Degradable light-cured resin and preparation method and application thereof

A light-curing resin, unsaturated technology, applied in coatings, polyester coatings, etc., can solve the problems of low curing crosslink density and poor hardness, achieve excellent hardness and mechanical properties after curing, high production efficiency, and improve The effect of crosslink density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

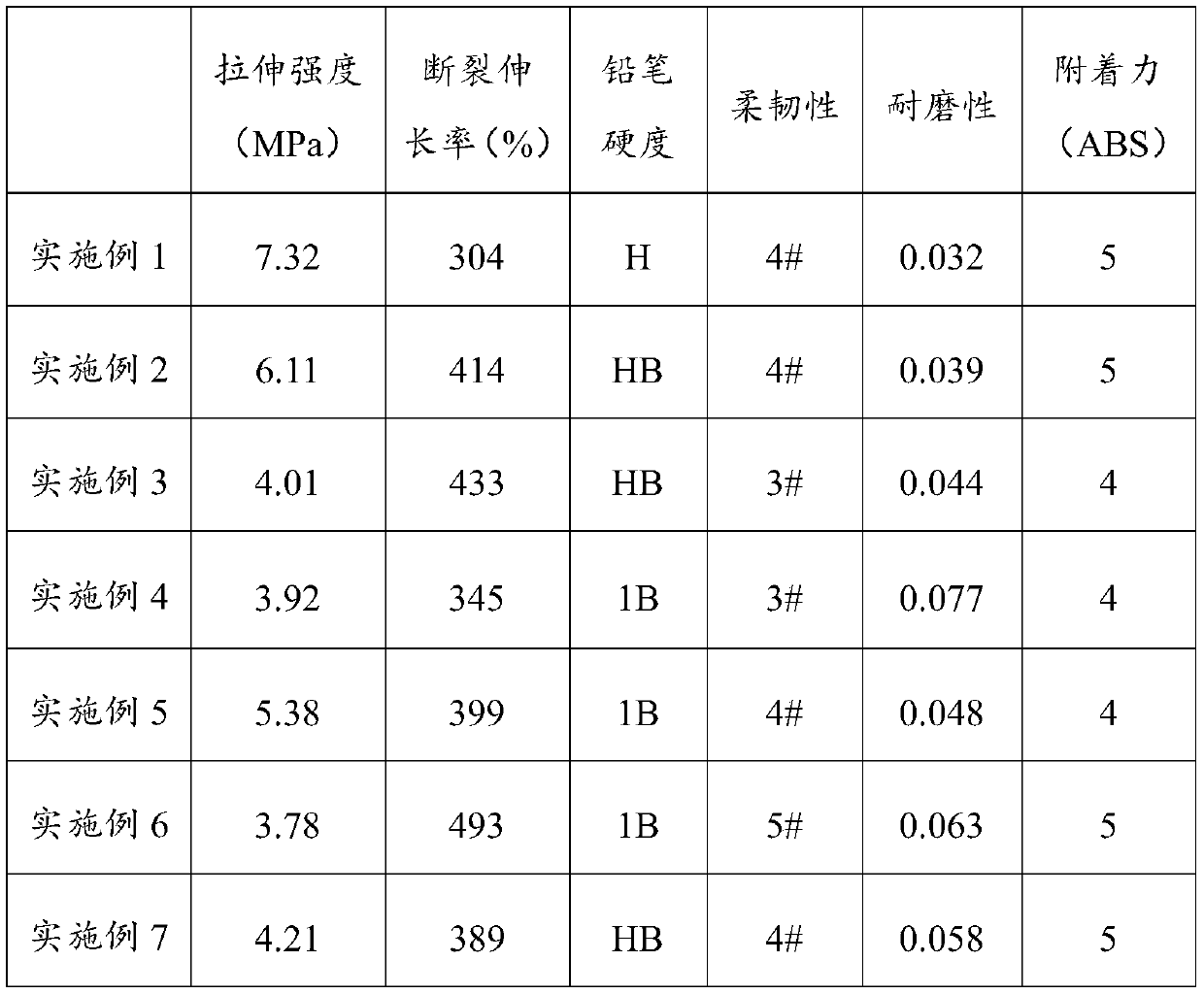

Examples

Embodiment 1

[0037] This embodiment provides a degradable photocurable resin, the preparation method of which is as follows:

[0038] After lactide and ethylene glycol are mixed evenly according to the molar ratio of 6.8:1, add stannous octoate (the amount of stannous octoate accounts for 0.5% of the total mass of lactide and ethylene glycol), and then heat up to 120°C , After reacting for 4 hours, the polylactic acid diol was obtained; the number average molecular weight of the polylactic acid diol was determined to be 1000.

[0039] Add 200 g of the above-mentioned polylactic acid diol, 41.19 g of maleic anhydride and 0.24 g of 4-methylaminopyridine into a four-necked flask with a stirring device, and then raise the temperature to 70° C. After 2 hours of reaction, detect the acid value of the system, when When the acid value of the reaction system is less than 100mgKOH / g, add 48.5g hydroxyethyl acrylate, 0.1g hydroquinone and 0.18g dibutyltin dilaurate, then raise the temperature to 160°...

Embodiment 2

[0041] This embodiment provides a degradable photocurable resin, the preparation method of which is as follows:

[0042] After lactide and 1,3-propanediol are mixed evenly according to the molar ratio of 14:1, add stannous octoate (the addition of stannous octoate accounts for 0.5% of the total mass of lactide and 1,3-propanediol), and then After raising the temperature to 120°C and reacting for 4 hours, the polylactic acid diol was obtained; the number average molecular weight of the polylactic acid diol was determined to be 2000.

[0043] Add 200 g of the above-mentioned polylactic acid diol, 21.57 g of maleic anhydride and 0.22 g of triethylamine into a four-necked flask with a stirring device, and then raise the temperature to 70°C. After 2 hours of reaction, detect the acid value of the system. When the value is less than 60mgKOH / g, add 27.5g hydroxypropyl acrylate, 0.1g 4-methoxyphenol and 0.13g bismuth isooctanoate, then raise the temperature to 140°C and continue the r...

Embodiment 3

[0045] This embodiment provides a degradable photocurable resin, the preparation method of which is as follows:

[0046] After lactide and 1,3-propanediol are mixed evenly according to the molar ratio of 20.5:1, add stannous octoate (the addition of stannous octoate accounts for 0.5% of the total mass of lactide and 1,3-propanediol), and then After raising the temperature to 120°C and reacting for 4 hours, the polylactic acid diol was obtained; the number average molecular weight of the polylactic acid diol was determined to be 3000.

[0047] Add 200g of the above-mentioned polylactic acid diol, 16.52g of itaconic anhydride and 0.20g of 4-methylaminopyridine into a four-necked flask with a stirring device, then raise the temperature to 70°C, and react for 2 hours to detect the acid value of the system. When the acid value of the system is less than 40mgKOH / g, add 25.6g hydroxyethyl acrylate, 0.05g p-hydroxyanisole and 0.11g n-butyl titanate, then raise the temperature to 180°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com