Method for preparing convex micro lens and method for manufacturing white light LED device

A micro-lens and convex technology, applied in the optical field, can solve the problems that the optical characteristics of the micro-lens cannot be well exerted, cannot achieve light emission, light conversion, filtering, and cannot obtain the aspect ratio, etc., and achieve unique optical performance and cost. low, good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

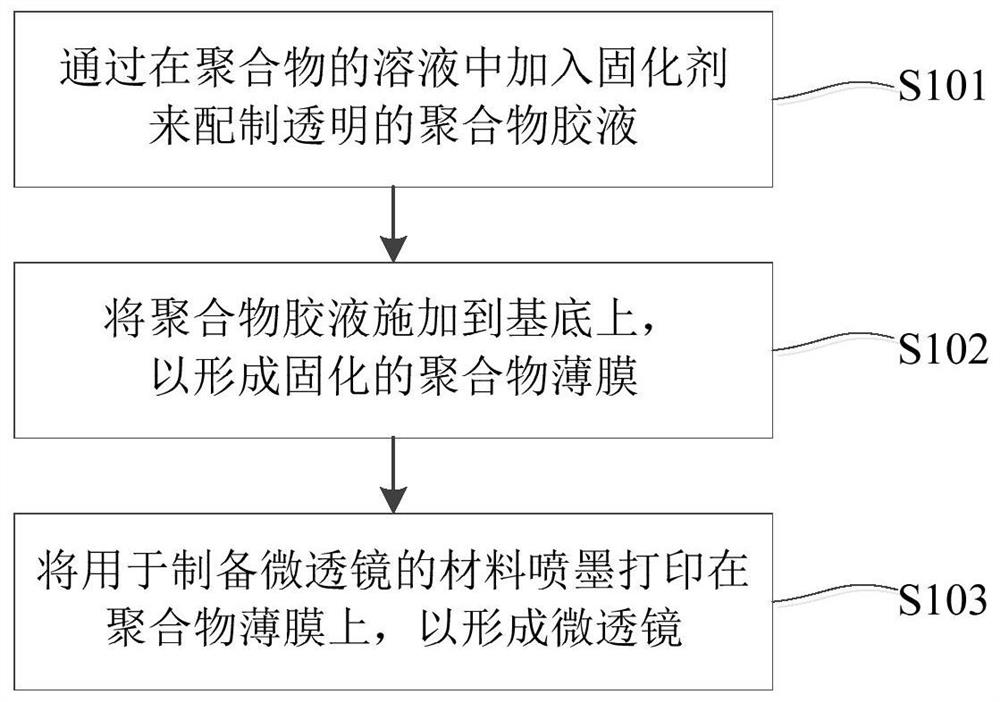

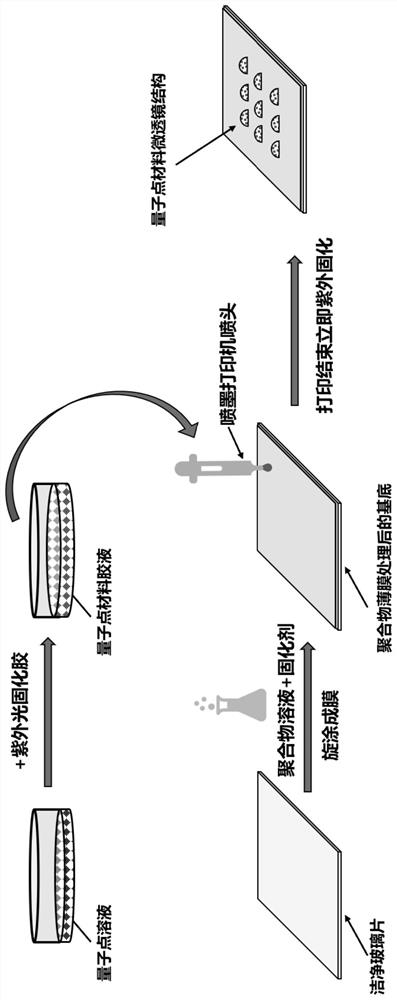

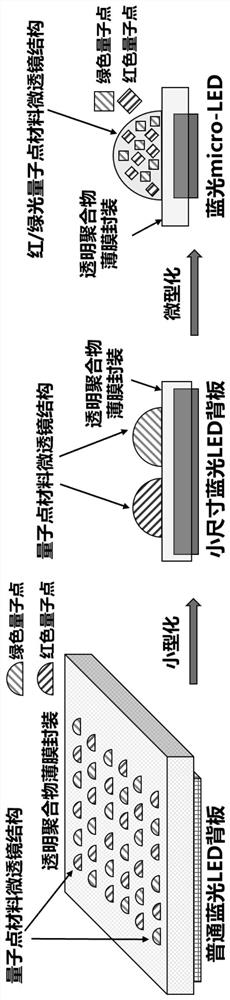

[0039] On the basis of the above method for preparing convex microlenses, the present invention also provides a method for preparing a microlens structure based on quantum dot materials. The quantum dot material is mixed into the ultraviolet light curing glue, and the microlens structure is directly printed on the specially treated substrate by inkjet printing to realize the fluorescent quantum dot microlens array, so that the quantum dot material and the microlens structure realize The one-step combination brings into play the excellent characteristics of quantum dot materials and the unique optical performance of the microlens structure. figure 2 The process flow chart of preparing the quantum dot material microlens structure is exemplarily shown. The method may mainly include the following steps.

[0040] Quantum dot solutions with high quantum yields and different wavelengths of light are synthesized by using relatively mature methods known in the art (such as microemuls...

example 1

[0053] Preparation of polymer glue: Dissolve 0.32g of PAN polymer powder in 1.4ml of DMF, and stir at room temperature for more than 3 hours using a magnetic stirrer to obtain a clear and transparent polymer glue.

[0054] The above polymer glue was spin-coated on a 2.5cm×2.5cm clean glass sheet at a speed of 1000 rpm using a homogenizer, and dried on a temperature controller at 80°C for 30min to obtain a polymer film with good flatness. And test the contact angle of the printed material on its surface.

[0055] Place the glass sheet treated with the polymer film on the MicroplotterⅡ (Sonoplot high-precision micro-nano material deposition inkjet printing system) printing platform, and print the UV-curable glue (Fanli 3217, Shenzhen Feili Electronic Commerce Co., Ltd.), Print a 5×5 microlens array with a preset pattern. Immediately after printing, use a 365nm hand-held UV lamp (1.3W, Trident, Ningbo Hongyi Electronics) to irradiate the printed area vertically for 30 seconds, an...

example 2

[0057] Preparation of polymer glue: Dissolve 0.25g of PVDF polymer powder in 1.4ml of DMF, and stir at room temperature for more than 3 hours with a magnetic stirrer to obtain a clear and transparent polymer glue.

[0058] The above polymer glue was spin-coated on a 2.5cm×2.5cm clean glass sheet at a speed of 1000 rpm using a homogenizer, and dried on a temperature controller at 80°C for 30min to obtain a polymer film with good flatness. And test the contact angle of the printed material on its surface.

[0059] Place the glass sheet treated with the polymer film on the MicroplotterⅡ (Sonoplot high-precision micro-nano material deposition inkjet printing system) printing platform, and print the UV-curable glue (Fanli 3217, Shenzhen Feili Electronic Commerce Co., Ltd.), Print a 5×5 microlens array with a preset pattern. Immediately after printing, use a 365nm hand-held UV lamp (1.3W, Trident, Ningbo Hongyi Electronics) to irradiate the printed area vertically for 30 seconds, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com