Board exterior trimming machine

An exterior decoration machine and plate technology, which is applied in the field of plate processing, can solve the problems of increased difficulty in plate making and high production costs for all steel, and achieve the effects of aesthetics and practicality, low manufacturing cost, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

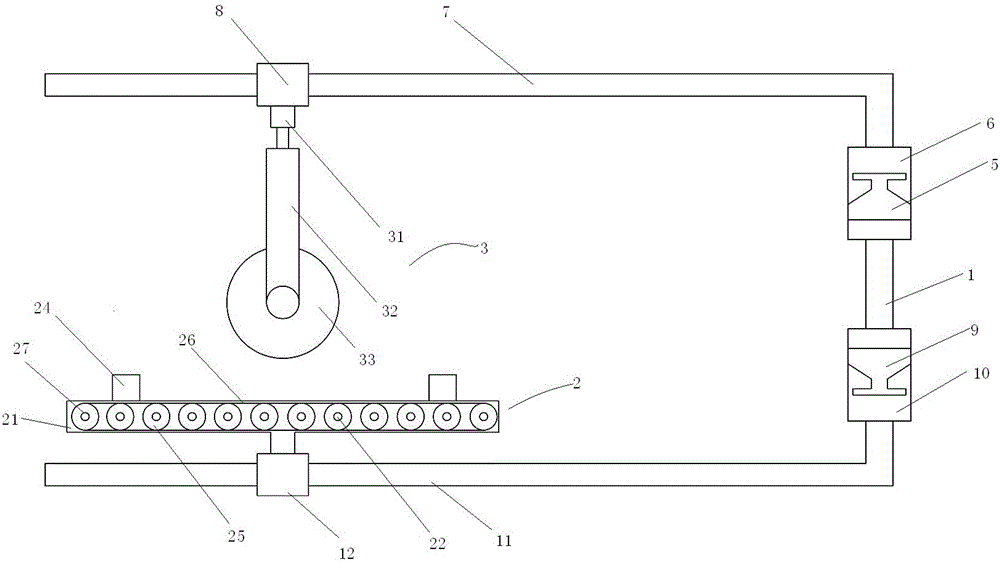

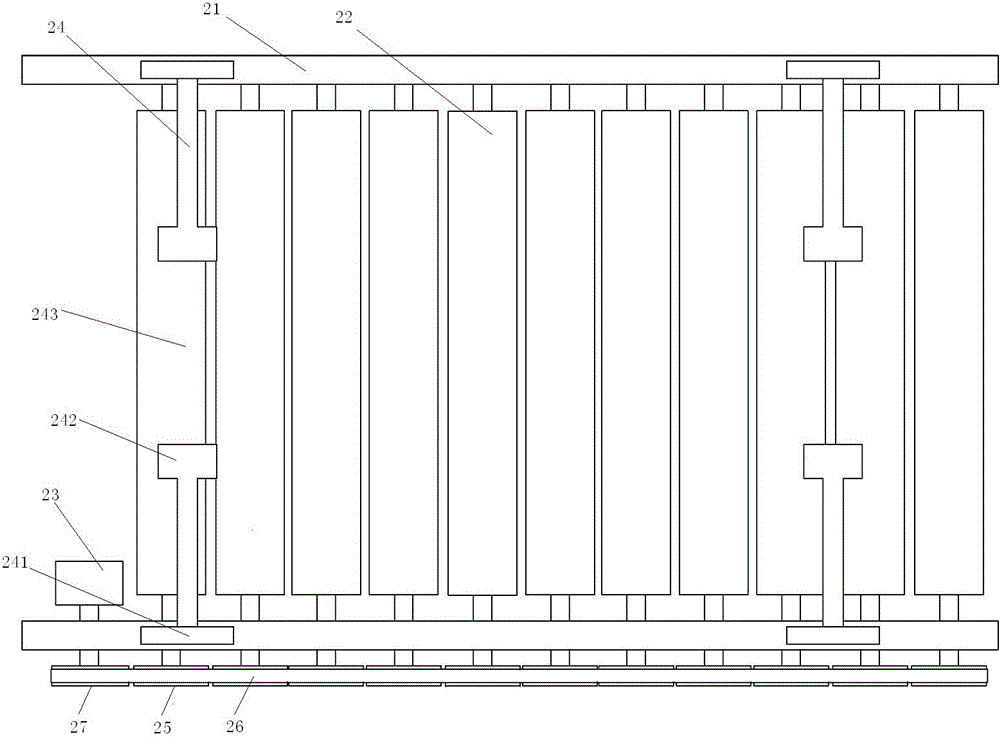

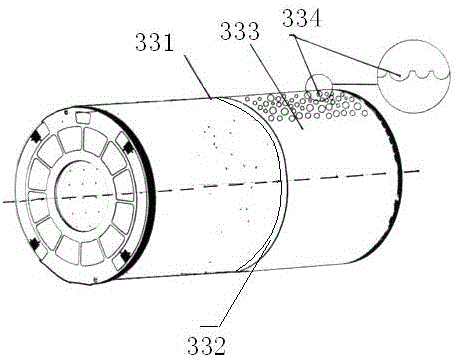

[0018] like figure 1 , figure 2 As shown, a board exterior decoration machine includes a frame 1, a conveying and fixing mechanism 2, and an exterior printing mechanism 3. The frame 1 is in the shape of an I-shaped; the upper position of the frame 1 is connected with an upper vertical rod 5, the upper vertical rod 5 is slidably provided with an upper vertical motor 6; the upper vertical motor 6 is fixedly connected with an upper horizontal rod 7, and the upper horizontal rod 7 is slidably provided with an upper horizontal motor 8; The lower position of the frame 1 is connected with a lower vertical rod 9, and the lower vertical rod 9 is slidably provided with a lower vertical motor 10; the lower vertical motor 10 is fixedly connected with a lower horizontal rod 11, and the lower horizontal rod 11 is slidingly provided with a lower horizontal motor 12; the exterior decoration printing mechanism 3 includes a telescopic cylinder 31, a fixed bracket 32, and a printing roller 33,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com