Method for preparing hydrophilic antifogging coating

An anti-fog coating and hydrophilic technology, which is applied in the field of preparation of hydrophilic anti-fog coatings, can solve the problems of poor anti-fog performance, poor dispersion of anti-fog coatings, and long curing time of coatings, so as to promote photocatalysis and photodegradation effect, enhanced anti-fog performance, and increased cured crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

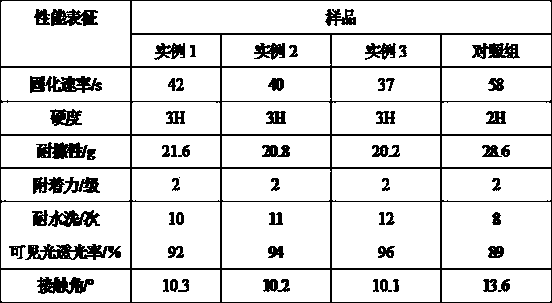

Examples

example 1

[0019] In parts by weight, weigh 45 parts of deionized water, 15 parts of 2% sodium alginate solution by mass fraction, 10 parts of 2% polycaprolactone chloroform solution by mass fraction, 5 parts of gemini quaternary ammonium salt YND1233 and 35 parts The pH is 7.0. Disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution is placed in a beaker, stirred and mixed for 10 minutes, and left to age to obtain a mixed solution. The mass fraction of 10% calcium chloride solution is added dropwise at a volume ratio of 1:10 Into the mixed solution, control the dropping rate at 3mL / min. After the dropwise addition is completed, continue to stir and mix and mature for 3h, centrifuge at 3500r / min and collect the lower precipitate, rinse with deionized water for 3 times, vacuum Freeze-dried and ground through a 200-mesh sieve to obtain modified microsphere powder; in parts by weight, weigh 45 parts of ethylene glycol ether, 10 parts of modified microsphere powder, 5 parts of...

example 2

[0021] In parts by weight, weigh 47 parts of deionized water, 17 parts of 2% sodium alginate solution by mass fraction, 12 parts of 2% polycaprolactone chloroform solution by mass fraction, 7 parts of gemini quaternary ammonium salt YND1233 and 37 parts The pH is 7.0. Disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution is placed in a beaker, stirred and mixed for 11 minutes, and left to age to obtain a mixed solution. The mass fraction of 10% calcium chloride solution is added dropwise at a volume ratio of 1:10 Into the mixed solution, control the dropping rate at 3mL / min. After the dropwise addition is completed, continue to stir and mix and ripen for 4h, centrifuge at 3750r / min and collect the lower precipitate, rinse with deionized water for 4 times, vacuum Freeze-dried and ground through a 200-mesh sieve to obtain a modified microsphere powder; in parts by weight, weigh 47 parts of ethylene glycol ether, 12 parts of modified microsphere powder, 6 parts o...

example 3

[0023] In parts by weight, weigh 50 parts of deionized water, 20 parts of 2% sodium alginate solution by mass fraction, 15 parts of 2% polycaprolactone chloroform solution by mass fraction, 8 parts of 12-3-12 type Gemini quarter Ammonium salt and 40 parts of pH 7.0 disodium hydrogen phosphate-sodium dihydrogen phosphate buffer solution were placed in a beaker, stirred and mixed for 12 minutes, and left to age to obtain a mixed solution. The volume ratio was 1:10, and the mass fraction was 10% chlorine Add the calcium chloride solution dropwise to the mixed solution, and control the dropping rate at 3mL / min. After the dropwise addition is completed, continue to stir and mix and mature for 5h, centrifuge at 4000r / min and collect the lower precipitate, rinse with deionized water After 5 times, vacuum freeze-dry and grind through a 200-mesh sieve to obtain modified microsphere powder; in parts by weight, weigh 50 parts of ethylene glycol ether, 15 parts of modified microsphere powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com