Method for preparing lanthanide series-based NaYF4 up-conversion luminescence ink and transparent anti-fake label

A technology of luminescent ink and lanthanide series, applied in ink, identification device, instrument and other directions, can solve the problems of restricting the application of rare earth up-conversion luminescent ink, high cost of converting luminescent ink, poor anti-counterfeiting effect, etc., to achieve high anti-counterfeiting performance, high Concealment and anti-counterfeiting, high transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

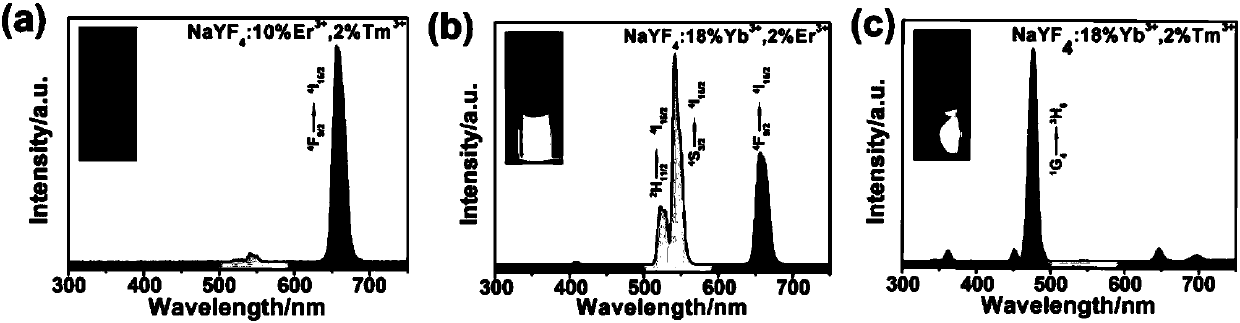

[0027] Embodiment 1 of the present invention relates to lanthanide NaYF 4 Preparation of up-conversion red luminescent ink and preparation method of transparent anti-counterfeiting label. The details are as follows: 1) First, 2 mmol of sodium citrate is dissolved in 10 mL of aqueous solution, and it is completely dissolved under magnetic stirring (400 rpm), and then 1 mmol of rare earth chloride (Y:Er:Tm=88%:10 %: 2%) is dissolved in the water of 5ml, is slowly added dropwise in the above-mentioned solution to obtain mixed solution, then the oleic acid of 10ml and 5ml ethylene glycol are added to mixed solution. Finally, 1 ml of an aqueous solution in which 2.88 mmol of sodium chloride was dissolved and 4 ml of an aqueous solution in which 6 mmol of ammonium fluoride was dissolved were added dropwise in sequence. After stirring for 30 minutes, it was added and then transferred to a 50ml reaction kettle, and the reaction was continued for 6 hours in an oven at 180°C. The obta...

Embodiment 2

[0029] Embodiment 2 of the present invention relates to lanthanide NaYF 4 Preparation method of up-conversion green luminescent ink and transparent anti-counterfeit label. The details are as follows: 1) First, 2 mmol of sodium citrate is dissolved in 10 mL of aqueous solution, and it is completely dissolved under magnetic stirring (400 rpm), and then 1 mmol of rare earth chloride (Y:Yb:Er=80%:18 %: 2%) is dissolved in the water of 5ml, is slowly added dropwise in the above-mentioned solution to obtain mixed solution, then the oleic acid of 10ml and 5ml ethylene glycol are added to mixed solution. Finally, 1 ml of an aqueous solution in which 2.88 mmol of sodium chloride was dissolved and 4 ml of an aqueous solution in which 6 mmol of ammonium fluoride was dissolved were added dropwise in sequence. After stirring for 30 minutes, it was added and then transferred to a 50ml reaction kettle, and the reaction was continued for 6 hours in an oven at 180°C. The obtained precipitate...

Embodiment 3

[0031] Embodiment 3 of the present invention relates to lanthanide NaYF 4 Preparation method of up-conversion blue luminescent ink and transparent anti-counterfeit label. The details are as follows: 1) First, 2 mmol of sodium citrate is dissolved in 10 mL of aqueous solution, and it is completely dissolved under magnetic stirring (400 rpm), and then 1 mmol of rare earth chloride (Y:Yb:Tm=80%:18 %: 2%) is dissolved in the water of 5ml, is slowly added dropwise in the above-mentioned solution to obtain mixed solution, then the oleic acid of 10ml and 5ml ethylene glycol are added to mixed solution. Finally, 1 ml of an aqueous solution in which 2.88 mmol of sodium chloride was dissolved and 4 ml of an aqueous solution in which 6 mmol of ammonium fluoride was dissolved were added dropwise in sequence. After stirring for 30 minutes, it was added and then transferred to a 50ml reaction kettle, and the reaction was continued for 6 hours in an oven at 180°C. The obtained precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com