Plasticizer-precipitation-preventing UV viscosity-reducing adhesive tape and preparation method thereof

A plasticizer and tape technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of unstable antistatic layer processing, poor heat resistance of PVC, easy precipitation of plasticizers, etc., to increase curing. Crosslinking density, good antistatic effect, low surface resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] On the other hand, the invention discloses a method for preparing an anti-plasticizer precipitation UV adhesive tape, comprising the following steps:

[0040] (1) Mix acrylic pressure-sensitive adhesive resin, crosslinking agent, photoinitiator, antistatic agent, and auxiliary agent in sequence, and stir for a preset time to obtain an anti-plasticizer precipitation UV vis-reducing adhesive;

[0041] (2) Coating the anti-plasticizer precipitation UV viscosity-reducing adhesive on the non-release surface of the release film, and drying at 125° C. for 10 minutes;

[0042](3) Pass the base film through a polyurethane surface treatment liquid, and then use it for surface treatment by nano-scale spraying;

[0043] (4) After the non-release surface is dried, the release film coated with UV adhesive reducing agent is transferred to the base film surface, and aged at 50°C for 48-72h to obtain the anti-plasticizer The precipitated high initial adhesion is then peeled off the UV ...

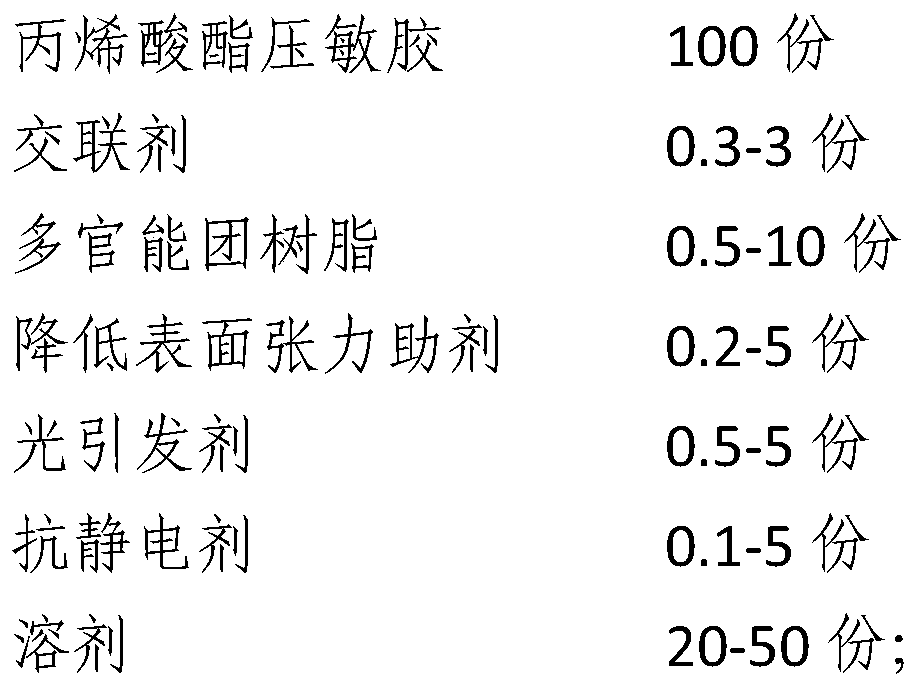

Embodiment 1

[0048]

[0049] Before UV irradiation, the 180° peel force of the antistatic UV adhesive layer is N / 25mm, and after UV irradiation, the 180° peel force of the antistatic UV adhesive layer is N / 25mm.

[0050] The special acrylic pressure-sensitive adhesive resin is solvent-based, its initial 180° peeling force is N / 25mm, and its solid content is 27%.

[0051] The curing agent is a polyisocyanate curing agent, the photoinitiator is 1-hydroxy-cyclohexylbenzophenone, and the antistatic agent is an organic lithium salt antistatic agent.

[0052] The preparation method of the high initial adhesion peeling tape of described antistatic type UV visbreaking comprises the following steps:

[0053] (1) Mix special acrylic pressure-sensitive adhesive resin, curing agent, photoinitiator and antistatic agent in sequence, and stir for a certain period of time to obtain UV viscous adhesive;

[0054] (2) Coating the UV viscous reducing adhesive on the non-release surface of the release film...

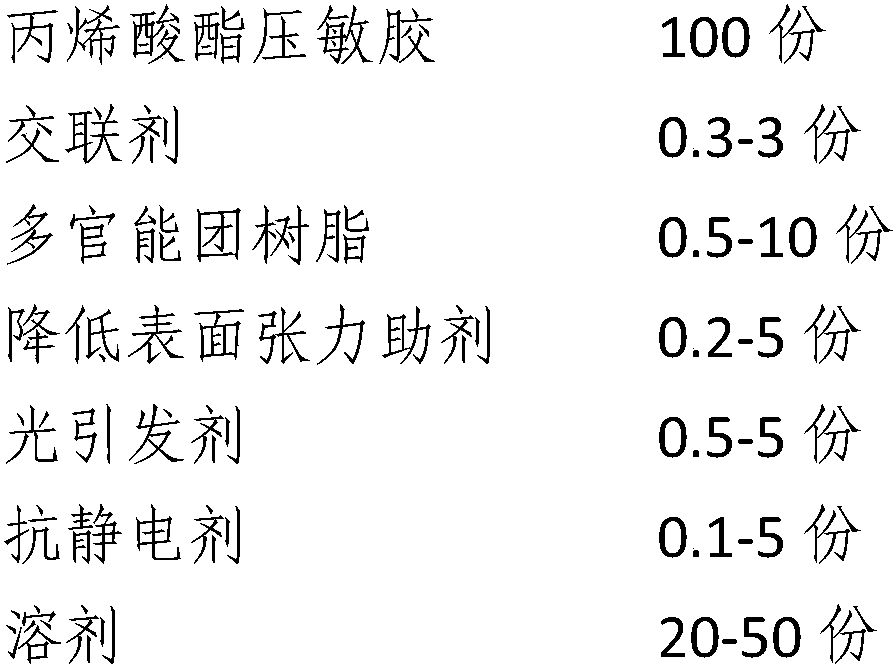

Embodiment 2

[0058]

[0059] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com