Polyacrylic acid rare earth fluorescent gel and preparation method thereof

A polyacrylic acid and rare earth fluorescence technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limiting the types and applications of polyacrylic acid gels, inability to form instability, and excessively strong electrostatic interaction with mineral salts. To achieve the effect of easy operation, simple preparation and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of polyacrylic rare earth fluorescent gel, its preparation method comprises the steps:

[0032] At room temperature, configure a total of 40 mL of a mixed aqueous solution containing 0.3 mol / L polyacrylic acid (molecular weight: 250 000) and 0.1 mol / L terbium chloride. Under vigorous stirring (stirring speed is 600 rpm), 10 mL of 0.1 mol / L sodium carbonate The aqueous solution was dripped into the mixed solution at a rate of 0.1 mL / min, and a milky white gel was gradually formed. The resulting gel was repeatedly washed with deionized water to obtain a pure polyacrylic acid rare earth composite gel.

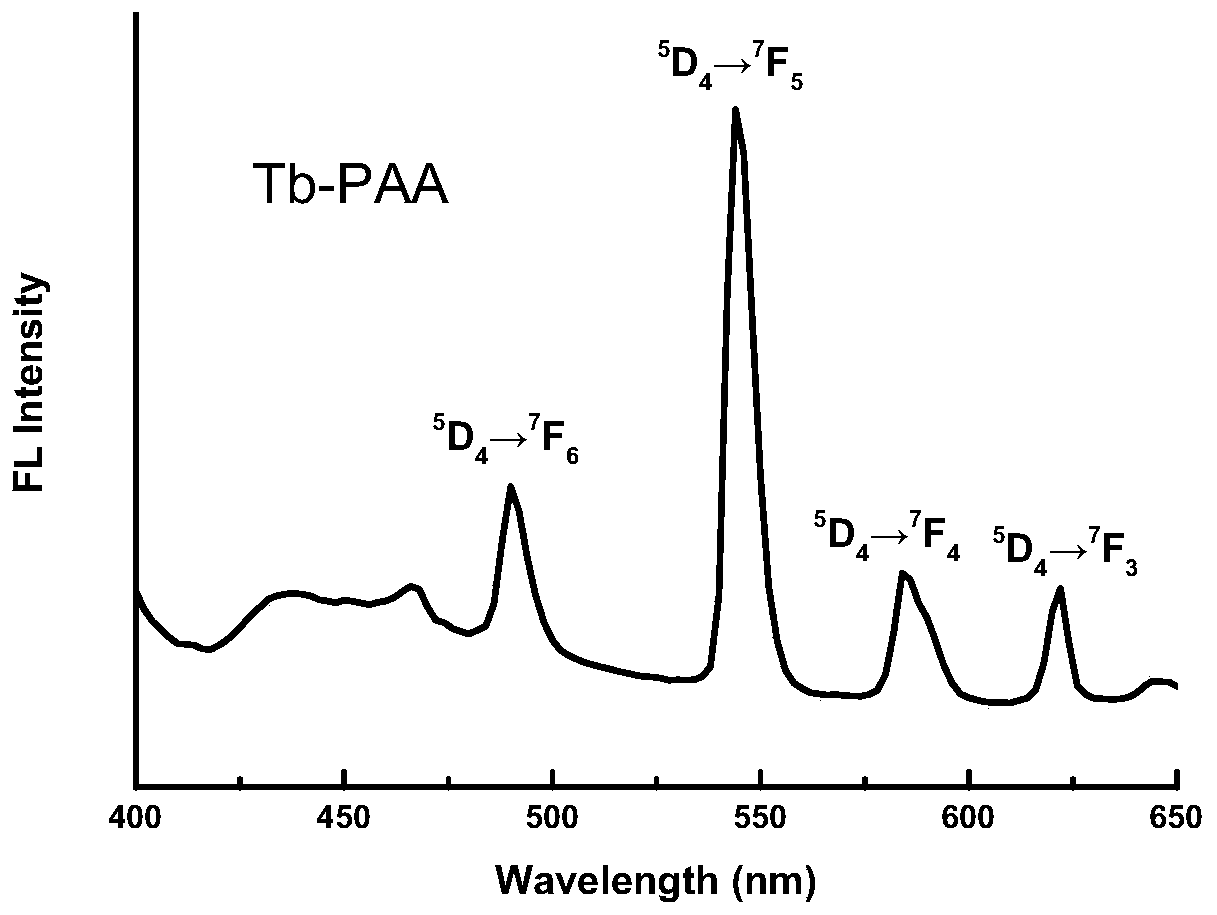

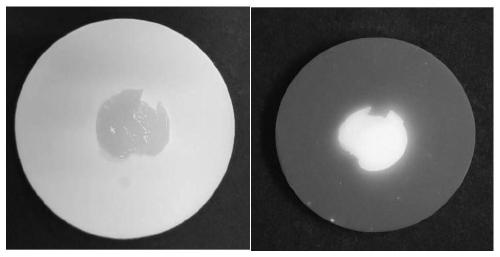

[0033] figure 1 It is the optical picture of the gel prepared in this embodiment under visible light and the optical picture under the excitation of 365nm ultraviolet light; from figure 1 It can be seen that the gel produced bright and uniform green fluorescence under UV light excitation.

[0034] Figure 4 It is the emission spectrogram of the gel prepared by th...

Embodiment 2

[0036] A kind of polyacrylic rare earth fluorescent gel, its preparation method comprises the steps:

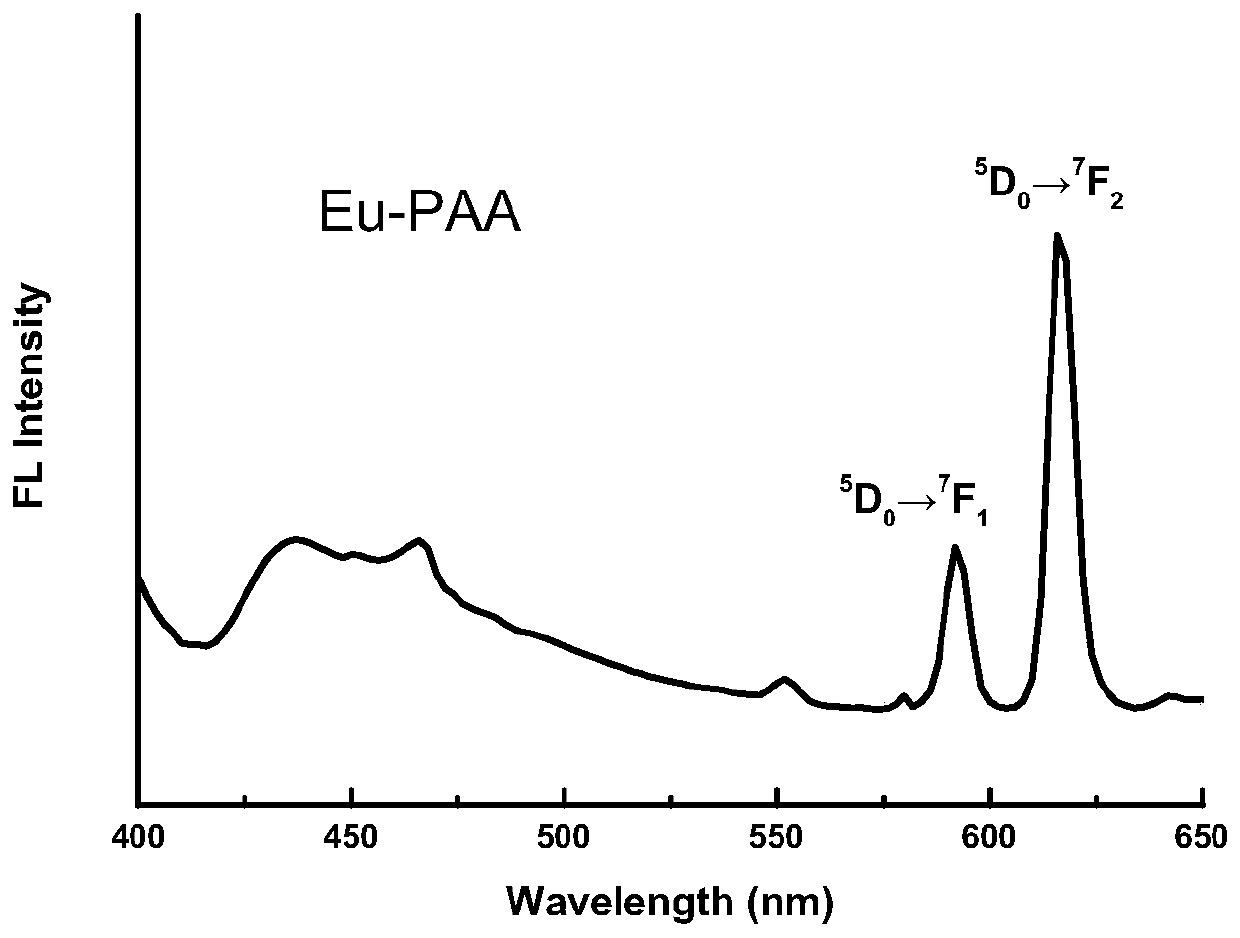

[0037] Under room temperature conditions, configure a total of 40 mL of a mixed aqueous solution containing 0.3 mol / L polyacrylic acid (molecular weight 250 000), 0.1 mol / L europium chloride, and 10 mL of 0.1 mol / L sodium carbonate aqueous solution under vigorous stirring (stirring speed is 600 rpm) Drop it into the mixed solution at a rate of 0.1mL / min, and gradually form a milky white gel. The resulting gel was repeatedly washed with deionized water to obtain a pure polyacrylic acid rare earth composite gel.

[0038] figure 2 It is the optical picture of the gel prepared in this embodiment under visible light and the optical picture under the excitation of 365nm ultraviolet light; from figure 2 It can be seen that the gel produced bright and uniform red fluorescence under UV light excitation.

[0039] image 3 It is the optical picture of the gel prepared in this exam...

Embodiment 3

[0042] A kind of polyacrylic rare earth fluorescent gel, its preparation method comprises the steps:

[0043] Under room temperature conditions, configure a total of 40 mL of a mixed aqueous solution containing 0.5 mol / L polyacrylic acid (molecular weight 250 000), 0.1 mol / L lanthanum chloride, and 20 mL of 0.1 mol / L sodium carbonate aqueous solution under vigorous stirring (stirring speed is 600 rpm) Drop it into the mixed solution at a rate of 0.1mL / min, and gradually form a milky white gel. The resulting gel was repeatedly washed with deionized water to obtain a pure polyacrylic acid rare earth composite gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com