Washing machine panel glass processing technology

A panel glass and processing technology, applied in other washing machines, glass tempering, glass manufacturing equipment, etc., can solve problems such as rigid appearance and inability to meet customer appearance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

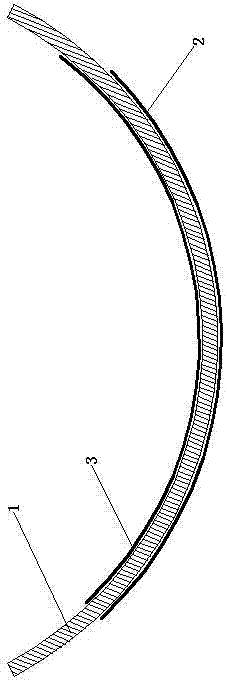

[0020] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0021] Such as figure 1 Shown, a kind of washing machine panel glass 1 processing technology comprises the following steps:

[0022] (1) Apply high-temperature ink pattern layer 2 on one side of panel glass 1;

[0023] (2) Send the panel glass 1 coated with the high-temperature ink pattern layer 2 into the tempering furnace for steel bending treatment;

[0024] (3) Apply the low-temperature ink pattern layer 3 on the other side of the panel glass 1 that has been treated with steel bending.

[0025] The high-temperature ink is screen-printed first, and the high-temperature ink is sintered by the high-temperature heating of the tempering furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com