Anti-fake package paperboard and its producing method and device

A technology of anti-counterfeiting packaging and anti-counterfeiting paper, applied in chemical instruments and methods, paper, papermaking, etc., can solve the problems of poor gloss, low grammage, color offset printing, etc., and achieve good printing effect, easy recognition, and high gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

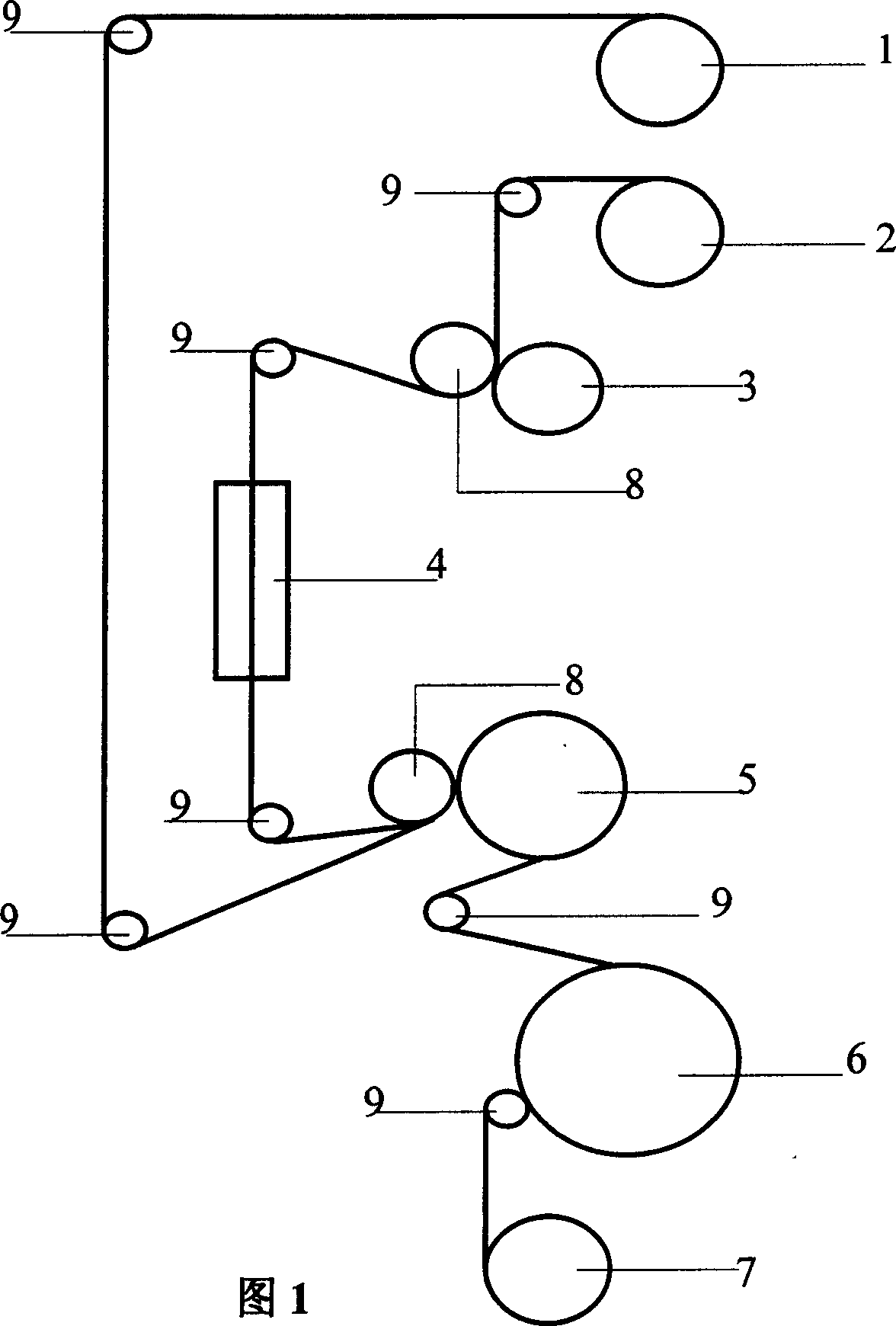

[0017] As shown in the figure, the anti-counterfeiting packaging board is made through the following process:

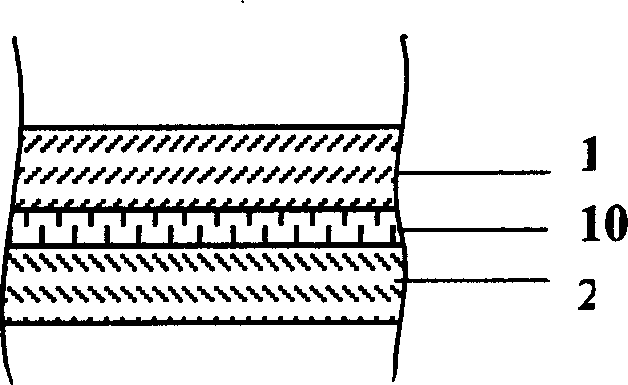

[0018] Put the cardboard layer 2 through the guide roller 9 to the glue applicator 3 and the pressure roller 8 to apply a layer of glue to form the glue layer 10 on the cardboard layer 2, and dry the moisture to about 80% through the guide roller 9 and the air flotation hot air dryer 4 , and then pass through the anti-counterfeit paper layer 1 of two guide rollers 9 after the guide roller 9, and enter the heating and shaping through the pressure roller 8 and the drying cylinder drier 5 simultaneously, and then pass through the guide roller 9 and then pass through the cooler 6 for cooling and setting. Form single-sided anti-counterfeiting packaging board 7, such as figure 2 shown.

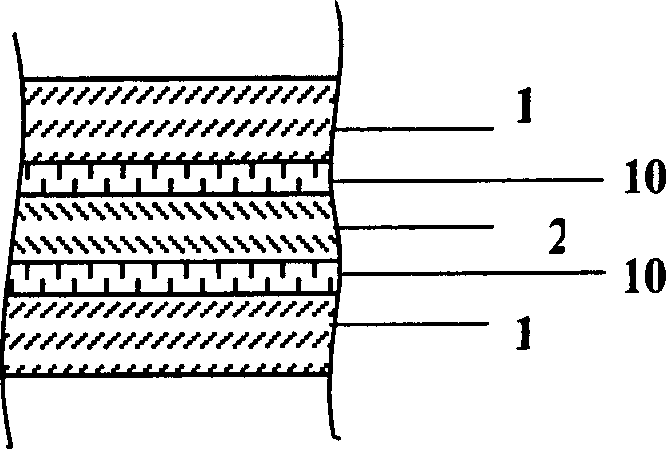

[0019] Such as image 3 As shown: the cardboard surface 2 of the above single-sided anti-counterfeiting wrapping paper 7 needs to be turned over to make the cardboard layer 2, and then g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com