UV viscosity-reducing adhesive and UV viscosity-reducing adhesive tape

A viscose and resin technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer organic compound adhesives, etc. Excellent adhesion, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

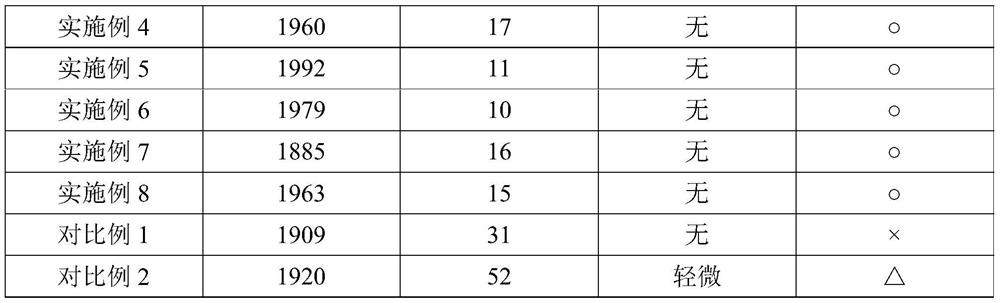

Examples

Embodiment 1

[0067] The invention provides a kind of acrylate resin, weighing 10g methyl methacrylate, 20g 2-ethylhexyl acrylate, 8g n-octyl acrylate, 10g butyl acrylate, 6g hydroxyethyl acrylate, 1.5g methacrylic acid shrinkage Glyceride and 0.1% thermal initiator azobisisobutyronitrile (AIBN) accounting for the total weight of the aforementioned monomers. Under the protection of nitrogen, heat and control the temperature at 80°C, and stir the reaction for 0.5h. Then add fluorinated diphenyl titanocene as a catalyst accounting for 1% of the total weight of the aforementioned monomers, and continue the reaction for 1 h. Cool to obtain acrylate resin A1.

[0068] The invention provides a UV viscosifying adhesive, which comprises the following components: 40g of acrylate resin, 8g of cationic curing resin, 8g of multifunctional monomer, 0.3g of cationic photoinitiator, 0.3g of free radical photoinitiator, 3g of curing agent, and 50g of solvent, the parts are parts by mass.

[0069] The ac...

Embodiment 2

[0075] The invention provides an acrylate resin, the preparation method of the acrylate resin is as follows: weigh 10g methyl methacrylate, 20g 2-ethylhexyl acrylate, 8g n-octyl acrylate, 10g butyl acrylate, 6g acrylic acid Hydroxyethyl ester, 1.5 g of glycidyl methacrylate and 0.1% of thermal initiator azobisisobutyronitrile (AIBN) accounting for the total weight of the aforementioned monomers. Under the protection of nitrogen, heat and control the temperature at 80°C, and stir the reaction for 0.5h. Then add fluorinated diphenyl titanocene as a catalyst accounting for 1% of the total weight of the aforementioned monomers, and continue the reaction for 1 h. Cool to obtain acrylate resin A2.

[0076] The invention provides a UV viscosifying adhesive, which comprises the following components: 40g of acrylate resin, 10g of cationic curing resin, 8g of multifunctional monomer, 0.3g of cationic photoinitiator, 0.3g of free radical photoinitiator, 3g of curing agent, and 25g of s...

Embodiment 3

[0083] The invention provides an acrylate resin, the preparation method of the acrylate resin is as follows: weigh 10g methyl methacrylate, 20g 2-ethylhexyl acrylate, 8g n-octyl acrylate, 10g butyl acrylate, 5g acrylic acid Hydroxyethyl ester, 1.5 g of glycidyl methacrylate and 0.1% of thermal initiator azobisisobutyronitrile (AIBN) accounting for the total weight of the aforementioned monomers. Under the protection of nitrogen, heat and control the temperature at 80°C, and stir the reaction for 0.5h. Then add fluorinated diphenyl titanocene as a catalyst accounting for 1% of the total weight of the aforementioned monomers, and continue the reaction for 1 h. Cool to obtain acrylate resin A3.

[0084] The present invention provides a UV viscosifying adhesive, which comprises the following components: 40g of acrylate resin, 10g of cationic curing resin, 7g of multifunctional monomer, 1g of cationic photoinitiator, 0.1 g of free radical photoinitiator, 2g of curing agent, and 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com