A kind of cathode material of magnesium secondary battery and preparation method thereof

A magnesium secondary battery and positive electrode material technology, applied in secondary batteries, battery electrodes, nanotechnology for materials and surface science, etc., can solve battery capacity decay, magnesium secondary battery sulfide positive electrode materials have not been applied and other issues, to achieve high charge-discharge specific capacity, easy large-scale production, and abundant raw materials for preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a positive electrode material for a magnesium secondary battery, the specific method is as follows:

[0031] a. Preparation of composite material ferrous disulfide / nano carbon:

[0032] Mix the iron source and the sulfur source in a molar ratio, and add them into 150-170mL of deionized water, stir vigorously until the mixture is completely dissolved, then add acid-treated carbon materials into the mixed solution, and fully stir for 0.5-1h, Transfer the mixed liquid to a reaction kettle lined with polytetrafluoroethylene for heating, keep stirring rapidly during the hydrothermal reaction, cool to room temperature naturally after the hydrothermal reaction, and perform centrifugation at a speed of 8000-10000r / min. The product was repeatedly washed with absolute ethanol and deionized water, and finally freeze-dried, pre-frozen at minus 70°C, and finally brought to room temperature to complete the freeze-drying process to obtain a composite material o...

Embodiment 1

[0044] Embodiment 1: the weight percent of carbon material and ferrous disulfide in the ferrous disulfide / nano carbon composite material of the present embodiment is: carbon material 2%, ferrous disulfide 98%

[0045] Multi-walled carbon nanotubes (MWCNTs) need to be pickled, and a certain amount of MWCNTs is placed in a mixed solution of hydrochloric acid (98% concentration) and nitric acid (98% concentration) at a volume ratio of 3:1 for ultrasonic dispersion. , after uniform dispersion, repeated washing was performed until the solution was neutral, and finally filtered, and the acid-washed MWCNTs were vacuum-dried at 60°C. Take 40 mg of acid-washed MWCNTs and place them in 40 mL of deionized water for ultrasonic dispersion. After the dispersion is uniform, transfer them to 2.22 g of FeSO 4 ·7H 2 O and 3.87g C 3 h 7 NO 2 In the S mixed solution (the molar ratio is 1:4), the total amount of deionized water in the solution is 160mL, and it is fully stirred. Transfer the a...

Embodiment 2

[0050] Embodiment 2: The weight percentages of carbon material and ferrous disulfide in the ferrous disulfide / nano-carbon composite material of this embodiment are: 2% of carbon material and 98% of ferrous disulfide.

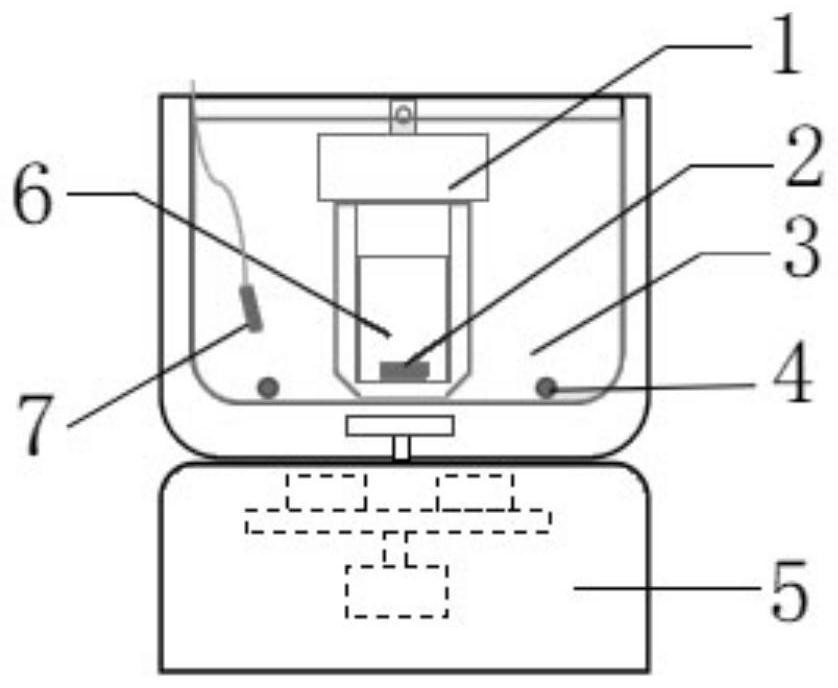

[0051] Take 40mg of graphene and place it in 40mL of deionized water for ultrasonic dispersion. After the dispersion is uniform, transfer it to 2.22g of FeSO 4 ·7H 2 O and 3.87g C 3 h 7 NO 2 In the S mixed solution, the total amount of deionized water in the solution is 160mL, and fully stirred. Transfer the above mixed solution to a clean, smooth polytetrafluoroethylene-lined reactor (volume 200 mL). Under the condition of 160 ℃, the airtight reactor containing the mixture is heated and stirred by an oil bath (such as figure 1 shown), the stirring speed is 600-800rpm, the hydrothermal reaction is 12h, cooled to room temperature, the obtained product is first separated by a centrifuge, then repeatedly washed with deionized water and absolute ethanol, and fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com