Treating fluid for elastic fiber fabric

A technology of elastic fiber and treatment liquid, which is applied in the field of elastic fiber fabric treatment liquid, which can solve the problems of wearing comfort, irregularity, lack of three-dimensional effect, etc., and achieve the effect of promoting blood movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

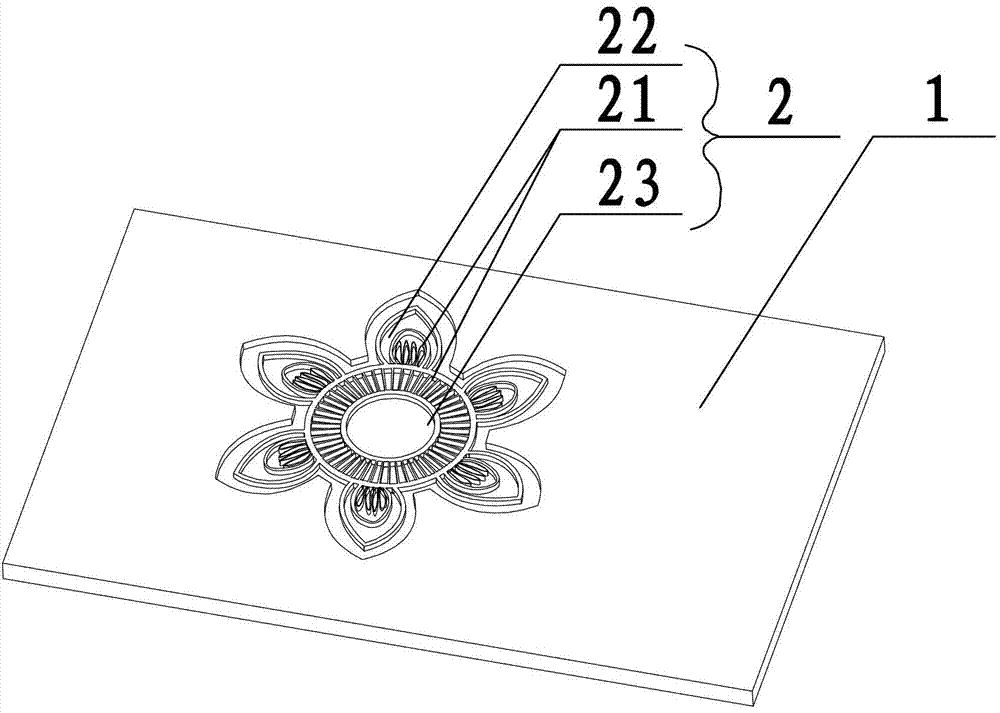

Embodiment 1

[0020] In this embodiment, printing is carried out by means of rotary screen printing, combined with figure 1 , the flower type is thin stem and small area flower type 21. The elastic fiber fabric is printed according to the following procedures: rolling → pine cloth → presetting → pretreatment → printing → steaming → washing → dehydration → drying → setting, wherein the fabric treatment liquid in the technical solution of the present invention is used In the printing process, the rigidizing liquid and the dyeing auxiliary sodium alginate paste are used together in a mass ratio of 1:1. After the rigidizing liquid and the sodium alginate paste are mixed evenly, the fabric is rigidified by rotary screen printing, flat screen printing or manual coating. Designed patterns and patterns. Among them, the fossilized liquid is a component with the following content: the content of diethylene glycol is 38wt%; the content of potassium acetate is 2wt%; the white oil is 15# in the SH...

Embodiment 2

[0038] The setting and principle of this embodiment are the same as that of Example 1, the difference is that the flower type is a block flower type 22, the mass ratio of the ossified liquid to the sodium alginate paste is 1:1.5, and diethylene glycol is used in the ossified liquid 30wt%; Potassium acetate 1wt%; White oil content 40wt%, Sodium alkylbenzene sulfonate 5wt%; During the rigidification process, choose No. 20 magnetic rod, the magnetic force is 90%.

Embodiment 3

[0040] This example is the same as Example 1, the difference is that: the pattern is a large noodle pattern 23, the mass ratio of the ossified liquid to the sodium alginate paste is 1:2, and the ossified liquid contains 50 wt% of diethylene glycol; Potassium acetate 5wt%; white oil content 60wt%, sodium alkylbenzene sulfonate 10wt%; choose No. 25 magnetic rod, magnetic force 90%.

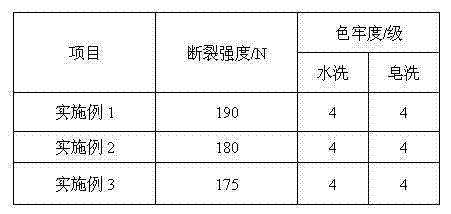

[0041] To the breaking strength, washing resistance / soaping color fastness of the fabrics prepared by the technical solutions in Examples 1-3, and compared the deformation degree of the patterns on the fabrics prepared by the technical solutions of the present invention after washing, the results See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com