Method for improving form of carbide in bearing steel

A bearing steel and carbide technology, which is applied in the field of carbide morphology in bearing steel, to achieve the effect of inhibiting the growth of carbides and avoiding large sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

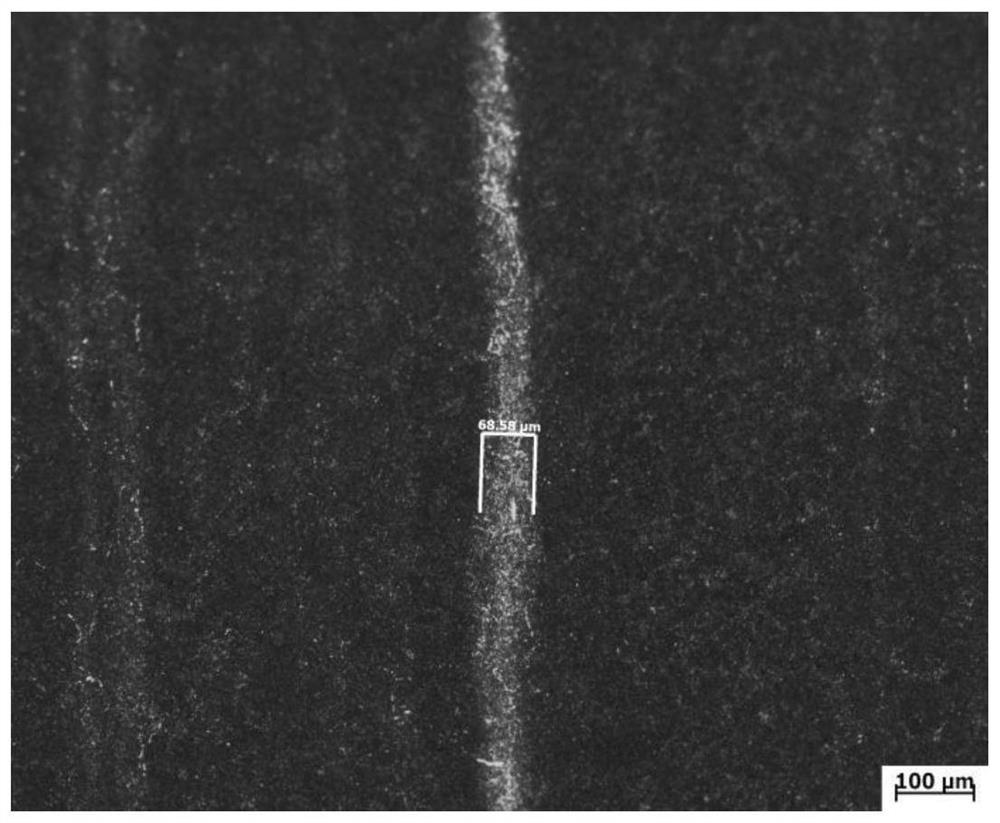

[0027] Such as figure 1 As shown, the molten iron is initially smelted in an electric furnace or a converter, and then LF refining and vacuum treatment are carried out to make the main alloying elements of C, Si, Mn, and P in the molten steel meet the composition requirements of bearing steel, and 102.52 tons of molten steel are obtained through preliminary refining treatment ; In particular, in the molten steel obtained, control the active oxygen content at 2-7ppm to avoid the reaction of magnesium and oxygen, resulting in deoxidation and generation of inclusions; Sampling, temperature measurement, and oxygen determination after emptying. Add magnesium-containing cored wire after the composition and temperature reach the standard.

[0028] Before feeding the magnesium-containing wire, it is necessary to ensure that the slag layer is 1-2mm, which can reduce the volatilization of magnesium in the steel after feeding, and the feeding speed of the magnesium-containing cored wire ...

Embodiment 2

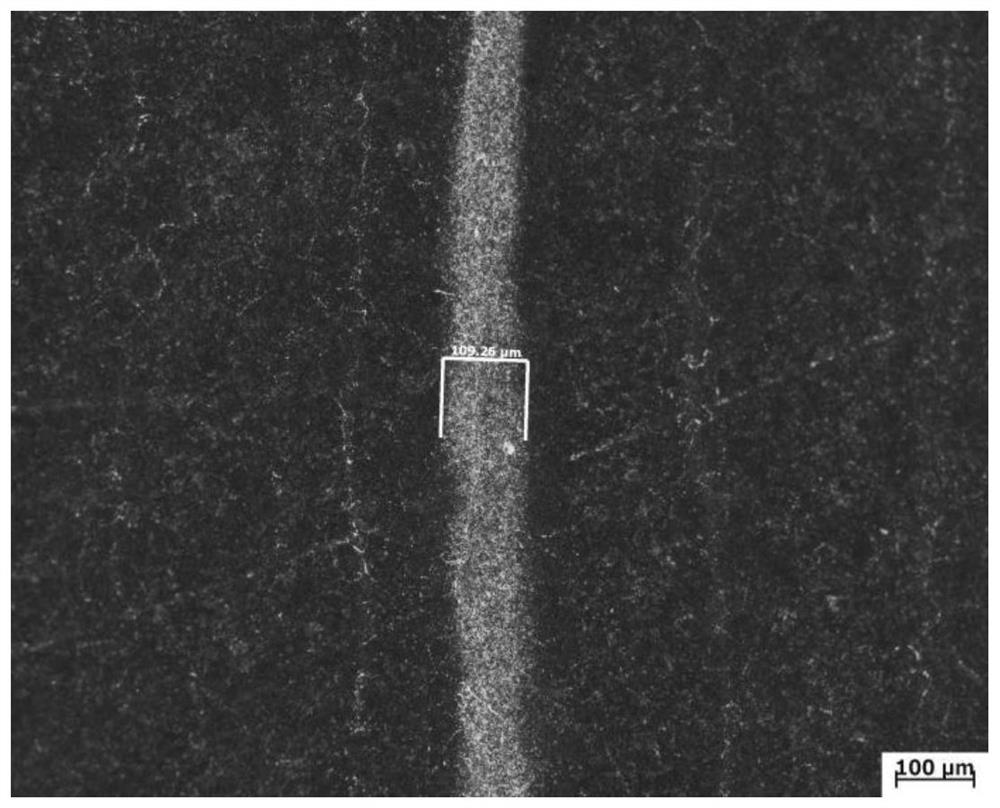

[0032] Such as figure 2 As shown, the molten iron is initially smelted in an electric furnace or a converter, and then after LF refining and vacuum treatment, the main alloying elements C, Si, Mn, and P in the molten steel meet the composition requirements of bearing steel, and about 100.10 tons of steel are obtained from the preliminary refining treatment. In particular, in the obtained molten steel, the content of active oxygen is controlled at 2-7ppm to avoid the reaction between magnesium and oxygen, resulting in deoxidation and inclusions; after the molten steel is refined, it enters the VD furnace, and the vacuum holding time is 10 minutes. Sampling, temperature measurement, and oxygen determination after air breaking, adding magnesium-containing cored wire after the composition and temperature reach the standard.

[0033] Before feeding the magnesium-containing wire, it is necessary to ensure that the slag layer is 1-2mm, which can reduce the volatilization of magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com