Low temperature ceramic blank glaze direct printing glaze ink and its application and ceramic products

A technology of low-temperature ceramics and blank glaze, applied in the field of daily-use ceramic decoration, which can solve the problems of poor color development, flammability, and limited selection range, etc., achieve good color and luster, reduce decoration costs, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

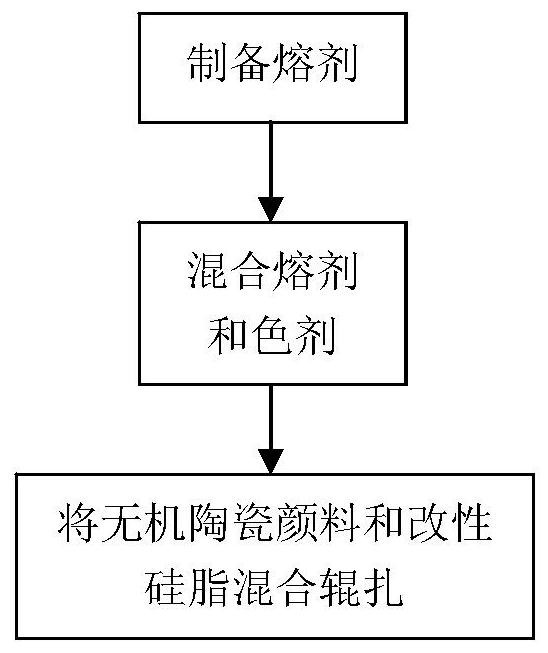

Method used

Image

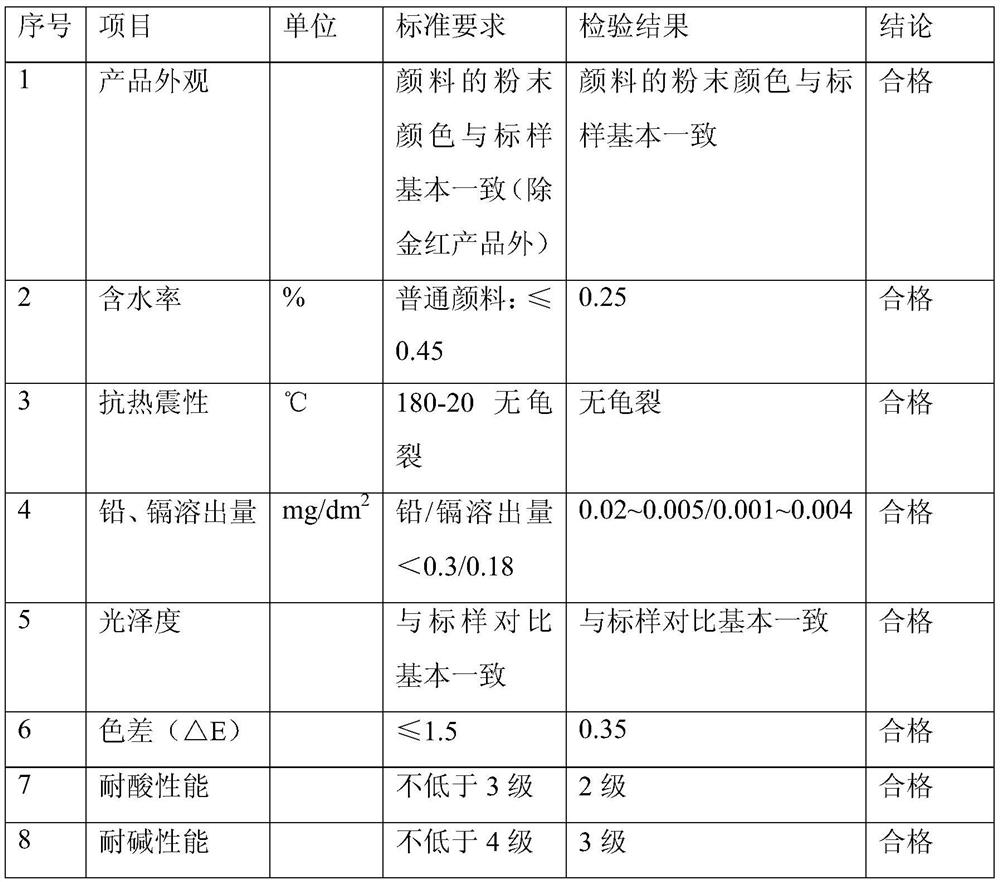

Examples

Embodiment 1

[0030] This embodiment provides a low-temperature ceramic blank glaze direct printing glaze ink, which is composed of 60% by weight of inorganic ceramic pigment and 40% of modified silicone grease.

[0031]Modified silicone grease is made of inorganic thickened modified silicone oil, non-toxic, tasteless, with excellent lubricity, water repellency, and long storage time. By effectively introducing the high-quality characteristics of organic materials into inorganic materials, the good complementarity between organic materials and inorganic materials can be brought into play, so as to meet the various properties required by direct printing glaze ink. Due to the excellent lubricity and moderate cohesiveness of this modified silicone grease, it can be directly printed on the original body or the raw glaze layer by mechanical screen printing or pad printing machine printing.

[0032] The inorganic ceramic pigment is composed of 60% flux and 40% coloring agent in weight percent.

...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the raw materials of the flux include 49% of potassium feldspar, 28% of quartz, 20% of borax pentahydrate, 2% of calcite and 1% of kaolin by weight percentage. All the other parts are the same as in Example 1.

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that the raw materials of flux include 55% potassium feldspar, 20% quartz, 20% borax pentahydrate, 3% calcite and 2% kaolin by weight percentage. All the other parts are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com