Nanoparticle copper paste suitable for high-precision direct writing 3D printing, preparation and application

A 3D printing and nanoparticle technology, which is used in heat treatment equipment, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as being easily oxidized, reduce costs, and improve adhesion performance, the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

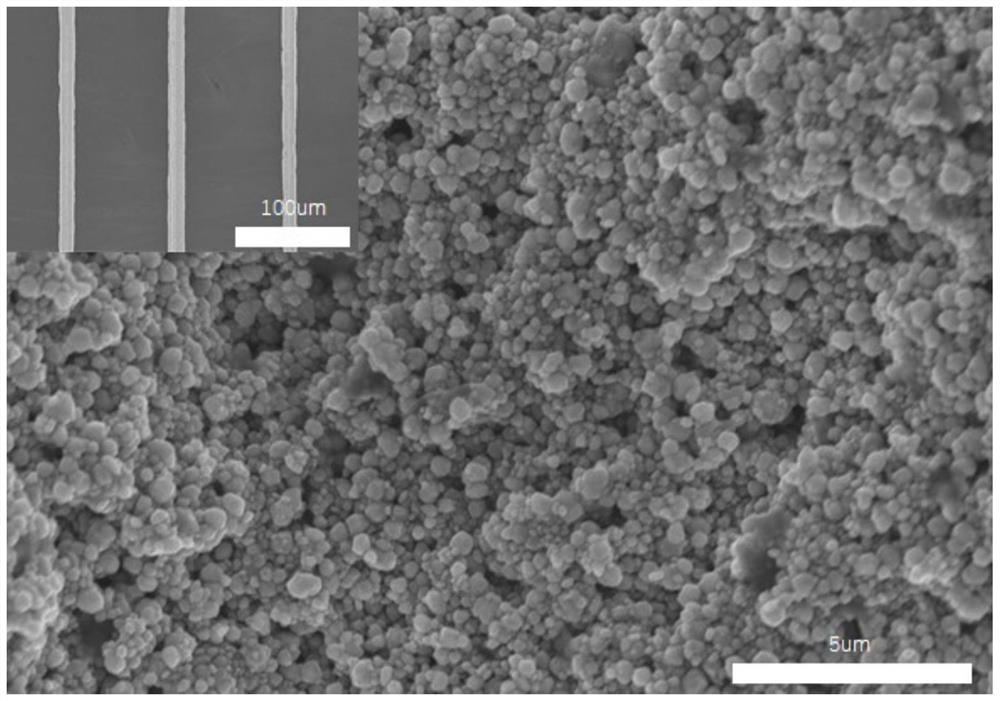

Embodiment 1

[0044] Weigh 8g of bisphenol A type epoxy resin, dissolve it in 15g of butyl acetate solvent, heat it to 80°C and keep it for 1 hour until it is completely dissolved to obtain the preliminary carrier; weigh 1g of acid anhydride curing agent, add it to the preliminary carrier, Use a high-speed disperser for high-speed dispersion, heat it to 30-35°C and age for 2 hours to obtain an organic carrier; weigh 70g of 100-200nm copper powder, 5g of reducing agent triphenylphosphine, and non-conductive filler nano-graphene powder 0.2g, 0.8g of 50nm silicon dioxide powder; fully mix with the organic carrier in a mixer, and then use a high-speed disperser to disperse at a high speed to obtain a uniform initial slurry; process the initial slurry on a three-roll machine Roll rolling for 6 times until the fineness of <1μm is reached, and then filter through a 10μm filter to obtain the finished copper paste A.

Embodiment 2

[0046] Weigh 6g of E-44 epoxy resin, dissolve it in 10g of polyethylene glycol solvent, heat it to 80°C and keep it for 1 hour until it is completely dissolved to obtain the preliminary carrier; weigh 0.5g of polythiol curing agent, add it to the preliminary carrier In the process, use a high-speed disperser to disperse at a high speed, heat it to 30-35°C and age for 2 hours after dispersing evenly, to obtain an organic carrier; weigh 70g of copper powder with a thickness of 500-600nm, 5g of reducing agent trioctylphosphine, and non-conductive filler nano-graphite olefin powder 0.2g, 50nm silicon dioxide powder 0.8g; fully mix with the organic carrier in a mixer, and then use a high-speed disperser to disperse at a high speed to obtain a uniform initial slurry; put the initial slurry on three rolls Rolling machine for 6 times until the fineness of <1μm is reached, and then filtered through a filter screen of 10μm to obtain the finished copper paste B.

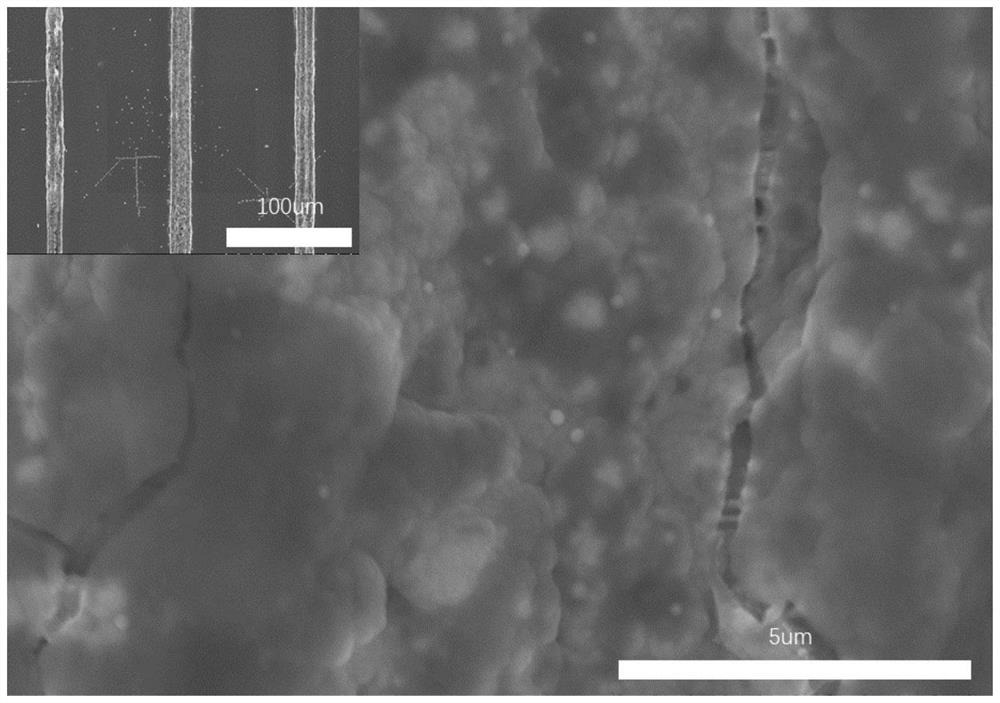

Embodiment 3

[0048] Weigh 5g of biphenyl oxygen-type epoxy resin, dissolve it in 7g of diethylene glycol ether acetate solvent, heat to 80°C for 1 hour, until completely dissolved to obtain a preliminary carrier; weigh 0.5g of dicyandiamide curing agent, Add it to the preliminary carrier, disperse at a high speed with a high-speed disperser, heat it to 30-35°C for 2 hours after dispersing evenly, and obtain an organic carrier; weigh 70g of copper powder with a thickness of 1-2μm, and the reducing agent tri-p-methylphenylphosphine 5g; fully mix with the organic carrier in a mixer, and then use a high-speed disperser to disperse at a high speed to obtain a uniform primary slurry; roll the primary slurry 6 times on a three-roll machine to achieve a fineness of <1 μm degree, and then filtered through a 10 μm filter to obtain the finished copper paste C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com