Polysiloxane modified epoxy resin and preparation method thereof

A technology of polysiloxane and epoxy resin, which is applied in the field of polysiloxane modified epoxy resin and its preparation, can solve the problems of poor UV aging resistance and poor flexibility, and achieve convenient technical parameters and short reaction cycle Short, energy-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] According to the proportioning of reactant, take 100g bisphenol A type epoxy resin E44 and 80g hydroxyl-terminated polydimethylsiloxane and place in the there-necked flask equipped with agitator, condensing reflux, nitrogen device and constant pressure dropping funnel , add ethylene glycol butyl ether to dissolve, 0.8g catalyst dibutyltin dilaurate is installed in the constant pressure funnel, nitrogen gas is passed into the three-necked flask, when the oil bath is heated to 70°C, the catalyst is added dropwise at a constant speed, and the dropwise addition is completed Finally, it was heated to 110°C at a stirring rate of 300rpm, reacted at a constant temperature for 2 hours, then added toluene to extract and remove unreacted polysiloxane, and then distilled under reduced pressure to remove ethylene glycol butyl ether to obtain a polysiloxane-modified ring Pure oxygen resin.

Embodiment 2

[0029] According to the proportioning of reactant, get 100g bisphenol A type epoxy resin E51 and 60g polymethylphenyl siloxane and place in the there-necked flask that agitator, condensation reflux, nitrogen device and constant pressure dropping funnel are equipped, Add xylene to dissolve, 1.2g catalyst titanate is installed in the constant pressure funnel, and nitrogen gas is passed into the three-necked flask. When the oil bath is heated to 80°C, the catalyst is added dropwise at a constant speed. After the dropwise addition, stir at 350rpm Heating to 130°C under high speed, constant temperature reaction for 3.5h, then adding n-hexane to extract and remove unreacted polysiloxane, and then distilling off xylene under reduced pressure to obtain pure polysiloxane modified epoxy resin.

Embodiment 3

[0031] According to the proportioning of reactant, get 100g bisphenol A type epoxy resin E51 and 100g polymethylphenyl siloxane and place in the there-necked flask that agitator, condensation reflux, nitrogen device and constant pressure dropping funnel are equipped, Add ethylene glycol butyl ether to dissolve, 2g catalyst dibutyltin dilaurate is housed in the constant pressure funnel, feed nitrogen into the three-necked flask, when the oil bath is heated to 80°C, add the catalyst dropwise at a constant speed, after the dropwise addition, Heated to 140°C at a stirring rate of 400rpm, reacted at a constant temperature for 4.5h, then extracted with heptane to remove unreacted polysiloxane, and then distilled off ethylene glycol butyl ether under reduced pressure to obtain a polysiloxane modified ring Pure oxygen resin.

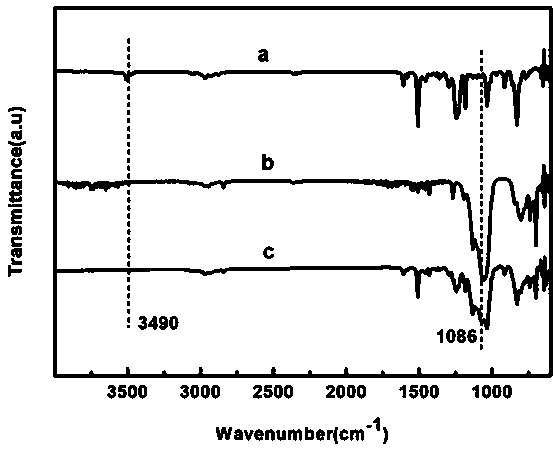

[0032] figure 1 It is the comparison chart of infrared spectrum of unmodified epoxy resin (a), polysiloxane (b) and polysiloxane modified epoxy resin (c) prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com