Patents

Literature

61results about How to "With anti-counterfeiting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

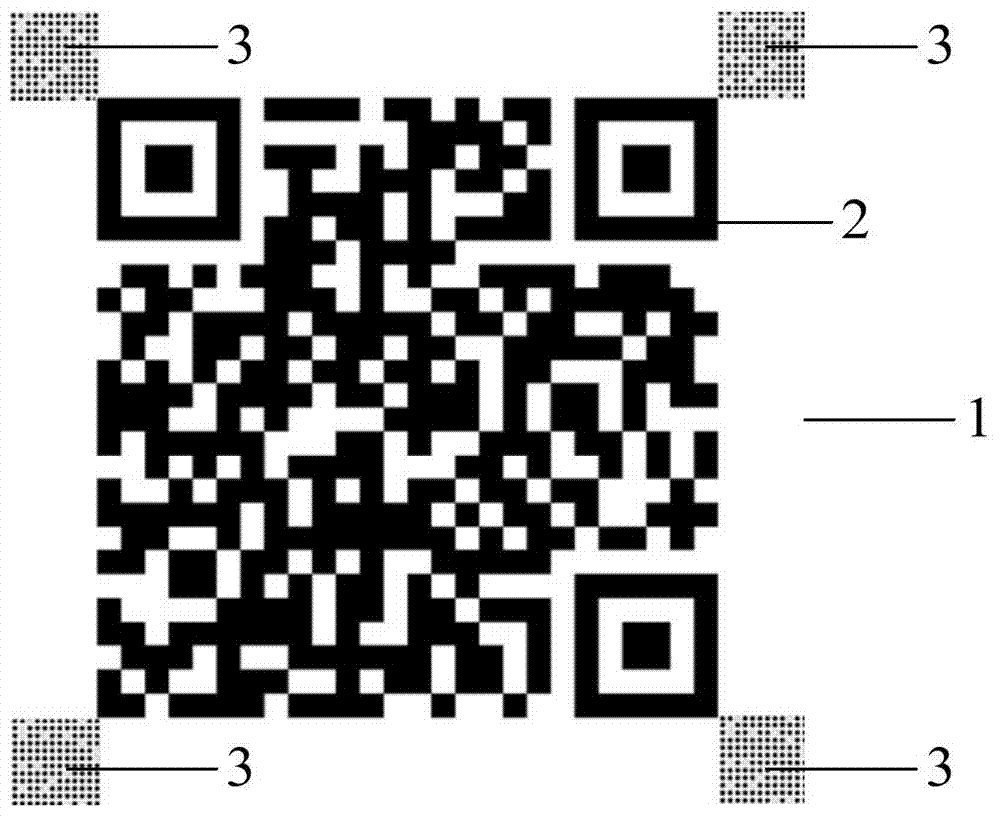

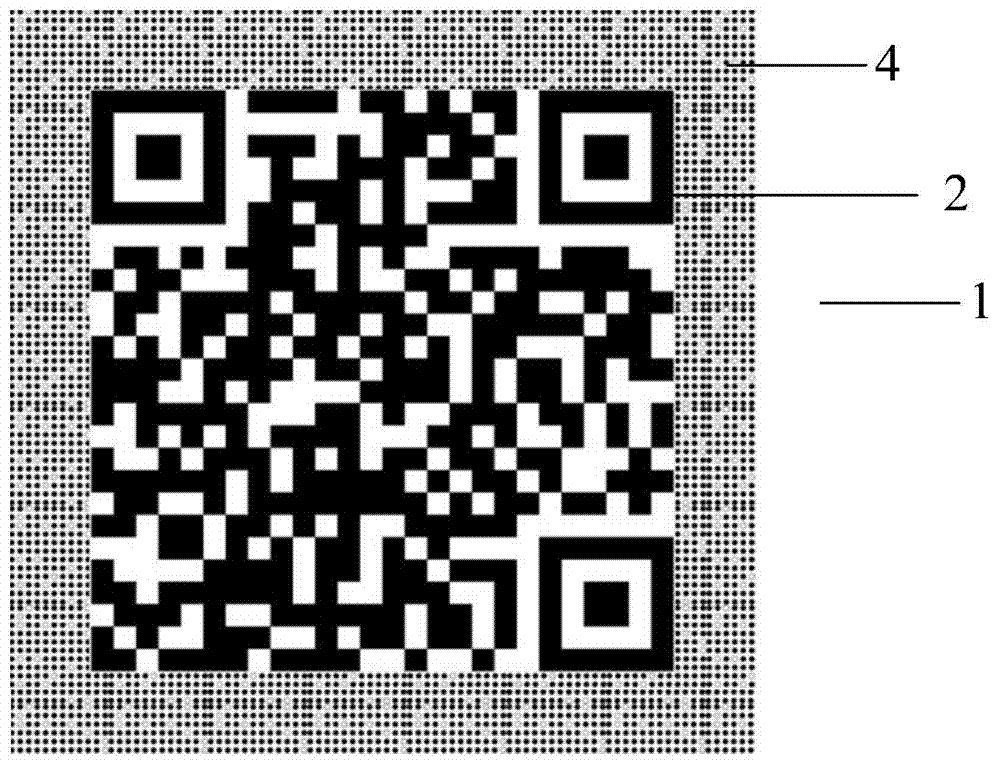

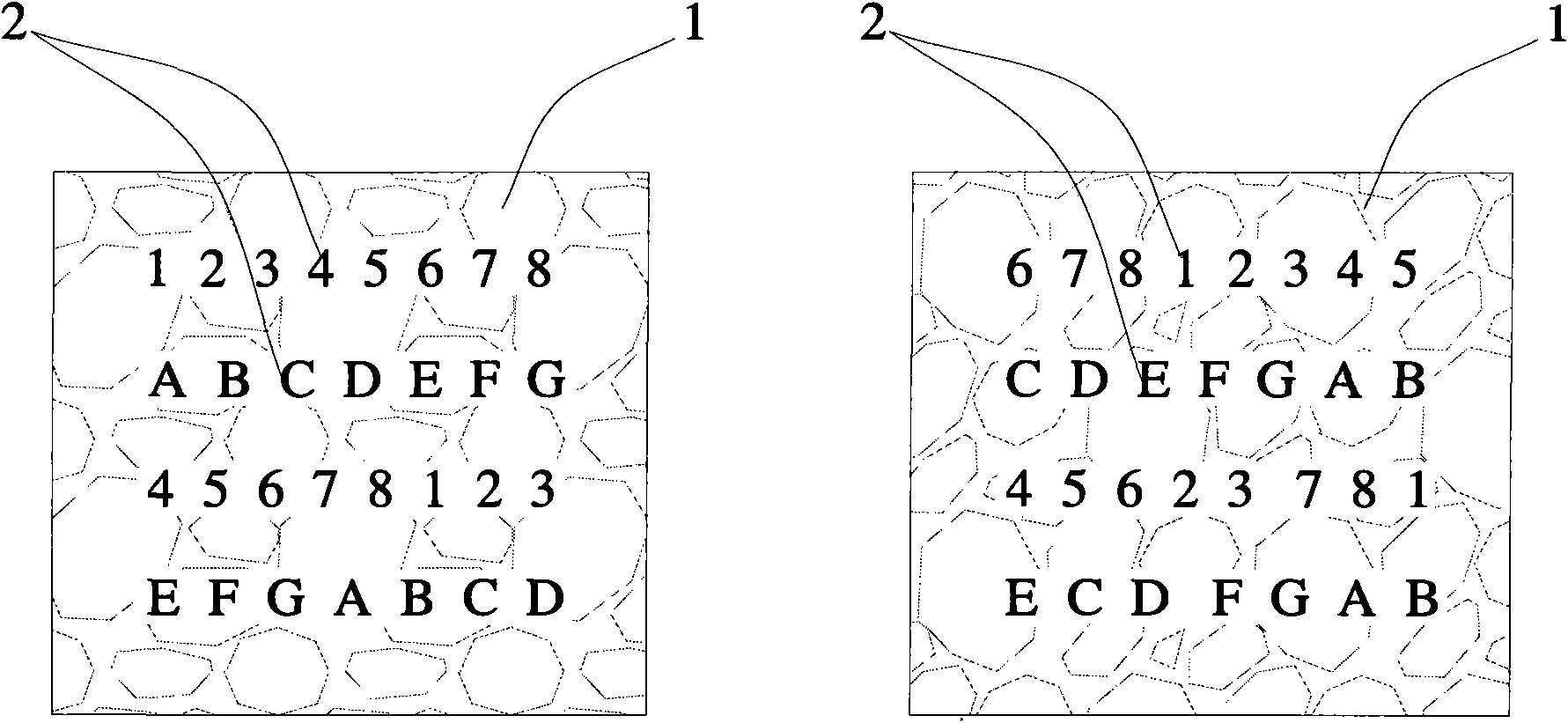

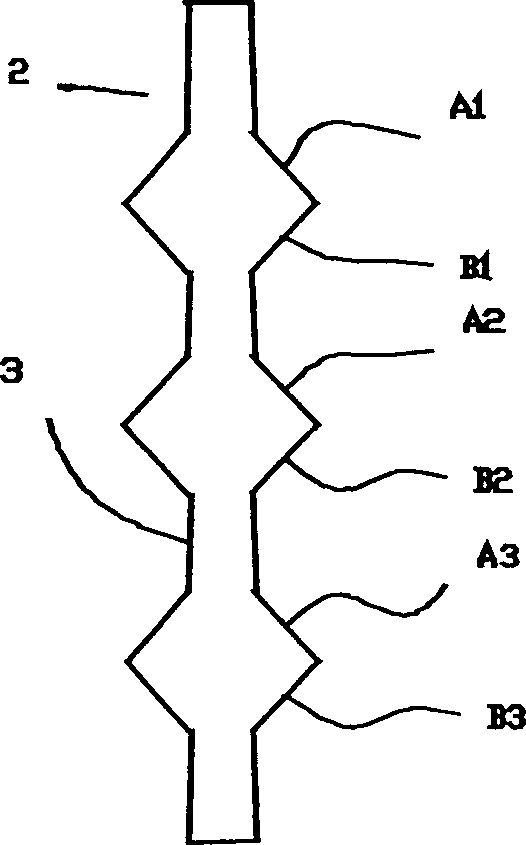

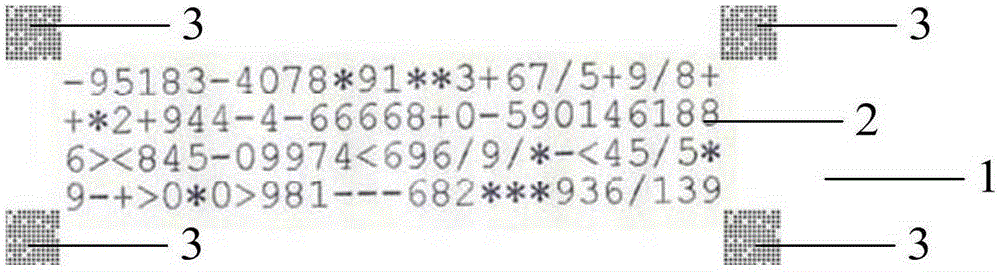

Mark formed by dot matrixes and two-dimensional code and generation and identification method of mark

ActiveCN103794135AAnti-counterfeiting and high reliabilityImprove anti-counterfeiting performanceStampsRecord carriers used with machinesMicrometerIdentification device

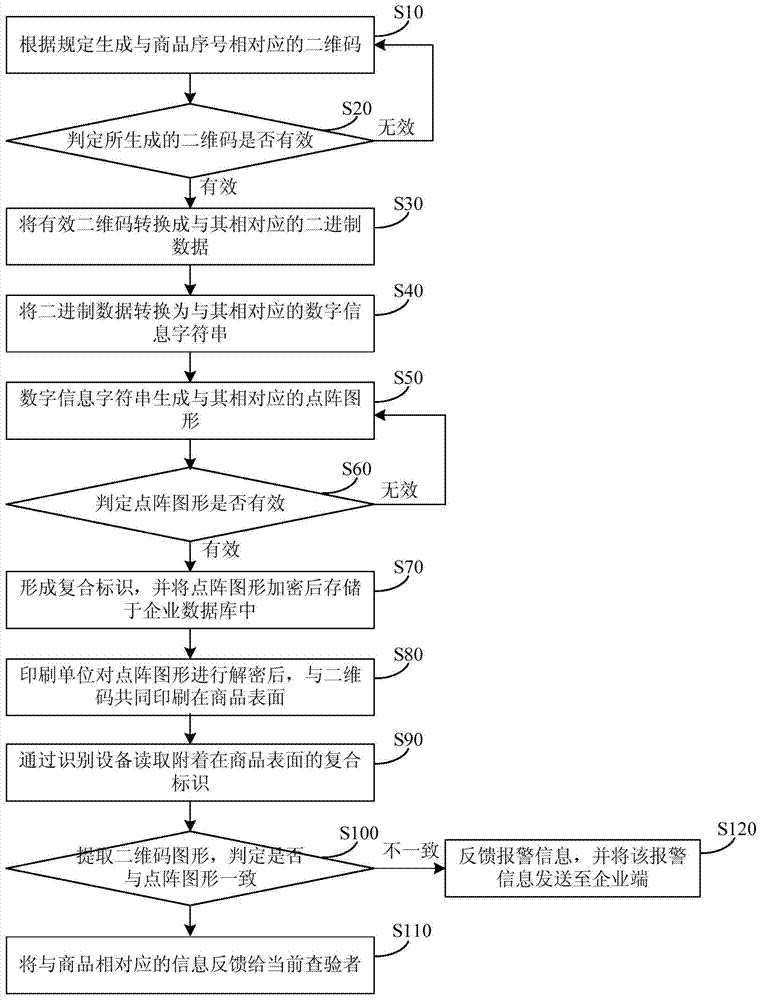

The invention provides a mark formed by dot matrixes and a two-dimensional code. The mark is formed by a plurality of sets of dot matrix patterns and the two-dimensional code. The dot matrix patterns are distributed on the outer sides of the two-dimensional code. Each dot matrix pattern is in a designated shape and can not be distinguished through naked eyes. The effective area of each dot matrix pattern is larger than or equal to 3*3 square millimeters, and each dot matrix pattern is formed by arraying at least one set of information points with the diameter ranging from 30 micrometers to 40 micrometers. A generation and identification method of the mark includes the first step of converting the two-dimensional code to a dot matrix pattern ID corresponding to the two-dimensional code and generating the dot matrix patterns through the dot matrix pattern ID, the second step of combining the dot matrix patterns and the two-dimensional code to form the composite mark and encrypting and storing the dot matrix patterns, the third step of printing the composite mark on the surface of a piece of commodity and reading the composite mark through an identification device, and the fourth step of extracting a two-dimensional code pattern in the composite mark, converting the two-dimensional code pattern into a digital information character string, comparing the digital information character string with the dot matrix pattern ID and feeding back information according to the comparison result. Compared with an existing common two-dimensional code, the composite mark generated through the method is more effective in anti-counterfeiting.

Owner:苏州智高嘉华科技有限公司

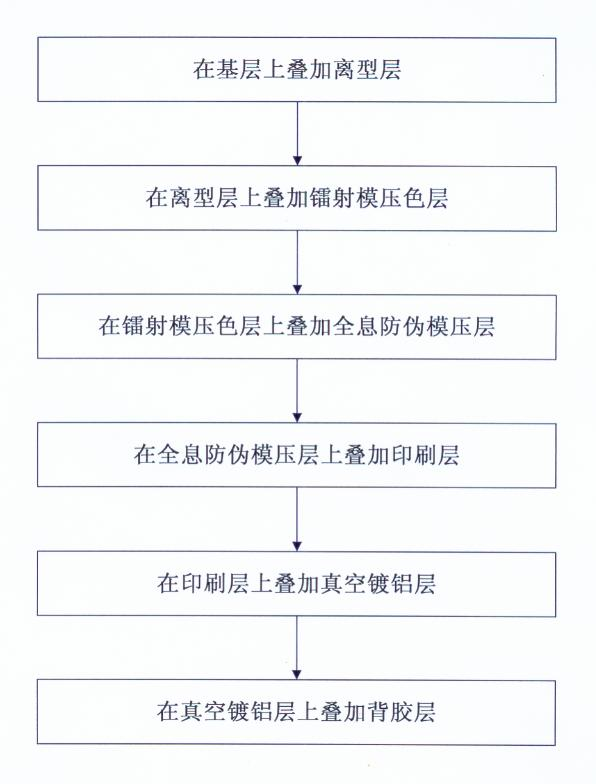

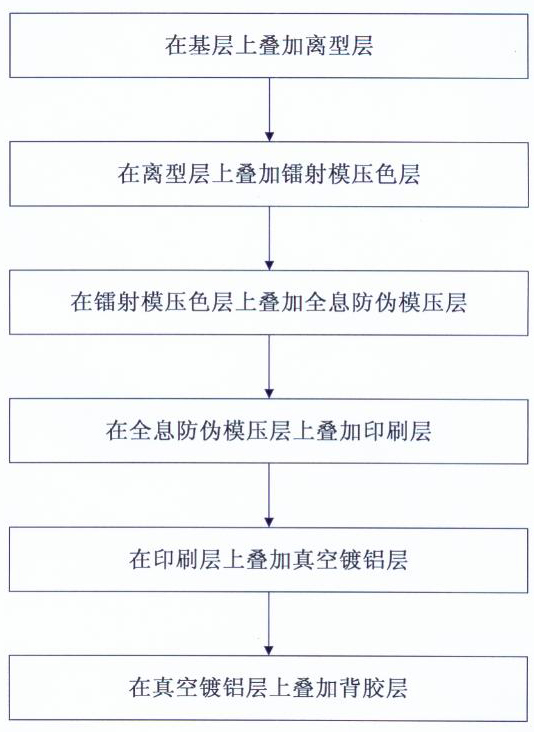

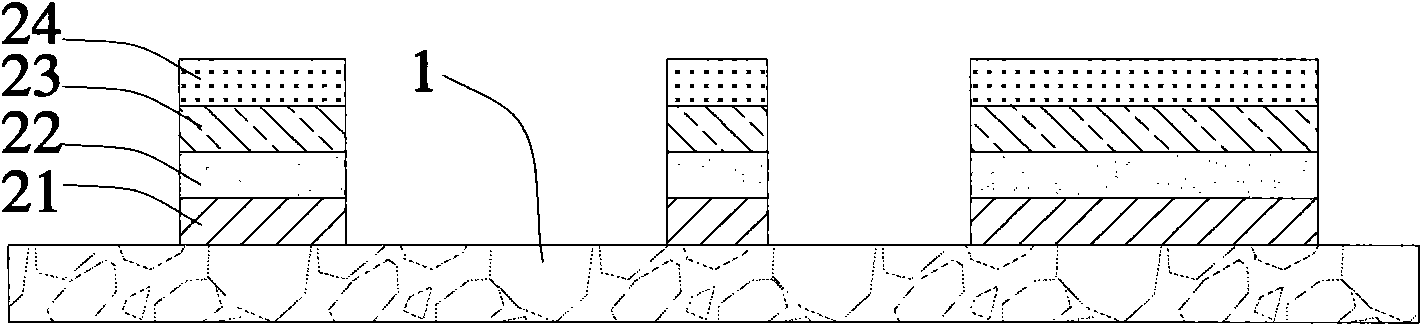

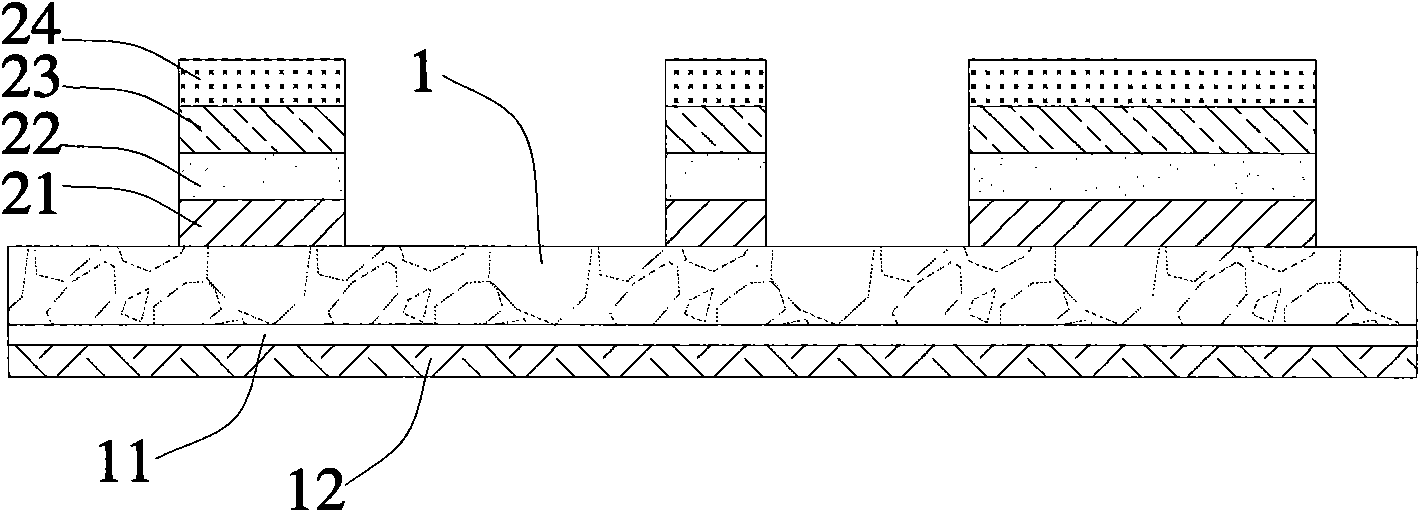

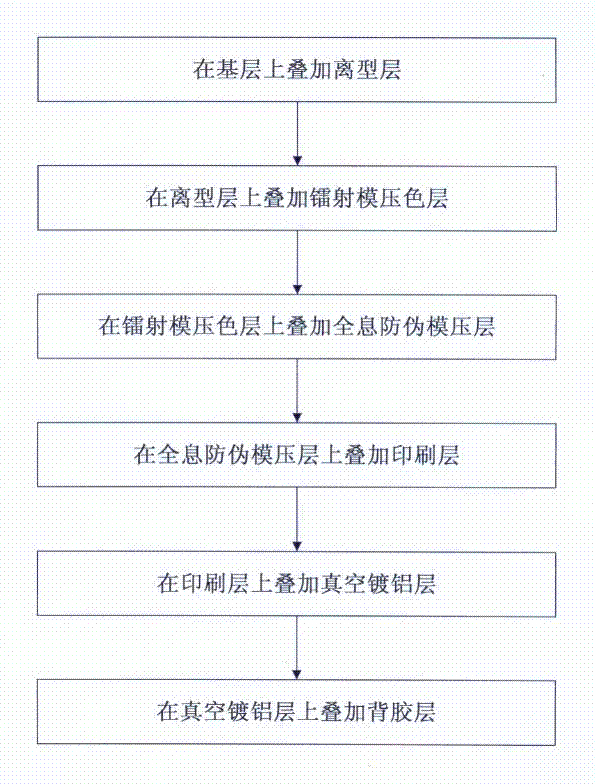

Method for manufacturing scratchable laser holography anti-fake foil

InactiveCN102092165AAdvantages of production methodHot stamping production efficiency is highSynthetic resin layered productsSpecial ornamental structuresInformation layerPolyester

The invention relates to a method for manufacturing scratchable laser holography anti-fake foil, taking a plastic polyester film as a substrate layer, comprising the following steps of: superposing a release layer on the substrate layer; superposing a laser molding color layer on the release layer, comprising evenly coating the dissolved resin on the surface of the release layer, and baking and drying via a five-section oven; superposing a holography anti-fake molding layer on the laser molding color layer, comprising forming visual laser patterns and information by a laser information layer via a roller coated with laser engraved laser plates; superposing a printing layer on the holography anti-fake molding layer; superposing a vacuum aluminized coating layer on the printing layer, comprising heating an evaporator to 1400-1500 DEG C, cooling the high-purity aluminum wires continuously sent to the evaporator into aluminum steam, evenly spraying aluminum molecules on the surface, and forming an aluminum film; and superposing a gum layer on the vacuum aluminized coating layer. The product manufactured by the method provided by the invention is high in printing production efficiency and is scratched once; the product has certain anti-fake effects and can replace a traditional method for scratching ink by a squeegee.

Owner:SHANGHAI SHENYONG STAMPING FOIL

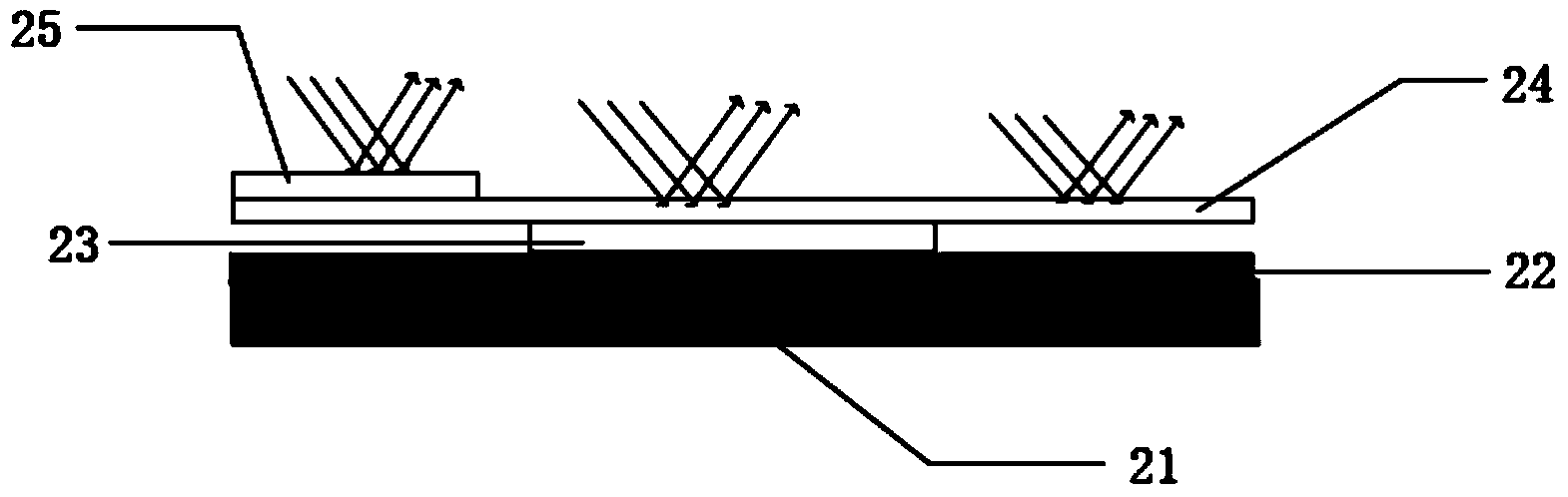

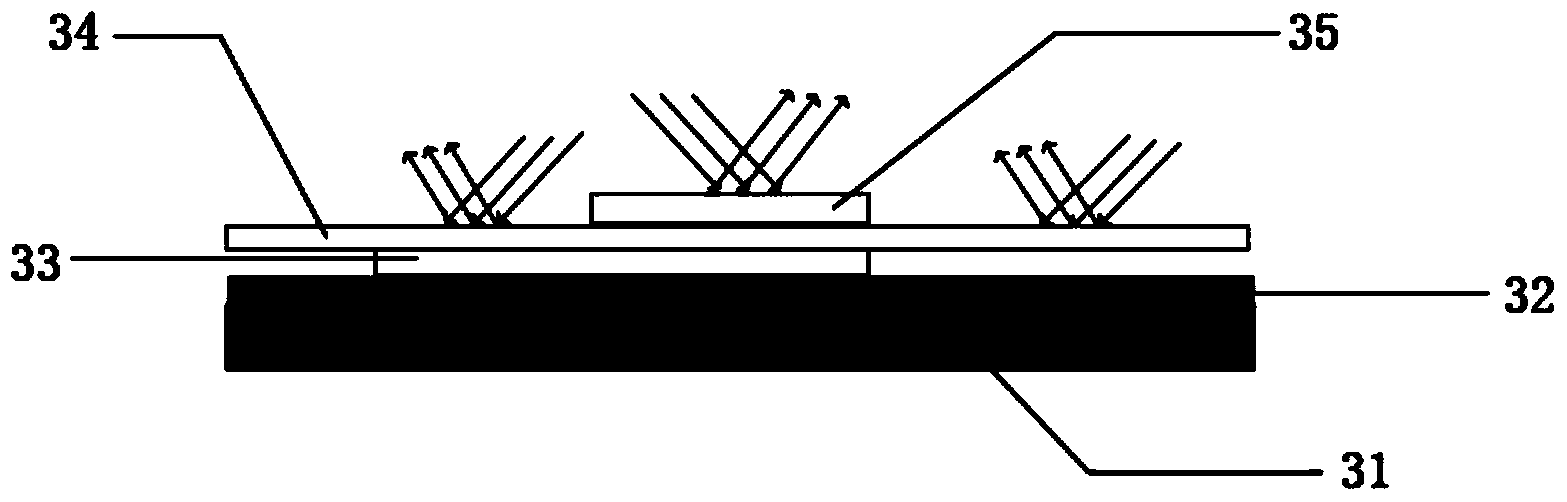

Laser anti-counterfeit texture label and manufacturing method thereof

ActiveCN101966784AUniqueness guaranteedDifficult to copyStampsPattern printingDigital printingEngineering

The invention relates to a laser anti-counterfeit technology, in particular to a laser anti-counterfeit texture label and a manufacturing method thereof. The method of the invention comprises the following steps: step 1, manufacturing a texture carrier with laser holographic effect on one side; step 2, printing transparent ink or color ink on one side of a transparent photosensitive material by a digital printing mode, wherein the printed image-text units have diversity; step 3, carrying out high-strength ultraviolet exposure on the printed surface; step 4, washing the transparent photosensitive material layer uncovered by the transparent ink and a transparent release transfer layer and a metal layer under the photosensitive material layer with an alkaline solution; step 5, cutting the carrier by taking each image-text unit as a unit; and step 6, applying the anti-counterfeit unit to an anti-counterfeit package. The method of the invention realizes anti-counterfeiting by forming hollowed-out image-text units with the laser holographic effect and diversity on the carrier, i.e. the invention realizes laser variable data anti-counterfeiting.

Owner:GUANGZHOU HUADU LIANHUA PACKING MATERIAL CO LTD

Method for preparing lanthanide series-based NaYF4 up-conversion luminescence ink and transparent anti-fake label

InactiveCN107641375AUnique Optical PropertiesUnique means of detectionStampsInksPolyethylene terephthalate glycolFluorescence

The invention relates to a method for preparing lanthanide series-based NaYF4 up-conversion red, green and blue luminescence ink and a transparent anti-fake label. The method comprises the following steps: changing types of doping rare-earth ions, and preparing a rare-earth up-conversion material for generating red, green and blue luminescence colors with laser of 980nm; mixing up-conversion luminescence granules, ethanol and a polyacrylic resin, so as to obtain up-conversion luminescence ink. Compared with conventional luminescence ink, the up-conversion luminescence ink is excellent in florescence property, an ink formula is hard to copy, and the anti-fake property of a printed product is greatly improved. The method needs no product purification, is rapid and visible and is a novel luminescence ink preparation method which is simple and rapid to operate and high in yield. Based on a PET (Polyethylene Terephthalate) substrate, a series of transparent anti-fake labels are prepared from the red, green and blue up-conversion luminescence ink with conventional low-cost technique process spinning, silk screen printing and stamping, colored patterns can be displayed on the transparentlabels under excitation of laser of 980nm, and relatively good shielding performance and anti-fake performance are achieved.

Owner:WUHAN UNIV

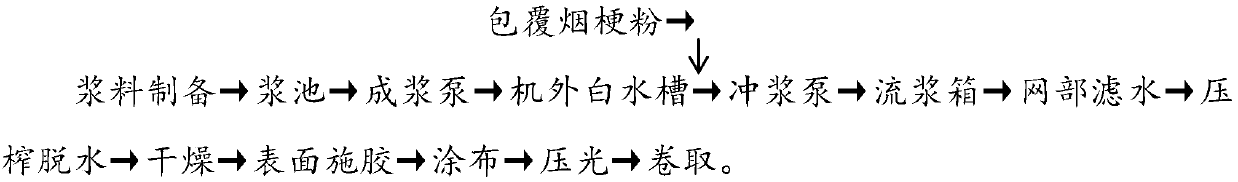

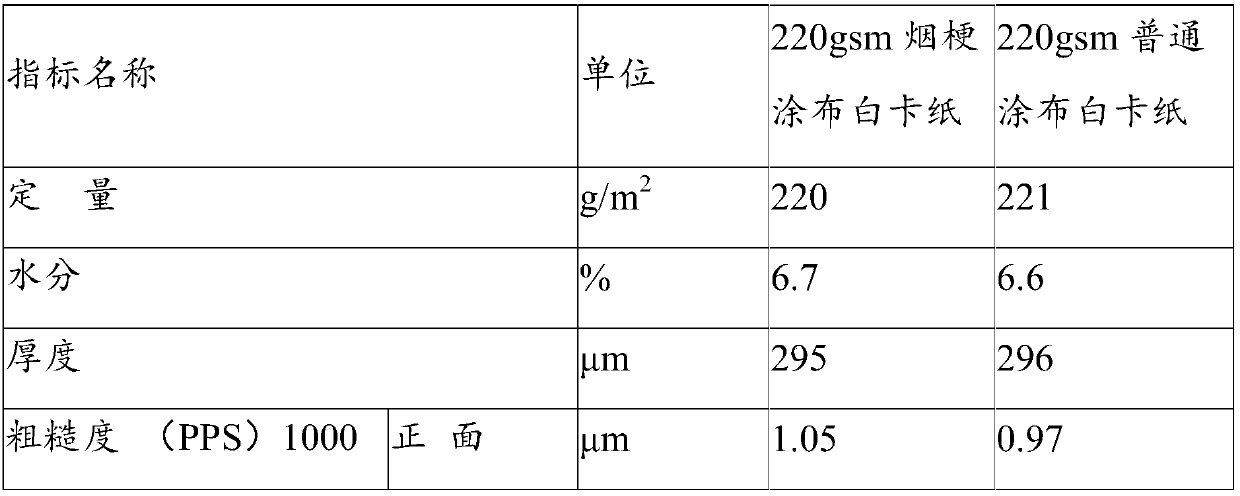

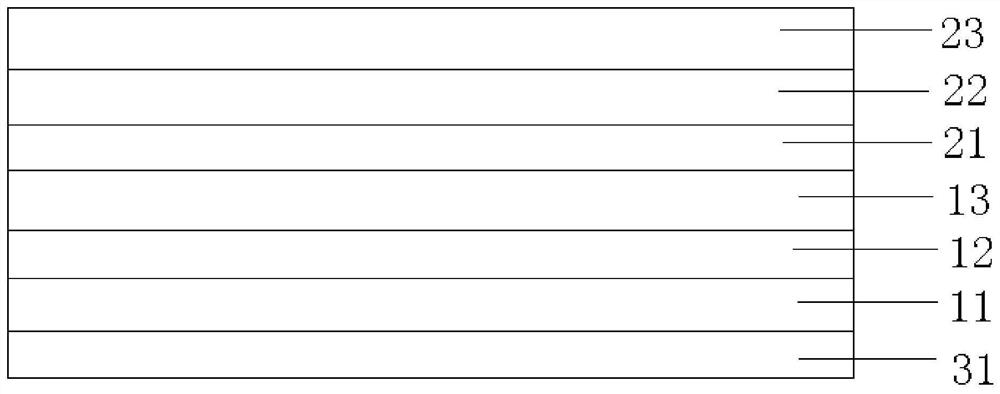

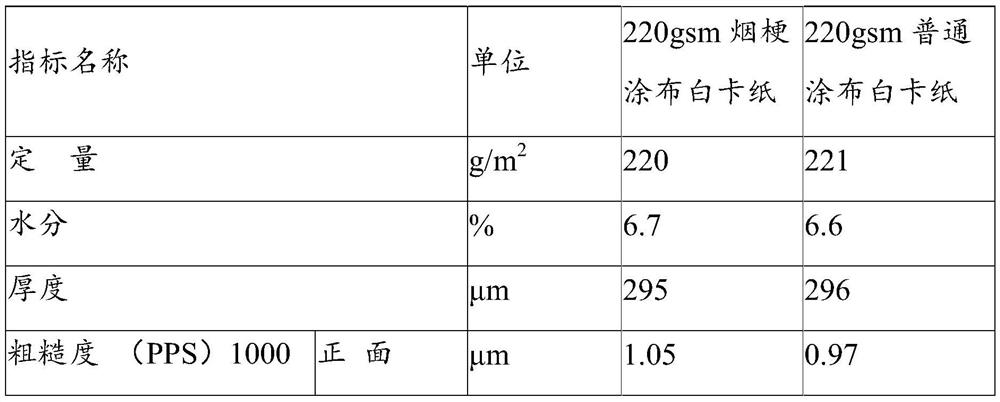

Tobacco-stem-coated white card paper and preparation method and application thereof

ActiveCN109082928AReduce manufacturing costSmall particle sizeWaste product additionSpecial paperPaper sheetChemistry

The invention discloses tobacco-stem-coated white card paper and a preparation method and application thereof. The preparation method includes the following steps that S1, tobacco stem powder with theparticle diameter of 1 micron to 200 microns is taken, water is added, suspension liquid is prepared, and then the suspension liquid is extracted and / or subjected to filter pressing; S2, the tobaccostem powder after being treated with the step S1 is taken and subjected to cationic starch coating; S3, the tobacco stem powder after being coated in the step S2 and pulp are mixed, then pulp distribution, water filtering, squeezing, dewatering, drying and coating are carried out, and the tobacco-stem-coated white card paper is prepared. The tobacco-stem-coated white card paper prepared with the technical scheme can be used for preparation of packaging paper or packaging boxes. Compared with the prior art, the technical scheme is economical and environmentally friendly, and the prepared tobacco-stem-coated white card paper has the good performance.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

Printing ink having the function of changing color and shining and suitable for film products

The present invention relates to a printing ink having the function of changing color and shining and suitable for lamination, the raw material formula of which comprises the following constituents by weight: 5% to 30% of acrylic resin, 40% to 85% of butanone, 3% to 5% of glycol ether, 0.6% to 1% of acetate, 2% to 25% of nano powder and 0.9% to 1.8% of conductive salt. The nano powder comprises one or more of the following powder: temperature-sensitive color-changeable nano powder, light-sensitive color-changeable, ultraluminescence nano powder and infrared-luminescent nano powder. By adopting the above technical scheme including taking acrylic resin as binder and using mixed solvents with specific formula accordingly, the adhesion between the ink and glass with smooth surface, polypropylene films and PET films is enhanced greatly. Particularly, the color-changeable or luminous nano powder is used in the ink, but the adhesion between the ink and the materials with smooth surface is strong. Therefore the ink can be applied to film products.

Owner:SUZHOU XILIN OPTOELECTRONICS TECH IND

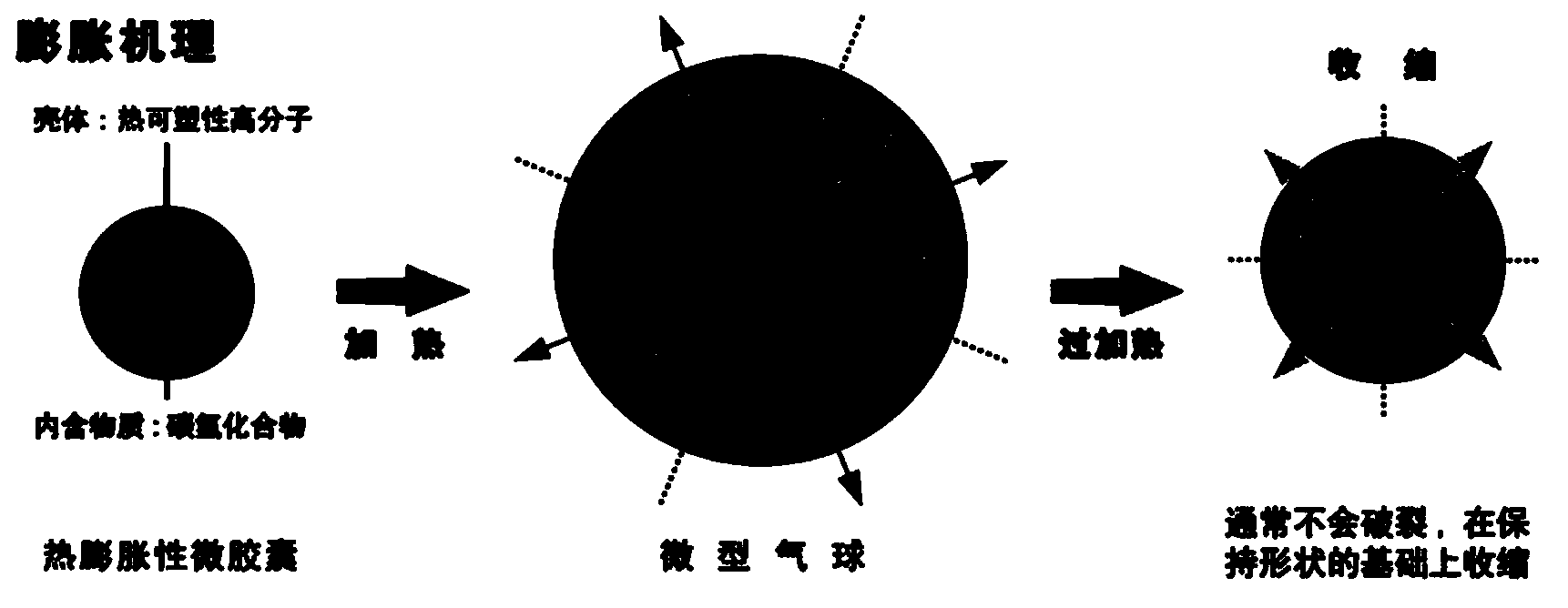

Process for preparing printing artificial flocking paper

InactiveCN103352399AFeel goodTo achieve the effect of flockingSpecial visual effect coatingsSpecial paperFoaming agentPolyethylene terephthalate

The invention discloses a process for preparing printing artificial flocking paper. The process comprises the following steps: mixing self-drying color ink, polyethylene terephthalate (PET) gloss oil and a low-temperature expansive type microsphere foaming agent and stirring uniformly to obtain a mixed material; and printing the mixed material on paper through silk screen and curing at 80 to 100 DEG C for 3 to 5 seconds to obtain the printing artificial flocking paper, wherein the mass ratio of the self-drying color ink to the PET gloss oil is from 3:4 to 3:1, and the weight of the low-temperature foaming agent is 1 to 80 percent of the total weight of the self-drying color ink and the PET gloss oil. By the process, a medium-and-low-temperature foaming material is adopted, the foaming temperature is low and the foaming time is short, a foaming effect can be realized through one-step heating of an infrared or ultraviolet drying channel of a common screen printer, and the processing requirement of paper packaging is met. Compared with a static flocking process, the process has high production efficiency, low cost and good adhesive force of a finished product, and can prepare the printing artificial flocking paper with different colors by adjusting the color of the color ink. Colorless and transparent bubbles are densely distributed on the surface of the printing artificial flocking paper prepared by the process, and an anti-counterfeit effect is achieved.

Owner:SHENZHEN NINE STARS PRINTING & PACKAGING GRP

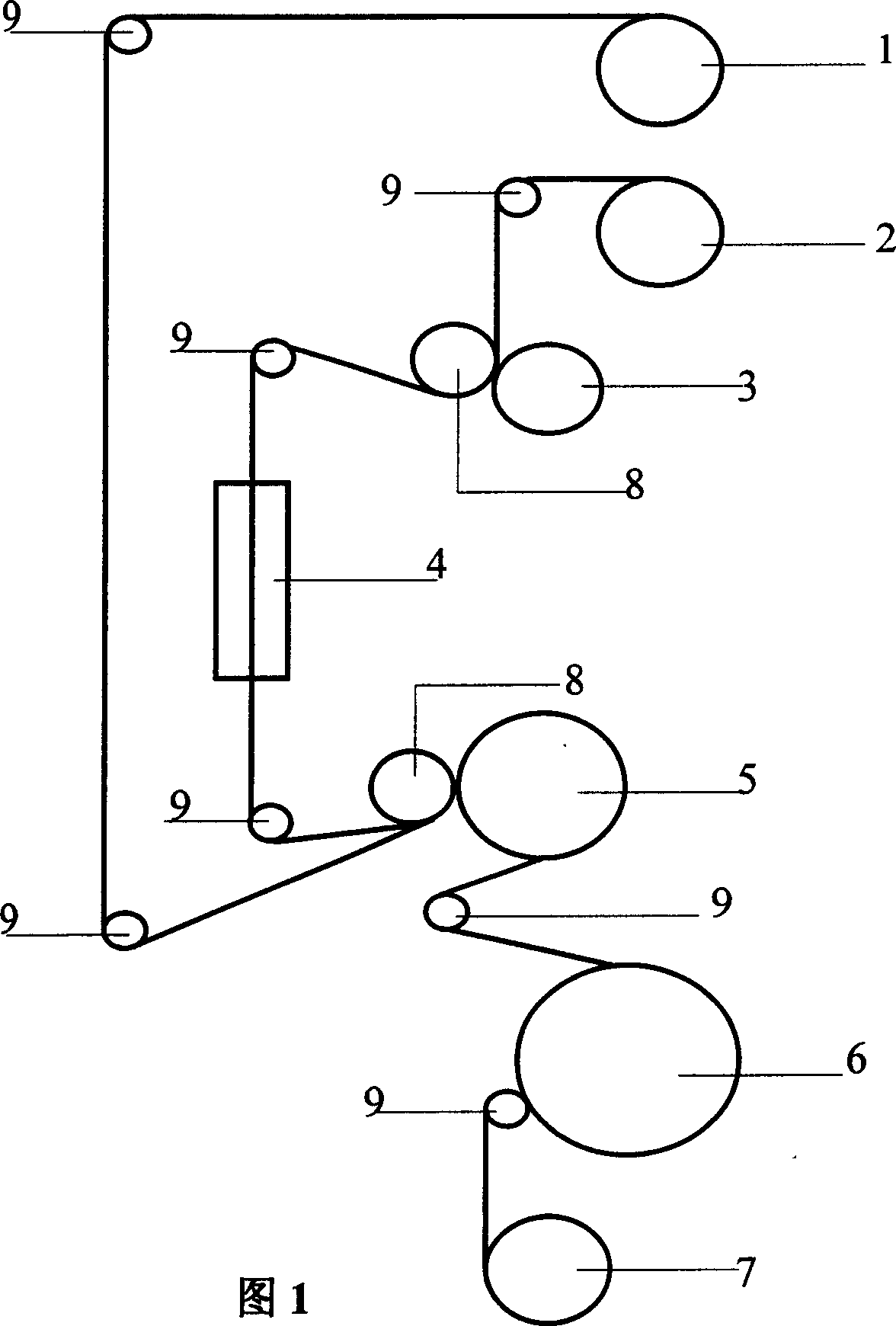

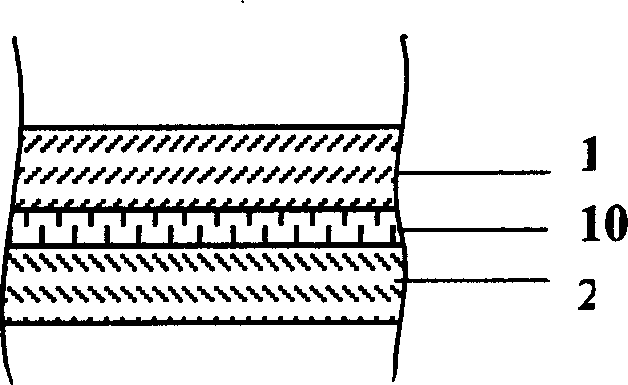

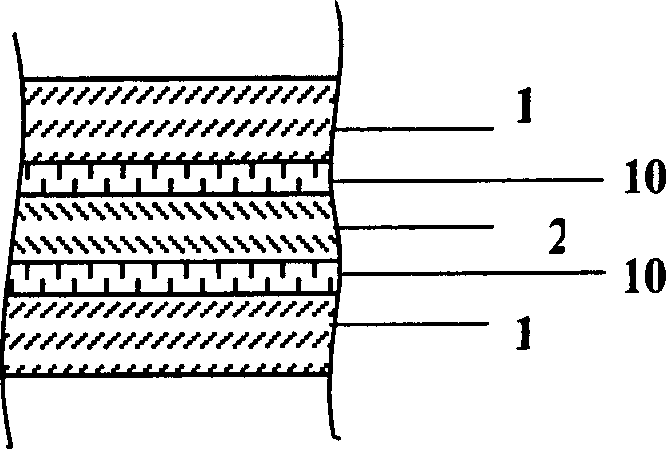

Anti-fake package paperboard and its producing method and device

InactiveCN1587516AHigh glossImprove printing effectNon-fibrous pulp additionSpecial paperPaperboardPulp and paper industry

The present invention is single-sided or double-sided anti-fake package paperboard. The single-sided anti-fake package paperboard is made through making the paperboard layer pass through successively guide roller, press roller, gluer, guide rod, airfloat heat drier and guide roller; making anti-fake paper layer pass through two guide rollers; and making the paperboard layer pass and the anti-fake paper layer pass through successively press roller, stoving drier, and the composite mechanism comprising guide rod, cooler and guide roller simultaneously. The double-sided anti-fake package paperboard is made through turning the single-sided anti-fake package paperboard and repeating the said process. The present invention has the anti-fake mark made inside the material and is safe, reliable and convenient.

Owner:王爱洲 +2

Aluminum-free cast coating holographic tipping base paper for cigarette and preparation method and application of the tipping base paper

The invention relates to the field of cigarette making, particularly to tipping base paper and a preparation method and application of the tipping base paper. The aluminum-free cast coating holographic tipping base paper for a cigarette comprises tipping paper, a transfer glue layer, a reflecting layer and laser holographic coating in sequence, wherein the reflecting layer is formed of a composite material comprising silicon oxide and zinc oxide by vapor deposition, the weight ratio of silicon oxide to zinc oxide ranges from 1:3 to 3:1, and the gram weight range of cast coated silicon oxide and zinc oxide is 3-10g / m<2>. The tipping base paper provided by the invention has the advantages of improved processing characteristics, better elegant and aesthetic appearance, improved safety feature, and certain anti-counterfeiting effect.

Owner:CHINA TOBACCO ZHEJIANG IND

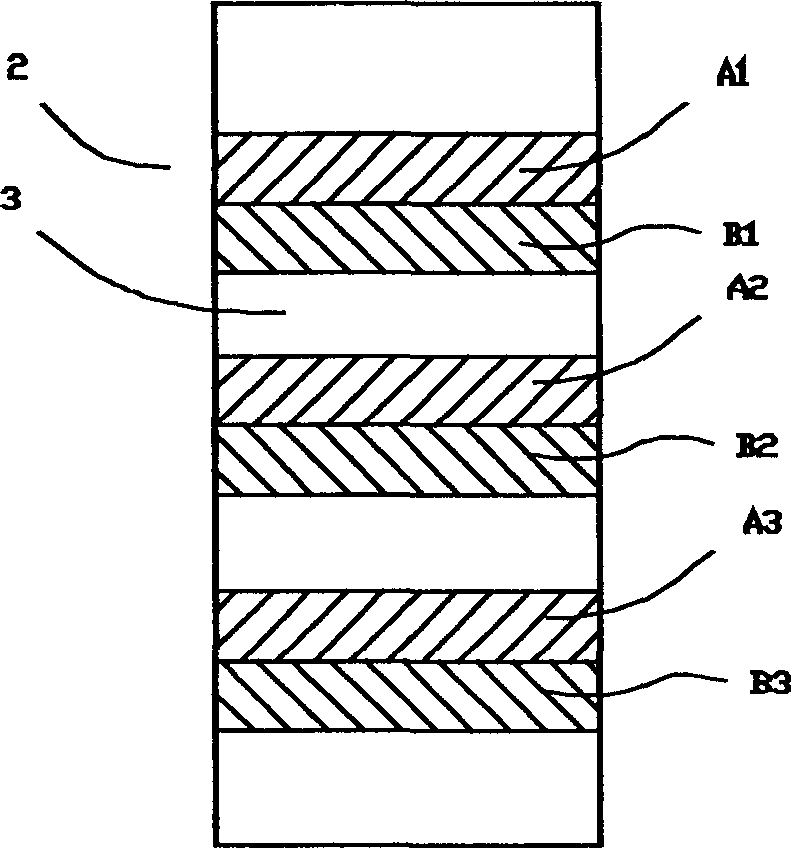

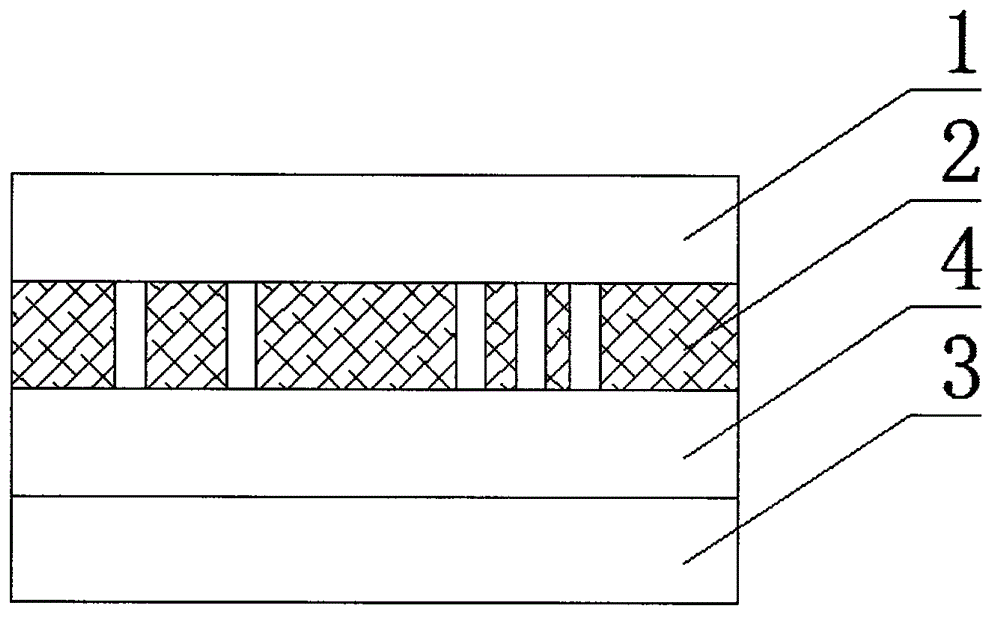

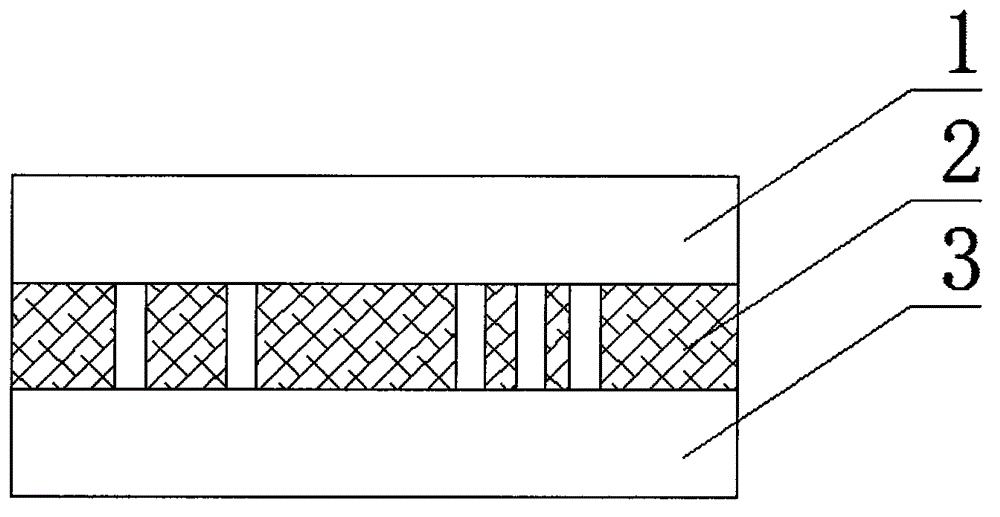

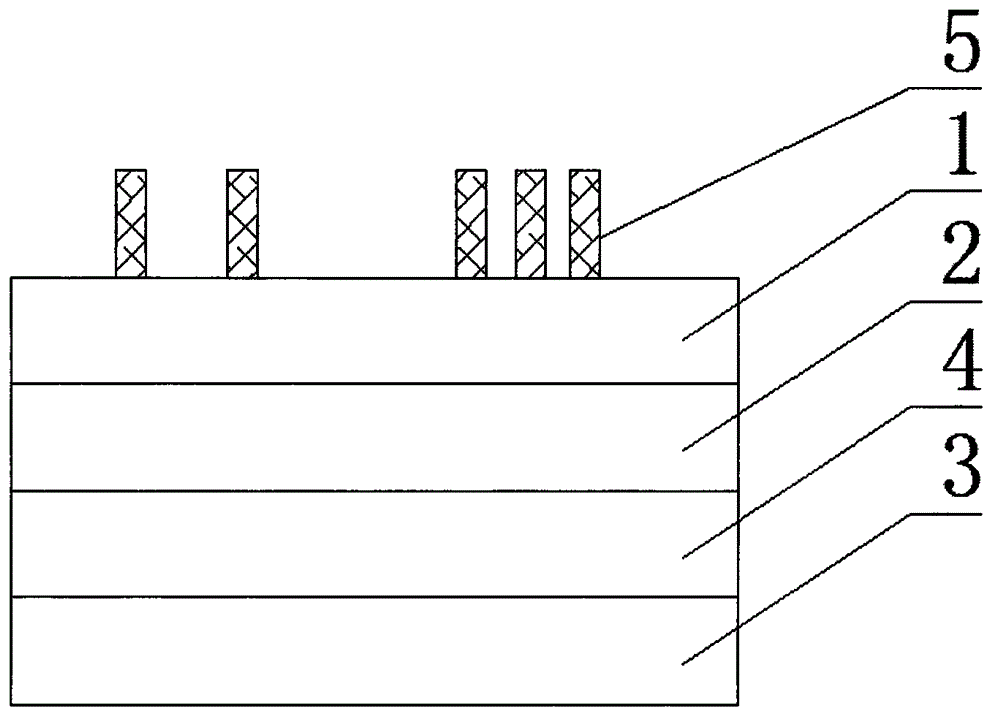

Novel composite packaging material structure of see-through multilayer coextrusion color transformation film

ActiveCN103922034AHighlight personalized packaging requirementsWith anti-counterfeiting effectFlexible coversWrappersPersonalizationColor transformation

The invention relates to the technical field of printing and packaging material and packaging containers, in particular to a novel composite packaging material structure of a see-through multilayer coextrusion color transformation film. The structure comprises five layers of structures, the first layer is base material, the second layer is a highlight reflection metal layer, the third layer is a lower ink layer at least comprising white ink, the fourth layer is the see-through multilayer coextrusion color transformation film, and the fifth layer is an upper ink layer. The highlight reflection metal layer is manufactured on the surface of the base material through a compositing, or evaporating or transferring process, the surface of the highlight reflection metal layer is covered with the lower ink layer at least comprising the white ink, and the lower ink layer at least comprising the white ink is covered with the see-through multilayer coextrusion color transformation film, and the upper ink layer is printed on the see-through multilayer coextrusion color transformation film. The novel composite packaging material structure has the advantages that in the aspect of packaging, a prominent metal color part is provided, besides, a prominent color transformation part is provided, on the premise that cost is not changed, personalization of commodities is prominent, and an anti-fake effect is achieved.

Owner:MARKETING MFG & TECH SHANGHAI

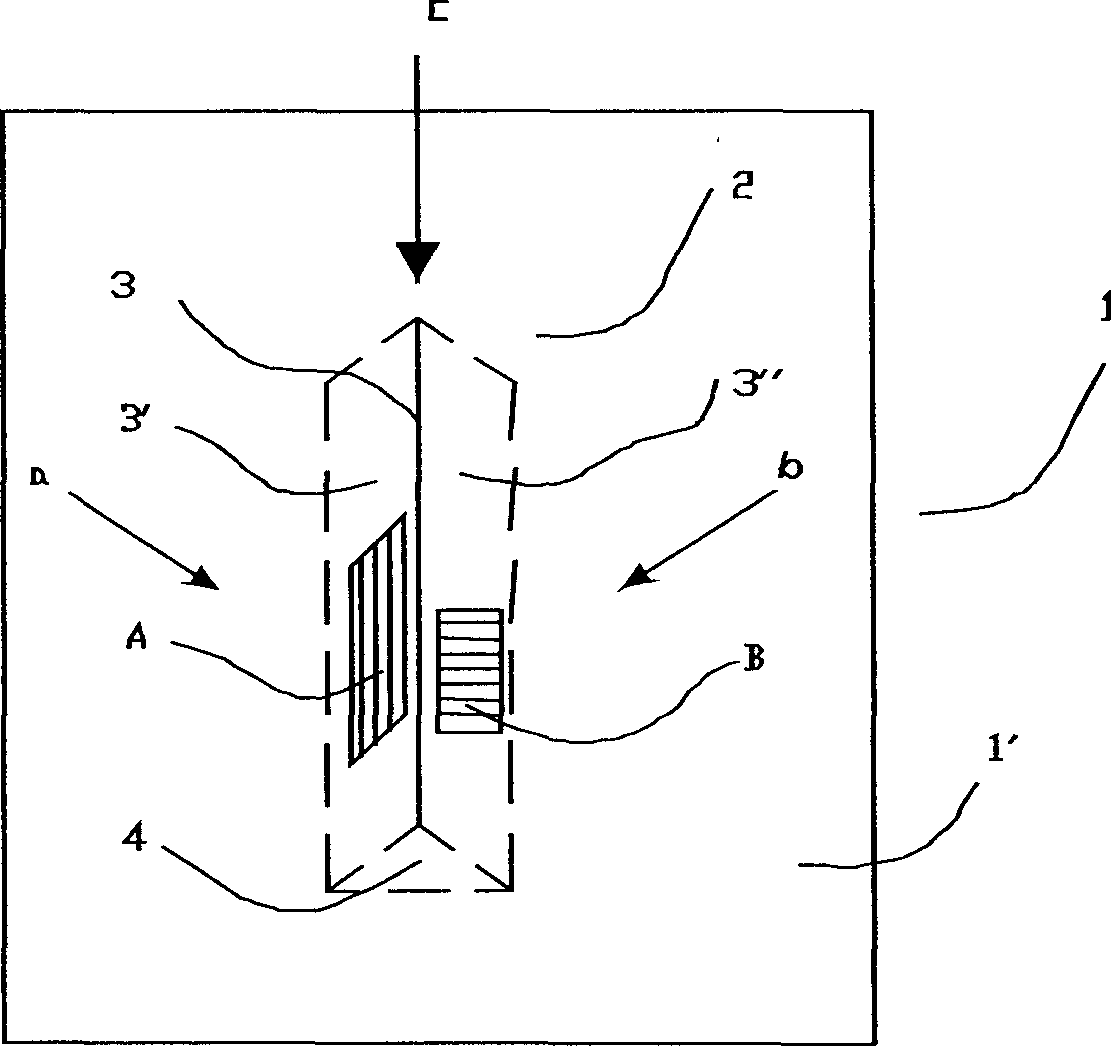

Anti-fraud material

InactiveCN1600988APrevent counterfeitingRealize first-line anti-counterfeitingNon-fibrous pulp additionInformation cardsFiberComputer science

Owner:孙显林

Tobacco stem coated white cardboard and its preparation method and application

ActiveCN109082928BSmall particle sizeHigh retention rateWaste product additionSpecial paperCardboardBiology

The invention discloses tobacco-stem-coated white card paper and a preparation method and application thereof. The preparation method includes the following steps that S1, tobacco stem powder with theparticle diameter of 1 micron to 200 microns is taken, water is added, suspension liquid is prepared, and then the suspension liquid is extracted and / or subjected to filter pressing; S2, the tobaccostem powder after being treated with the step S1 is taken and subjected to cationic starch coating; S3, the tobacco stem powder after being coated in the step S2 and pulp are mixed, then pulp distribution, water filtering, squeezing, dewatering, drying and coating are carried out, and the tobacco-stem-coated white card paper is prepared. The tobacco-stem-coated white card paper prepared with the technical scheme can be used for preparation of packaging paper or packaging boxes. Compared with the prior art, the technical scheme is economical and environmentally friendly, and the prepared tobacco-stem-coated white card paper has the good performance.

Owner:ZHUHAI S E Z HONGTA RENHENG PAPER

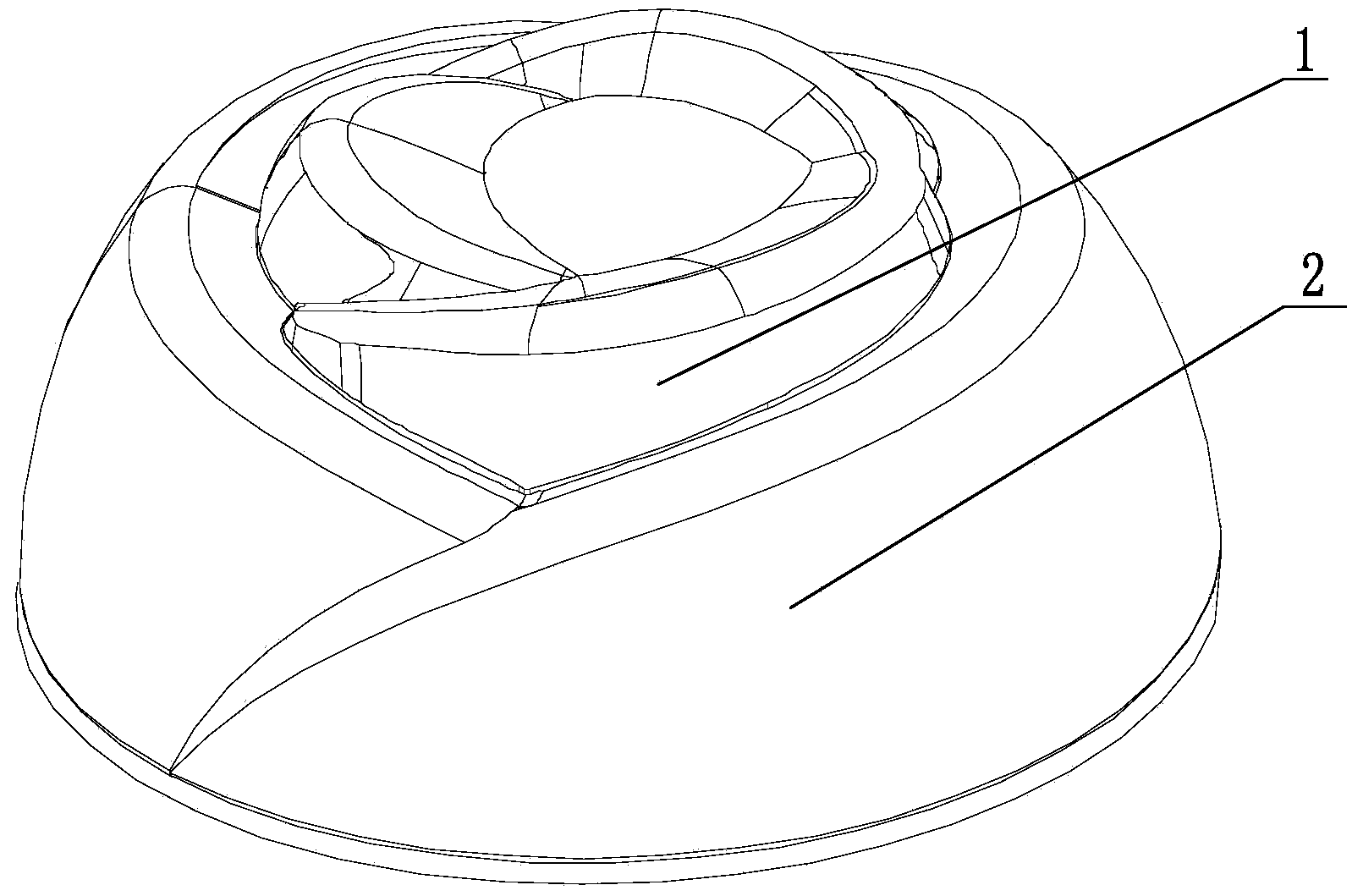

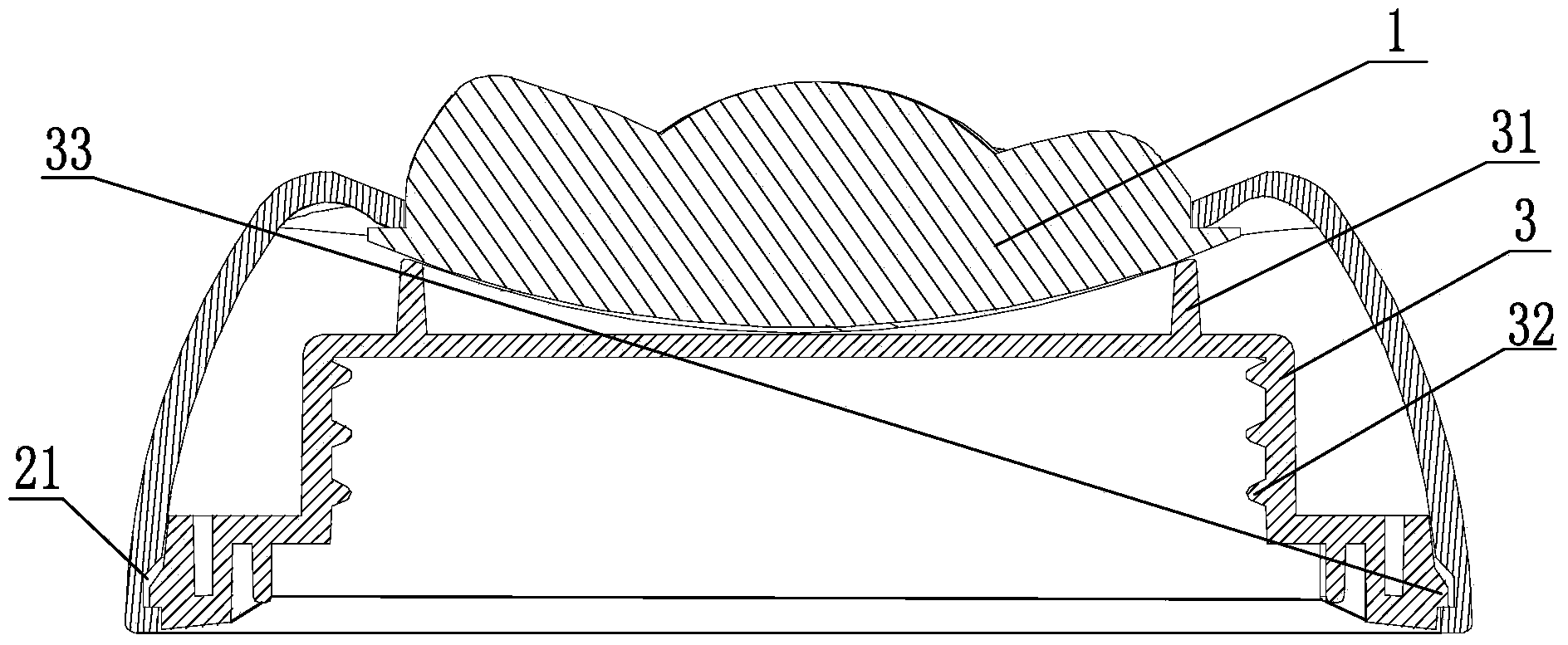

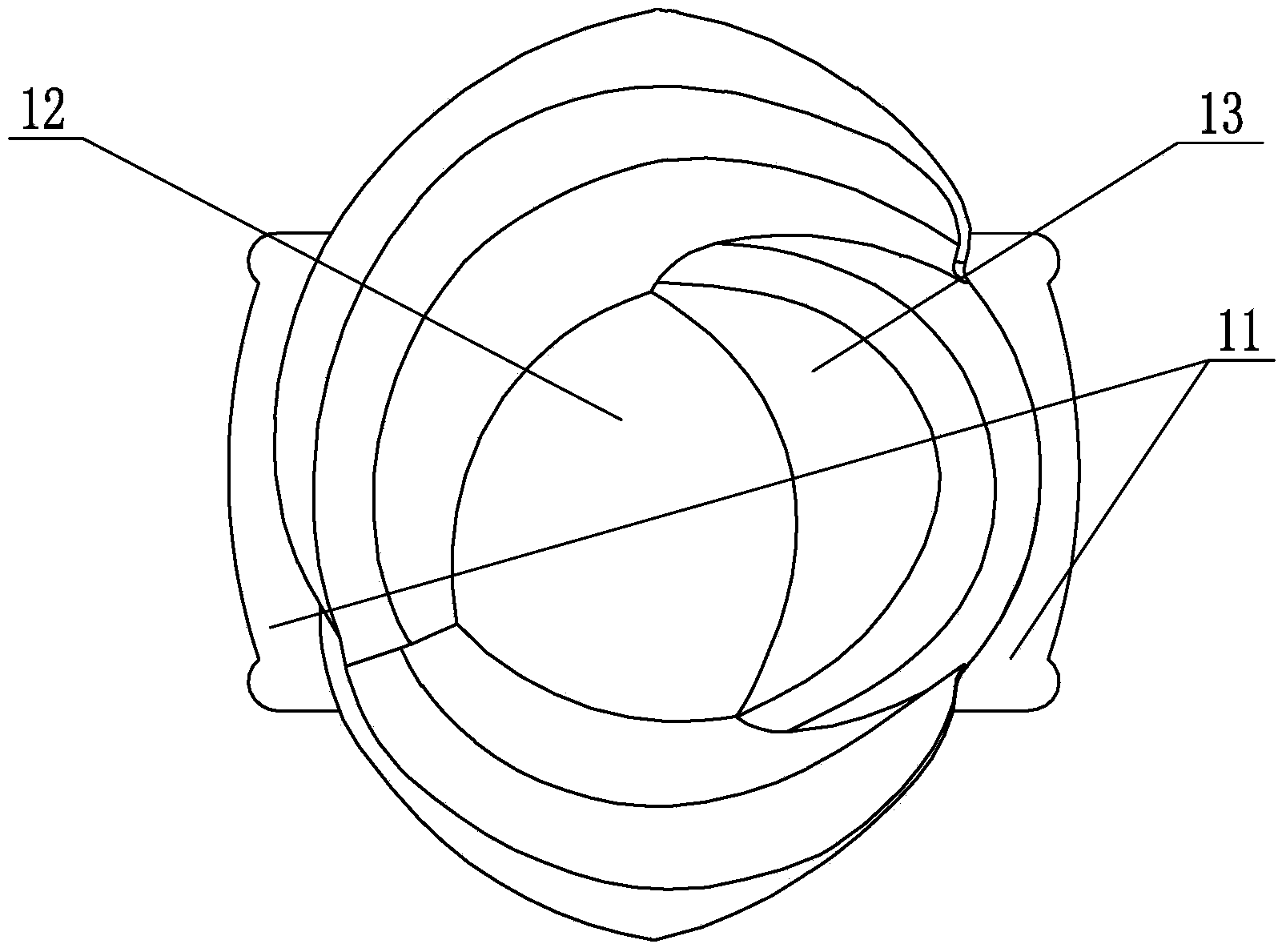

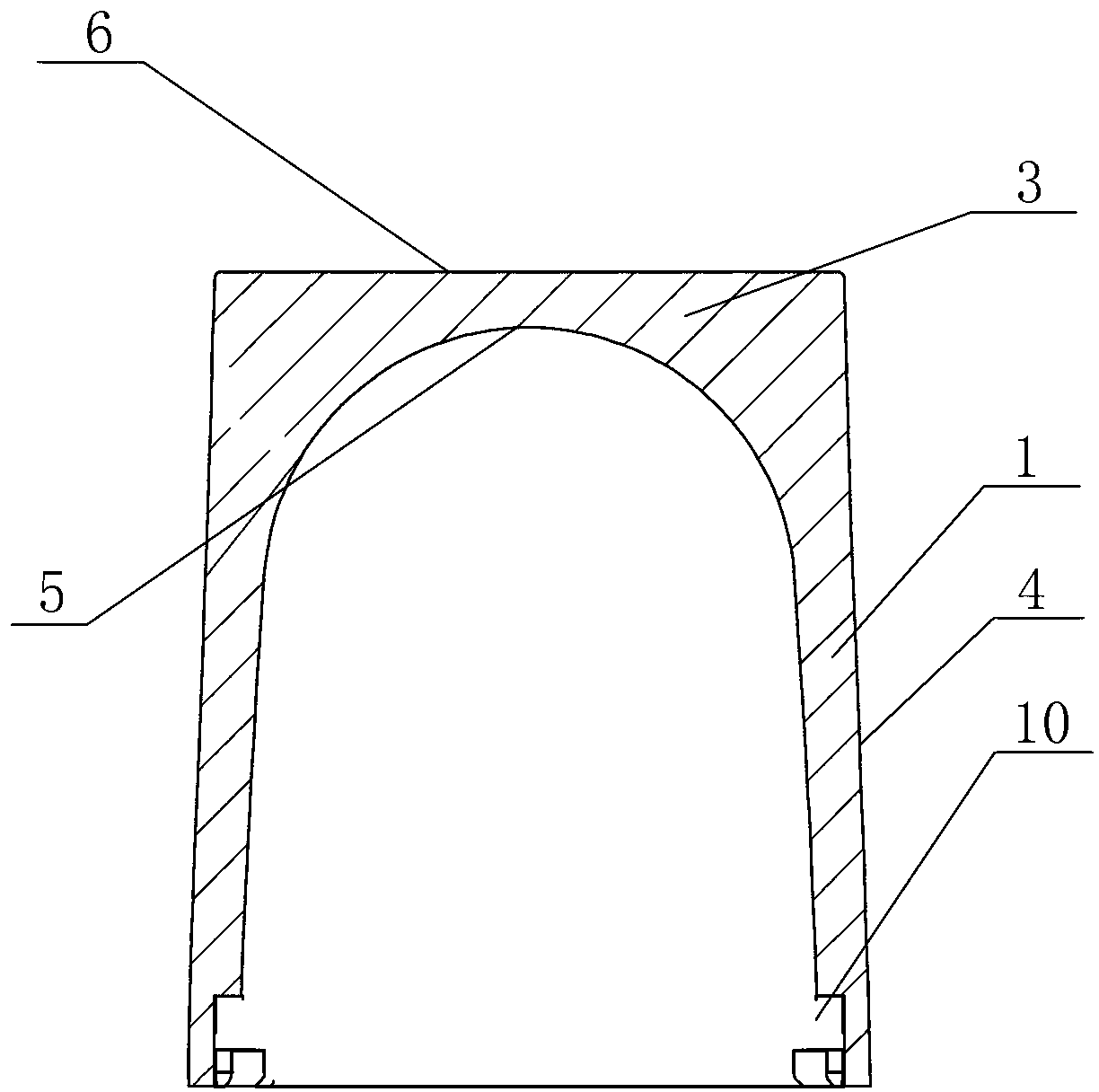

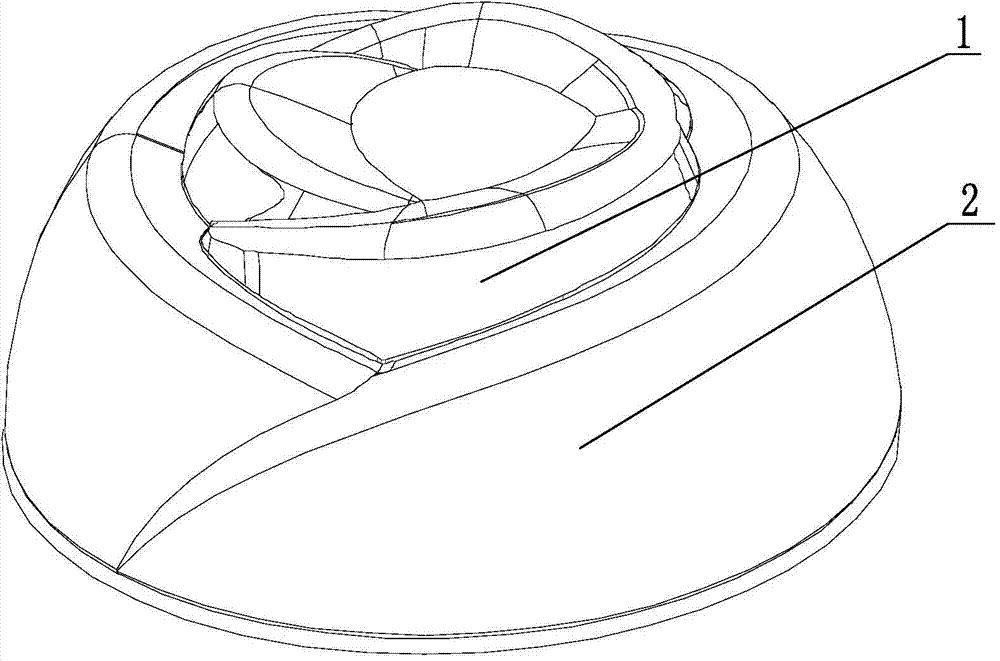

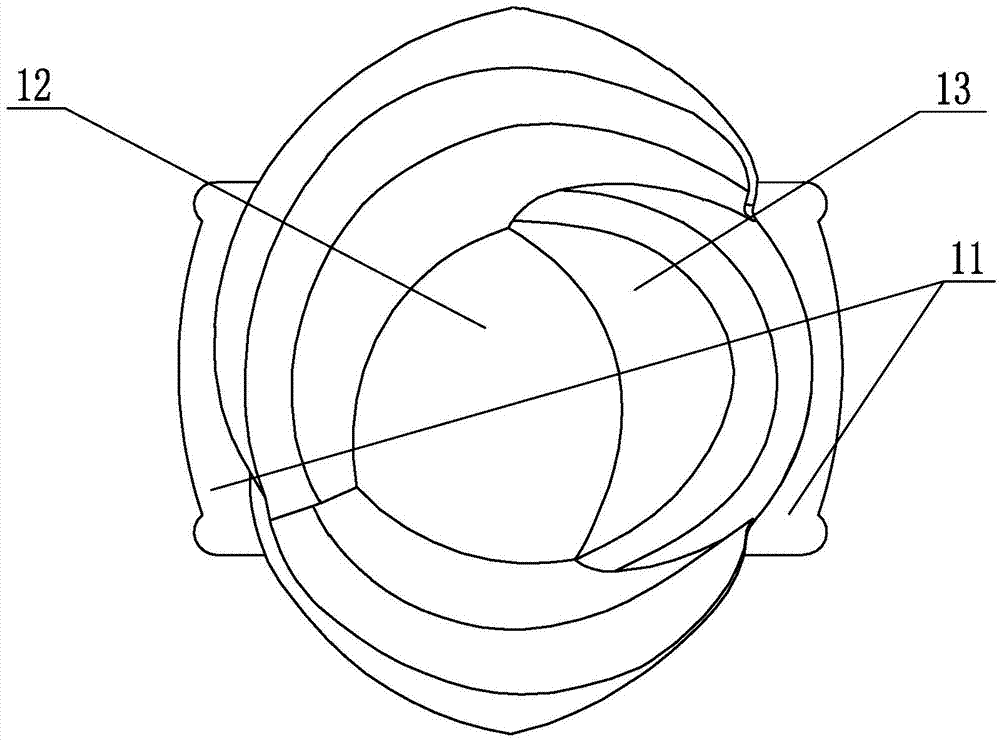

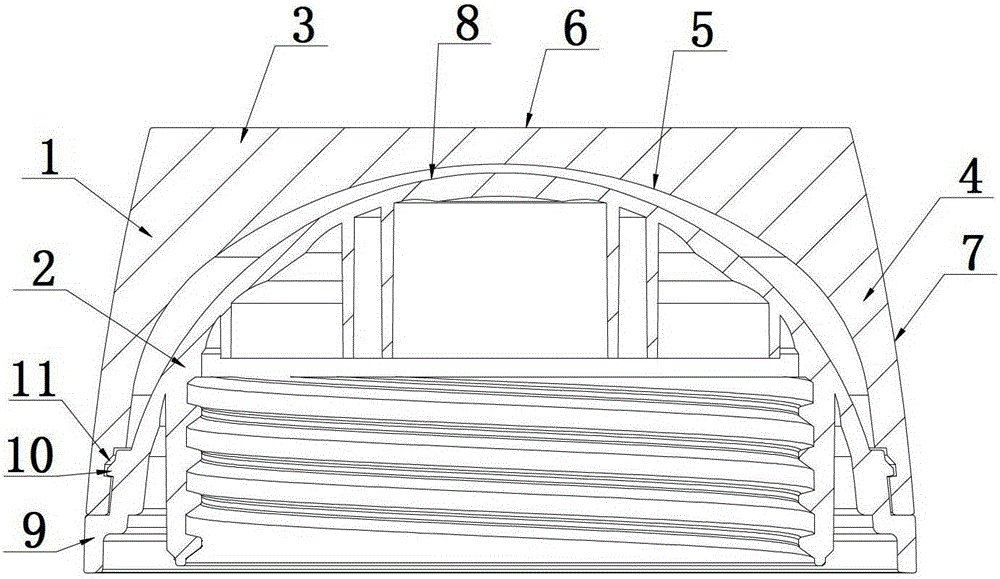

Cosmetic bottle cap

The invention relates to a cosmetic bottle cap, which comprises an outer shell, an inner cap and a decoration, wherein the inner cap is fixedly connected with the outer shell; the upper part of the outer shell consists of two budding petal-shaped bumps; the two petal-shaped bumps and the lower part of the outer shell are molded integrally; an embedding port is formed between the two petal-shaped bumps; the decoration is embedded into the embedding port; the decoration is made of a transparent material; the bottom of the decoration is provided with a reflecting layer; the decoration is provided with a middle cambered surface bump and a plurality of edge bumps; and the edge bumps are arranged around the middle cambered surface bump. The cosmetic bottle cap disclosed by the invention is simple in structure, and is convenient to implement; the embedding port is matched with the decoration, and flowers are displayed on the end face of the bottle cap of a cosmetic bottle with high quality in a three-dimensional way, so that the features of product are highlighted; and the cosmetic bottle cap has beautifying and anti-counterfeiting effects.

Owner:OSMUN BIOLOGICAL

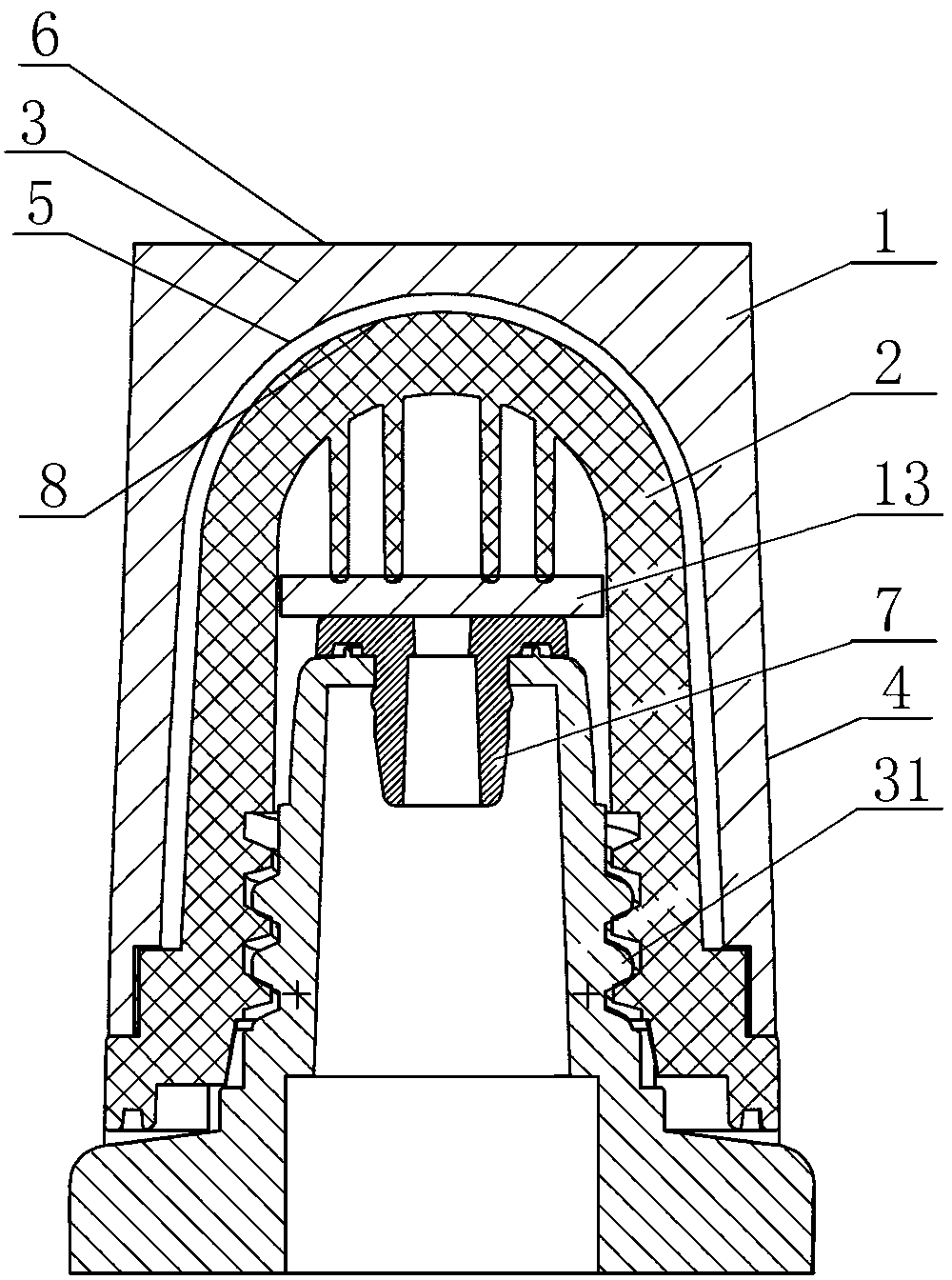

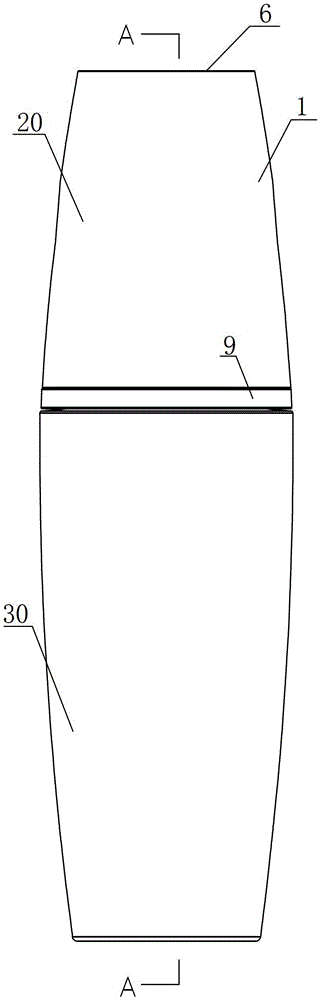

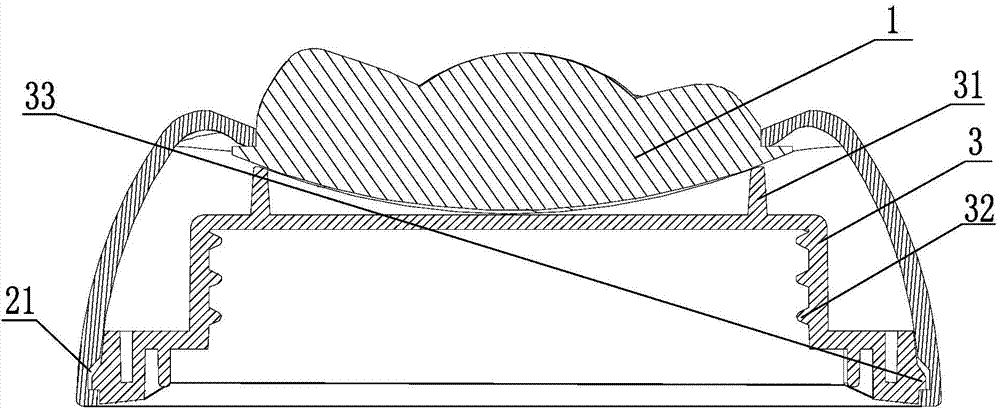

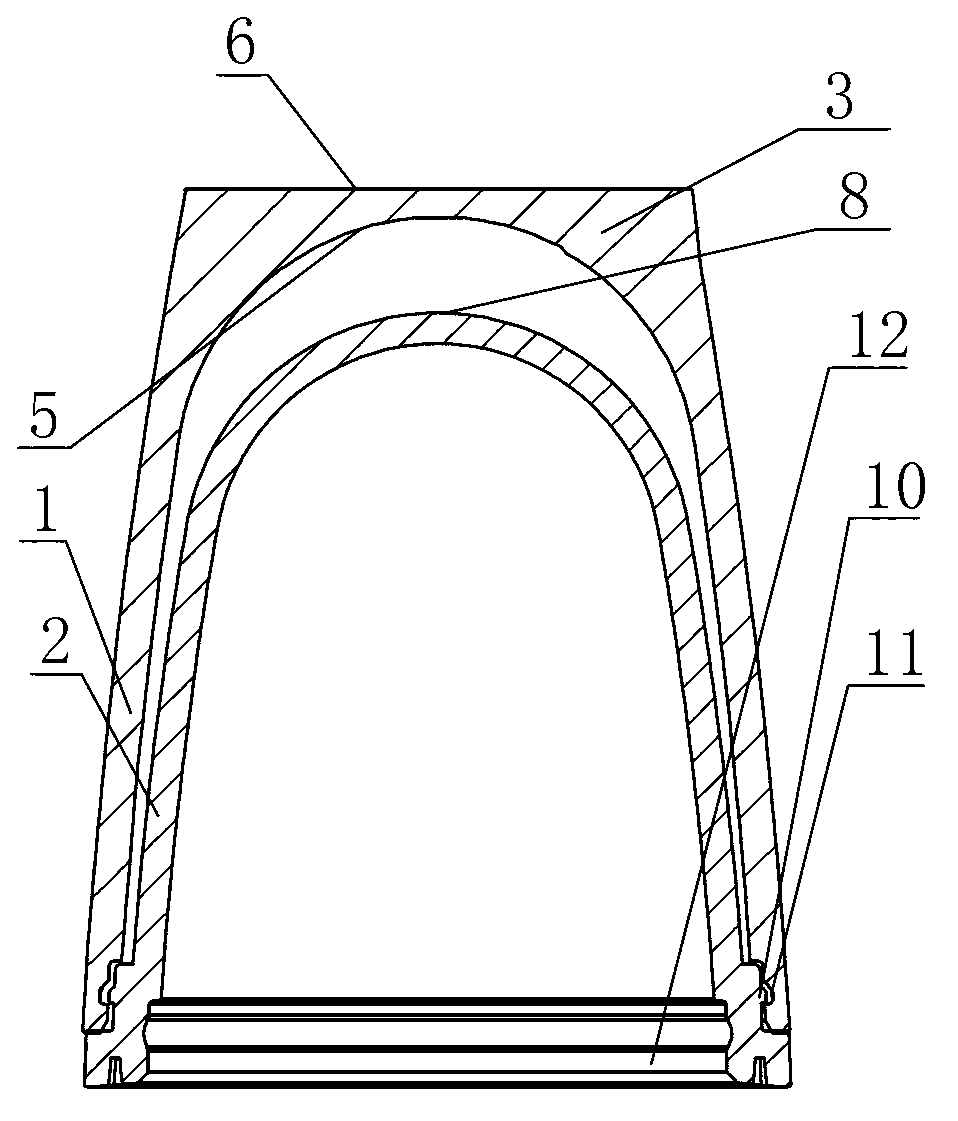

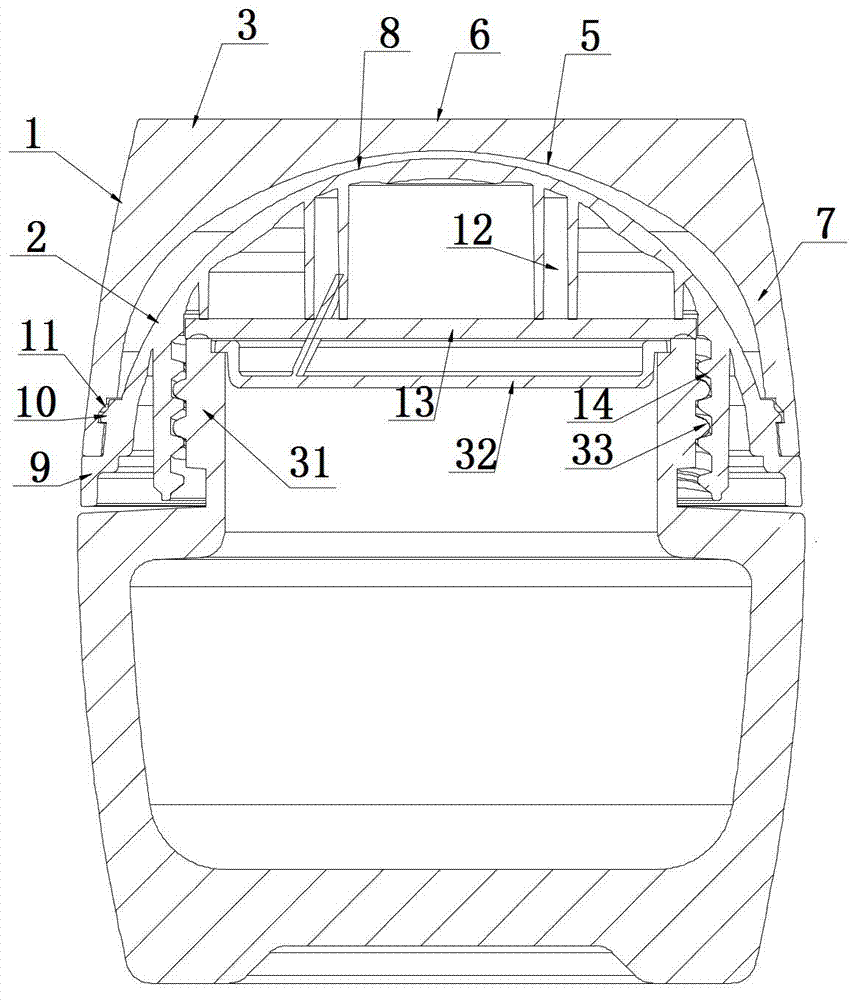

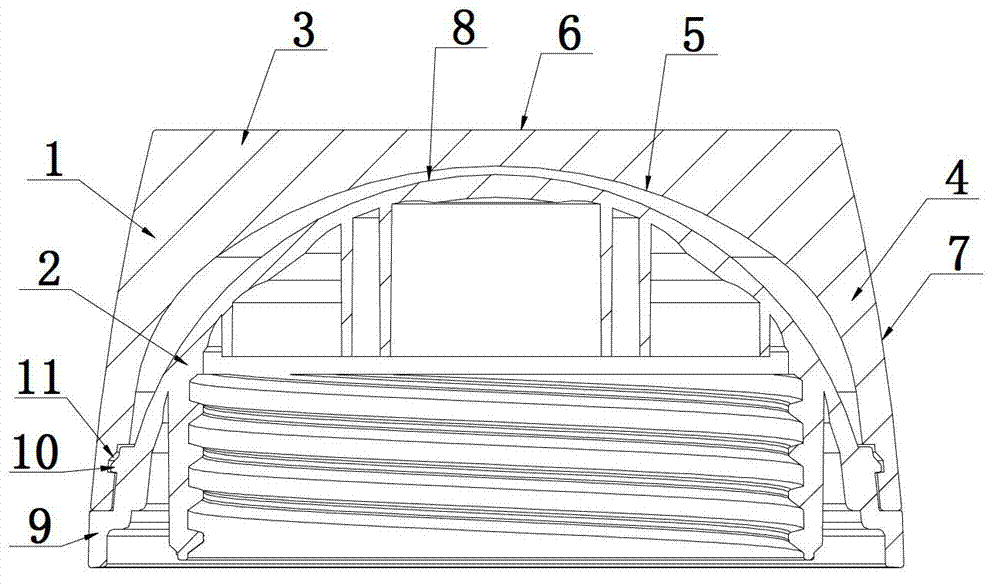

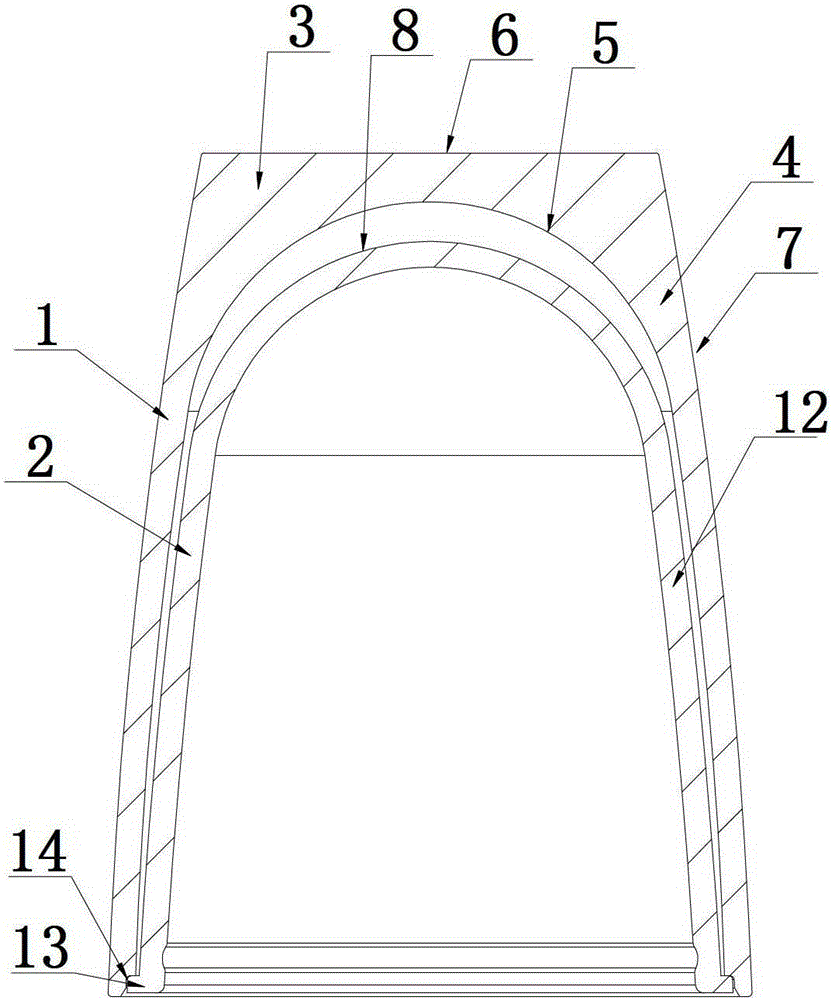

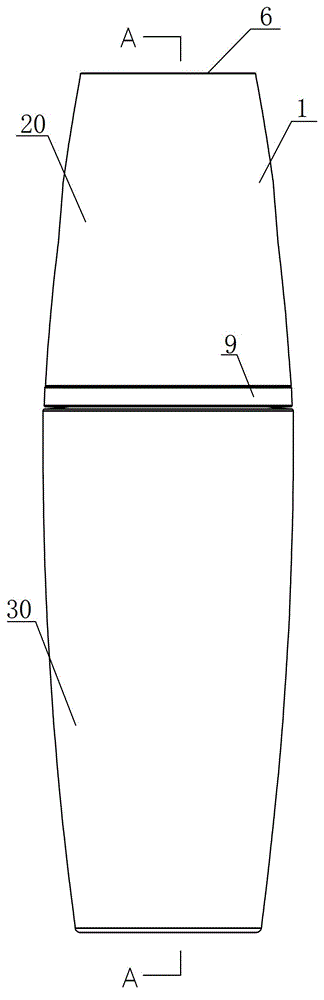

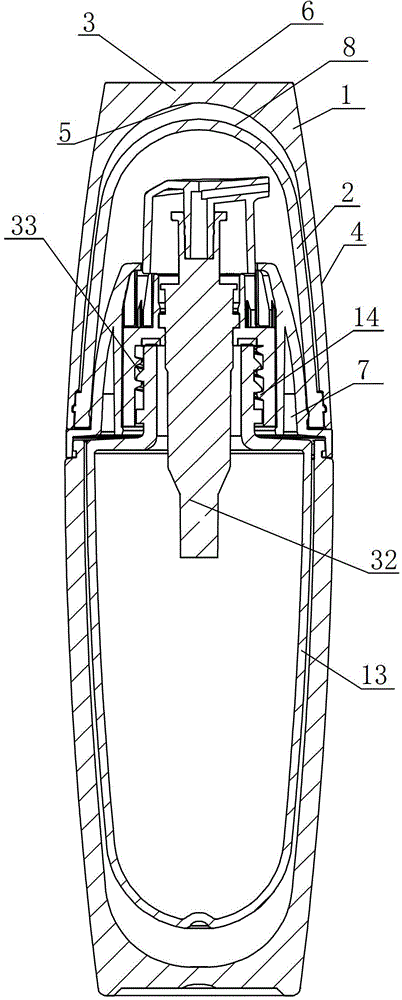

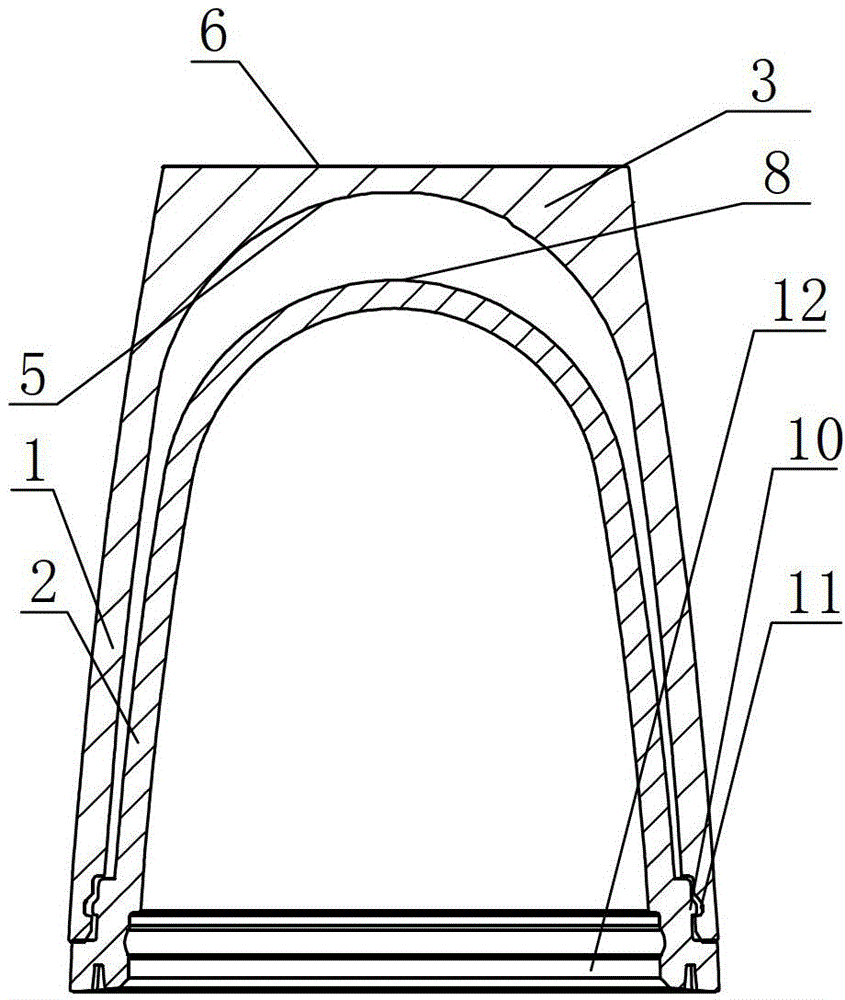

Cosmetic tube

ActiveCN103057830ASimple structureEasy to implementClosure with auxillary devicesBiomedical engineeringCosmetics

The invention relates to a cosmetic tube. The cosmetic tube comprises a tube cap and a tube body, a plug is arranged at the mouth of the tube body, the tube cap consists of an inner cap and a shell which are fixedly connected, the tube body is in threaded connection with the tube cap, a support ring is arranged above a threaded opening, a packing piece is arranged on the support ring, the shell consists of a top and a side wall, the top is a concave lens, the upper surface of the inner cap protrudes upwards to form an arc protrusion, the outer surface of the arc protrusion is in pearl color, is a first spherical crown surface or consists of a first spherical crown surface and more than one spherical table side face in connection, the height of the first spherical crown surface is smaller than or equal to the radius of the first spherical crown surface, and the arc protrusion arranged in an inner cavity of the shell appears in the stereoscopic shape of a pearl at the top.

Owner:OSMUN BIOLOGICAL

Method for processing kraft paper or black card paper tag

ActiveCN101725085AFeel goodNovel appearanceChemical/biochemical paper treatmentPhysical paper treatmentBlack cardWork in process

The invention discloses a method for processing a kraft paper or black card paper tag. The method comprises the following steps of: a, adding water, the volume of which is two thirds of the capacity of a water scouring machine, to the water scouring machine, adding a penetrant 66 in a ratio of 2 to 5g / L, adding a softening agent JSS in a ratio of 10 to 20g / L to prepare solution of scouring water; b, placing a processed semi-finished paper tag in the solution of scouring water, and adding glue balls in a weigh ratio of the glue balls to the tag of 1:1; c, setting the rotary speed of the water scouring machine as 50 to 60rev / min, and after 30 to 45 minutes, taking out the semi-finished paper tag and washing the paper tag by pure water; d, placing the paper tag washed by the pure water in a dewaterer for dewatering at a rotary speed of 250 to 300rev / min for 10 seconds; and e, spreading the dewatered paper tag in an oven, drying the paper tag by hot air at the temperature of between 70 and 80 DEG C for 50 to 60 minutes to obtain the finished product. The method has the advantages that: the kraft paper or black card paper tag can be scoured by water; the finished product of the tag is soft and good in hand touch; the difference not caused by tag quality exists among the tags; and the tag has certain counterfeiting effect.

Owner:广东康派环创科技有限公司

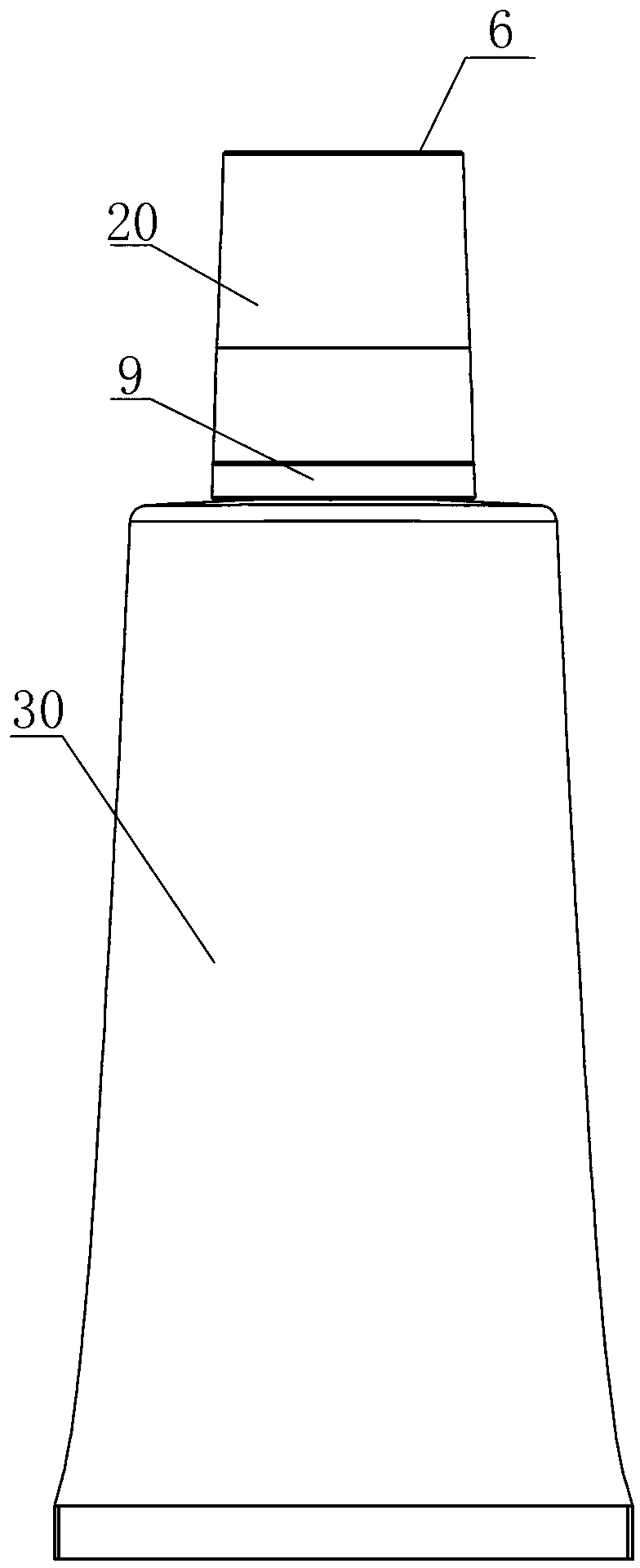

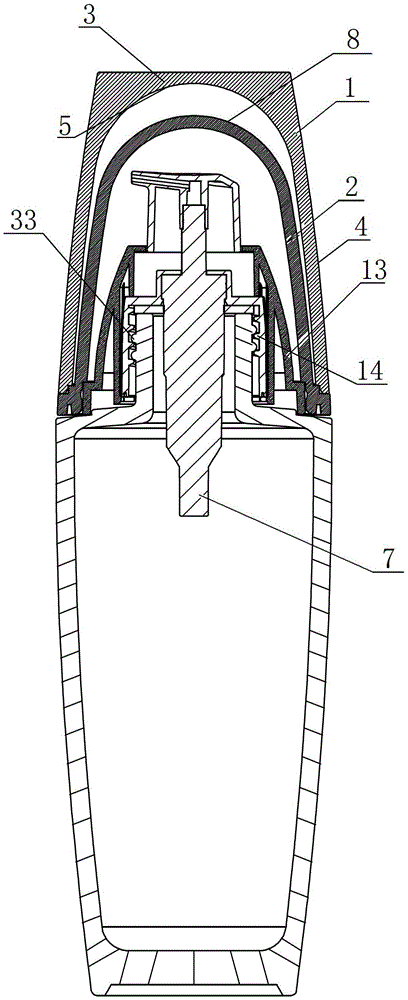

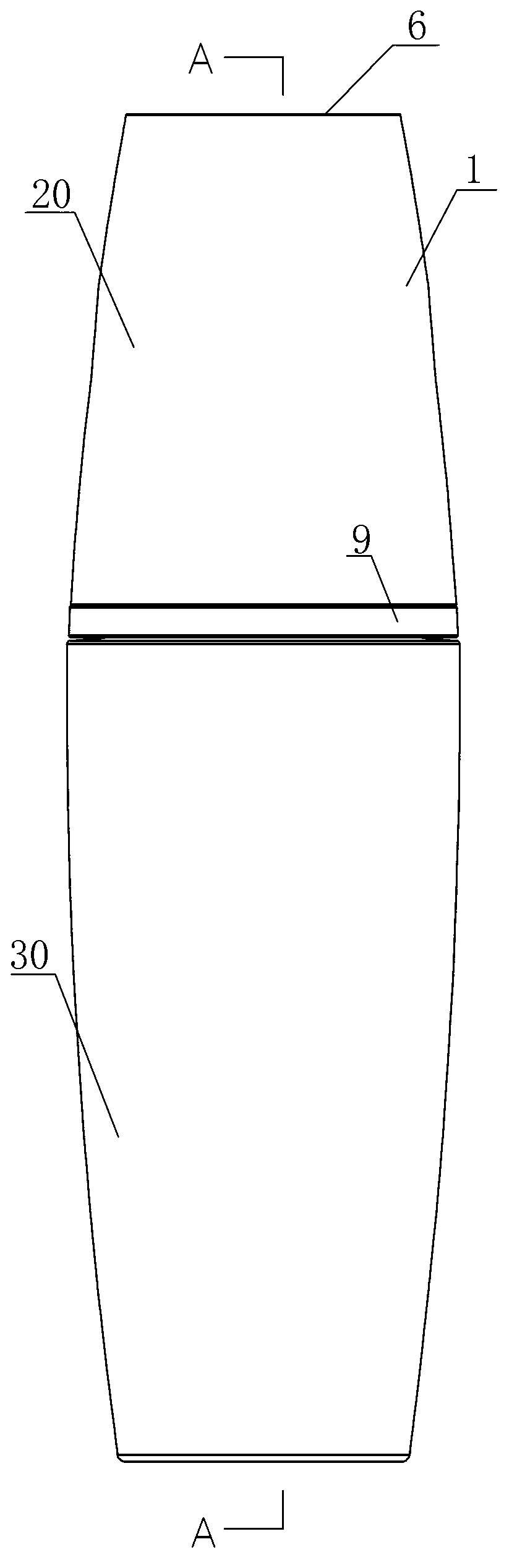

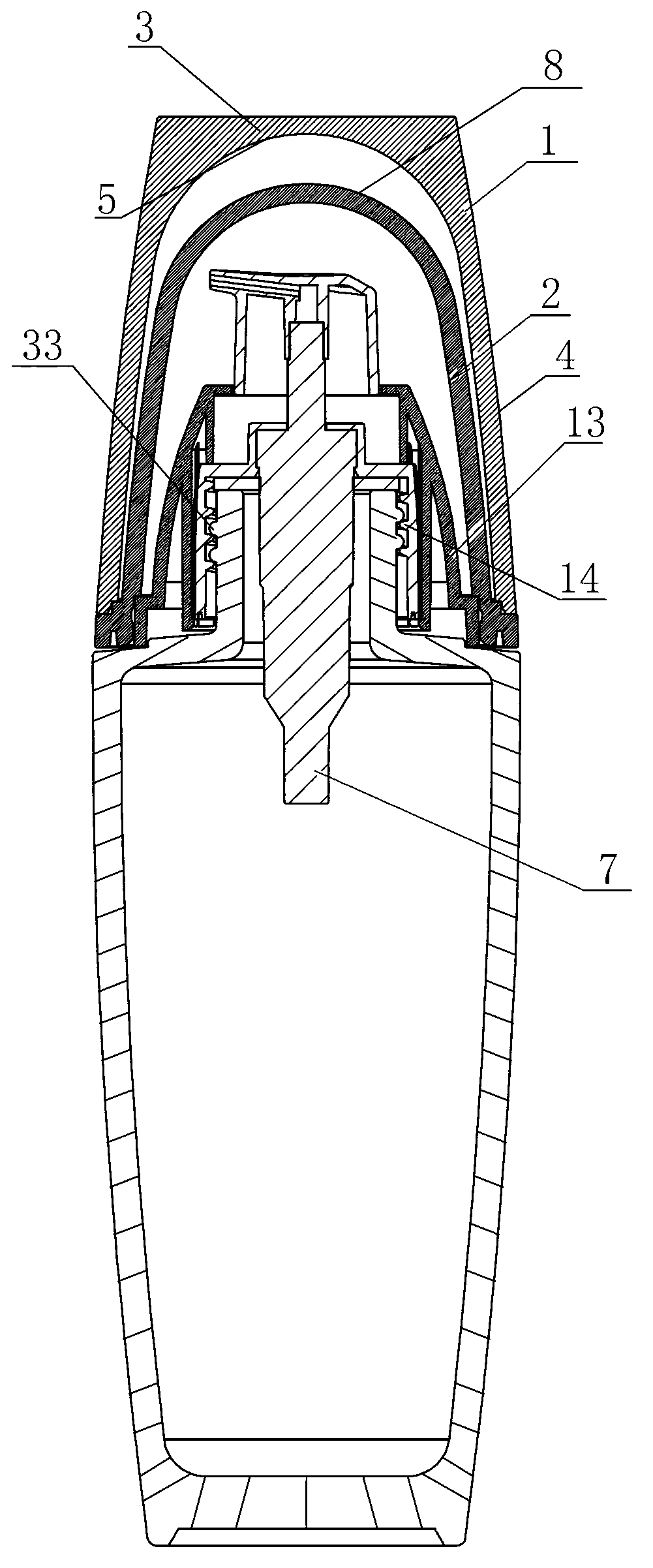

A cosmetic bottle with a pump head

ActiveCN103054310BSimple structureEasy to implementPackaging toiletriesPackaging cosmeticsPump headBottle cap

The invention relates to a cosmetic bottle with a pump. The cosmetic bottle comprises a bottle cap, the pump and a bottle body. The pump is fixedly connected with the bottle body and the bottle cap through a peripheral middle sleeve. The bottle cap consists of an inner cap and a shell which are fixedly connected, a groove in a circle is arranged on the lower portion of an inner ring of the inner cap and matched with a protrusion, the shell is composed of a top and a side wall, and the top is a concave lens. The upper surface of the inner cap protrudes upwards to form an arc-shaped protrusion, the outer surface of the arc-shaped protrusion is formed by a first spherical crown surface or connecting the first spherical crown surface with more than one spherical table surface, the height of the first spherical crown surface is smaller than or equal to the radius of the first spherical crown surface, and the outer surface of the arc-shaped protrusion appears in pearl color on the outer surface of the arc-shaped protrusion. The arc-shaped protrusion is arranged in an inner cavity of the shell, so that the arc-shaped protrusion can show a stereoscopic shape of a pearl on the top.

Owner:OSMUN BIOLOGICAL CO LTD

Laser-marked and halogen-free flame-retardant polyamide composite material

ActiveCN102093707BWith anti-counterfeiting effectStable temperature resistanceAntioxidantFilling materials

The invention relates to a laser-marked and halogen-free flame-retardant polyamide composite material with excellent flame-retardant property and laser marking effect. The polyamide composite material is characterized by comprising the following substances: at least one or more of polyamide resins, at least one or more of inorganic packing materials, at least one or more of halogen-free flame retardants which can provide the excellent flame-retardant property for the composite material, at least one or more of aids which can provide excellent laser marking for the composite material, and other unessential aids such as lubricants, antioxidants, pigments and the like. The composite material has the comprehensive performance of excellent temperature resistance, flame retardance, and dimensional stability, easiness of processing and molding and the like, and also has clear and attractive laser marking effect at the same time. The composite material is widely applied in the fields of household products, electronic appliances, laser handles and the like and has huge market prospect.

Owner:BENSONG ENG PLASTICS HANGZHOU

cosmetic bottle cap

Owner:OSMUN BIOLOGICAL CO LTD

Cosmetic bottle with pump

ActiveCN103054310ASimple structureEasy to implementPackaging toiletriesPackaging cosmeticsBottle capChemical engineering

The invention relates to a cosmetic bottle with a pump. The cosmetic bottle comprises a bottle cap, the pump and a bottle body. The pump is fixedly connected with the bottle body and the bottle cap through a peripheral middle sleeve. The bottle cap consists of an inner cap and a shell which are fixedly connected, a groove in a circle is arranged on the lower portion of an inner ring of the inner cap and matched with a protrusion, the shell is composed of a top and a side wall, and the top is a concave lens. The upper surface of the inner cap protrudes upwards to form an arc-shaped protrusion, the outer surface of the arc-shaped protrusion is formed by a first spherical crown surface or connecting the first spherical crown surface with more than one spherical table surface, the height of the first spherical crown surface is smaller than or equal to the radius of the first spherical crown surface, and the outer surface of the arc-shaped protrusion appears in pearl color on the outer surface of the arc-shaped protrusion. The arc-shaped protrusion is arranged in an inner cavity of the shell, so that the arc-shaped protrusion can show a stereoscopic shape of a pearl on the top.

Owner:OSMUN BIOLOGICAL

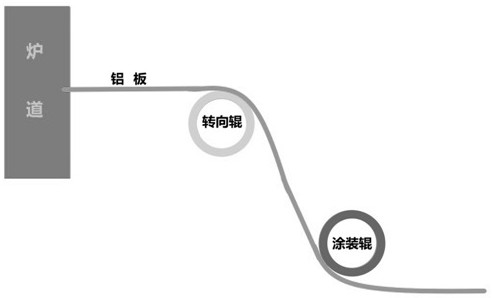

Production process of aluminum plate for three-dimensional pattern anti-counterfeiting wine cap

PendingCN114558765AWith anti-counterfeiting effectOvercome the defect of not being able to print very thickLiquid surface applicatorsMagnetic paintsProduction lineWine

The invention provides a production process of an aluminum plate for a three-dimensional pattern anti-counterfeiting wine cap. The production process comprises the following process steps: 1) preparing a soft magnetic rubber coiled material; 2) cutting into a required size; 3) wrapping the soft magnetic rubber coiled material on a turning roller of a coating unit in a surrounding manner; (4) firstly coating with a colored paint and drying to serve as a primer; 5) coating the colored primer with a transparent coating containing colored magnetic powder through a coating machine; (6) in the running process of the roller coating production line, the aluminum coil coated with the colored magnetic powder coating is discharged from a coating machine head, and three-dimensional patterns in different shapes are formed when the aluminum coil passes through a steering roller; and 7) drying. The soft magnetic rubber coiled material is arranged on the steering roller, in the running process of a roller coating production line, when an aluminum coil coated with colored magnetic powder coating comes out of a coating machine head and passes through the steering roller, magnetic powder is influenced by the magnetic force of magnetic rubber wrapping the steering roller, the magnetic powder rapidly moves in the coating which is not dried, and the coating is not dried. And three-dimensional patterns are formed.

Owner:盛源创科(烟台)包装股份有限公司

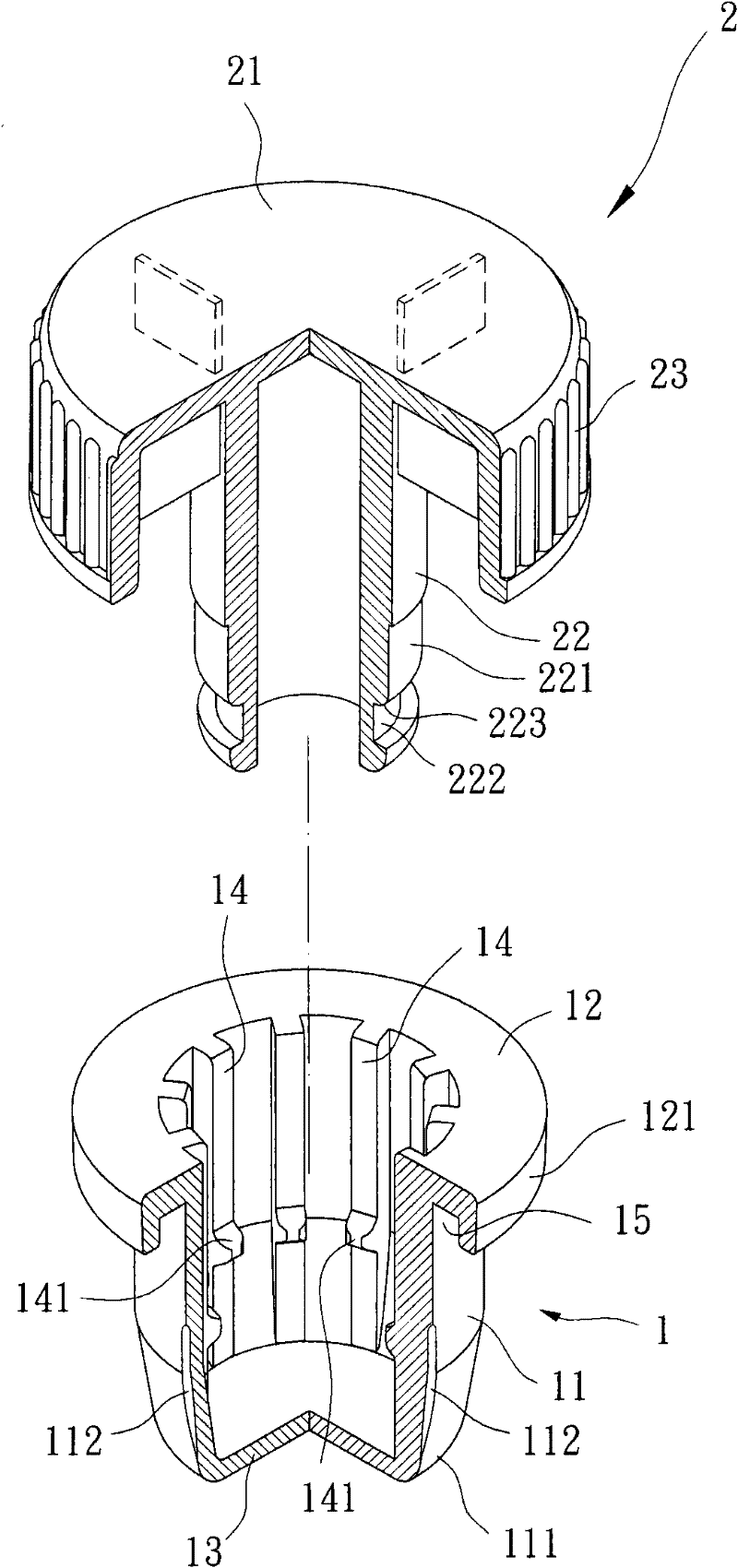

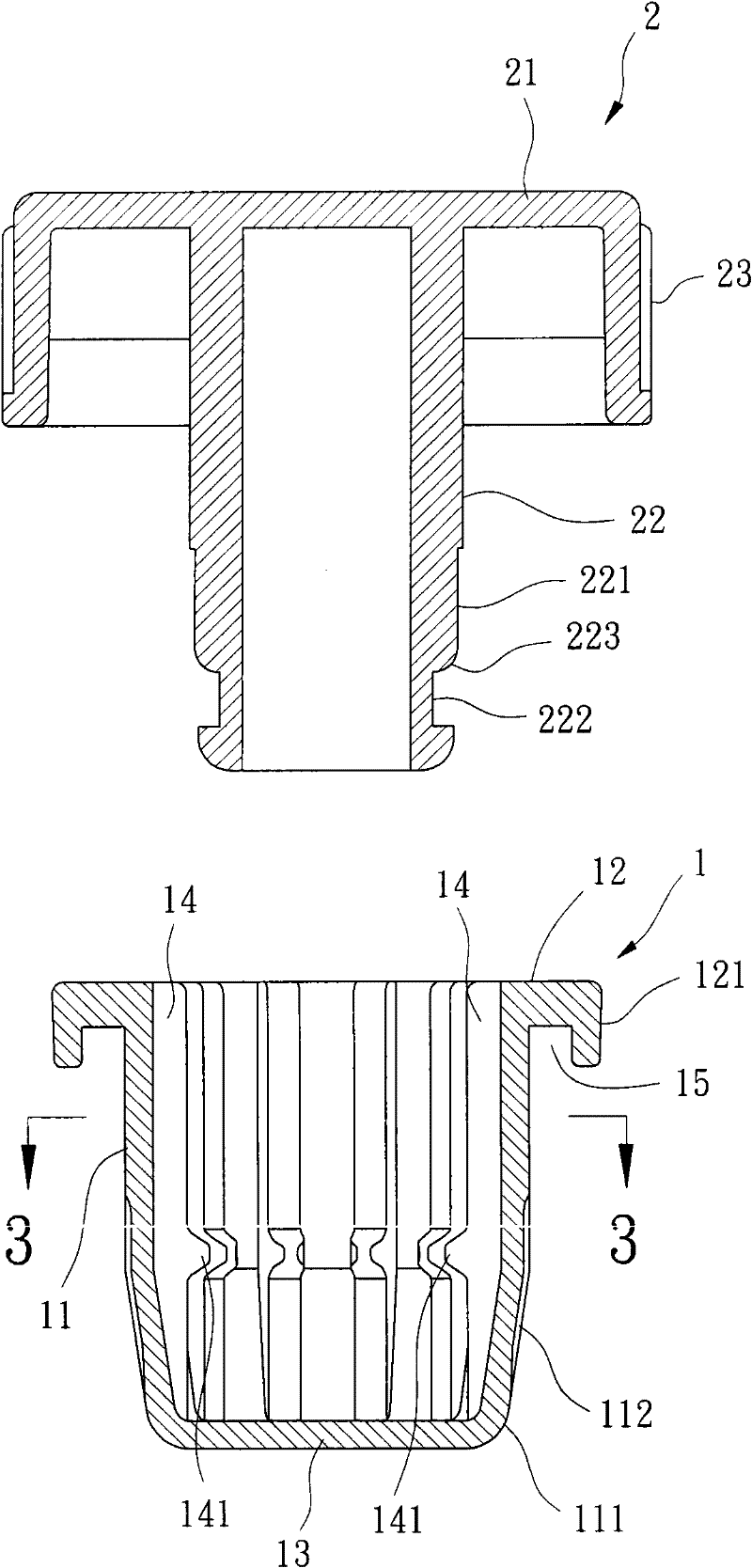

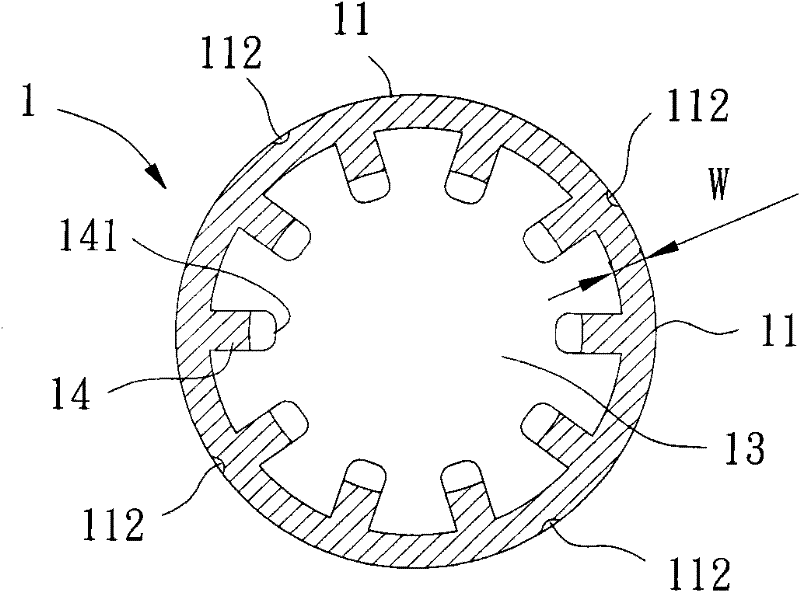

Two-piece bottle plug

InactiveCN102190115BEasy to manufactureReduce manufacturing costExpansible closuresBottleEngineering

The invention relates to a two-piece bottle plug which mainly comprises a plug body and a pressing piece, wherein the plug body is integrally formed in a cup shape and is provided with a barrel part, a top disc and a plurality of rib parts inside the barrel part; the top disc is connected to the opening end of the barrel part; the diameter of the top disc is more than that of the barrel part; theplurality of rib parts protrude radially on the inner wall of the barrel part and are mutually separated without connection; each rib part is provided with a butting part; the plurality of butting parts are positioned on the same circumference and protrude towards the central direction; a top part and a pole are formed on the pressing piece; the pole extends from one surface of the top part; a jacking part and a bucking part are formed on the surface of the pole; and the diameter of the buckling part is less than that of the jacking part. The bottle plug can be easily manufactured so that themanufacturing cost of the bottle plug can be reduced; in addition, when the bottle plug is used at the opening part of a vessel, the opening of the vessel can be closely sealed.

Owner:SUNLOT BOTTLE STRPPER

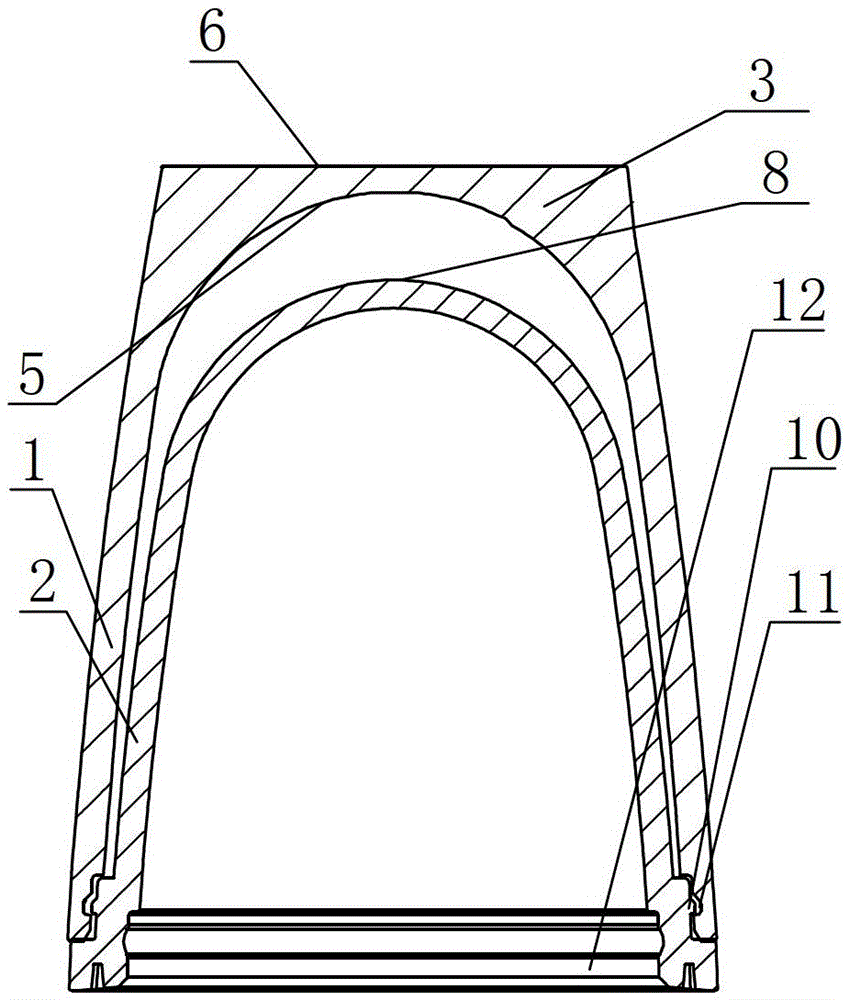

A cosmetic bottle with a glass body

ActiveCN103054309BSimple structureEasy to implementClosuresPackaging toiletriesThree dimensional shapeScrew thread

The invention relates to a glass cosmetics bottle which consists of a bottle cap and a bottle body. The bottle body is made of glass, and the outside of the mouth of the bottle body is provided with external threads. The bottle cap consists of an inner cap and an outer casing, and the inner cap is fixedly connected with the outer casing. The lower part of the inside track of the inner cap is provided with a screw thread mouth matching with the external threads. The outer casing consists of a top and a sidewall, and the top is a concave lens. The upper surface of the inner cap upwardly protrudes and forms an arc-shaped projection, and the outer surface of the arc-shaped projection is a first spherical crown or is a combination of the first spherical crown with more than one table connected sides. The height of the first spherical crown is less than or equal to the radius thereof, and the outer surface of the arc-shaped projection is of a pearl color. The arc-shaped projection is arranged in the cavity of the outer casing, so that the top of the arc-shaped projection seems to be in a three-dimensional shape of a pearl.

Owner:OSMUN BIOLOGICAL

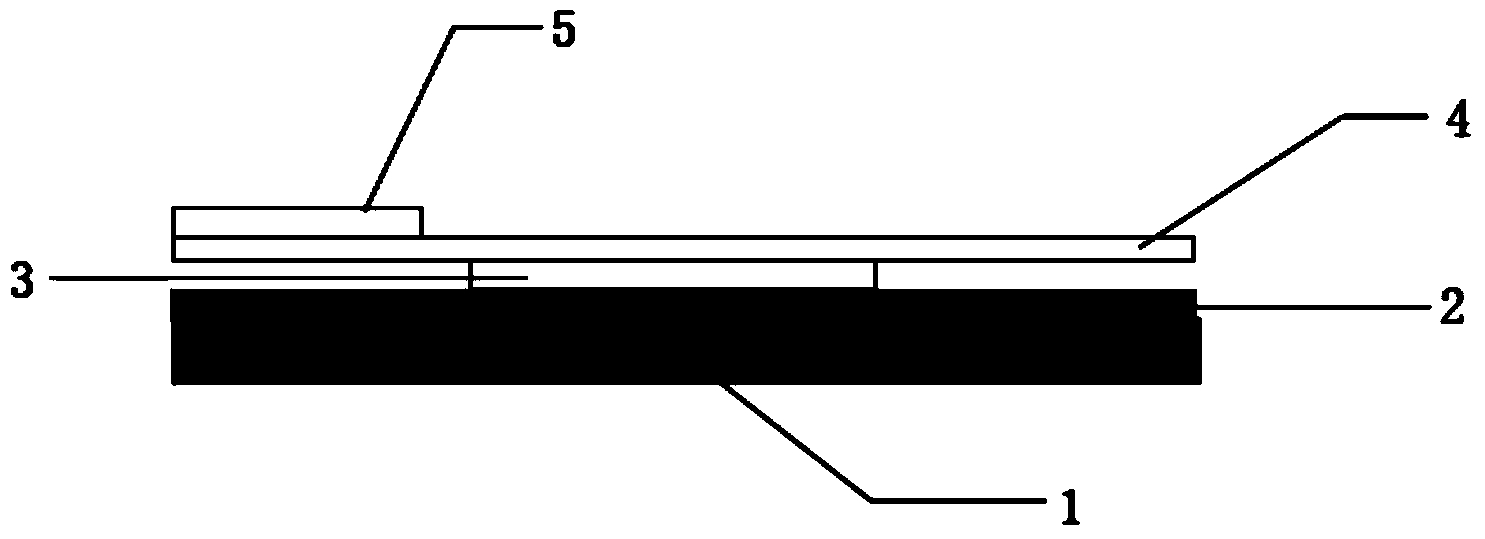

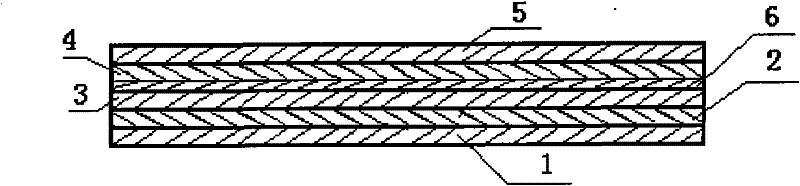

Laser variable two-dimensional-code plastic composite package

InactiveCN106144217ASolve the easy wipe problemNot wipeableFlexible coversWrappersEngineeringMechanical engineering

The invention relates to the field of laser anti-counterfeiting technologies and packages, in particular to a laser variable two-dimensional-code plastic composite package. The laser variable two-dimensional-code plastic composite package comprises a printed layer, an ink layer, a middle layer (which is only for a structure with two or more layers), and a thermally sealed layer from outside to inside, wherein ink is printed on the printed layer; the ink layer is used for forming patterns; the middle layer has barrier property and other functions; and the thermally sealed layer has the thermal bonding effect. The package disclosed by the invention has the advantages that a two-dimensional code is located on the inner side of the printed layer, cannot be wiped, and is hard to destroy, so that the uniqueness and the permanency of a product are guaranteed, and the anti-counterfeiting effect is achieved; no consumables and no damageable parts are used, and the package has an unmatchable cost advantage; and furthermore, the package is environment-friendly and pollution-free, and has a unique style which is different from the existing style.

Owner:杭州顶正包材有限公司 +1

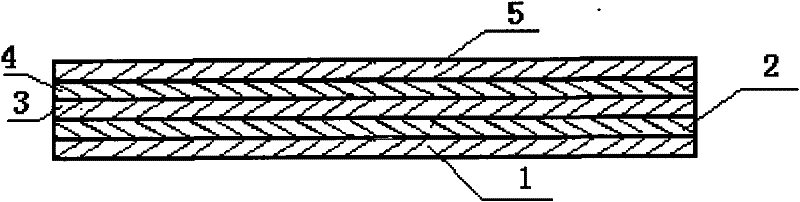

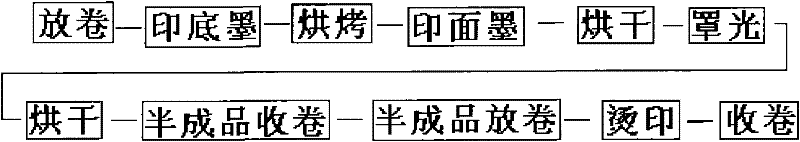

Tipping paper for cigarette and production technology thereof

InactiveCN101718060BStrong adhesionDo not lose inkFlexible coversWrappersHot stampingLaser engraving

The invention discloses tipping paper for cigarette and a production technology thereof. The tipping paper for cigarette has a structure that a bottom layer is a basic layer, a bottom color layer is arranged on the basic layer, a surface color layer is arranged on the bottom color layer, a finish coat is arranged on the surface color layer and a gold stamping layer is arranged on the finish coat.The production technology thereof comprises the steps of unreeling, printing bottom ink, baking, printing surface ink, drying, glaring, drying, rolling semi-manufactures, unreeling semi-manufactures,lettering, and reeling. The invention has the advantages that because an electrostatic blotting coloration technology is adopted, coloring is firm and the color layers have strong adhesive force and do not drop ink; because laser engraving is adopted and the engraving depth of a printing plate roller from one end to the opposite end is from the shallower to the deeper, the surface color layer hasstrong color layering; and phenomena of gold falling, hot stamping miss and needle holes during gold stamping are overcome by adjusting pressure and hot stamping temperature between a hot stamping plate roller and a rubber covered roller so as to enable the gold stamping color to be stable and even.

Owner:WUHU CIGARETTE MATERIAL FACTORY

Method for manufacturing scratchable laser holography anti-fake foil

InactiveCN102092165BHot stamping production efficiency is highWith anti-counterfeiting effectSynthetic resin layered productsSpecial ornamental structuresInformation layerPolyester

The invention relates to a method for manufacturing scratchable laser holography anti-fake foil, taking a plastic polyester film as a substrate layer, comprising the following steps of: superposing a release layer on the substrate layer; superposing a laser molding color layer on the release layer, comprising evenly coating the dissolved resin on the surface of the release layer, and baking and drying via a five-section oven; superposing a holography anti-fake molding layer on the laser molding color layer, comprising forming visual laser patterns and information by a laser information layer via a roller coated with laser engraved laser plates; superposing a printing layer on the holography anti-fake molding layer; superposing a vacuum aluminized coating layer on the printing layer, comprising heating an evaporator to 1400-1500 DEG C, cooling the high-purity aluminum wires continuously sent to the evaporator into aluminum steam, evenly spraying aluminum molecules on the surface, and forming an aluminum film; and superposing a gum layer on the vacuum aluminized coating layer. The product manufactured by the method provided by the invention is high in printing production efficiency and is scratched once; the product has certain anti-fake effects and can replace a traditional method for scratching ink by a squeegee.

Owner:SHANGHAI SHENYONG STAMPING FOIL

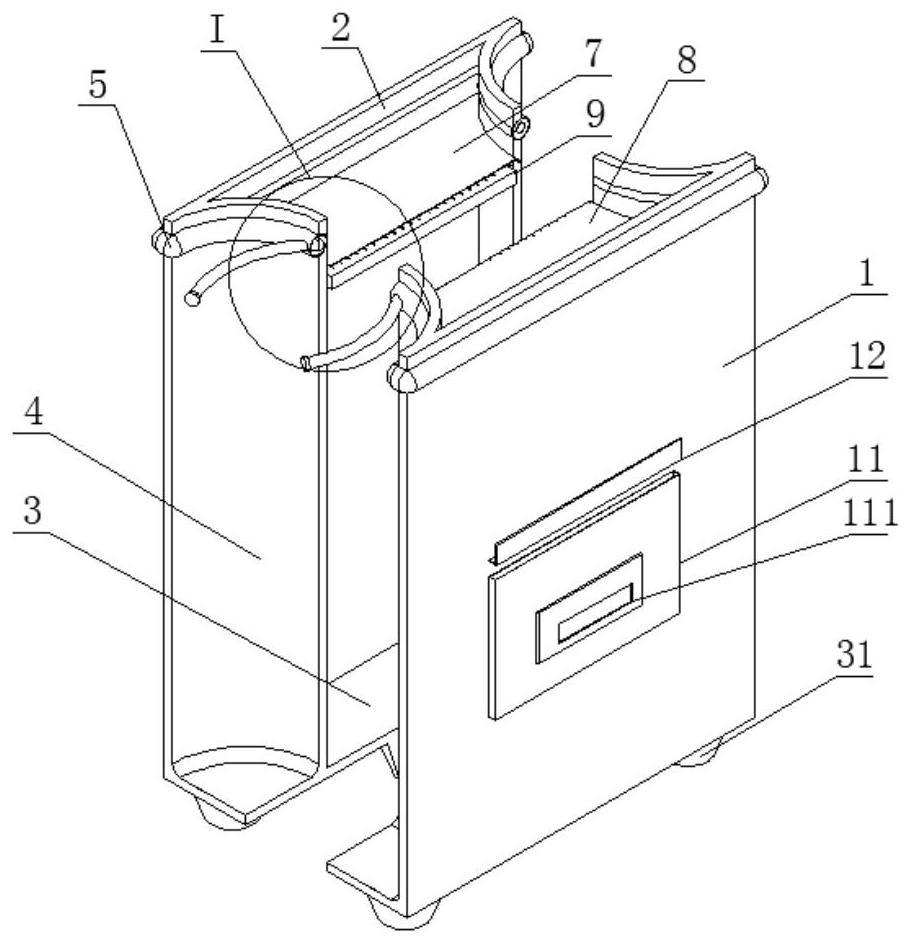

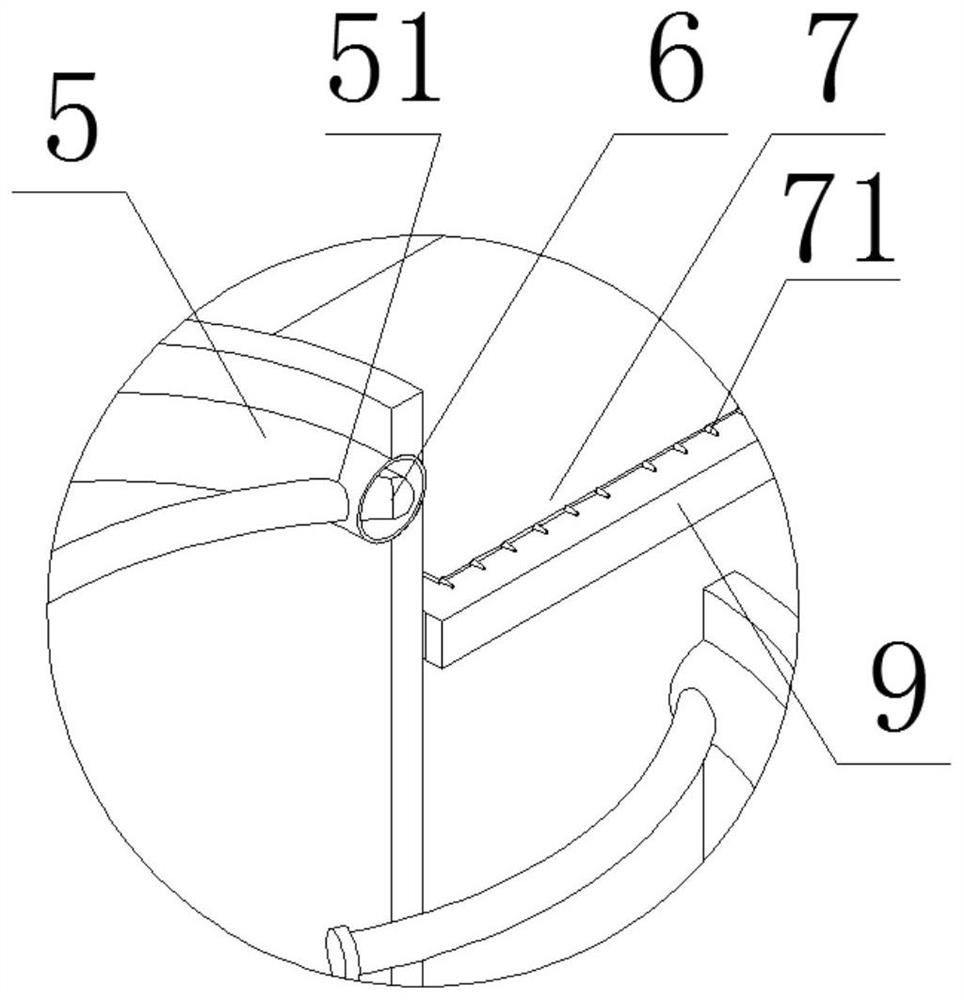

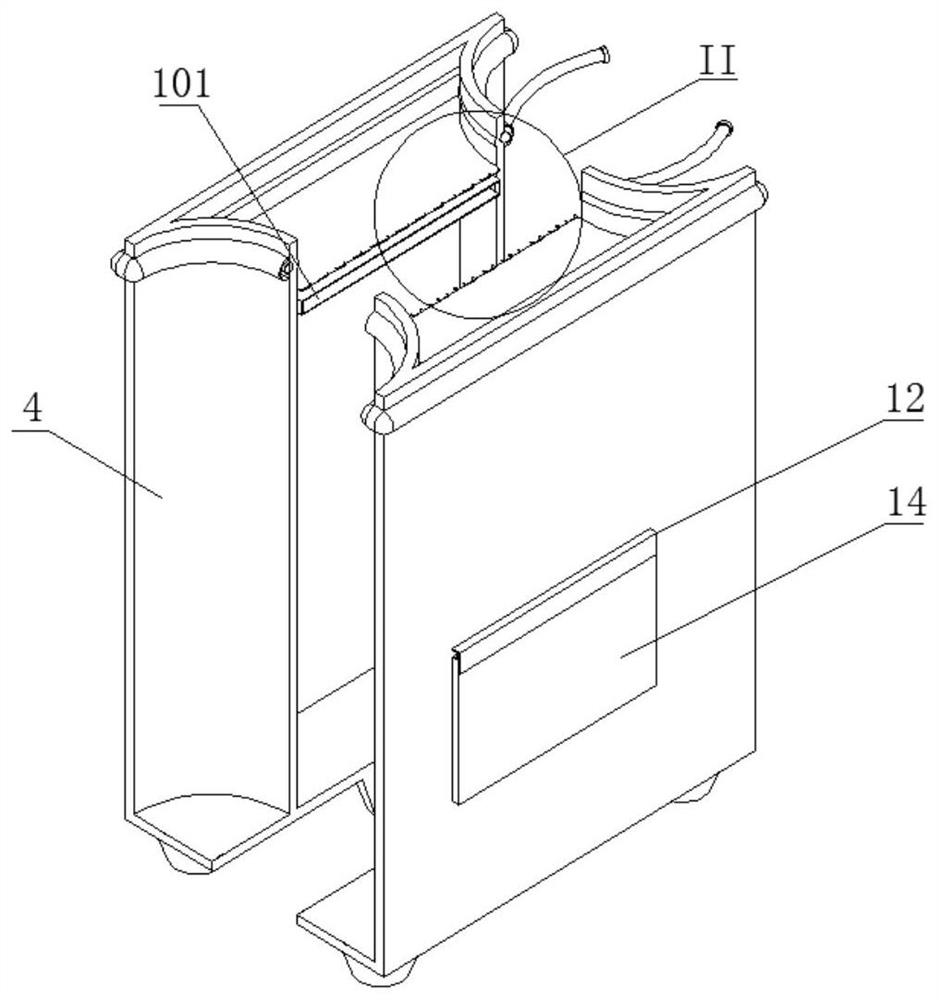

A multi-functional packaging body that is easy to pack

ActiveCN110092057BEasy to place verticallyGuarantee product qualityDischarging meansVariable capacity containersEngineeringIndustrial engineering

The invention discloses a novel multifunctional package convenient to tie. The package is composed of a first face plate, a second face plate, a bottom face plate and side face plates. The bottom faceplate is fixedly arranged on the lower ends of the first face plate and the second face plate. The front and rear ends of the bottom face plate are respectively fixedly connected to the lower ends ofthe first face plate and the second face plate. The side face plates are arranged on the two sides of each of the first face plate and the second face plate. The package is provided with a first sealing device, a second sealing device and a third sealing device. The novel multifunctional package convenient to tie facilitates the protection of a product and helps a user to place the package with the product perpendicular to a supporting surface during use so as to facilitate the taking of the product in the package by the user and effectively prevent the product from being contaminated due tothe tilt of the package, thereby effectively ensuring the quality of the product in the package. Therefore, the novel multifunctional package convenient to tie has the characteristics of small contamination, simple structure and good use flexibility.

Owner:郑笑遥

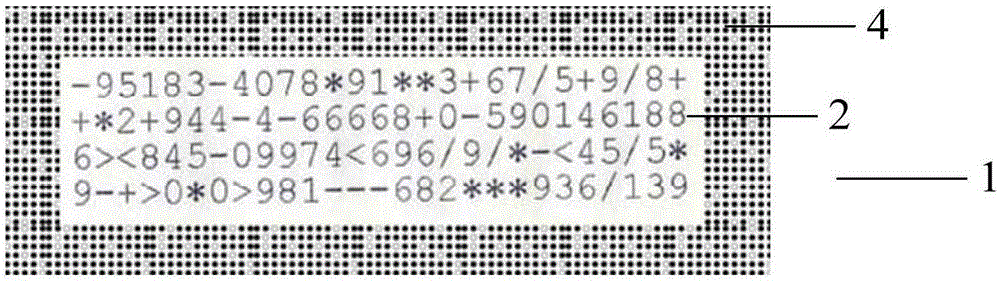

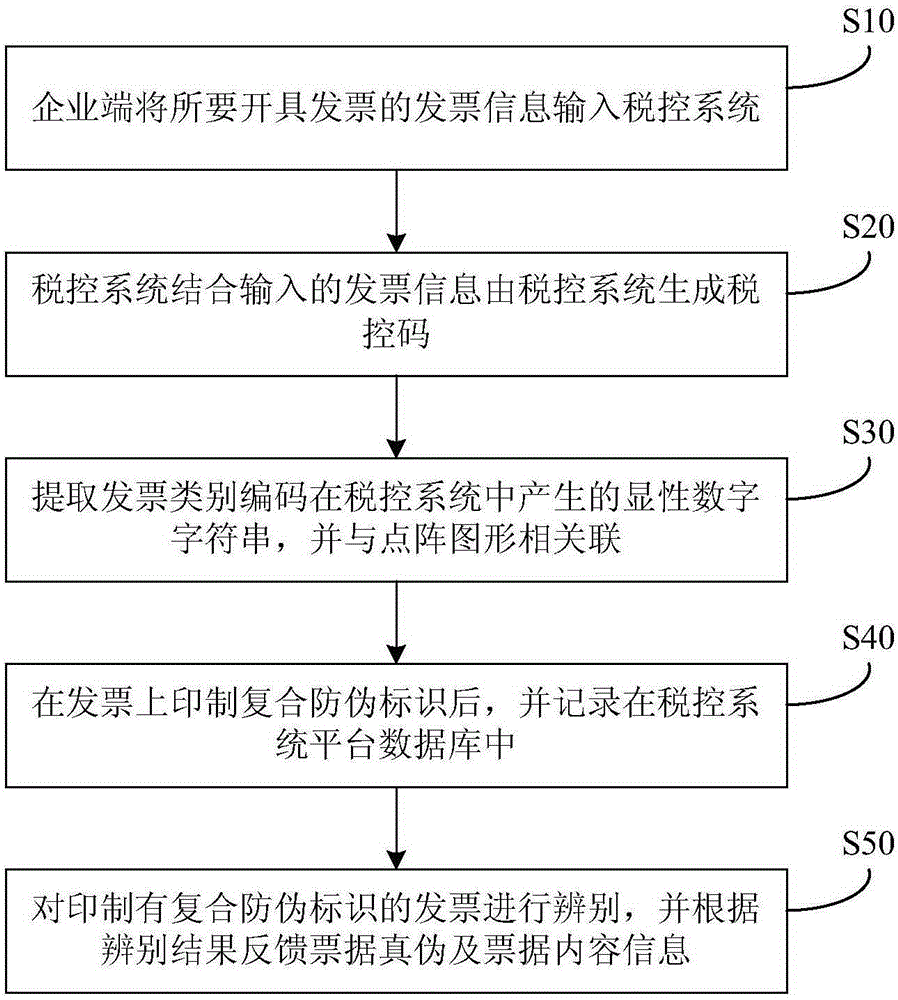

Method for generating and identifying anti-counterfeit marks formed by dot matrix and tax control code

ActiveCN103794136BWith anti-counterfeiting effectImprove anti-counterfeiting performanceStampsRecord carriers used with machinesGraphicsSquare Millimeter

The invention provides an anti-counterfeiting mark formed by dot matrixes and a tax-control code. The anti-counterfeiting mark is formed by a plurality of sets of dot matrix patterns and the tax-control code. The dot matrix patterns are distributed on the outer sides of the tax-control code. Each dot matrix pattern is in a designated shape and cannot be distinguished through naked eyes. The effective area of each dot matrix pattern is larger than or equal to 3*3 square millimeters, and each dot matrix pattern is formed by arraying at least one set of information points with the diameter ranging from 30 micrometers to 40 micrometers. A generation and identification method of the anti-counterfeiting mark includes the first step of inputting invoice information of an invoice to be issued into a tax control system, the second step of allowing the tax control system to generate the tax-control code, the third step of extracting a dominant figure character string of invoice class codes in the tax control system and enabling the dominant figure character string to be associated with the dot matrix patterns, the fourth step of printing the composite anti-counterfeiting mark on the invoice and recording the anti-counterfeiting mark in a platform database of the tax control system, and the fifth step of distinguishing the invoice printed with the anti-counterfeiting mark and feeding back the authenticity and the content information of the invoice according to the distinguishing result. According to the anti-counterfeiting mark, the tax-control code and the dot matrix patterns on the invoice are combined to form the composite anti-counterfeiting mark, so the antifalsification and reliability of the anti-counterfeiting mark are higher.

Owner:SUZHOU MAICHUANG INFORMATION TECH

a cover

ActiveCN103057831BSimple structureEasy to implementClosure with auxillary devicesEngineeringMechanical engineering

Owner:OSMUN BIOLOGICAL CO LTD

A cosmetic bottle with liner

ActiveCN103057825BSimple structureEasy to implementClosure with auxillary devicesPackaging toiletriesBottle capCosmetics

The invention relates to a cosmetic bottle with an inner container. The cosmetic bottle comprises a bottle cap, a pump, an inner container and a bottle body. The bottle body is fixedly connected with the inner container, and the pump is fixedly connected with the bottle cap and the inner container through a middle sleeve. The bottom cap consists of an inner cap and a shell which are fixedly connected, a groove in a circle is arranged on the lower portion of an inner ring of the inner cap and matched with a protrusion, the shell is composed of a top and a side wall, and the top is a concave lens. The upper surface of the inner cap protrudes upwards to form an arc-shaped protrusion, the outer surface of the arc-shaped protrusion is formed by a first spherical crown surface or connecting the first spherical crown surface with more than one spherical table surfaces, the height of the first spherical crown surface is smaller than or equal to the radius of the first spherical crown surface, and the outer surface of the arc-shaped protrusion appears in pearl color on the outer surface of the arc-shaped protrusion. The arc-shaped protrusion is arranged in an inner cavity of the shell, so that the arc-shaped protrusion can show a stereoscopic shape of a pearl on the top.

Owner:OSMUN BIOLOGICAL

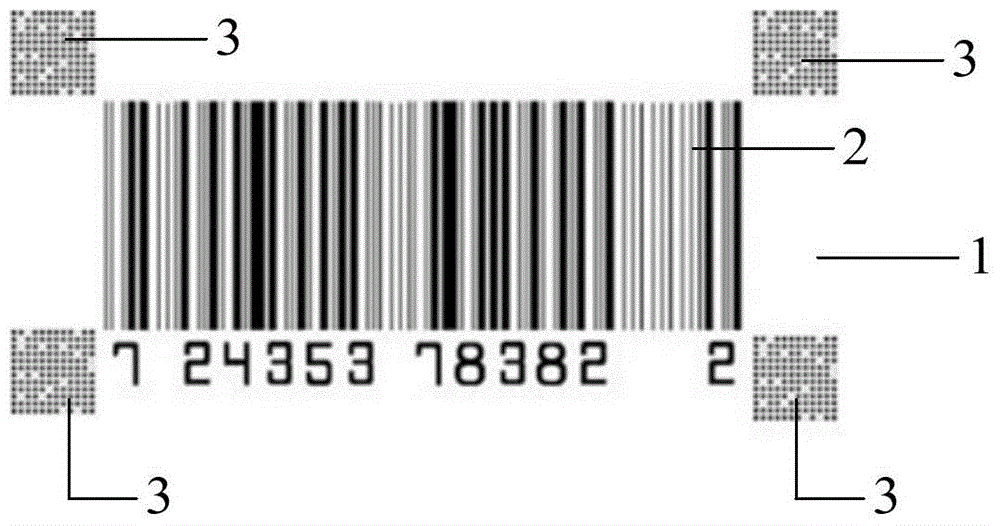

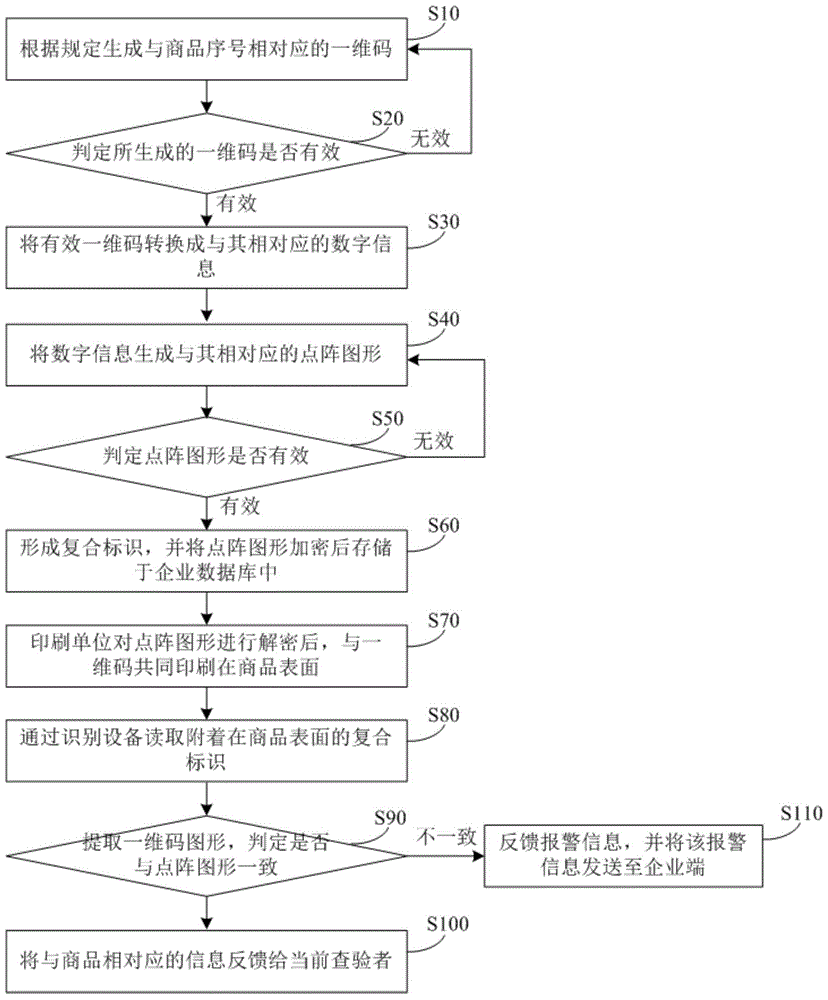

Method for generating and recognizing marks formed by dot matrix and one-dimensional code

ActiveCN103793736BWith anti-counterfeiting effectImprove anti-counterfeiting performanceRecord carriers used with machinesSensing by electromagnetic radiationGraphicsPattern recognition

The invention provides a mark formed by dot matrixes and a one-dimensional code. The mark is composed of a plurality of sets of dot matrix images and the one-dimensional code. The multiple sets of dot matrix images are distributed on the outer side of the one-dimensional code, are in assigned shapes and cannot be distinguished by naked eyes, and the effective area of the dot matrix images is not less than 3*3 square millimeters and is formed by arranging at least one set of information dots with the diameter ranging from 30 microns to 40 microns. The method for generating and recognizing the mark comprises the steps that the one-dimensional code is converted into the dot matrix image ID corresponding to the one-dimensional code, and the dot matrix images are generated through the dot matrix image ID; the dot matrix images are combined with the one-dimensional code to form a composite mark, and the dot matrix images are encrypted and stored; the surface of a product is printed with the composite mark, and the composite mark is read through a recognizing device; a one-dimensional image of the composite mark is extracted and converted into a digital information character string, the digital information character string is compared with the dot matrix image ID, and information is fed back according to a comparison result. Compared with an existing ordinary one-dimensional code, the generated composite mark has the anti-fake effect.

Owner:TAICANG DENASEN MECHANICAL & ELECTRICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com