Nickel cobalt lithium manganate positive electrode material and preparation method thereof, lithium ion battery positive electrode slurry, lithium ion battery positive electrode and lithium ion battery

A technology of lithium-nickel-cobalt-manganese-manganese-oxide and lithium-ion batteries, applied in nickel-cobalt-lithium-manganese-oxide cathode materials and its preparation, and in the field of lithium-ion battery cathodes. Performance and other issues, to achieve the effect of reducing impedance, increasing layer spacing, improving structural stability and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

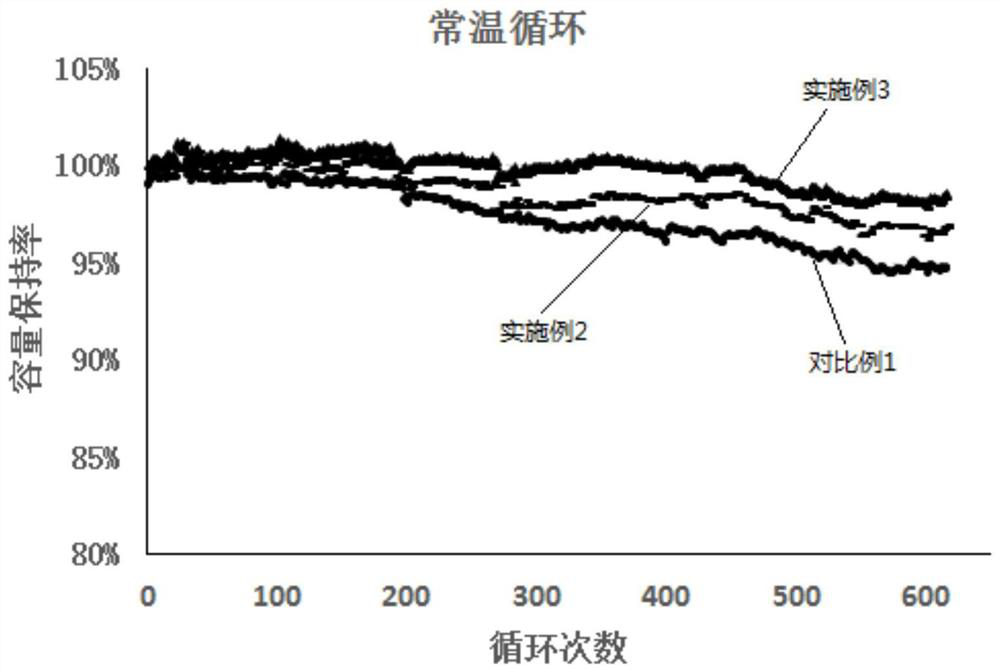

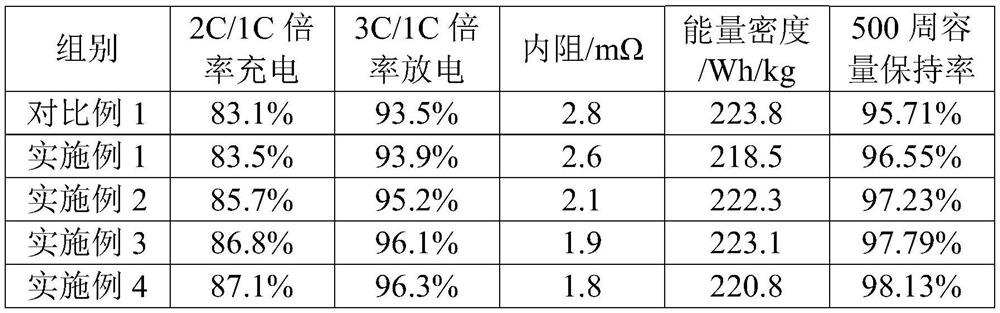

Examples

Embodiment 1

[0064] Preparation of nickel cobalt lithium manganese oxide cathode material:

[0065] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O is mixed and placed in a beaker according to the molar ratio of 0.6:0.2:0.19, and dissolved in deionized water to obtain a solution with a metal ion concentration of 1.5mol / L;

[0066] Slowly add 3.0mol / L NaOH solution and 1.2mol / L ammonia water into the above solution according to the volume ratio of 1:1, adjust the pH to 10, stir in a 50°C water bath until the precipitation is complete, and wash it with deionized water several times at the same time; Soak the obtained precipitate in absolute ethanol for 1 hour, and then dry the precipitate in a constant temperature vacuum box at 85°C for 12 hours to obtain the nickel cobalt lithium manganese oxide cathode material precursor Ni 0.6 co 0.2 mn 0.19 (OH) 2 .

[0067] Mix the precursor of nickel cobalt lithium manganese oxide positive electrode material and basic copper carbonate according...

Embodiment 2

[0074] Preparation of nickel cobalt lithium manganese oxide cathode material:

[0075] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O is mixed and placed in a beaker according to the molar ratio of 0.6:0.2:0.18, and dissolved in deionized water to obtain a solution with a metal ion concentration of 1.5mol / L;

[0076] Slowly add 2.0mol / L NaOH solution and 1.5mol / L ammonia water into the above solution according to the volume ratio of 1:3, adjust the pH to 12, stir in a 40°C water bath until the precipitation is complete, and wash it with deionized water several times at the same time; Soak the obtained precipitate in absolute ethanol for 1.5h, and then dry the precipitate in a constant temperature vacuum box at 80°C for 14h to obtain the nickel cobalt lithium manganese oxide cathode material precursor Ni 0.6 co 0.2 mn 0.18 (OH) 2 .

[0077] Mix the precursor of nickel cobalt lithium manganese oxide positive electrode material and basic copper carbonate according to the...

Embodiment 3

[0084] Preparation of nickel cobalt lithium manganese oxide cathode material:

[0085] NiSO 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O is mixed and placed in a beaker according to the molar ratio of 0.6:0.2:0.14, and dissolved in deionized water to obtain a solution with a metal ion concentration of 2.0mol / L;

[0086] Slowly add 4.0mol / L NaOH solution to the above solution, adjust the pH to 11, stir in a 60°C water bath until the precipitation is complete, and wash it with deionized water several times at the same time; place the obtained precipitate in absolute ethanol for soaking 0.5h, and then put the precipitate in a constant temperature vacuum oven at 100°C and dry for 10h to obtain the nickel cobalt lithium manganese oxide cathode material precursor Ni 0.6 co 0.2 mn 0.14 (OH) 2 .

[0087] Mix the precursor of nickel cobalt lithium manganese oxide positive electrode material and basic copper carbonate according to the molar ratio of 1:0.06 for ball milling, then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com