Process for preparing printing artificial flocking paper

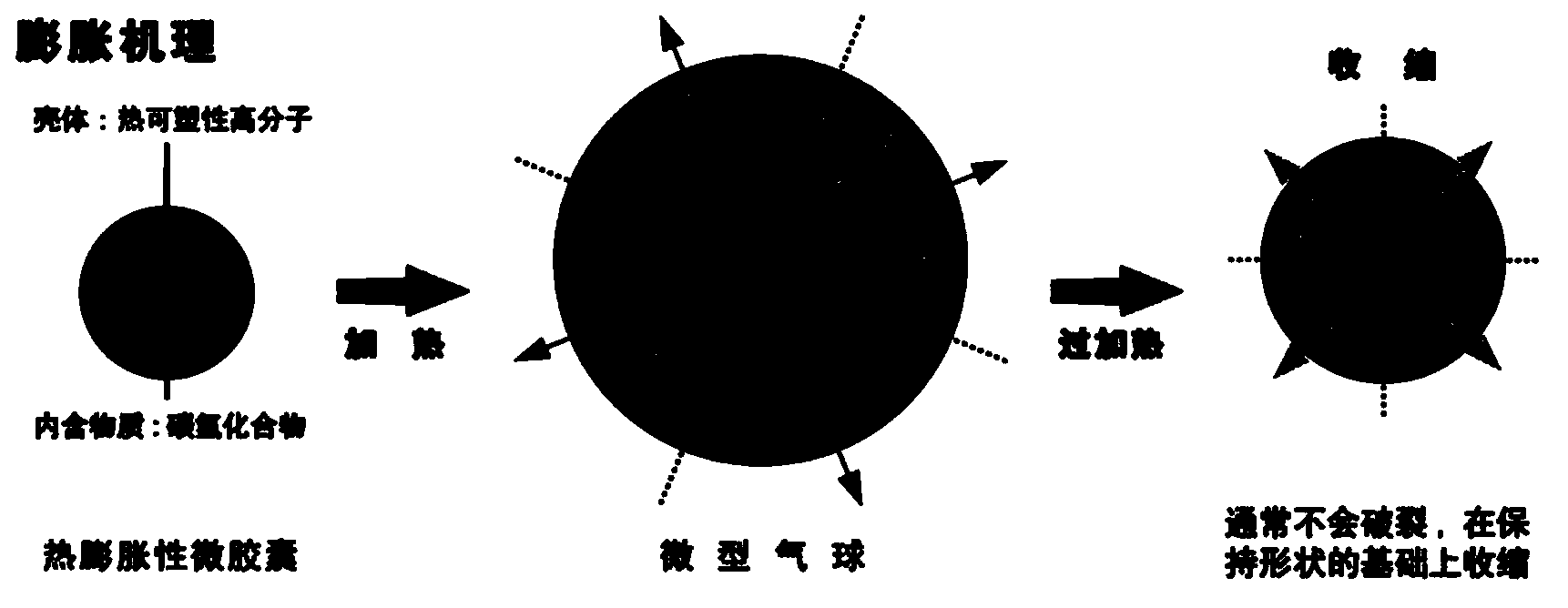

A technology imitating flocking and paper, applied in paper, special paper, papermaking, etc., can solve the problems of discoloration, deformation, burning, etc., and achieve the effect of low foaming temperature, good adhesion of finished products, and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 300g green self-drying ink (mix 150g of YS-200 self-drying yellow and 150g of YS-300 self-drying red from Dongguan Quanyin Rhenium Chemical Co., Ltd. to obtain 300g self-drying green ink.), 100g PET light Oil and 4g of low-temperature expansion microsphere foaming agent (manufacturer: Matsumoto Yushi Pharmaceutical Co., Ltd., model F-36D) were mixed, and stirred evenly to obtain a mixed material; the mixed material was screen-printed (200-mesh screen was selected, and bamboo patterns were used to make silk) screen) on the paper material, cured at 80°C (ultraviolet lamp power is 1000W*2, drying tunnel running speed is 5R / min) for 5 seconds, and green printed imitation flocking paper with bamboo pattern is obtained.

Embodiment 2

[0024] Mix 300g of yellow self-drying color ink (the model of Dongguan Quanyin Rhenium Chemical Co., Ltd. is YS-200 self-drying yellow), 300g of PET varnish and 300g of low-temperature expansion microsphere foaming agent (manufacturer: Matsumoto Yushi Pharmaceutical Co., Ltd., Model F-36D) mixed and stirred evenly to obtain the mixed material; screen-print the mixed material (select 200-mesh screen, use the chrysanthemum pattern to make the screen plate) on the paper material, and cure it at 90°C (the power of the ultraviolet lamp is 1000W*2 pieces , the speed of the drying tunnel is 5R / min) for 4.5 seconds, and the yellow printed imitation flocking paper with the chrysanthemum pattern is obtained.

Embodiment 3

[0026] Mix 300g of white self-drying ink (the model of Dongguan Quanyin Rhenium Chemical Co., Ltd. is YS-1100 self-drying white), 400g of PET varnish and 560g of low-temperature expansion microsphere foaming agent (manufacturer: Matsumoto Yushi Pharmaceutical Co., Ltd., Model F-36D) mixed and stirred evenly to obtain the mixed material; screen-print the mixed material (select 200-mesh screen, use snowflake pattern to make a screen plate) on the paper material, and cure at 100°C (ultraviolet lamp power is 1000W*2 , the speed of the drying tunnel is 5R / min) for 4 seconds, and the white printed imitation flocking paper with snowflake pattern is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com