Production process of aluminum plate for three-dimensional pattern anti-counterfeiting wine cap

A technology of three-dimensional pattern and production process, which is applied to the device for coating liquid on the surface, magnetic paint, coating and other directions, can solve the problems of no anti-counterfeiting means and poor anti-counterfeiting ability in the production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

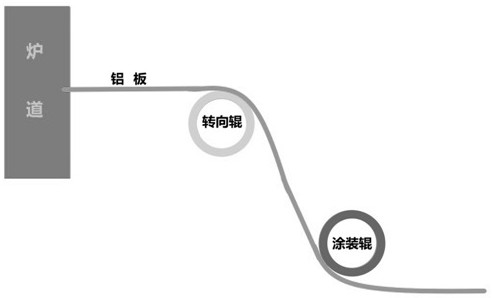

[0020] In order to better understand and implement, the following is combined with the attached Figure 1-2 To further describe the present invention: a production process of an aluminum plate for anti-counterfeit wine caps with three-dimensional patterns, including the following process steps:

[0021] 1) Prepare soft magnetic rubber coils. The thickness of the magnetic rubber is 1mm and the width is 1.2-1.5m. limitation;

[0022] 2) Cut the soft magnetic rubber coil to the required size according to the required size of the steering roller of the coating unit;

[0023] 3) Wrap the soft magnetic rubber coil on the steering roller of the coating unit;

[0024] 4) Put the aluminum coils required for the production of wine caps on one of the coating heads of the coating line, first coat and dry them with colored paint as a primer, and use them as the background color of the three-dimensional pattern. The aluminum coils can be selected One of 8011H16\5052H16\3014H24 aluminum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com