Dissolving printing technique of elastic fiber fabric

A technology of elastic fiber and printing technology, which is applied in printing, printing devices, textile decoration, etc., can solve the problems of poor air permeability and wearing effect, stiff hand feeling of fabrics, and easy running of patterns, etc., and achieve good washing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

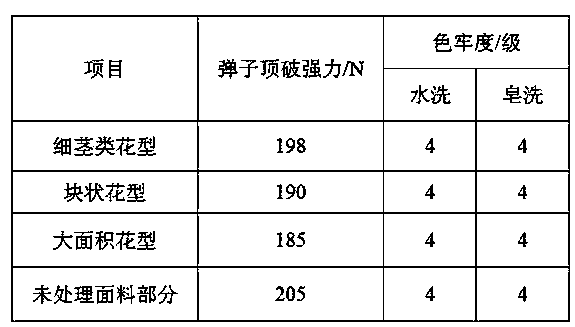

[0021] In the present invention, the thin-stem flower type area<blocky flower-type area<large surface flower-type area, the difficulty of dyeing the thin-stem and small-area flower types is greater than that of blocky flower types and large-surface flower types , the structure is more complex.

[0022] In this embodiment, printing is carried out by means of rotary screen printing, and the elastic blended fabric interwoven with spandex and cotton, hemp, bamboo, tencel, modal or polyester / cotton is printed according to the following procedures: weaving open-width winding → loosening Cloth→(steaming)→pre-shaping→pretreatment→(dyeing)→(spandex solution solution treatment)→printing→steaming→water washing→dehydration→drying→setting, wherein the solution is each component with the following content : N,N-dimethylformamide (analytical grade, HCON (CH 3 ) 2 ) 88%; dibutyltin dilaurate (C 32 h 64 o 4Sn) 2%; white oil 10%, the dissolving solution is soluble spandex; in the disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com