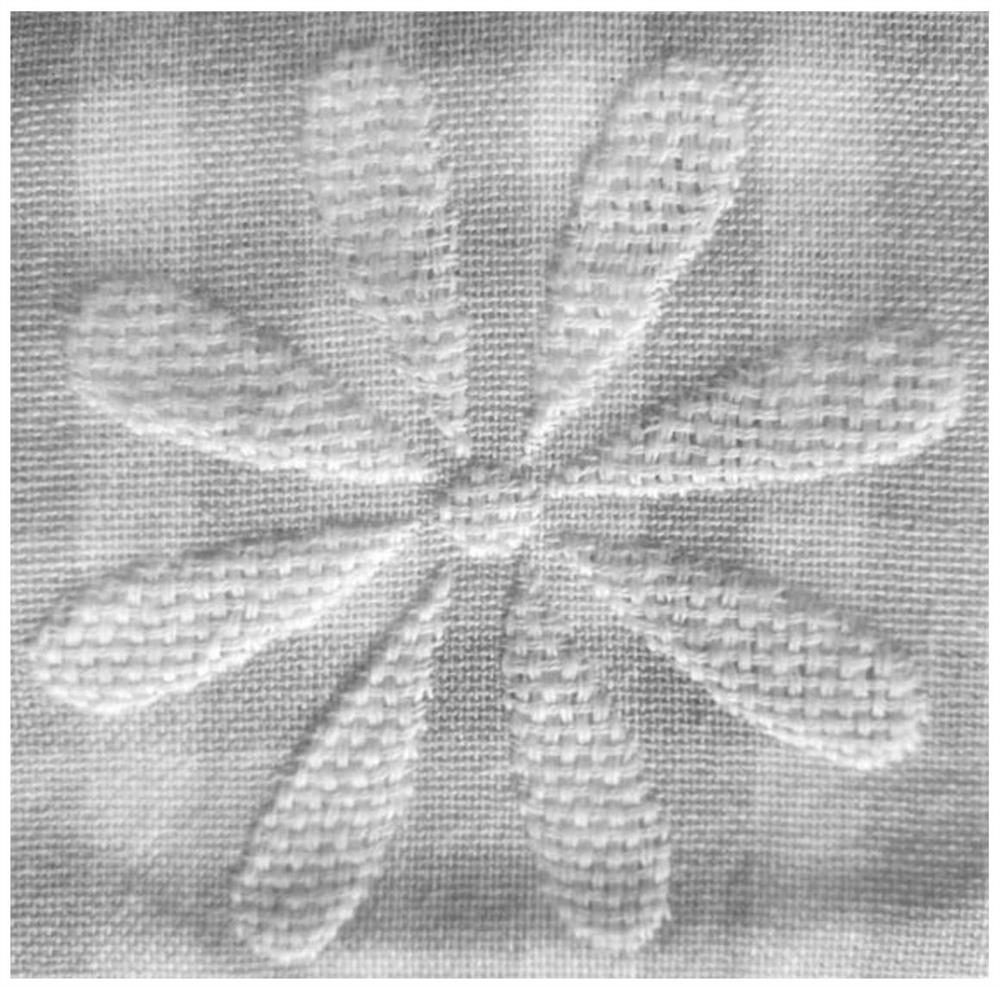

Embossed elastic fiber fabric

ActiveCN102912657APromote blood movementFull of three-dimensional senseDyeing processWoven fabricDiethylene glycol

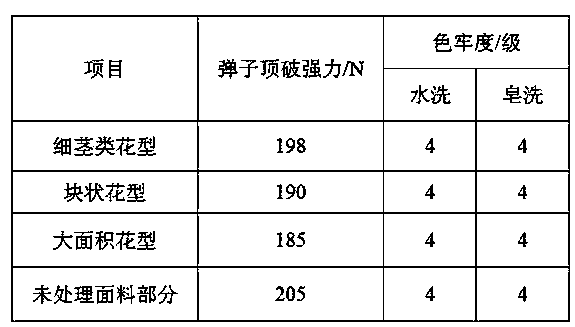

The invention discloses an embossed elastic fiber fabric and belongs to the technical field of woven fabrics having different appearances or effects due to shrinking differences. The elastic fiber fabric has an embossed effect which is obtained by rigidifying the fabric by rigidifying liquor under a certain rigidify condition, and the rigidify condition includes that magnetic bars and magnetic force for the rigidifying liquor are selected according to sizing quantity needed by fabrics, a Zimmer Austria computer-controlled rotary screen printing machine is used, a magnetic bar No.10 or No.12 is used for a fibrous and small-area flower type, and the magnetic force is 80%; a magnetic bar No.15 or No.20 is used for a block flower type, and the magnetic force is 90%; and a magnetic bar No.25 is used for a large-block flower type, and the magnetic force is 100%. The rigidifying liquor comprises 35-40% of diethylene glycol, 2-5% of potassium acetate, 50-55% of white oil and 5-10% of alkylbenzene sulfonate. The embossed elastic fiber fabric has the advantages that the embossed effect is matched with the flower types and patterns, the flower types are rich in stereoscopic impression, and the embossed elastic fiber fabric can be used as clothing fabrics for making underclothes and skirts and can be used as decorative fabrics for making pillowcases, bed spreads, curtains and the like.

Owner:ZHEJIANG GANGLONG WEAVING TECH

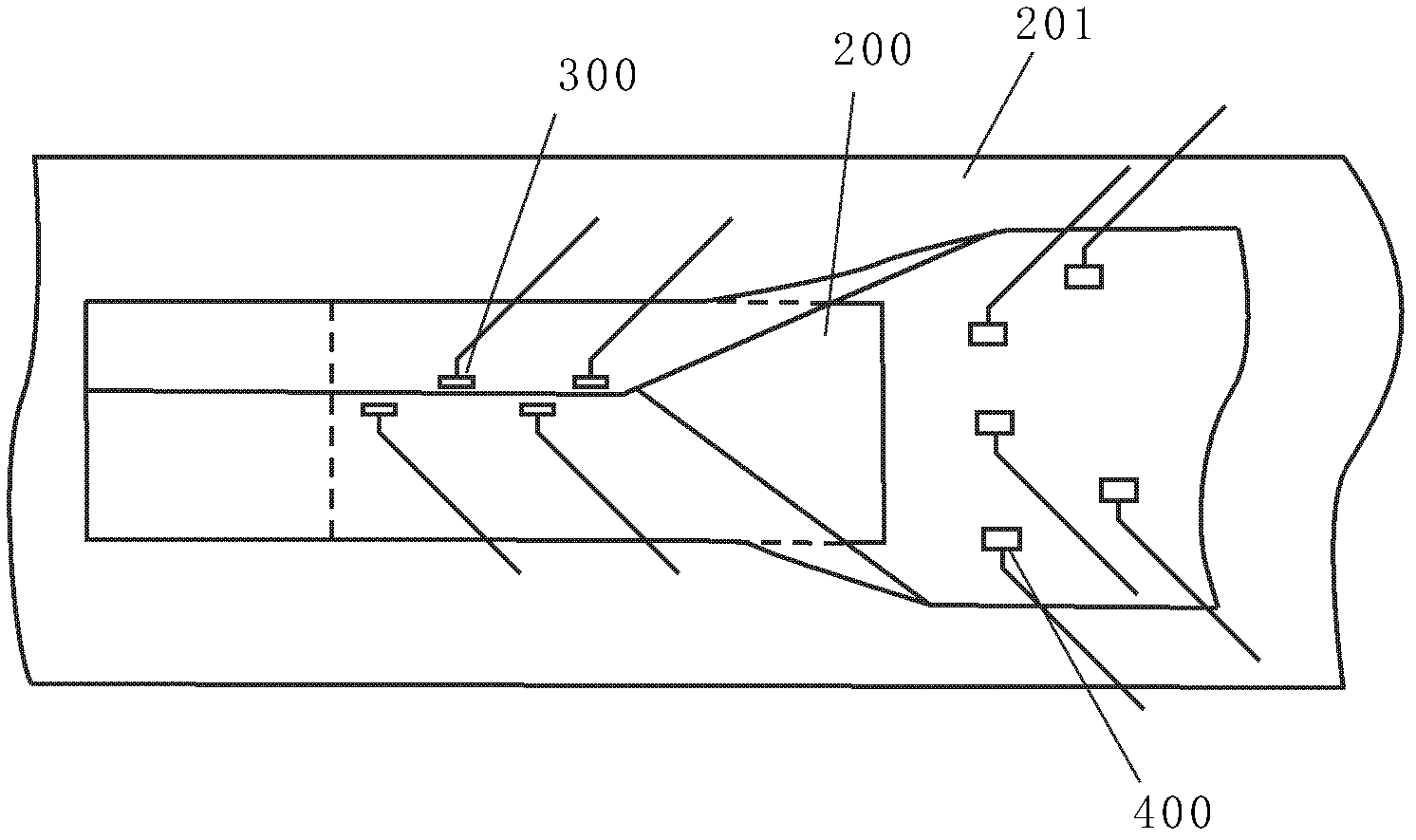

Label center-sealing method, label center-sealing device and center-sealed label

InactiveCN102514244AAvoid deformationImprove product qualityStampsMechanical working/deformationData mining

The invention discloses a label center-sealing method, a label center-sealing device and a center-sealed label. The label center-sealing method comprises the step that concave-convex embossed patterns are embossed in a non-center-sealing position area on the label before or after the label is center-sealed. Through embossing the concave-convex embossed patterns on the center-sealed label, tension caused by an arch in a center-sealing position after the label is rolled can be offset, thereby avoiding the problem of deformation occurring after the center-sealed label is rolled; as the deformation of the center-sealed label is overcome, blockage of label sleeving can also be overcome, thereby avoiding the label sleeving efficiency from being influenced and improving the product quality after the center-sealed label is sleeved.

Owner:SHANGHAI ZIQUAN LABEL CO LTD

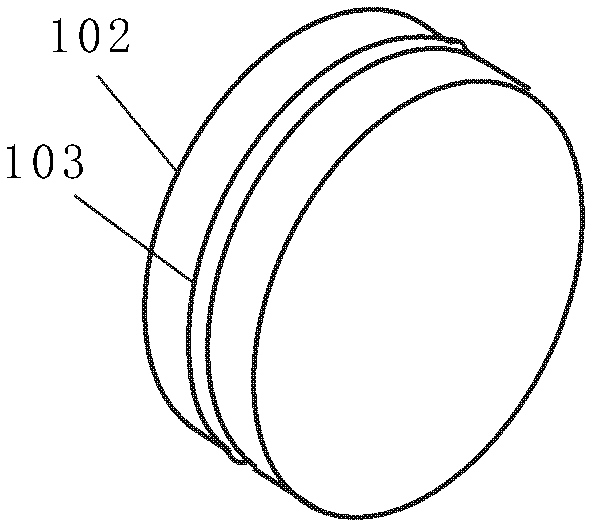

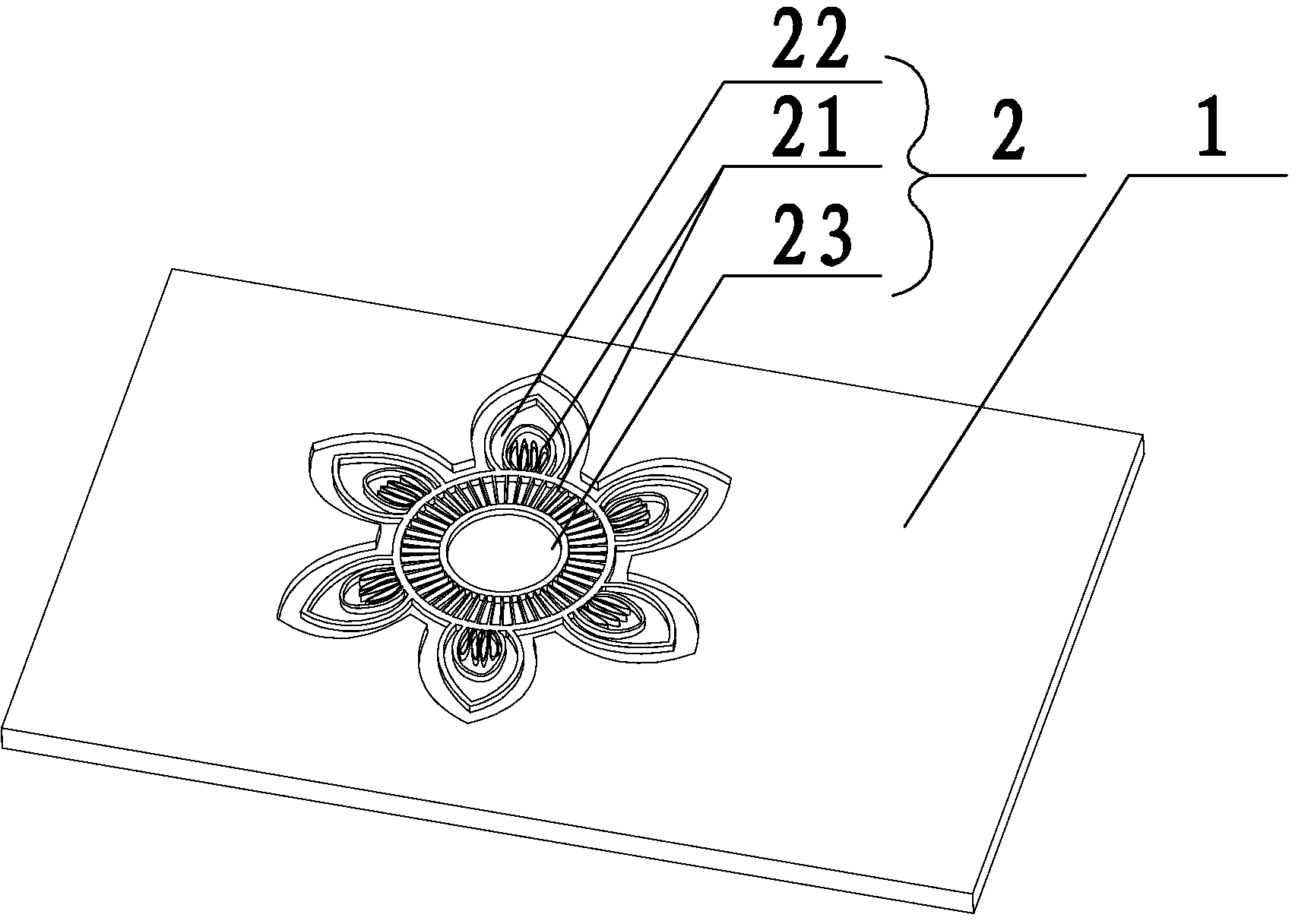

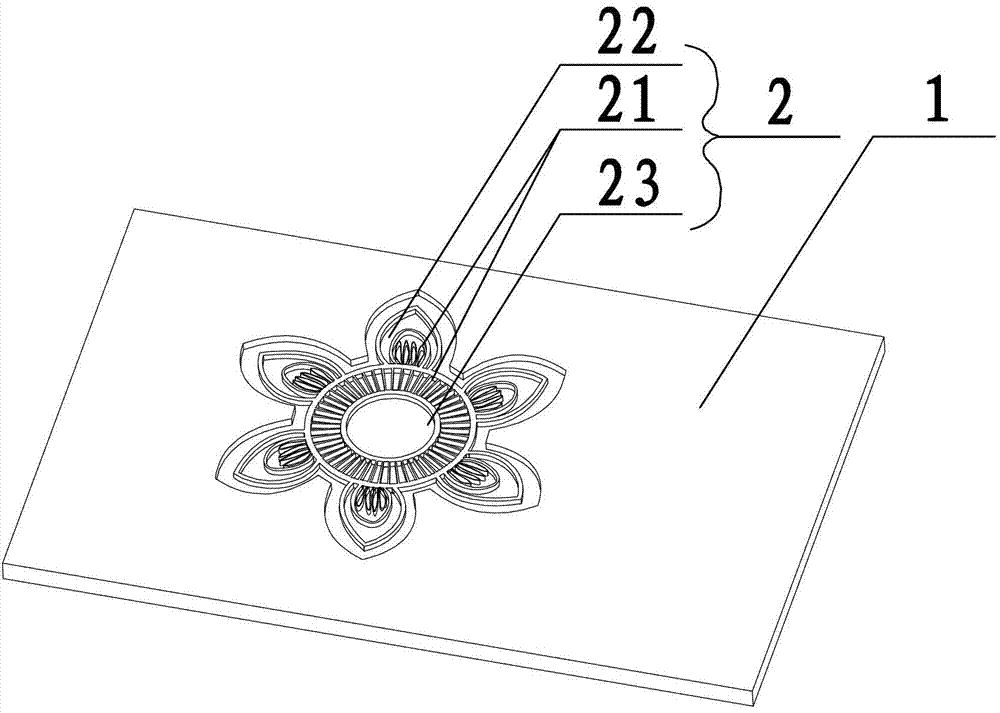

Panel glass of washing machine

The invention relates to panel glass of a washing machine. The panel glass comprises arc-shaped panel glass and a printing ink pattern layer, wherein the printing ink pattern layer is coated and printed on at least one surface of the panel glass; the panel glass is characterized in that a high-temperature printing ink pattern layer or a low-temperature printing ink pattern layer is coated and printed at the inner side of the arc-shaped structure of the panel glass, the low-temperature printing ink or the high-temperature printing ink pattern layer is coated and printed at the outer side of the arc-shaped structure of the panel glass, and the minimum radius R of the arc shape of the panel glass is 500mm. According to the panel glass which is of the arc-shaped structure, disclosed by the invention, an attractive appearance curve is provided, and thus the appearance of the washing machine cannot be inflexible; the printing ink pattern layers protrude out of the panel glass, relief sense can be felt when the panel glass is touched by hand, and the panel glass has the characteristic of skid resistance; two surfaces are coated and printed by the printing ink pattern layers, and thus the attractiveness can be shown on both the two surfaces.

Owner:苏州市灵通玻璃制品有限公司

Elastic fiber dissolved fabric

ActiveCN103774473AGuaranteed feelFeel goodTextile decorationOther printing apparatusFiberDibutyl tin dilaurate

The invention relates to an elastic fiber dissolved fabric, belonging to the technical field of special woven fabrics. The elastic fiber dissolved fabric has concave-convex patterns, through solution, elastic fibers in elastic blended fabric are dissolved to form depressions and other coils are restored to form bulges, the depressions and bulges are staggered to obtain the concave-convex patterns, and the solution comprises the following compositions in percentage by weight: 88% of N,N-dimethylformamide, 2% of dibutyltin dilaurate, and 10% of mineral oil. The elastic fiber dissolved fabric obtained by adopting the technical scheme has the advantages of excellent breathability, uniform color, regular patterns, good three-dimensional effect and the like.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Sand painting manufacturing method

PendingCN113147247AMaterials are readily availableStrong decorationSpecial ornamental structuresSpecial artistic techniquesAdhesive glueLine drawings

The invention discloses a sand painting manufacturing method. The method comprises the steps that on-board composition is conducted, and the line outline of a sand painting is drawn on a drawing board; the convex outline is pasted, a line object is pasted according to the drawn outline by using a glue, and the redundant line object is cut off by using scissors after the pasting is finished; glue smearing and sand covering are conducted, specifically, the glue is dipped through a brush, the drawing board is evenly coated with the glue, the glue is evenly covered with fine sands, the whole drawing board is full of the fine sands, the drawing board is inclined after sand covering is completed, and the redundant fine sands are poured out; colors are painted, the sand painting is painted with the appropriate colors through a paintbrush; line drawing and forming are conducted, the colors are painted on the adhered line object by using the paintbrush, and the line outline of the sand painting is drawn to finish the manufacturing of the sand painting. The imagination and creativity of children are exercised by drawing the outline of the sand painting and coloring the sand painting, the painting level of the children is improved, and the interest of the children in painting is stimulated. The practical ability of the children is improved through sand painting making exercise.

Owner:谢建华

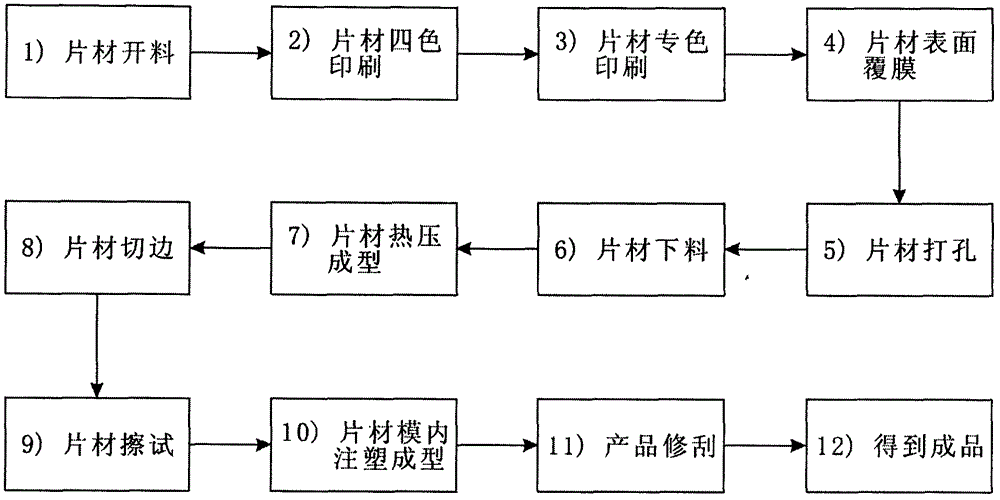

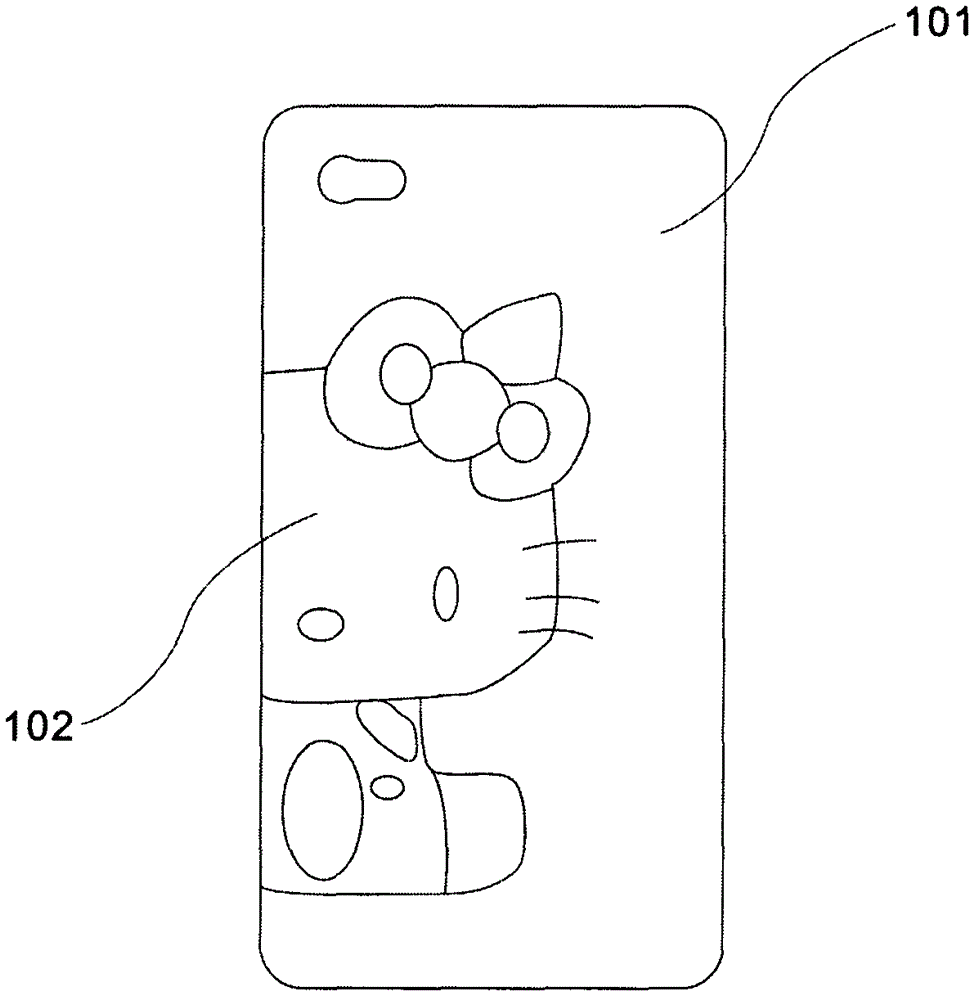

In-mold molding injection product relief production process

The invention discloses a relief production process of an injection molding product for in-mold molding. The process comprises the following steps of: 1) sheet cutting; 2) sheet four-color printing; 3) sheet special color printing; 4) sheet surface coating; 5) sheet punching; 6) sheet blanking; 7) sheet thermo-compression formation; 8) sheet edging; 9) sheet wiping; 10) sheet in-mold injection molding; 11) product polishing; and 12) obtaining of an injection molding finished product with a relief pattern effect. With the adoption of the relief production process of the injection molding product for in-mold molding provided by the invention, the plane pattern product has the relief effect; the pattern has a good convex effect, has richer three-dimensional sense and better hand sense, and has richer dynamic sense in vision.

Owner:SHENZHEN KANGCHENGTAI IND CO LTD

Elastane dissolving fabric

ActiveCN103774473BGuaranteed feelFeel goodTextile decorationOther printing apparatusFiberN dimethylformamide

The invention relates to an elastic fiber dissolved fabric, belonging to the technical field of special woven fabrics. The elastic fiber dissolved fabric has concave-convex patterns, through solution, elastic fibers in elastic blended fabric are dissolved to form depressions and other coils are restored to form bulges, the depressions and bulges are staggered to obtain the concave-convex patterns, and the solution comprises the following compositions in percentage by weight: 88% of N,N-dimethylformamide, 2% of dibutyltin dilaurate, and 10% of mineral oil. The elastic fiber dissolved fabric obtained by adopting the technical scheme has the advantages of excellent breathability, uniform color, regular patterns, good three-dimensional effect and the like.

Owner:ZHEJIANG GANGLONG WEAVING TECH

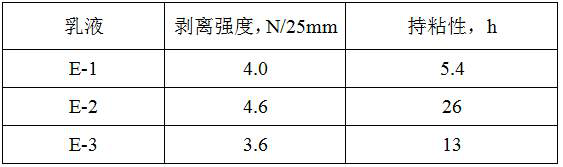

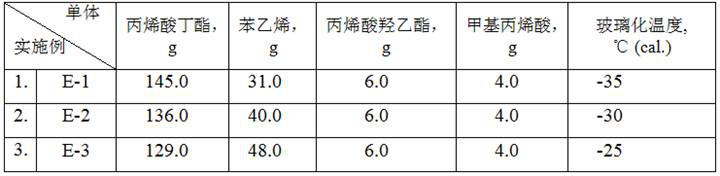

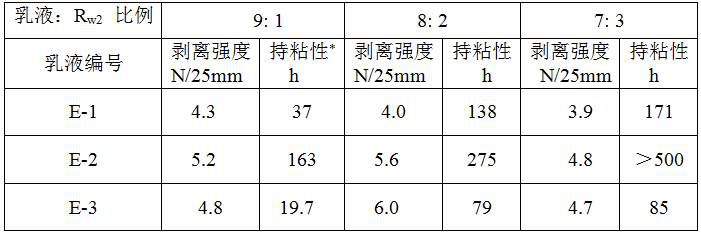

Composite acrylic resin hot-melt adhesive and preparation method thereof

ActiveCN114214004AHigh peel strengthStrong holding powerEster polymer adhesivesPolymer scienceAcrylic resin

The invention relates to a composite acrylic resin hot-melt adhesive. The adhesive is prepared by mixing an acrylic resin emulsion and a solid acrylic resin aqueous dispersion in proportion. The composite hot-melt adhesive is high in peel strength, strong in holding power and stable in storage, has the characteristics of no film stripping, embossing resistance and the like after a plastic film and color printing packaging paper are compounded, has good thermal bonding performance on a BOPP (biaxially-oriented polypropylene) film and printing paper, can be used for a dry laminating process for field coating, and also can be used as adhesive resin in a pre-coating film.

Owner:河南省中凌煜新材料科技有限公司

Manufacturing method of stone carving calligraphy and painting items with embossing effect

InactiveCN109080365AEmbossedEnhance layeringDecorative surface effectsSpecial ornamental structuresLight sensingStone carving

The invention discloses a manufacturing method of stone carving calligraphy and painting items with an embossing effect. The manufacturing method comprises the procedures of provision of calligraphy and painting items, pretreatment of the items, stone treatment, film pasting treatment, light sensing treatment, development treatment, etching treatment, demolding treatment and spraying treatment. Inthe manufacturing method, after the selected calligraphy and painting items and stones are treated, the calligraphy and painting items are copied on the stones by using a light sensing technology; then, the stones are carved by using etching liquid; and finally, the stone carving calligraphy and painting items with a concave-convex effect are manufactured according to corresponding colors needingto be filled. The manufactured stone carving calligraphy and painting items achieve the embossing effect, good layering sense, no distortion, lower cost, simple and convenient operation, large-batchproduction and permanent collection, and are another choices of appreciating and collecting calligraphy and painting artwork.

Owner:黄其明

Double-layer screen stretching method for silk-screen printing

ActiveCN113085347AWith anti-counterfeiting effectChange depthForme preparationScreen printingEngineering

The invention provides a double-layer screen stretching method for silk-screen printing, and relates to the technical field of package printing. The double-layer screen stretching method comprises the following steps that S1, a steel stencil is welded and pressed on a stencil frame; S2, a gauze element is stretched on the stencil frame welded with the steel stencil; S3, a CCD camera is used to shoot the shape of meshes after double-layer screen stretching; and S4, the overlapping angle and position of the gauze element and the steel stencil are adjusted according to shot images, so that the mesh shape meets a preset requirement. Through matching of different shapes, mesh numbers and overlapping angles in the two layers of stretching nets, the shapes and sizes of the meshes can be adjusted at will, and the printing effect different from that of traditional silk-screen printing is achieved. And the special mesh-shaped printed image-text has a certain anti-counterfeiting effect. By arranging the steel stencil and the gauze element which are different in thickness, the depth of the meshes can be changed, so that printed images and texts are concave and convex, a certain embossment effect is achieved, and more exquisite images and texts are presented.

Owner:SHANXI JINYE PRINTING CO LTD +1

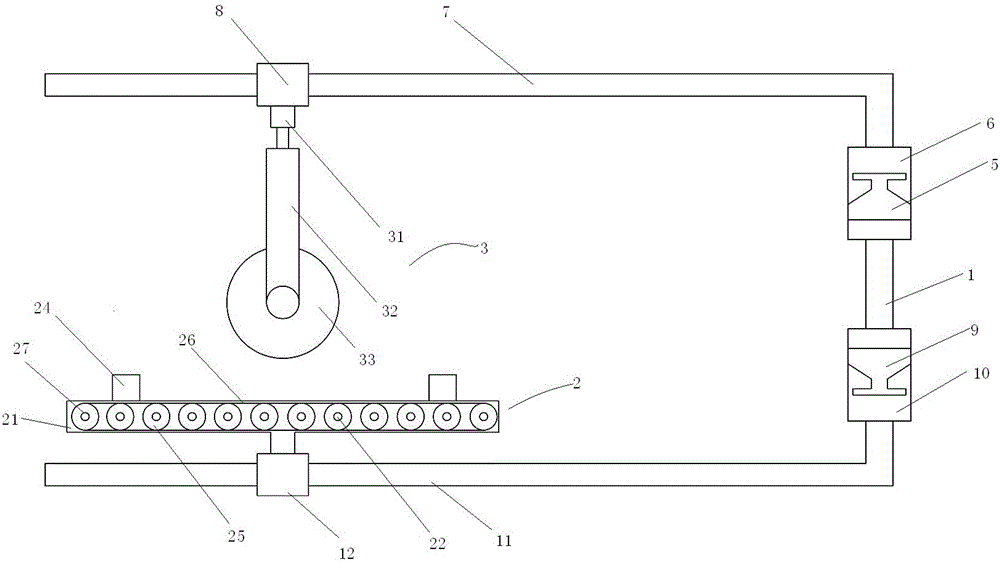

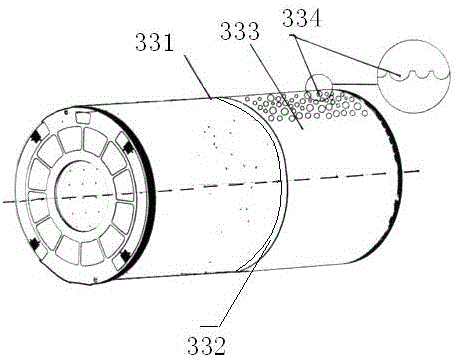

Board exterior trimming machine

PendingCN107521276AReduce manufacturing costEasy to makeEmbossing decorationsTextile printerElectric machinery

The invention discloses a board exterior trimming machine. The board exterior trimming machine comprises a rack, a conveying fixed mechanism and an exterior trimming printing mechanism, wherein the rack is I-shaped; the upper part of the rack is connected to an upper vertical bar; an upper vertical motor is arranged on the upper vertical bar in a sliding manner and is fixedly connected to an upper horizontal bar; an upper horizontal motor is arranged on the upper horizontal bar in a sliding manner; the lower part of the rack is connected to a lower vertical bar; a lower vertical motor is arranged on the lower vertical bar in a sliding manner and is fixedly connected to a lower horizontal bar; a lower horizontal motor is arranged on the lower horizontal bar in a sliding manner; the exterior trimming printing mechanism comprises a telescopic cylinder, a fixed support and a printing roller; and the conveying fixed mechanism comprises a supporting bracket, a plurality of conveying rollers, a conveying motor and two groups of fixed parts. The board exterior trimming machine has the beneficial effects that machinery and automation integration is realized; and the board exterior trimming machine is low in manufacturing cost and simple to manufacture and meanwhile has good appearance, practicability, an embossment effect and high pattern simulation.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

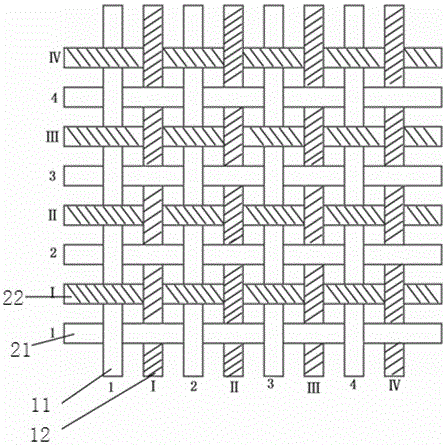

A double-sided embossed different pattern multi-layer non-terry towel fabric and its weaving method

ActiveCN107740216BGuaranteed softnessEmbossedBed linenHeating/cooling textile fabricsEngineeringMechanical engineering

The invention discloses a double-sided embossed and different pattern multi-layer non-terry terry towel fabric and its manufacturing process. The fabric is composed of wool warp, ground warp and weft yarn interlaced into at least four layers, and the first group of weft yarn and the second group One group of ground warps or the first group of wool warps are interwoven into the first layer of A-side weave one; the second group of weft yarns and the first group of wool warps or the first group of ground warps are interwoven into the second layer of A-side weave two; The third group of weft yarns and the second group of ground warps or the second group of wool warps are interwoven into the third layer of B surface organization; the fourth group of weft yarns and the second group of wool warps or the second group of ground warps are interwoven into the fourth layer. B-side weave 2; A-side weave 1 and A-side weave 2 are different fabric weaves; B-side weave 1 and B-side weave 2 are different fabric weaves; at least four layers of weave are connected by interleaved layers and interlaced joints together. The fabric of the invention has no distinction between the front and the back, improves the utilization rate of the product, truly achieves multiple uses of one towel, improves the functionality of the product, has high weaving efficiency and is suitable for mass production.

Owner:SUNVIM GROUP

Embossed elastic fiber fabric

The invention discloses an embossed elastic fiber fabric, which belongs to the technical field of woven fabrics with different shapes or effects due to shrinkage differences. The elastic fiber fabric has an embossing effect, and the embossing effect is obtained by ossifying the fabric under certain ossifying conditions with the ossified liquid. , use the Austrian Zima full computer to control the garden screen printing machine, choose No. 10 or No. 12 magnetic rods for thin stems and small-area patterns, and the magnetic force is 80%; select No. 15-20 magnetic rods for block patterns, and the magnetic force is 90%; Choose the No. 25 magnetic rod for the flower type, and the magnetic force is 100%; the ossified liquid is the following components: diethylene glycol 35-40%; potassium acetate 2-5%; white oil 50-55%; alkylbenzene Sulfonate 5-10%. The embossed elastic fiber fabric of the present invention has embossed effects matched with patterns and patterns, and the pattern is full of three-dimensional effect. It can be used as clothing fabrics for underwear and skirt materials, and can also be used as decorative fabrics such as pillowcases, bedspreads, and curtains.

Owner:ZHEJIANG GANGLONG WEAVING TECH

A kind of curtain fabric with embossed effect

InactiveCN103882636BEmbossedImprove the artistic effectHeating/cooling textile fabricsWoven fabricsPolyesterPolymer science

The invention discloses a curtain fabric with embossed effect and a preparation method thereof. The curtain fabric with embossed effect includes a pattern with embossed effect and eight pieces of satin as the pattern carrier of the curtain. The pattern with embossed effect is made of wool thread and The silk thread is needle-punched, the wool thread is 7 threads with 3 strands, the silk thread is 10 threads with 4 strands, and the eight satins are 50Dx50D modified polyester. The preparation method of the curtain fabric with embossed effect includes steps such as pattern design, color design, plate making, drawing, embroidery, glue spraying, shaping, finishing, etc., and finally obtains the curtain fabric with embossed effect of the present invention, which is thick, Thermal insulation, with a strong artistic effect, no less than a beautiful wall hanging.

Owner:VIOLET HOME TEXTILE TECH

Treating fluid for elastic fiber fabric

The invention discloses an elastic fiber fabric treatment liquid, which belongs to the technical field of elastic fiber fabric printing treatment. Including sodium alginate paste, also includes ossified liquid, ossified liquid is used in conjunction with sodium alginate paste, said ossified liquid is the following components: diethylene glycol 35-40wt%; potassium acetate 2-5wt %; white oil 50-55wt%; alkylbenzene sulfonate 5-10wt%. The elastic fiber fabric treated with the elastic fiber fabric treatment liquid in the technical solution of the present invention is not only uniform in coloring, but also has regular patterns on the fabric after repeated washing, and has a good three-dimensional effect. At the same time, the entire production process can be applied to the present In some printing equipment and printing process, there is no need to add too much equipment, not only the production control is convenient, but also the production cost is low, which can be applied to printing and other processes.

Owner:ZHEJIANG GANGLONG WEAVING TECH

A kind of decorative painting and its manufacturing method

ActiveCN103879221BStrong three-dimensional senseEmbossedSpecial ornamental structuresSpecial artistic techniquesFeltedMechanical engineering

The invention discloses a decorative painting, which is composed of a three-layer structure of a fabric layer, a felt cloth layer and an interlining cloth layer. The fabric layer is the front layer, the felt cloth layer is the middle layer, and the interlining layer is the back layer, and the fabric layer and the interlining layer are bonded by ironing. The production method is to cut out the pattern on the felt cloth, iron the fabric, place the felt cloth cut piece on the back of the fabric, cover the felt cloth cut piece with the interlining cloth, press the whole three-layer fabric evenly to form a three-dimensional pattern, and finally iron the pattern , cropped. This kind of decorative painting has a strong sense of three-dimensionality, has a certain relief effect, and has the texture of cloth. The technique for making the decorative painting of the present invention is simple, easy to implement, does not consume a lot of materials and time, has abundant raw materials, various patterns, and is very light and convenient.

Owner:NANTONG TEXTILE VOCATIONAL TECH COLLEGE

Lace product weaving process

InactiveCN110171243AImprove work efficiencyImprove economic efficiencySpecial ornamental structuresSevering textilesComputer generationWoven fabric

The invention belongs to the field of textile production, and particularly relates to a lace product weaving process. The process comprises the following steps of (1), designing, specifically, adopting CAD draft design and BPM process control, designing a lace shape through a computer, and generating an automatic production control instruction of the lace shape by the computer; (2), manufacturinga lace; (3), manufacturing a hollowed-out part; (4), manufacturing embroidery; and (5), manufacturing a finished product, specifically, carrying out steam ironing and shaping on a semi-finished product, then carrying out inspection on the semi-finished product, and carrying out folding, packaging and storing treatment after the semi-finished product is qualified through inspection. According to the process, an enjoyable style and an exaggerated means of the Chinese painting are merged into a modern production technology, so that the artistry, the ornamental value, the practicability and the collection value are integrated; and through the process, the working efficiency is improved by 60%, the economic benefit is improved by 30%, and popularization in the industry is extremely high.

Owner:SHANDONG ARTS & CRAFTS INST

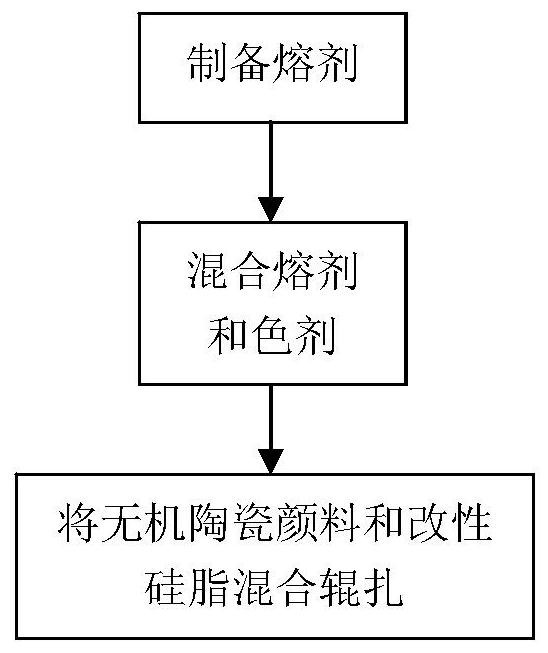

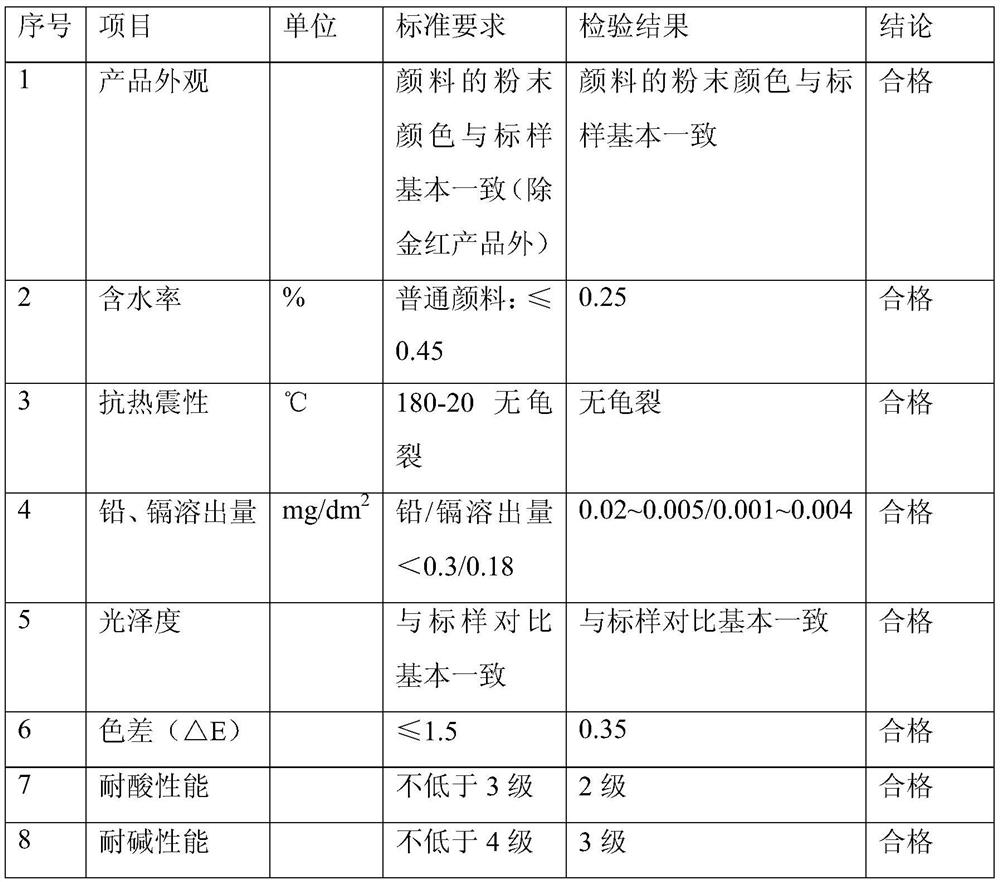

Low temperature ceramic blank glaze direct printing glaze ink and its application and ceramic products

The invention discloses a low-temperature ceramic blank glaze direct printing glaze ink and its application and ceramic products. The glaze ink includes 60%-75% of inorganic ceramic pigment and 25%-40% of modified silicone grease; The inorganic ceramic pigment includes 60%-75% flux and 25%-40% colorant by weight; the raw materials of the flux include 49%-55% potassium feldspar, 20% quartz ~28%, borax pentahydrate 20%~26%, calcite 2%~8%, kaolin 1%~6%. Inorganic ceramic pigments and the modified silicone grease are evenly mixed and then rolled to make direct printing glaze ink. The glaze ink is printed on the ceramic blank or raw glaze layer by mechanical printing methods such as screen printing or pad printing machine printing. During production, the ceramic blank, glaze and glaze ink pattern are fired at one time to completely remove traditional ceramics. The volatilization of lead and cadmium in the high-temperature firing of the decal paper, and the harm to the human body caused by the lead and cadmium remaining in the ceramic after the high-temperature reaction of the ceramic decal paper, are suitable for firing in the low temperature range. The production process is simple, the color is bright, and the cost is low. , with a sense of relief and the effect of glaze color.

Owner:朱宝山 +1

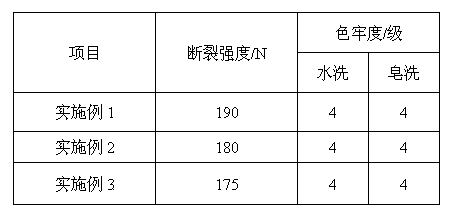

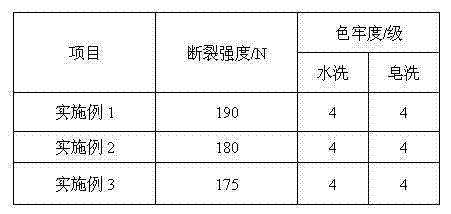

A production process of positioning transfer paper with embossed effect

ActiveCN110626046BAvoid destructionHigh strengthLamination ancillary operationsSpecial paperTemperature controlPaper production

The invention relates to a production process of positioning transfer paper with embossed effect, which comprises the following steps: step 1: choose PET as the carrier, lay a laser board, carry out laser positioning molding on the laser board to produce a relief effect, and spray on the laser board Acrylic resin; Step 2: Select cardboard, and plate aluminum on the cardboard to form an aluminum plate; Step 3: Use a compound machine to use curing glue to fit the plated PET and aluminum plate together, and then put it in a temperature-controlled room for curing. That is the finished product. The invention has the advantages that the positioning transfer paper has a relief effect, and the surface of the positioning transfer paper has high transparency and strong visibility.

Owner:WENZHOU LIKEDA PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com