Tipping paper for cigarette and production technology thereof

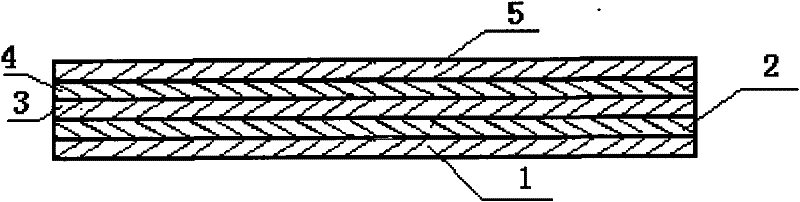

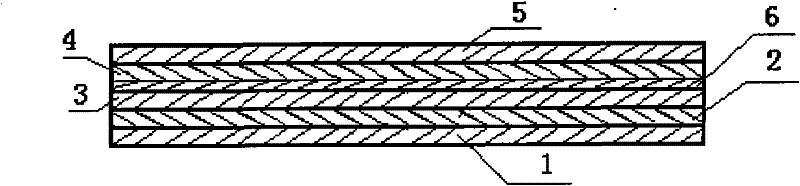

A cigarette tipping paper and production process technology, which is applied to wrapping paper, wrapping paper, filter paper, etc., can solve the problems of pinholes, easy gold off, missing ironing, etc., to increase surface color, overcome gold off, The effect of strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

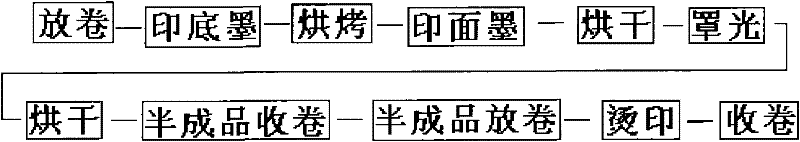

[0029] a. The base paper is unrolled, and the unwinding tension is controlled at 6N; the unwinding machine speed is controlled at 105m / min;

[0030] b. Printing base ink, printing pressure 0.3MPa;

[0031] c. Bake at a temperature of 92°C;

[0032] d. Use electrostatic ink absorption to color the printing surface ink, the printing pressure is 0.3MPa, the printing ink viscosity is 13s, and the printing plate roller is a laser engraving plate roller;

[0033] e. Bake at a temperature of 92°C;

[0034] f. The surface of the face ink is covered with varnish oil;

[0035] g. Drying, the oven temperature is set at 42°C, and the baking time is 0.7s;

[0036] h. Rewinding of semi-finished products, the winding tension is controlled at 5N, and the speed of the winding machine is synchronized with the speed of the unwinding machine;

[0037] i. Unwinding of semi-finished products, the unwinding tension is controlled at 12N, and the unwinding machine speed is controlled at 70m / min; ...

Embodiment 2

[0042] a. The base paper is unrolled, and the unwinding tension is controlled at 15N; the unwinding machine speed is controlled at 138m / min;

[0043] b. Printing base ink, printing pressure 0.4MPa;

[0044] c. Bake at a temperature of 100°C;

[0045] d. Use electrostatic ink absorption to color the printing surface ink, the printing pressure is 0.4MPa, the printing ink viscosity is 14s, and the printing plate roller is a laser engraving plate roller;

[0046] e. Baking, the temperature is 100°C;

[0047] f. The surface of the face ink is covered with varnish oil;

[0048] g. Drying, the oven temperature is set at 50°C, and the baking time is 0.4s;

[0049] h. Rewinding of semi-finished products, the winding tension is controlled at 6N, and the speed of the winding machine is synchronized with the speed of the unwinding machine;

[0050] i. Unwinding of semi-finished products, the unwinding tension is controlled at 13N, and the unwinding machine speed is controlled at 78m / m...

Embodiment 3

[0055] Such as Figure 4 As shown, the steps are substantially the same as those in Example 2, except that the characters and patterns are printed while printing the surface ink in step d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com