Double-layer screen stretching method for silk-screen printing

A technology of screen printing and stretching, applied in the field of double-layer stretching of screen printing, can solve the problems of single mesh shape, insufficient to meet diversified needs, etc., and achieve the effect of exquisite pictures and texts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for screen printing double-layer stretching, comprising the steps of:

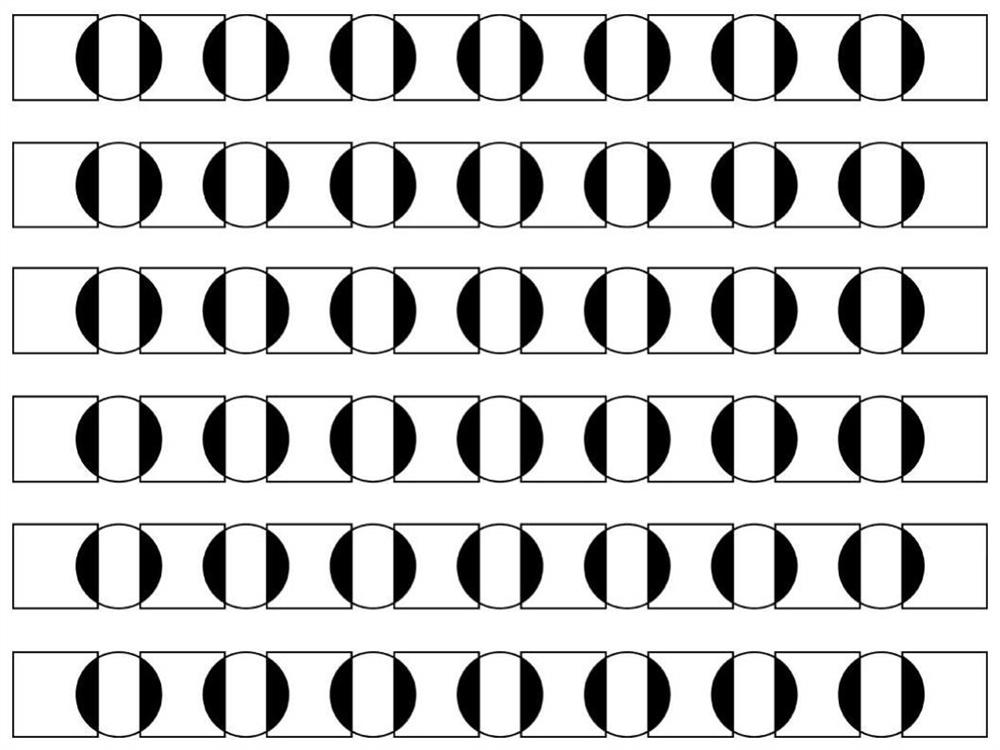

[0033] S1: welding and pressing the 50-mesh square mesh steel mesh on the mesh frame;

[0034] S2: Stretch the 50-mesh circular mesh gauze on the screen frame welded with steel mesh;

[0035] S3: Use the CCD camera to capture the shape of the mesh after the double-layer stretched mesh;

[0036] S4: Adjust the angle and position of the gauze and the steel net according to the captured image, so that the overlapping angle is 0°, and the position is shifted by a half-purpose distance along the horizontal direction, so that the shape of the mesh meets the predetermined requirements.

Embodiment 2

[0038] A method for screen printing double-layer stretching, comprising the steps of:

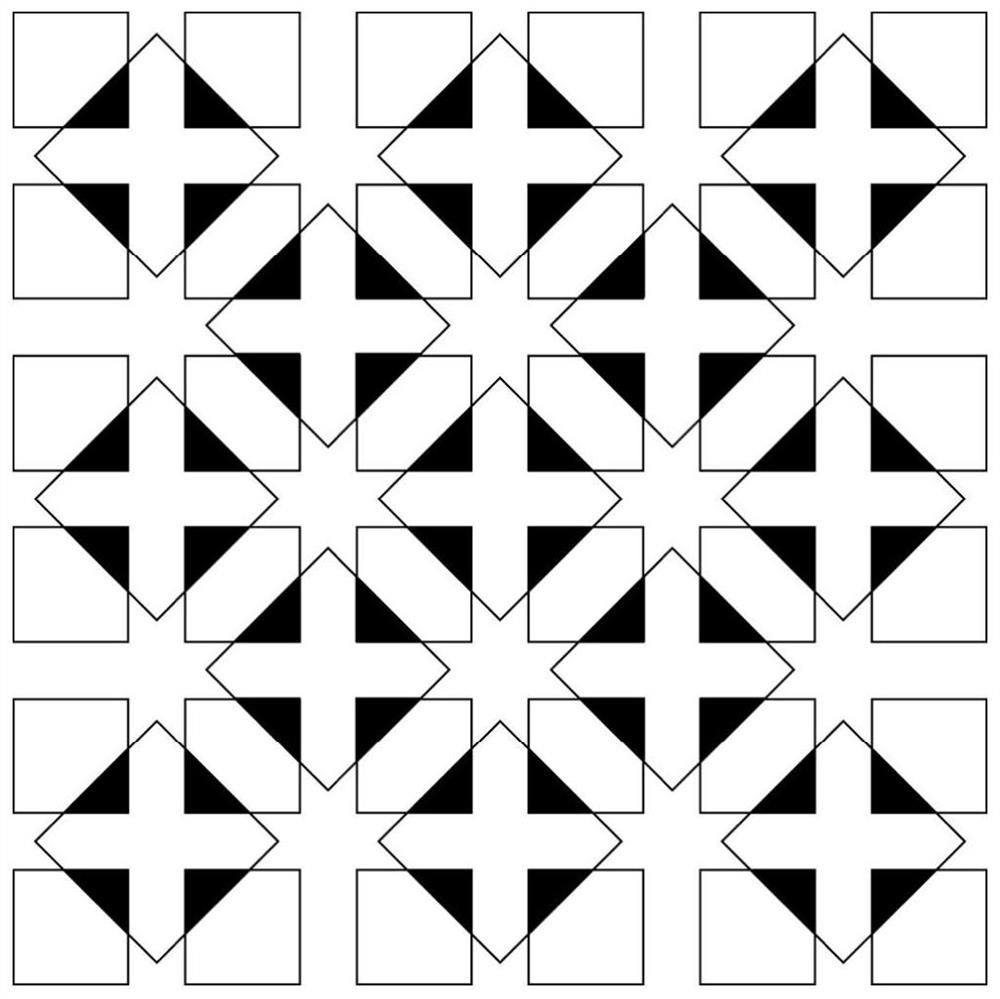

[0039] S1: Weld and press the 50-mesh diamond mesh steel mesh on the mesh frame;

[0040] S2: Stretch the 100-mesh circular mesh gauze on the screen frame welded with steel mesh;

[0041] S3: Use the CCD camera to capture the shape of the mesh after the double-layer stretched mesh;

[0042] S4: Adjust the angle and position of gauze and steel mesh according to the captured image, so that the overlapping angle is 45°, and the positions are offset by half the purpose distance along the horizontal direction and the vertical direction, so that the shape of the mesh meets the predetermined requirements.

Embodiment 3

[0044] A method for screen printing double-layer stretching, comprising the steps of:

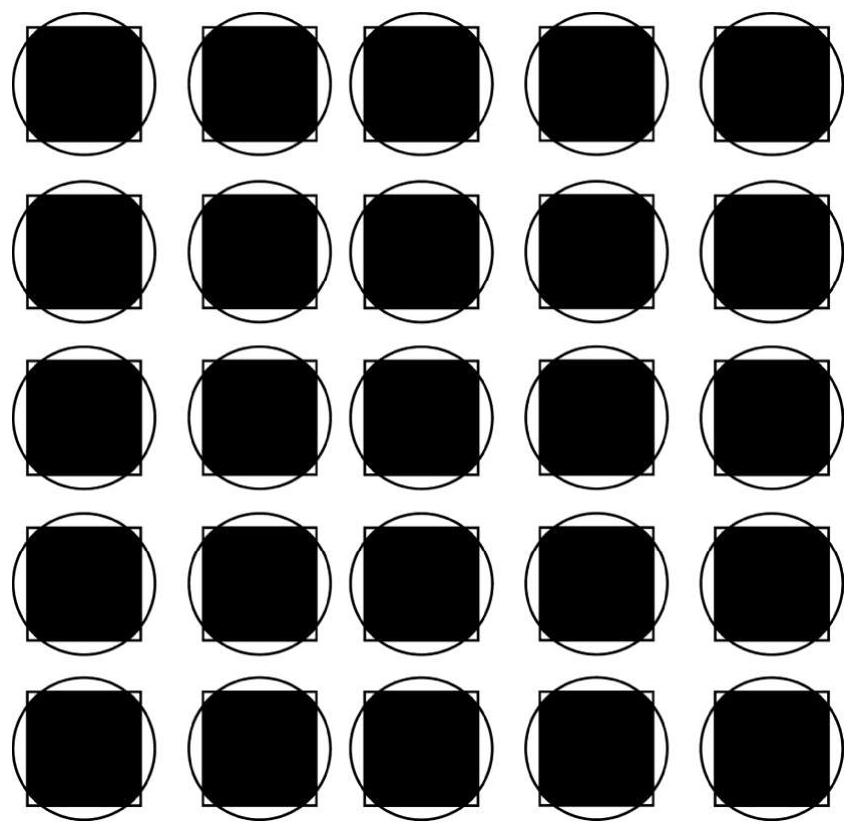

[0045] S1: welding and pressing the 100-mesh square mesh steel mesh on the mesh frame;

[0046] S2: Stretch the 100-mesh circular mesh gauze on the screen frame welded with steel mesh;

[0047] S3: Use the CCD camera to capture the shape of the mesh after the double-layer stretched mesh;

[0048] S4: Adjust the angle and position of gauze and steel mesh according to the captured image, so that the overlapping angle is 0°, and the position does not shift along the horizontal direction and the vertical direction or is shifted by an integer distance, so that the shape of the mesh meets the predetermined requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com