Label center-sealing method, label center-sealing device and center-sealed label

A label and palm pressing technology, applied in the field of label palm pressing device, label palm pressing method, and palm pressing label field, can solve the problems of label deformation, affecting sleeve labeling efficiency, and producing waste products, so as to avoid deformation, avoid sleeve labeling efficiency, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

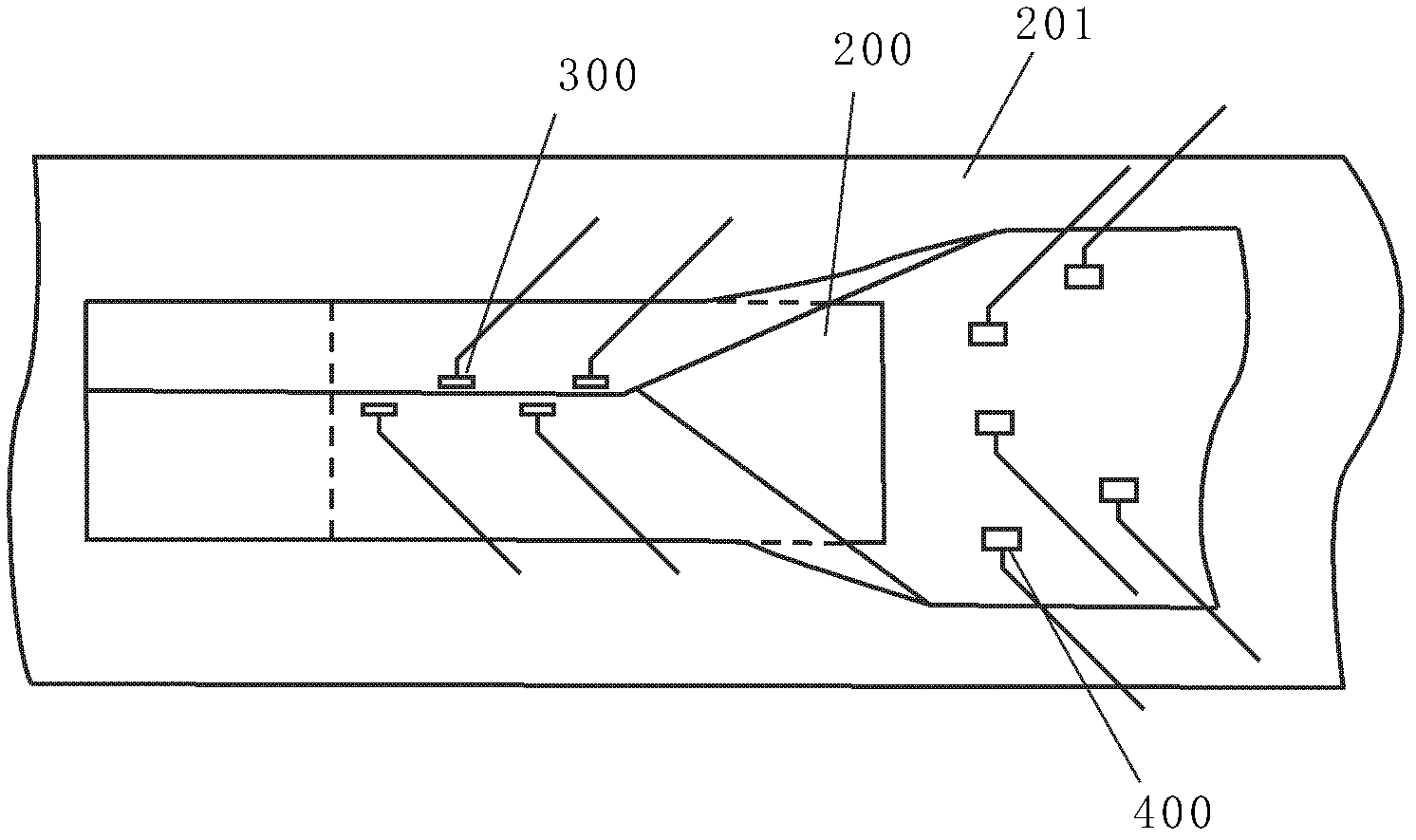

[0020] Such as image 3 As shown, the label folding device includes a table top 201, a template 200 on the table 201 and a palm pressing wheel 300 on the template 200, and a plurality of embossing wheels 400 are arranged behind the template 200 on the table 201, so that the embossing wheels The setting position of 400 should avoid the two sides of the main body of the label.

[0021] In this way, many embossings are made on the film label by the embossing wheel 400 before the hands are folded together, and then the film label is made into a folded palm label by the template 200 and the folded palm press wheel 300 .

Embodiment 2

[0023] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the embossing wheel 400 is arranged in front of the template 200 instead of being arranged behind the template 200 as in Embodiment 1. However, the position of the embossing wheel 400 It is also required to avoid the position of joining hands. Such a structure is to perform the gassing of the film label first, and then emboss the embossing on the gassing label.

[0024] By embossing the concave-convex embossing on the folded palm label, this can offset the tension caused by the arching of the closed palm position after the label is rolled, so as to avoid the deformation of the closed folded label and overcome the deformation of the folded palm label. It can overcome the poor sleeve label, avoid affecting the sleeve label efficiency, and improve the product quality of the Gasshang label sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com