Novel composite packaging material structure of see-through multilayer coextrusion color transformation film

A composite packaging material and multi-layer co-extrusion technology, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of singleness of packaging products, failure to highlight consistent color changes, and inability to highlight consistent color changes, etc., to achieve Enhance the effect of changing colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

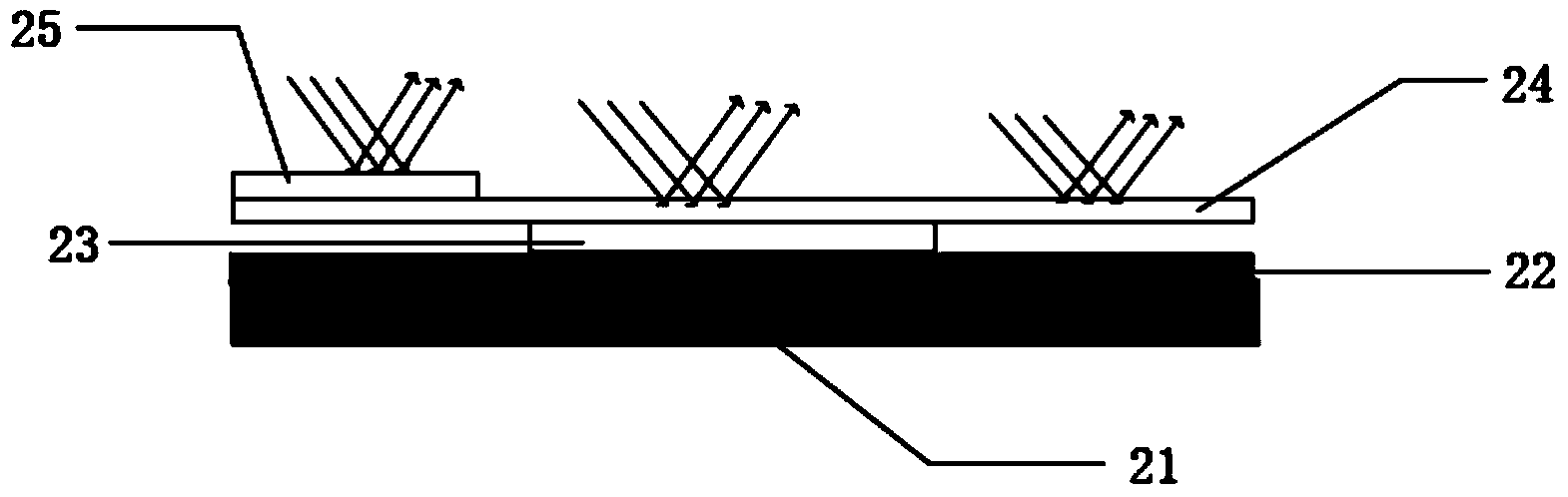

[0036] Such as figure 2 As shown, the white ink 23 is printed on the cardboard 21 of the aluminized film 22, then the printing surface is covered with a magic color film 24, and finally the yellow ink 25 is printed on the magic color film 24. When the light shines on the place with white ink, because the covering power of white ink is very strong, it will prevent the reflective degree of aluminum foil, so the packaging material in the place with white ink mainly shows a magic color. When the light shines on the place where there is no white ink, the packaging material is almost entirely silver. Where there is no lower white ink but an upper yellow ink layer, the packaging material is yellow with a silvery effect. Finally, the structure of packaging and decoration products with yellow with silver effect, outstanding metallic texture and outstanding effect of consistent changing colors is obtained.

Embodiment 2

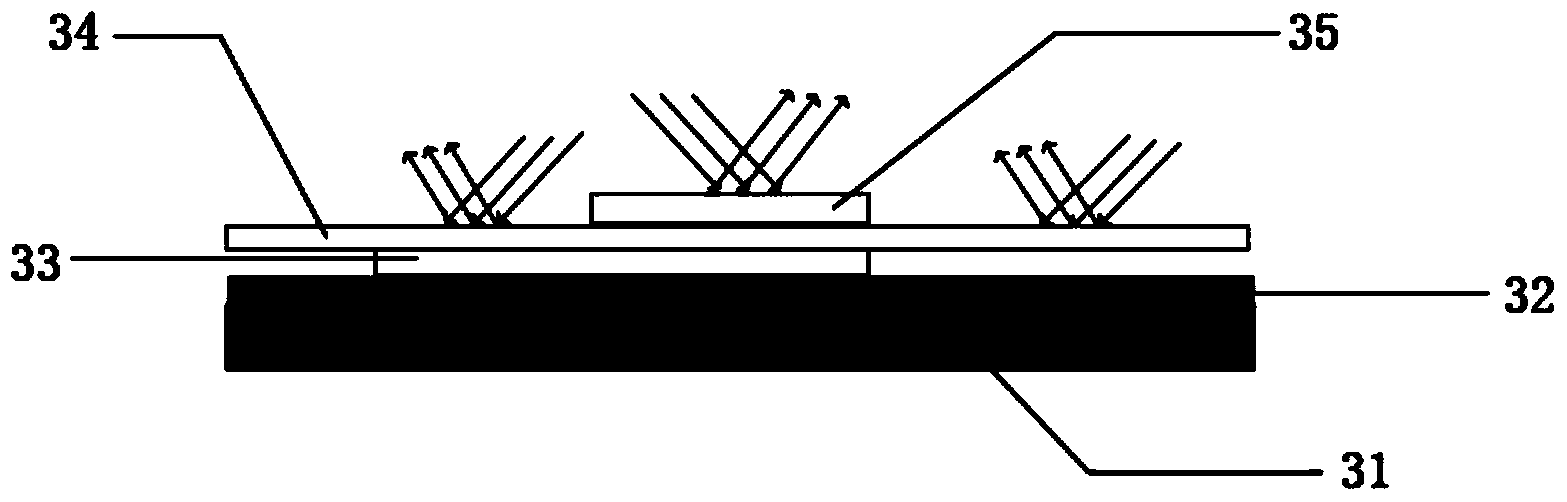

[0038] Such as image 3 As shown, part of the white ink 33 is printed on the transfer cardboard 31 of the transfer aluminum layer 32, and then the printing surface is covered with a magic film 34, and then a part of the blue ink 35 is printed on the magic film with the lower white ink. When the light shines on the place with the lower white ink but no upper blue ink layer, the main body presents the changing colors of the magic film. When the light hits the place where there is lower white ink and upper blue ink layer, the packaging material mainly presents a blue color with illusion effect. When the light shines on the area where there is neither white ink nor white ink, the packaging material is almost entirely silver of aluminum foil. Finally, the structure of packaging and decoration products with blue color, outstanding metallic texture and outstanding effect of consistent color is obtained.

Embodiment 3

[0040] Such as Figure 4 Shown, print part of white ink 43 on the cardboard 41 of aluminized film 42, then cover iris film 44 on the printing surface, then print part of white ink 46 on iris film 44, finally print red ink 45 on white ink 46. When the light shines on the place where there are white ink on the top and bottom but no upper layer of red ink, the packaging material appears white; when the light shines on the place where there are white ink on the upper and lower layers and the upper layer of red ink, the main effect is red; when the light When the light shines on the place where there is white ink on the bottom and no white ink on the top and no red ink layer on the top, the packaging material mainly shows changing colors; when the light shines on the place where there is no white ink on the top and bottom, the packaging material almost shows the silver color of aluminum foil. Finally, the structure of packaging and decoration products with red effect, prominent met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com