Two-piece bottle plug

A two-piece, bottle stopper technology, applied in the bottle stopper field, can solve the problems that the manufacturing cost of the airtight bottle stopper 7 cannot be effectively reduced, the airtight bottle stopper 7 cannot be airtight, etc. The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

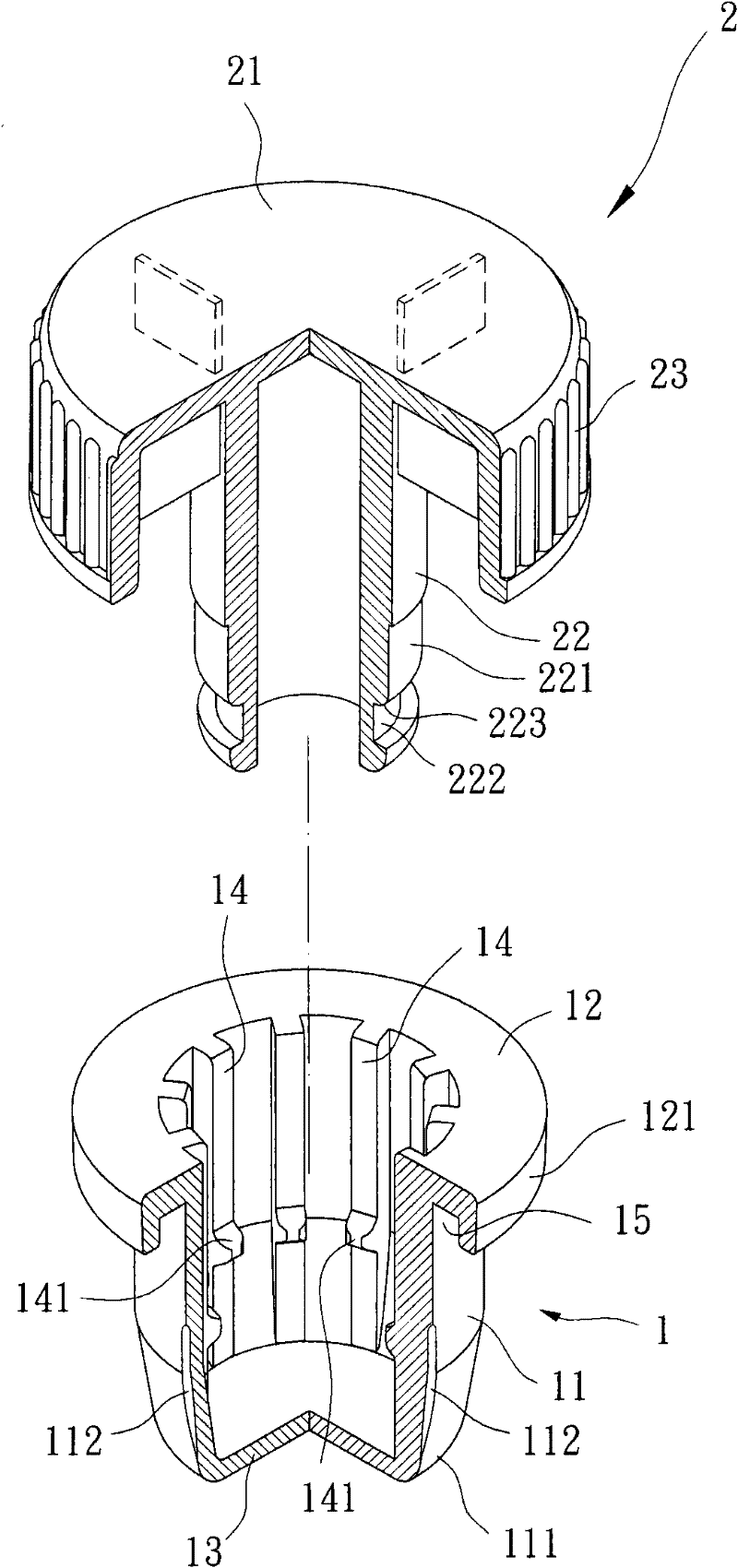

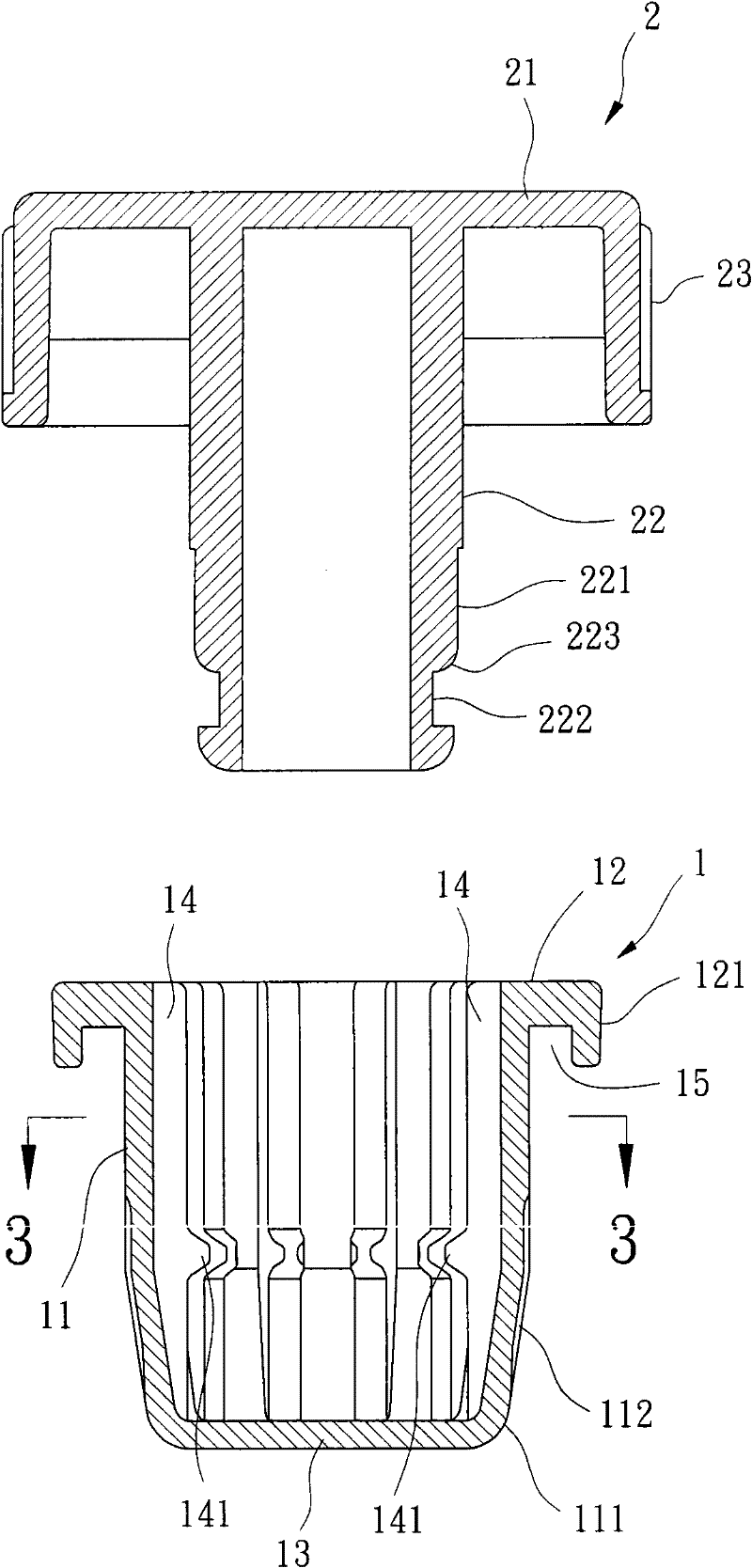

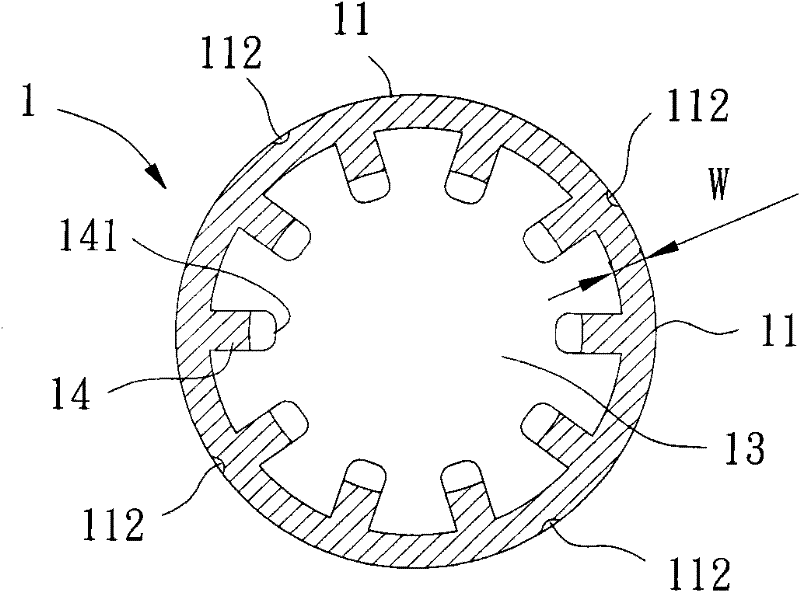

[0046] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0047] Please read figure 1 , 2 As shown, it is the first preferred embodiment of the present invention. In this embodiment, the bottle stopper is mainly composed of a plug body 1 and a pressing member 2 . Wherein the plug body 1 is used to place the opening 31 of the container 3 (such as Figure 4 shown), the pressing member 2 can force the plug body 1 to make a radial change, so that the plug body 1 can tightly seal the opening 31 of the container 3, or the plug body 1 can be taken out from the opening 31 of the container 3 .

[0048] Please read figure 1 , 2 , 3, the plug body 1 is made of thermoplastic material, preferably polypropylene (PP), polyethylene (PE), or a thermoplastic material obtained by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com