Tobacco-stem-coated white card paper and preparation method and application thereof

A cloth white card and tobacco stem technology, applied in the field of papermaking, can solve the problems of paper machine not being able to make paper normally, adverse effects of paper strength, excessive organic volatile content, etc., so as to solve difficult control of water absorption value, improve retention rate and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

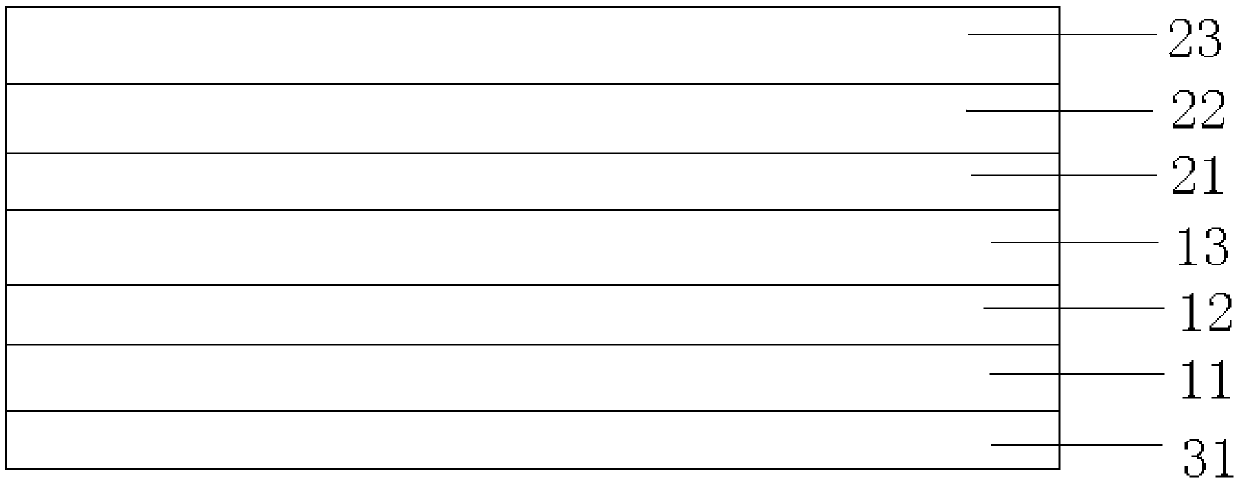

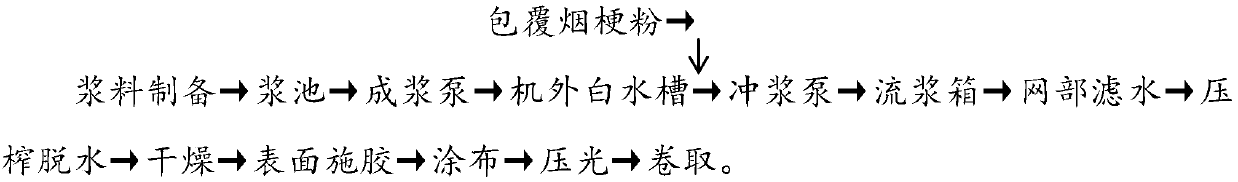

[0027] A preparation method for tobacco stem coated white cardboard, comprising the following steps:

[0028] S1. Taking tobacco stem powder with a particle size of 1-200 μm, adding water to prepare a suspension, and then performing leaching and / or pressure filtration on the suspension;

[0029] S2, taking the tobacco stem powder treated in step S1 and performing cationic starch coating treatment;

[0030] S3. After mixing the tobacco stem powder coated in the step S2 with the pulp slurry, the tobacco stem coated white cardboard is prepared through pulp distribution, water filtration, dehydration by pressing, drying, and coating.

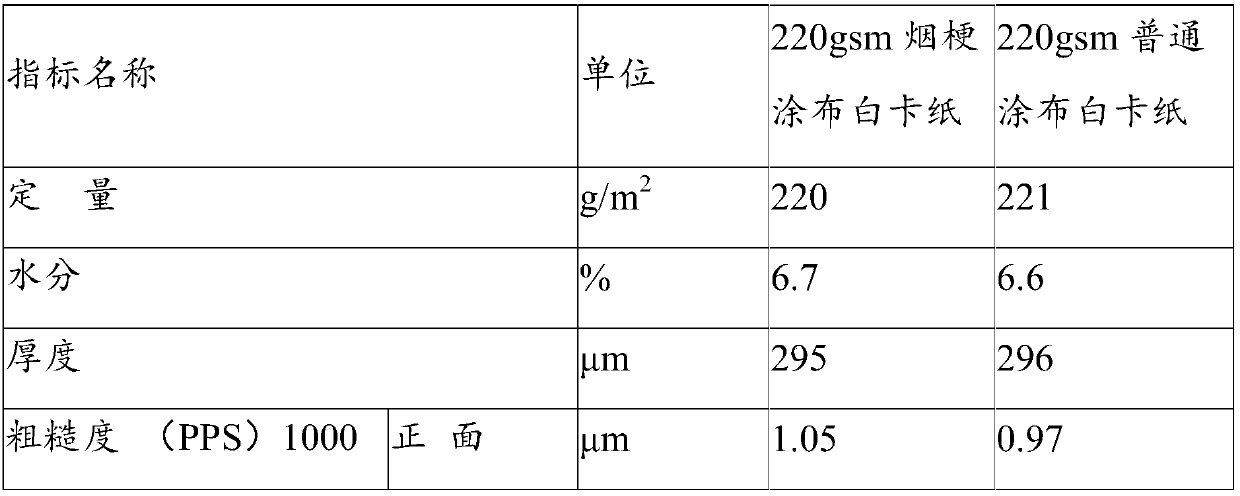

[0031] From the above description, it can be seen that the beneficial effect of the present invention lies in that the scheme of the present invention adds recycled tobacco stem powder to the pulp slurry, which reduces the production cost, and at the same time, the coated white cardboard added with tobacco stem powder also has an anti-counterfeiting...

Embodiment 1

[0058] Embodiment 1 of the present invention is: a kind of preparation method of tobacco stem coated white cardboard, comprises the following steps:

[0059] 1), the preparation and processing of tobacco stem powder: the control of the particle size of tobacco stem powder is by grinding the tobacco stem powder to a particle size of 180-200 μm; the tobacco stem powder is pretreated to remove organic matter, and the tobacco stem powder is diluted with water to prepare 10% solution, using a plate and frame filter press to filter; the tobacco stem powder treated by the filter is then coated with cationic starch, specifically:

[0060] a. Preparation of tobacco stem powder particle size control: the dried tobacco stem raw material is pulverized and pulverized by a mill to make tobacco stem powder of 180-200 μm, wherein the dried tobacco stem raw material can be dried by hot air Drying, the moisture in the tobacco stem after drying is usually controlled to be 6-10%.

[0061] b. Tob...

Embodiment 2

[0077] Embodiment 2 of the present invention is: a preparation method of white cardboard coated with tobacco stems, which differs from Embodiment 1 of the present invention only in that the number of press filtrations is twice.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com