Method for manufacturing scratchable laser holography anti-fake foil

A production method, laser holographic technology, applied in chemical instruments and methods, decorative arts, special decorative structures, etc., can solve the problems of single function, weak anti-counterfeiting function, easy counterfeiting, etc. The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

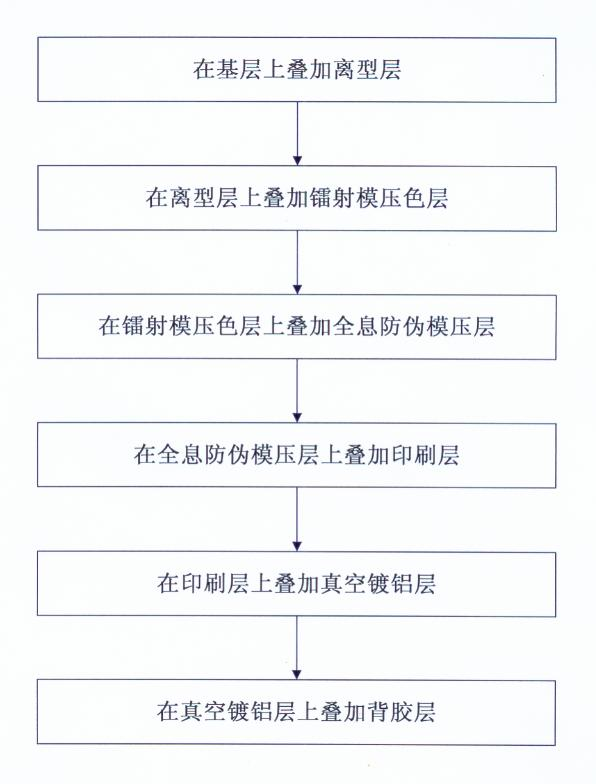

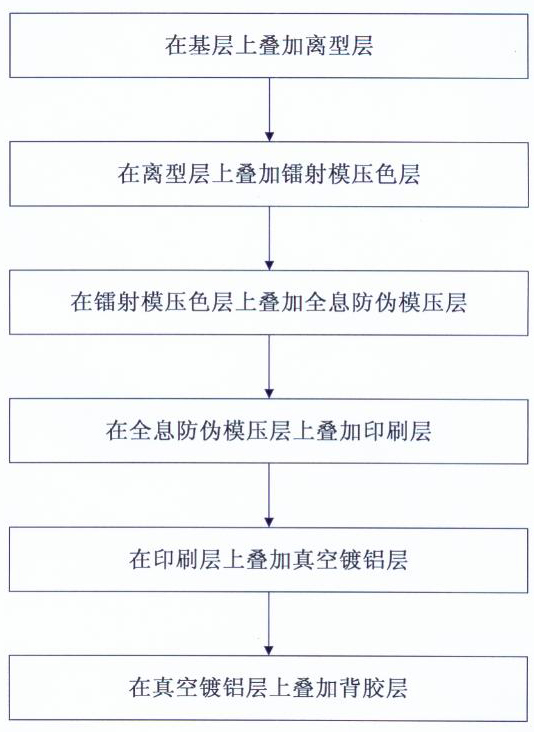

[0028] see figure 1 , a scratchable laser holographic anti-counterfeiting foil manufacturing method of the present invention comprises the following steps:

[0029] (1) Superimpose the release layer on the base layer: After dissolving the high-brightness and transparent synthetic solid wax with a solvent, it is evenly coated on the polyester film by an anilox roller, and dried in a five-stage oven. The temperature sequence of the five-stage oven is 100°C-110°C-120°C-130°C-120°C, the pressure is 20pa, and the speed is 150m / min.

[0030] (2) Superimpose the laser molded color layer on the release layer: evenly coat the dissolved resin on the surface of the release layer through an anilox roller, and bake and dry in a five-stage oven. The temperature sequence of the five-stage oven is 110°C-120°C-130°C-140°C-150°C, the pressure is 20pa, and the speed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com