In-mold molding injection product relief production process

A technology of injection molding products and in-mold molding, which is applied in printing devices, printing, etc., can solve the problems of insufficient concave-convex feeling and weak three-dimensional effect, and achieve a three-dimensional, dynamic and hand-feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

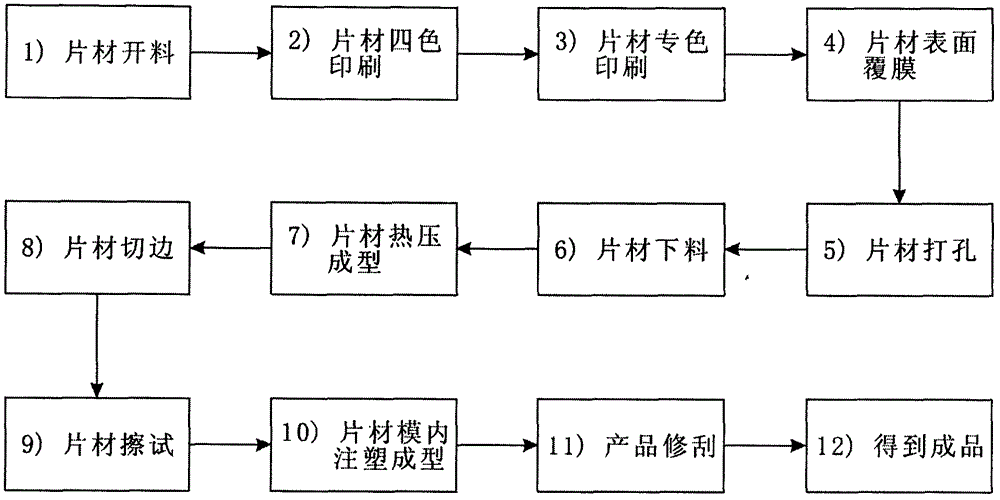

[0026] see figure 1 , the in-mold molding injection molding product relief production process of the present invention comprises the following steps:

[0027] 1) Sheet cutting: select a suitable sheet and cut the sheet;

[0028] 2) Four-color printing on sheets: use four-color printing to form color patterns on the pre-cut sheets;

[0029] 3) Spot color printing on sheet: use spot color printing on the sheet with color pattern to improve the pattern color and make the pattern more gorgeous;

[0030] 4) Covering the surface of the sheet: cover the sheet with a gorgeous pattern with a protective film;

[0031] 5) Sheet punching: punch holes in the sheet covered with protective film;

[0032] 6) Sheet blanking: blanking the perforated sheet;

[0033] 7) Hot press forming of sheet material: use hot pressing proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com