Manufacturing method of tank top steel skin plate of large-scale stainless steel tank

A manufacturing method and a technology for a skin plate, which are applied in the field of tank roof manufacturing, can solve the problems of slow manufacturing of tank roofs, poor forming degree of tank roofs, inconvenient manufacturing of tank roofs, etc. Good, beautiful appearance, ensure the effect of radian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

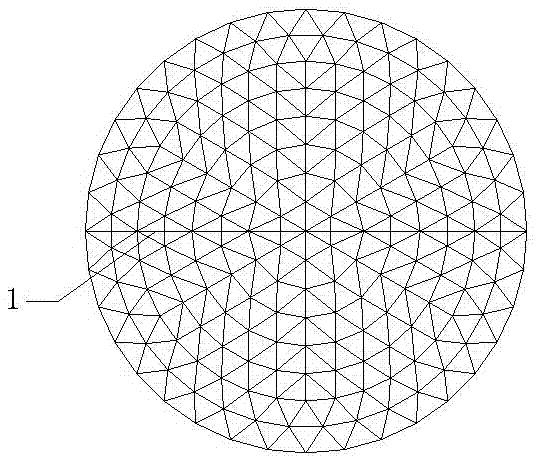

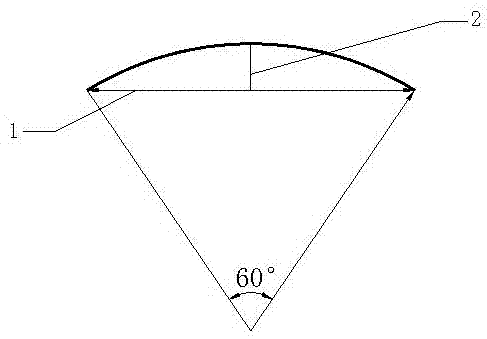

[0023] The manufacturing method of the large-scale stainless steel tank roof steel skin plate of the present invention, the tank roof is a spherical vault, the spherical vault adopts a triangular grid structure, the tank diameter is 38m, the tank height is 24.55m, and the tank wall height is 19.1m m, the tank roof steel skin plate is laid on the spherical vault triangular grid, and the tank tank roof is provided with edge ring beams, which is characterized in that it includes the following steps:

[0024] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of a spherical vault triangular grid structure according to an embodiment of the present invention, figure 2 It is a schematic diagram of a spherical vault structure according to an embodiment of the present invention.

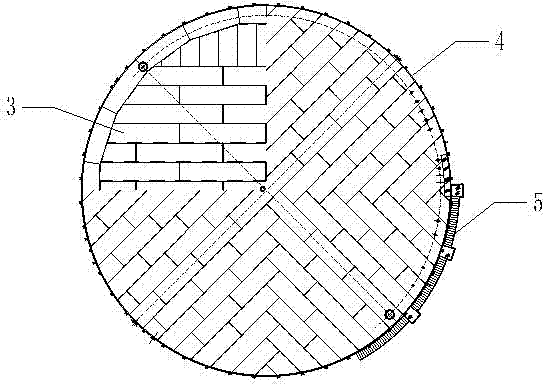

[0025] a. According to the design and construction drawings of large stainless steel tanks, draw the typesetting diagram of steel skin panels on the top of the tank;

[0026] image 3 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com