Waterproof cloth surface flexible composite material and preparation method thereof

A composite material and cloth surface technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, liquid-repellent fibers, etc., can solve the problems of unsatisfactory durability and fastness, and achieve improved service life and excellent durability The effect of improving the durability and fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] (1) Preparation of 3,5-bis(trifluoromethyl)aniline diazonium salt

[0061] The three-necked flask is equipped with a thermometer, the T-shaped tee is equipped with a balloon, and it is equipped with magnetic stirring. Add 60 ml of 1.5wt% hydrochloric acid solution, cool to 0°C in a cold bath, add 228 mg of sodium nitrite, cool to -5°C in a cold bath, stir and dissolve to form a sodium nitrite hydrochloric acid solution; then add 687.39 mg of 3,5- The diazotization reaction of bis(trifluoromethyl)aniline was incubated (-5°C) for 1 hour to generate 3,5-bis(trifluoromethyl)aniline diazonium salt, which was directly used in step (2).

[0062] (2) Generate 3,5-bis(trifluoromethyl)benzene radical

[0063] Add 2g of iron powder to the above diazonium salt solution, and heat the reaction solution to room temperature for 6 hours. 3,5-bis(trifluoromethyl)aniline diazonium salt is reduced to 3,5- Bis(trifluoromethyl)benzene radical, used directly in step (3).

[0064] (3) Prepa...

Embodiment 2

[0076] (1) Generate 3,5-bis(trifluoromethyl)aniline diazonium salt:

[0077] The three-necked flask is equipped with a thermometer, the T-shaped tee is equipped with a balloon, and it is equipped with magnetic stirring. Add 60 ml of 3wt% hydrochloric acid solution, cool to 0°C in a cold bath, add 228 mg of sodium nitrite, cool to -5°C in a cold bath, stir and dissolve to form a sodium nitrite hydrochloric acid solution. Add 687.39mg of 3,5-bis(trifluoromethyl)aniline and keep diazotization for 1h to generate 3,5-bis(trifluoromethyl)aniline diazonium salt.

[0078] (2) Generate 3,5-bis(trifluoromethyl)benzene radical:

[0079] Add 2g of iron powder to the above diazonium salt solution, and heat the reaction solution to room temperature for 8 hours. 3,5-bis(trifluoromethyl)aniline diazonium salt is reduced to 3,5- Bis(trifluoromethyl)benzene radical, used directly in step (3).

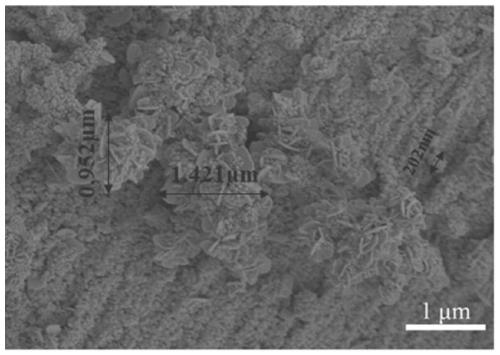

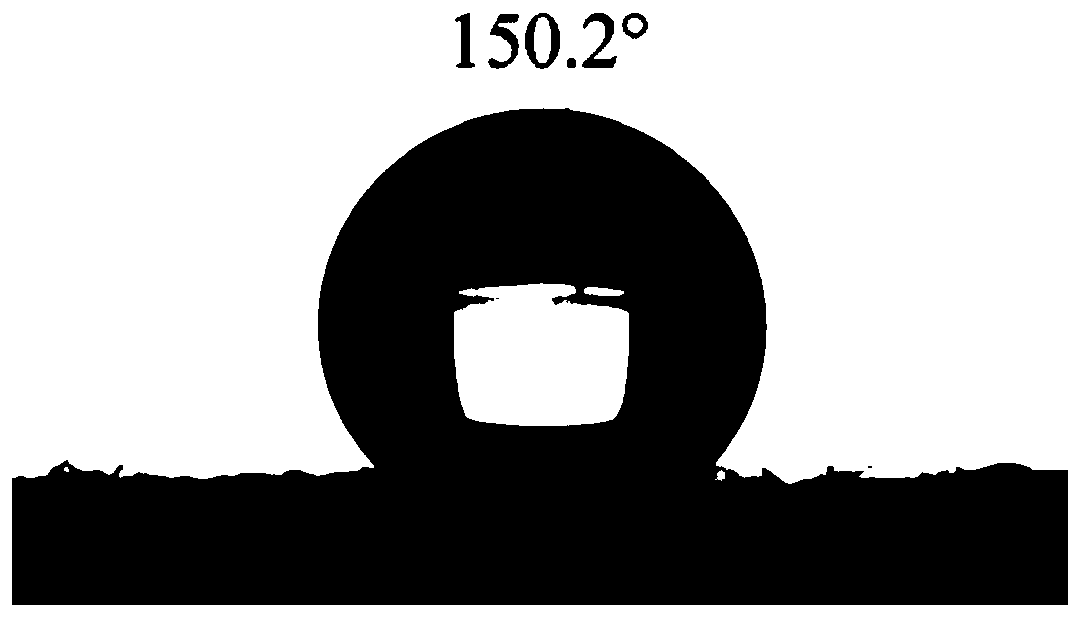

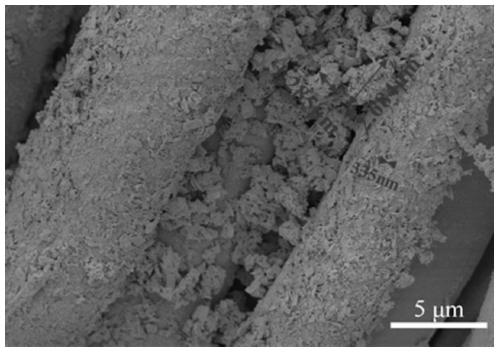

[0080] (3) Preparation of superhydrophobic fabric

[0081] Put a piece of 3×5cm 2 The cotton fab...

Embodiment 3

[0090] (1) generate m -Nafluorobutylaniline diazonium salt

[0091] The three-necked flask is equipped with a thermometer, the T-shaped tee is equipped with a balloon, and it is equipped with magnetic stirring. Add 60 ml of 1.5wt% hydrochloric acid solution, cool to 0°C in a cold bath, add 228 mg of sodium nitrite, cool to -5°C in a cold bath, stir and dissolve to form a sodium nitrite hydrochloric acid solution; then add 687.39 mg of 3,5-bis Equimolar amounts of (trifluoromethyl)aniline m -Nafluorobutylaniline was incubated for 1h to generate m -Nafluorobutylaniline diazonium salt, used directly in step (2).

[0092] The chemical structural formula of 3,5-bis(trifluoromethyl)aniline is as follows:

[0093]

[0094] m -The chemical structural formula of nonafluorobutylaniline is as follows:

[0095]

[0096] (2) generate m- nonafluorobutylbenzene radical

[0097] Add 2g of iron powder to the above-mentioned diazonium salt solution, and the reaction solution is warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com