High-crystallization silver powder, low-cost heterojunction silver paste and preparation method and application of high-crystallization silver powder and low-cost heterojunction silver paste

A high crystallization and heterojunction technology, which is applied to equipment for manufacturing conductive/semiconductive layers, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problem of high cost of using silver paste, The conductive performance is reduced, and the problem of copper oxidation cannot be solved, so as to achieve the effect of ensuring anti-oxidation performance, ensuring electrical conductivity, and improving the cured crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of the above-mentioned high crystallization silver powder, comprising the following steps: after the surface of the inorganic powder is smoothed, a layer of silver is coated on the surface of the inorganic powder by chemical reduction method, which has high crystallinity, thereby synthesizing a A silver-coated inorganic nano-powder type high crystallization spherical silver powder. Concrete, the preparation method of high crystalline silver powder of the present invention is as follows:

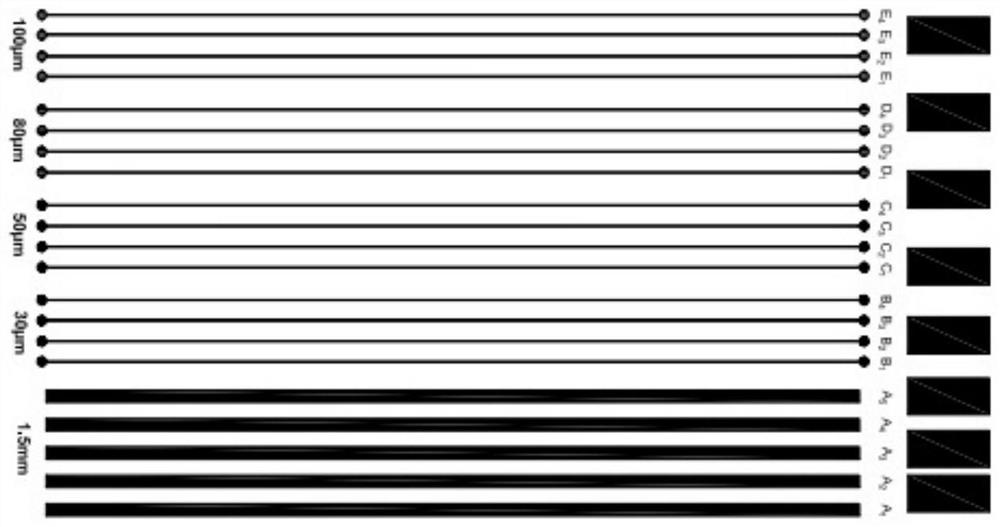

[0032] Step a. The inorganic nano-powder is subjected to surface smoothing treatment by impacting the polishing equipment (jet-milling equipment) with an airflow. The process uses dry nitrogen to avoid the agglomeration of the nano-powder due to moisture absorption, resulting in agglomerated internal powders that cannot be obtained well. The smoothing treatment; the air pressure is 0.05-0.5MPa, if the air pressure is too small, the impact fo...

Embodiment 1

[0059] Take the glass powder with D50=183nm, the product name is GF-01, the laser particle size test results are as follows Figure 5 Smoothing was performed using jet mill equipment as indicated. The working process of the jet mill equipment is a conventional technology, such as using dry compressed gas to continuously blow the powder from the inlet of the jet mill into the cavity of the jet mill, and the powder will be driven by the airflow to meet the wall of the jet mill cavity. Friction is carried out to achieve a smooth polishing effect. After the powder comes out of the jet mill chamber, the powder is separated from the air flow by a cyclone separator and a filter element. The equipment can control the smoothness of the powder by controlling the pressure of the air flow. In this embodiment, the airflow pressure is set at 0.25MPa. Take 1.5g smoothed GF-01 glass powder, 1.5g anti-flocculation agent polyvinylpyrrolidone PVP-K30, 0.3g dispersant (Tween-80), 1000g deionized...

Embodiment 2

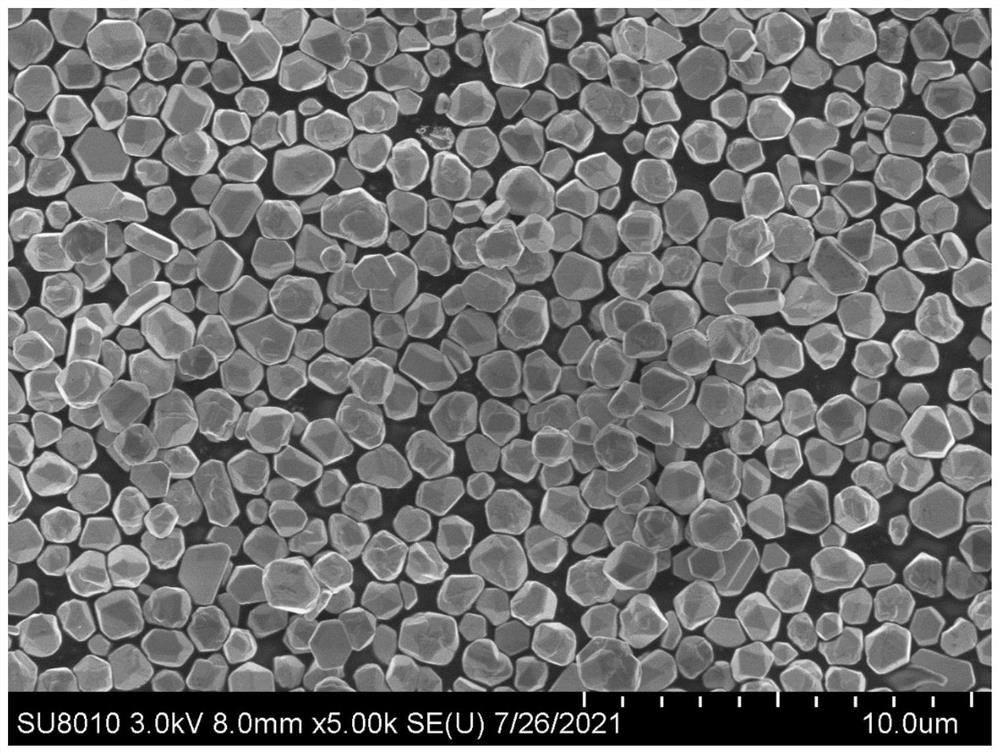

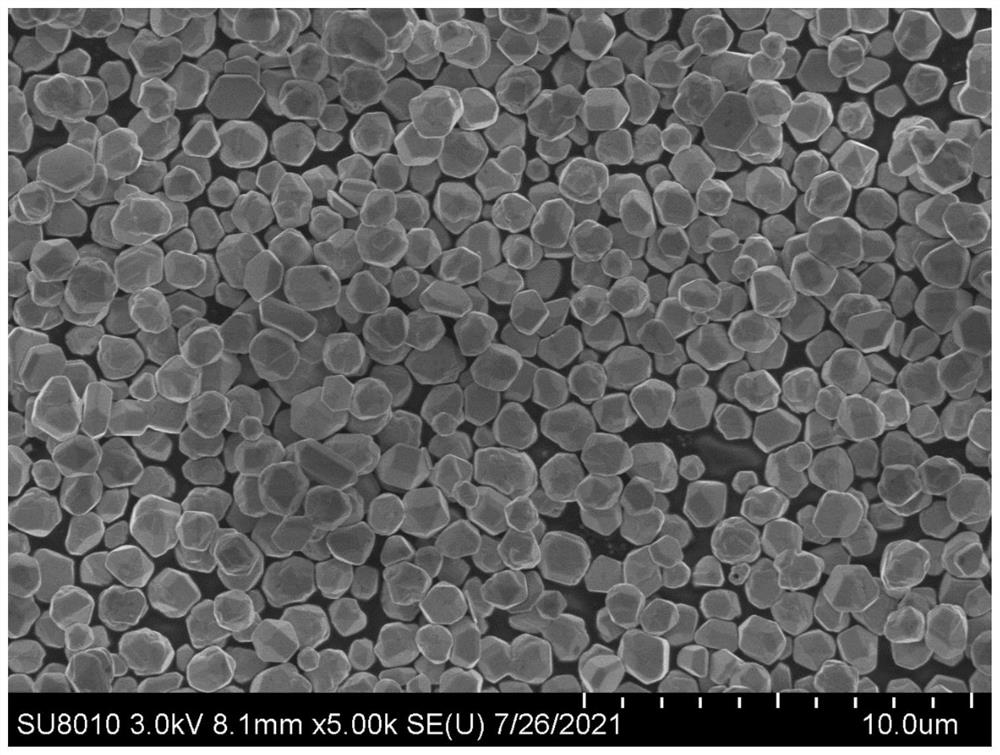

[0064] The inorganic nanocrystal core used is changed to D50=153nm zirconia type ceramic powder, the product name is TO-01, and the laser particle size test result is Figure 6 As shown, the usage amount is 2.3g, other processes are the same as in Example 1, the D50=1.98 μm of the obtained silver-coated ceramic powder, the high temperature heat loss=0.24%, and the specific surface area=0.34m 2 / g, tap density=6.02g / cm 3 , the scanning electron microscope image is shown in image 3 As shown, the laser particle size test results are Figure 8 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com