Acid resistance type protective ink and preparation method thereof

An acid type and ink technology, applied in the chemical industry, can solve the problems of easy corrosion of touch screen circuits, poor hydrofluoric acid resistance, and the generation of a large amount of waste alkali water, so as to improve the hydrofluoric acid resistance, high curing efficiency, The effect of increasing the curing crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

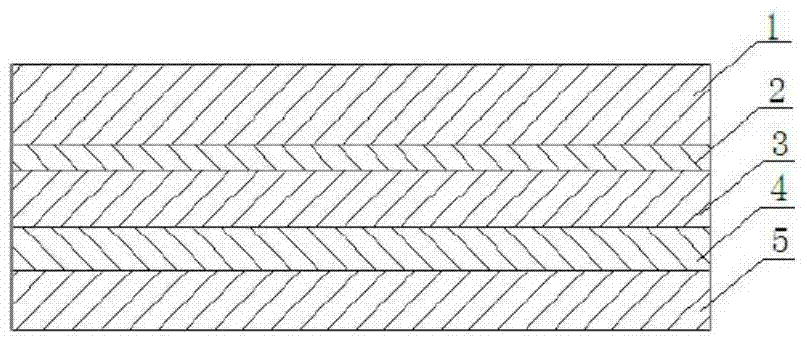

Image

Examples

Embodiment 1

[0029] Add 100 grams (0.61mol) of phenolic epoxy resin (NPPN-638S), 0.2 grams of triphenylphosphine, and 0.26 grams of hydroquinone into the reactor. The temperature is raised to 110°C, and 38.2 grams (0.53mol) of AA and 219.5 The mixed solution of gram (1.06 mol) AMPS was slowly and continuously dripped with a constant pressure funnel for 60 minutes, and after the dripping was completed, it was kept at 115° C. for 2 hours to obtain a novolac epoxy acrylic resin.

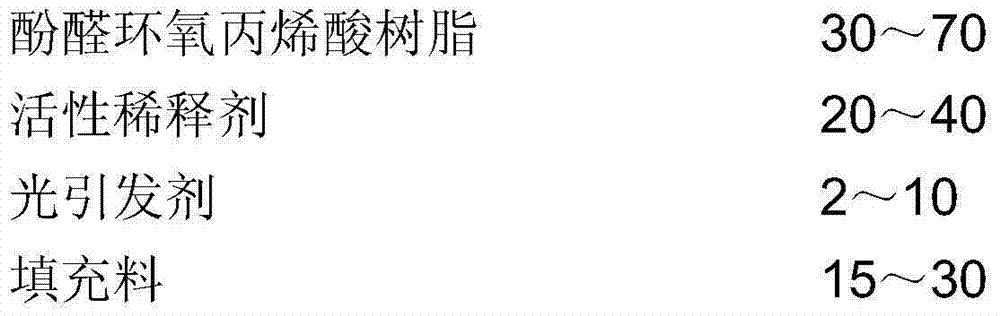

[0030] Weigh the following parts by weight: 50 parts of phenolic epoxy acrylic resin, 20 parts of 1,6-hexanediol diacrylate, 5 parts of 1-hydroxycyclohexyl phenyl ketone, 15 parts of talc, and 10 parts of barium sulfate , 0.5 parts of defoamer. The epoxy acrylic resin is mixed with the active diluent, mixed with the photoinitiator, filler, and defoamer. After high-speed stirring, a uniform viscous liquid is formed. The viscous liquid is ground in a grinder to obtain a protective ink product.

Embodiment 2

[0032] Add 100 grams (0.61mol) of phenolic epoxy resin (NPPN-638S), 0.2 grams of triphenylphosphine, and 0.26 grams of hydroquinone into the reactor. The temperature is raised to 110°C, and 38.2 grams (0.53mol) of AA and 219.5 The mixed solution of gram (1.06 mol) AMPS was slowly and continuously dripped with a constant pressure funnel for 60 minutes, and after the dripping was completed, it was kept at 115° C. for 2 hours to obtain a novolac epoxy acrylic resin.

[0033] Weigh the following parts by weight: 50 parts of phenolic epoxy acrylic resin, 20 parts of hydroxypropyl methacrylate, 5 parts of 1-hydroxycyclohexyl phenyl ketone, 15 parts of talc, 10 parts of barium sulfate, defoamer 0.5 copies. The epoxy acrylic resin is mixed with the active diluent, mixed with the photoinitiator, filler, and defoamer. After high-speed stirring, a uniform viscous liquid is formed. After the viscous liquid is ground in a grinder, the finished protective ink is obtained.

Embodiment 3

[0035] Add 100 grams (0.61mol) of phenolic epoxy resin (NPPN-638S), 0.2 grams of triphenylphosphine, and 0.26 grams of hydroquinone into the reactor. The temperature is raised to 110°C, and 38.2 grams (0.53mol) of AA and 219.5 The mixed solution of gram (1.06 mol) AMPS was slowly and continuously dripped with a constant pressure funnel for 60 minutes, and after the dripping was completed, it was kept at 115° C. for 2 hours to obtain a novolac epoxy acrylic resin.

[0036] Weigh the following parts by weight: 50 parts of novolac epoxy acrylic resin, 20 parts of 1,6-hexanediol diacrylate, 2-methyl-1-[4-(methylthio)phenyl]-2- 6 parts of morpholinyl-1-acetone, 3 parts of isopropyl thioxanthone, 15 parts of talc, 10 parts of barium sulfate, 0.5 parts of defoamer. The epoxy acrylic resin is mixed with the active diluent, mixed with the photoinitiator, filler, and defoamer. After high-speed stirring, a uniform viscous liquid is formed. After the viscous liquid is ground in a grinder, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com