Manufacturing method of nano thermal insulation color steel plate

A technology of nano heat insulation and production method, which is applied in chemical instruments and methods, devices for coating liquid on surfaces, mixers with rotary stirring devices, etc., can solve the problems of cumbersome production and no production method for color steel plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

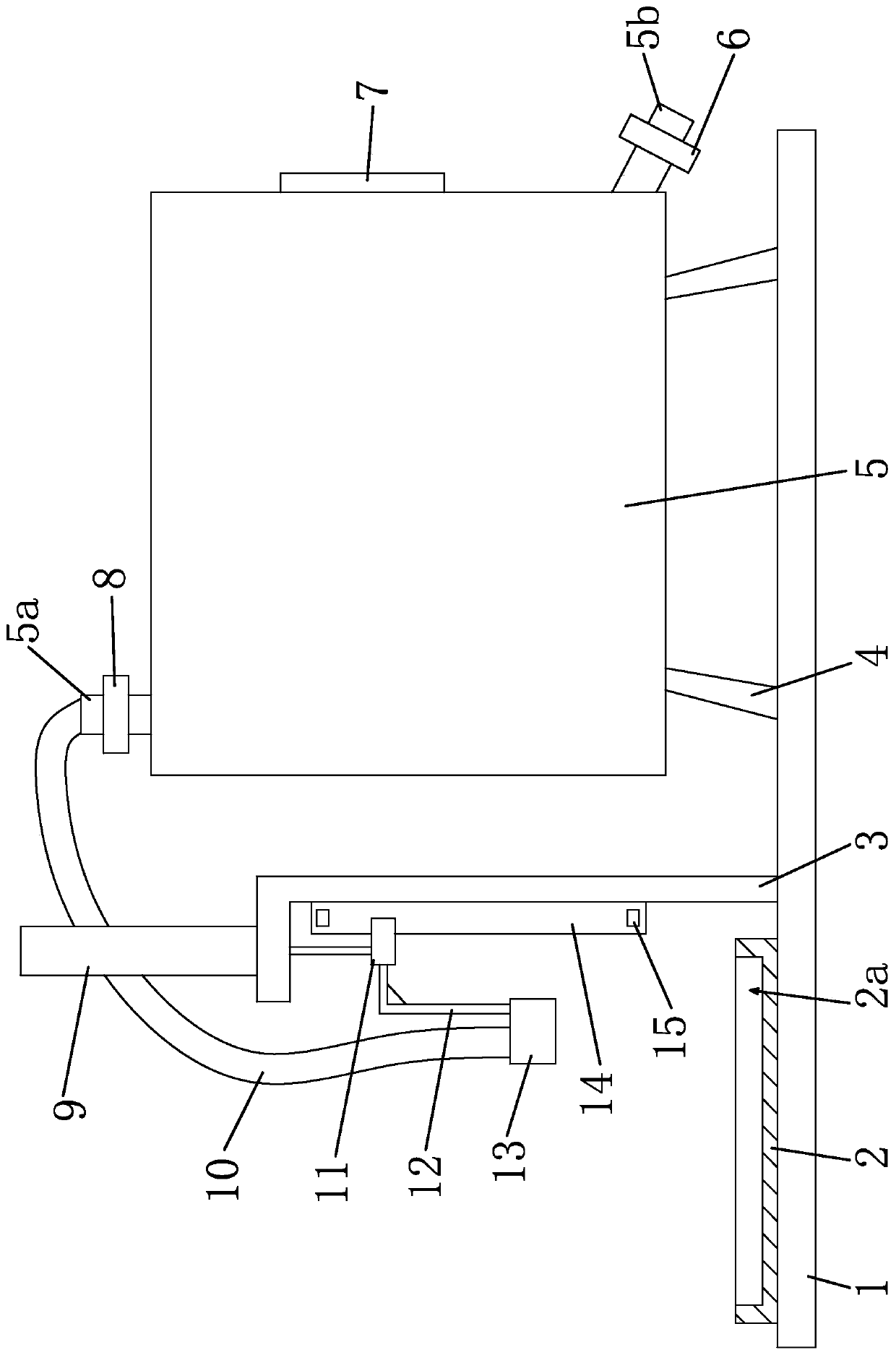

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

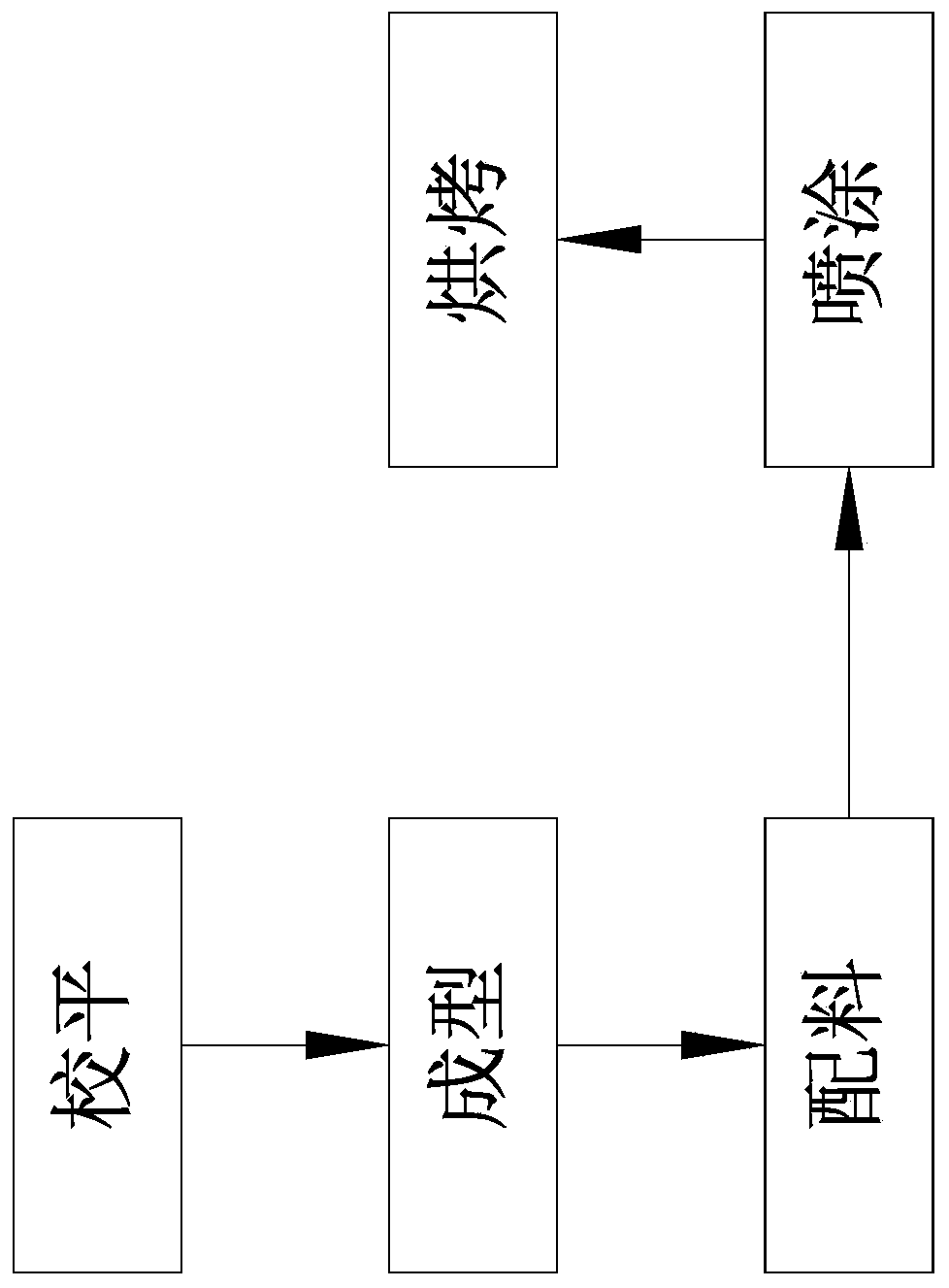

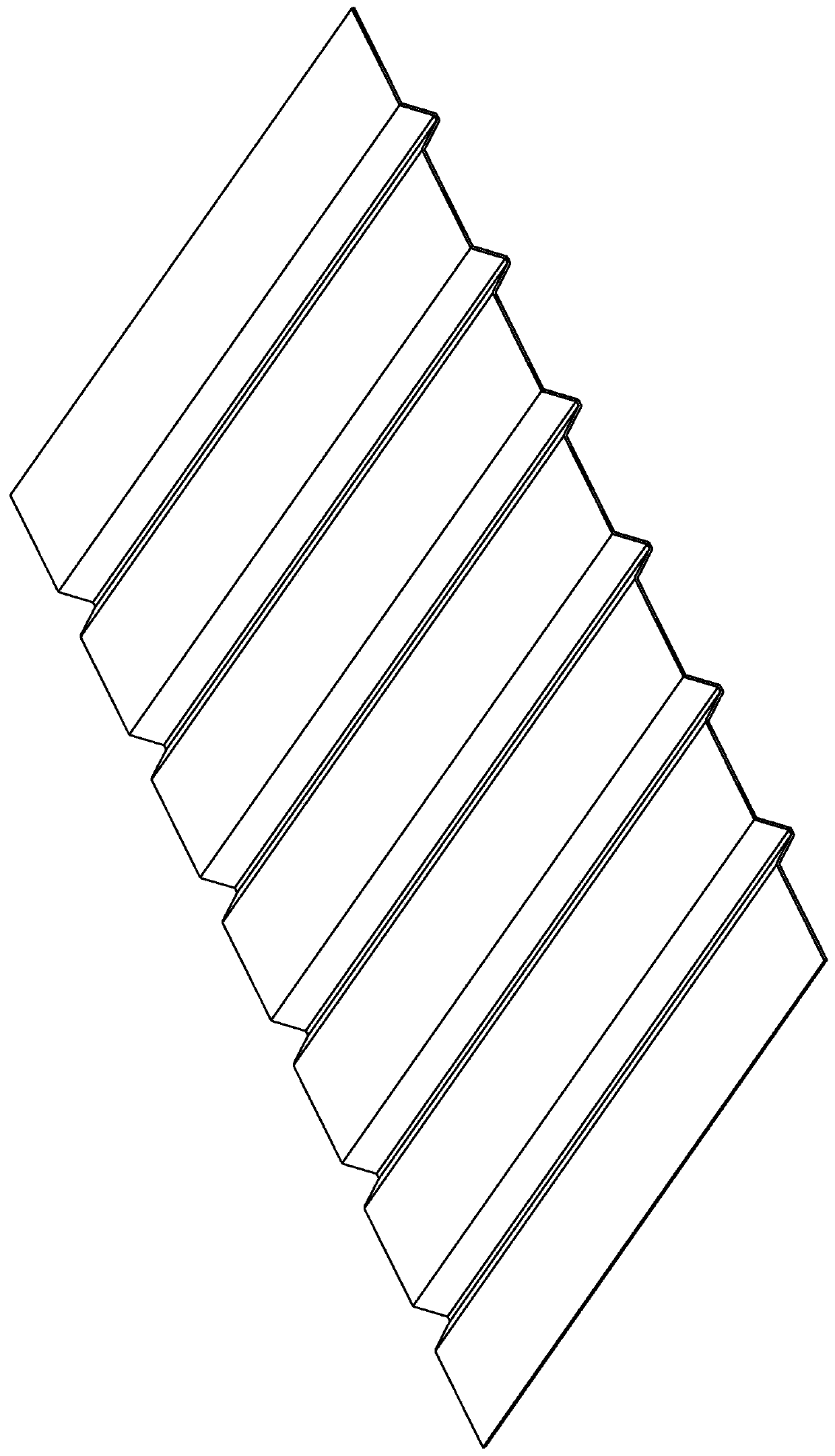

[0046] Such as figure 1 As shown, in the manufacturing method of the nano heat-insulating color steel plate, the nano heat-insulating color steel plate includes a substrate with a diversion groove, the upper surface of the substrate has a nano-heat insulation layer, and the specific structure of the nano-heat insulation color steel plate is as follows: figure 2 shown; including the following steps:

[0047] a. Leveling; the steel plate is leveled by a steel plate straightening machine;

[0048] b. Forming: roll forming the steel plate in step a by a steel plate rolling device to obtain a matrix;

[0049] c. Ingredients: According to parts by weight, weigh 40-50 parts of saturated polyester resin, 4-7 parts of silicon ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com